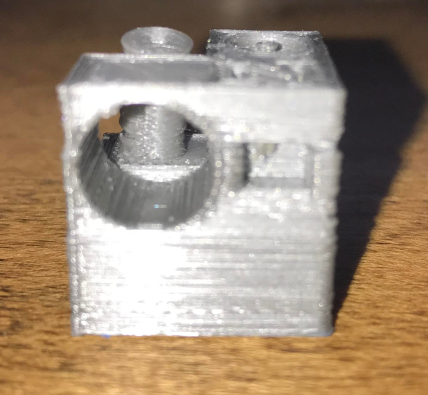

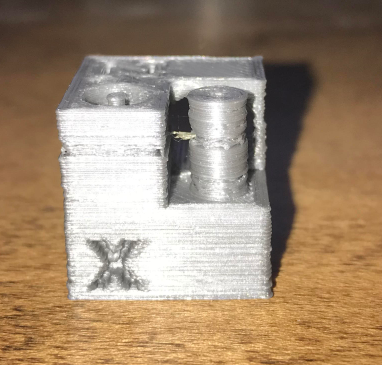

Terrible print

-

@apex2011 have you got the config from the old electronics you can share? Have you changed the extruder motor? I think the assumption has been it’s a 1.8 degree motor, but perhaps it’s a 0.9. Has it got a label on the extruder stepper motor? What does it say?

Did you retune the extrusion distance? See https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165

Ian

-

@droftarts I thought I saved the config but I can't find it now that I'm looking for it. The extruder is stock for ender 3, 1.8 deg. I have done the celebration several times, it feeds 100mm of filament like it's supposed to. Although, now that I am thinking about it there have been a few changes made, it's worth checking again.

I am sure I'm probably missing something really simple. Earlier this week I went right back to step 1 and walked through the entire setup.

-

So, I think I was right that it was something simple....I moved the filament and it's printing FAR better. Still not perfect but much better. I'll post a picture when it finishes but I think 1/2 my issue was filament tension that I didn't notice....

-

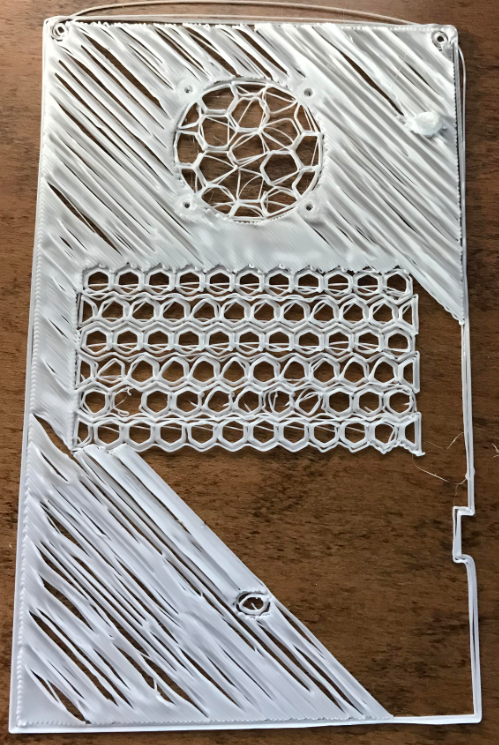

it's definitely not perfect but, it printed!

Thank you everyone! I think it's a matter of dialing things in now.

-

-

@Phaedrux There didn't look to be but there must have been. I think I'm going to look into a different filament holder.

-

I prefer a filament holder that uses a bearing hub on the center of the spool so that it can rotate completely freely. I hate the ones that just hang it on a peg and force the extruder to yank on it.

https://www.thingiverse.com/thing:2334107

There is a mod for the Ender than moves the stock filament holder to the side closer to the extruder and more in line with it. I think that helps a bit.

https://www.thingiverse.com/search?q=ender+3+side+spool&dwh=835e6e667e47eca

For my ender I just use one of the holder that uses bearings to set the spool on. It's less stable, but it does rotate the spool more easily.

-

@Phaedrux Thank you! One of these will be my next print

-

@apex2011 was the extruder skipping steps, or grinding away the filament? The first might have been overcome by increasing the motor current. If the second, better take the extruder apart and clean the teeth of the filament driver/hobbed insert.

Ian

-

@droftarts it didn’t look to be skipping. I took the gear out and cleaned it up as a preventative measure. There was some plastic “dust” in the gears, it all cleaned out with a quick blast of air.

-

Well, I thought I was onto good things. I tried to get a video but ti didn't work out very well. I was watching the print, it's almost like it forgets where z home is and tries to extrude too high part way through

-

Have you tried using babysteps to adjust the offset to z zero ?

Once you figure out the offset needed, you need to adjust the offset in your config.g file -

@jens55 Thank you, I will give that a try. What's odd to me is that it start off printing OK

-

I am not seeing any area where it prints ok. The circumference lines clearly show that it is printing too high.

-

reluctantly, I have given up on the duet board for now at least. I spent countless hours trying to dial in the settings and have not been able to get it to work properly. Sent it into a repair shop, they were also not able to get it to work properly. I have gone back to the stock wiring and Ender 3 board to find out why it is not extruding properly.

-

I am sorry to hear that .... such a shame ....

Hopefully there will come a time in the future when you can give things an other go as a Duet controller is really a much superior product compared to a standard Creality (or virtually all other) controller board.

The learning curve can be steep ..... but oh the rewards when you've climbed it and look back at your travels .... -

@apex2011

Skimming through the thread.Did you measure off 100mm of filament, mark it and then try extruding 100mm? If moving the spool about changed your prints, plus there was debris on the pinchwheel?

My first guess is the extruder drive is slipping. I have no idea how the compression force is adjusted on that extruder drive, but your fails look exactly like what you used to get on the old Makerbot Mk7 extruders. They used a delrin plunger that wore away, once that happens the filament just slips.

A good extruder drive should be able to drag a spool across the table, it needs to be able to exert a decent amount of force to extrude, even with a really good hotend.

I certainly wouldn't be expecting the board to be causing such a severe failure, not without a really obvious other symptom. -

@theruttmeister

Answered my own question:https://www.youtube.com/watch?v=FFCo5P0iQAI

I'd check your drive lever. Looks like a fundamentally flawed design. No wonder there are lots of upgrades on the market.

If they had just made that hole 4mm and used a shoulder bolt...

Guess that's how you get to a $300 printer.