Delta stepper upgrade - advice welcome

-

@Nxt-1 said in Delta stepper upgrade - advice welcome:

@sebkritikel Thank you for the suggestions. Do you have any experience with either of the motors you suggested?

I have also found these from the same supplier:

- Rated current: 2.80 A

- Holding torque: 1.32 Nm

- Inductance: 3.90 mH

- Rotor inertia: 290.0 gcm²

(6.35 mm shaft)

- Rated current: 2.80 A

- Holding torque: 1.40 Nm

- Inductance: 3.00 mH

- Rotor inertia: 310.5 gcm²

(8 mm shaft)

These see to be the longer versions of the ones you linked (54 mm vs 39 mm)

I don't have any experience with those models, however I do use two PKP264D28AA2 NEMA23s (2.8A/phase, 1.8°, 39mm, 74Ncm, 1.5mH inductance) on my printer, and they are fantastic.

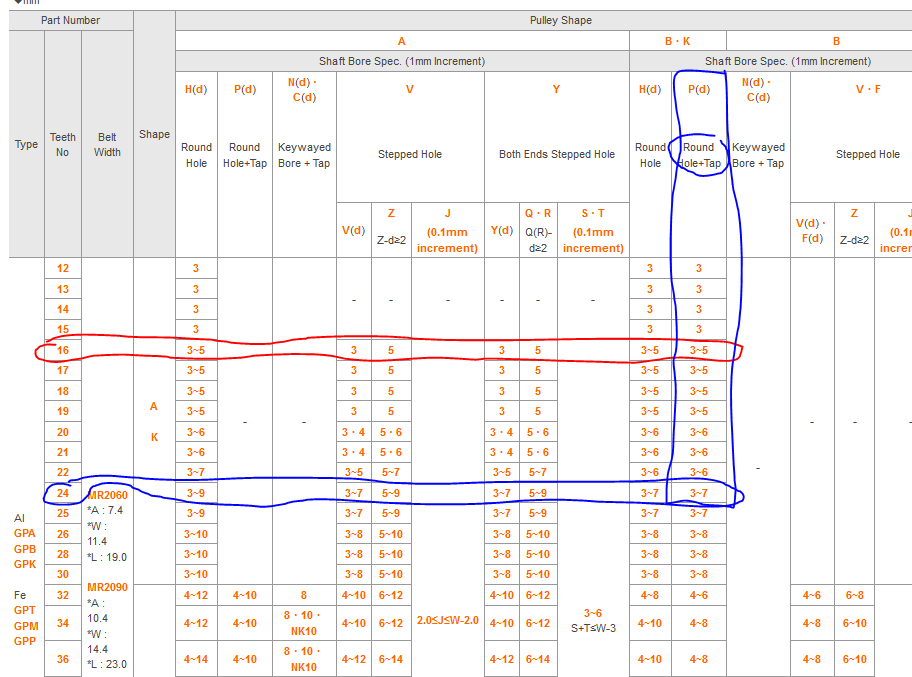

I see you're trying to hit 200steps/mm with a 2mm pitch belt @ 16teeth on a pulley... I don't know how realistic it will be to find a pulley with 16 2mm teeth, and 6.35mm or greater shaft bore

Excerpt from Misumi's 2mm PowerGrip

GT

GT 3 catalog listing

3 catalog listing

-

@sebkritikel Good point, a quick look at a local 3D printer parts supplier supports what you say. No 16T pulley with >5 mm ID bore. However jumping up to 20T pulleys (available in both 6,35 mm and 8 mm) is not per se a deal breaker for me. It will lower the steps/mm by 20% but I guess I can take that hit.

-

To keep a good overview of all the models that have been suggested, I am creating a google sheet with most characteristics in there. If you want to see a column added or spot an error be sure to give me a nudge.

You can find it here: Stepper Motor Chart

-

@Nxt-1 Ref the pulley thing, I hadn't even thought about that but I use 20 tooth in any case which is why I didn't have any problem finding ones with a bigger ID for my Nema23s.

-

I just added two more steppers from Nanotec. But I do not think they are major contenders as they are four coil motors (so eight leads). These specific ones have to wired so that only two coils are used to meet the spec requirements and then they are not that interesting anymore. Yet I added them for completeness sake.

-

@sebkritikel @deckingman I have just come to the sad conclusion that not only should I look at the correct shaft diameter, but length as well. For a 9 mm wide belt, the pulleys seem to be 20 mm wide. Most if not all of the steppers in the spreadsheet have ~20 mm main shafts. This does not leave any room at all for a bearing in front.

Wanting to add external bearings to motor shaft is partly what parked the whole idea of upgrading steppers, and is fully what lead to dual shaft steppers. I do not what to hijack this thread to talk about that, that is what this thread is meant for.

-

@Nxt-1 Ahh sorry. I was thinking that simply moving to NEMA 23s with bigger bearings would suffice. I didn't realise that even with bigger bearings, you still want to add extra support to the shaft.

-

@deckingman said in Delta stepper upgrade - advice welcome:

@Nxt-1 Ahh sorry. I was thinking that simply moving to NEMA 23s with bigger bearings would suffice. I didn't realise that even with bigger bearings, you still want to add extra support to the shaft.

That was the idea yeah, but you might be right that I should keep an open mind. The larger bearings in nema 23 motors might suffice just like that. Although there is no way of knowing that before I commit to a purchase I guess.

-

@Nxt-1 For info, for some time now I've been considering using "remote" motors. That is to say, use an "axel" with big beefy bearings at each end and two pulleys in the middle. One pulley being connected to the main printer belts, the second connected to the motor with a short continuous looped belt. That means that one could run with much higher (main) belt tension because the small stepper motor bearings wouldn't be subjected to the loads. But whether high belt tension would offer any benefit on my printer remains to be seen. I have a sneaky suspicion (unverified by any testing or analysis) that too high belt tension might cause steppers to have a tendency to "jump" to the nearest whole steps due to the sideways load on the bearings.

Another possible use for this "remote motor" arrangement is that one could use gearing with a small pulley on the motor shaft and a large one on the main belt shaft. In theory, this would increase effective torque and/or positional resolution, But then again, it might not because stepper motor torque drops off with speed and the motors would be turning faster. On the other hand, a big gear on the motor driving a small gear on the shaft would make for higher speeds at the expense of positional resolution. Sop quite a few options which would need to be evaluated.

I guess this is where we came in......

-

@Nxt-1 said in Delta stepper upgrade - advice welcome:

So the moonsindustries.com webpage for the nema 23 that is the highest contender at the moment, specs the stepper at 3.9 mH inductance. While the moonsindustries.eu catalogue (page 40) specifies winding inductance at 6.9 mH.

My guess this has to do with taking the inductance of one coil or both combined. It does confuse me to say the least. Any have any insight in this?

I just got back from Moons EU and they informed me that the 3.9 mH is a typing error and it should be 6.9 mH, which is quite a bummer. As it turns out actually all of the inductance of the moon' steppers in the sheet are mismatched with their catalog. I have replied to moon' CS with that information and will await their response.

-

This might sound like a crazy suggestion...

What if you used two stepper motors? One of them disconnected, facing the other one, just as a support shaft? Basically, the amount that the drive pulley extends past the end of the motor shaft can be supported by the shaft of the other stepper.

Another crazy Idea: find a bearing block with a bearing ID large enough to go around the part of the pulley with the set screw. Support the pulley directly!

I'm full of crazy ideas.

-

@bot said in Delta stepper upgrade - advice welcome:

This might sound like a crazy suggestion...

What if you used two stepper motors? One of them disconnected, facing the other one, just as a support shaft? Basically, the amount that the drive pulley extends past the end of the motor shaft can be supported by the shaft of the other stepper.

Another crazy Idea: find a bearing block with a bearing ID large enough to go around the part of the pulley with the set screw. Support the pulley directly!

I'm full of crazy ideas.

You indeed are crazy, I like it. Lets move this part of the discussion to the correct thread, just to keep it clear-ish to anyone digging up these threads later.

https://forum.duet3d.com/topic/14674/external-bearings-for-stepper-shafts -

The other thread has been crazy active the last couple of days.

The dust seems to be settling down and a nema 23 stepper -> rigid coupler -> shaft with two bearing and coupler is the major contender for me at this point. This drops the need for a double shaft stepper and I expected this to open quite a few new options. However, from what I have found the last few days, many of the higher end steppers models come both in a single and dual shaft variant.

Initially, the MS23HAAP4300-E from the stalls of Moons' was my 1st choice but since the inductance values have changed from 3.9 to 6.9 mH, it is no longer on my radar. Now the PKP266MD28B2 suggested by @sebkritikel

is looking like a solid candidate. It is not yet clear whether Oriental Europe has that model available though. If not, the PKP266MD28B is a very similar model that is available.EDIT: I might still go the dual shaft stepper option just to keep long term options open, the difference is something like €3/stepper.

EDIT2: One of the advantages of the PKP models is that ones I linked come in 8mm shaft versions. For which it is easier for me to get bearings for instead of the imperial 1/4''. -

@Nxt-1 said in Delta stepper upgrade - advice welcome:

The other thread has been crazy active the last couple of days.

The dust seems to be settling down and a nema 23 stepper -> rigid coupler -> shaft with two bearing and coupler is the major contender for me at this point. This drops the need for a double shaft stepper and I expected this to open quite a few new options. However, from what I have found the last few days, many of the higher end steppers models come both in a single and dual shaft variant.

Initially, the MS23HAAP4300-E from the stalls of Moons' was my 1st choice but since the inductance values have changed from 3.9 to 6.9 mH, it is no longer on my radar. Now the PKP266MD28B2 suggested by @sebkritikel

is looking like a solid candidate. It is not yet clear whether Oriental Europe has that model available though. If not, the PKP266MD28B is a very similar model that is available.EDIT: I might still go the dual shaft stepper option just to keep long term options open, the difference is something like €3/stepper.

EDIT2: One of the advantages of the PKP models is that ones I linked come in 8mm shaft versions. For which it is easier for me to get bearings for instead of the imperial 1/4''.It is quite similar - some difference in the inductance. It is the same part number, aside from a "reference" number (per the catalogs) appended to the end of the US part number.

-

Unless you are planning a really big delta, I suspect that all this talk about bigger stepper motors and supporting the shaft at additional points is overkill. Just turn the pulleys round (as I think was suggested in the other thread) so that the belts run closer to the face of the motor.

-

@sebkritikel said in Delta stepper upgrade - advice welcome:

It is quite similar - some difference in the inductance. It is the same part number, aside from a "reference" number (per the catalogs) appended to the end of the US part number.

Apparently they did some redesign of some of their models. This is what I got from their (exccellent) CS: "Due to minor design changes of the Motor (different electrical connectors), the motor windings have also changed.This results in different inductances and different torques. The electrical connector is either on the housing or it is embedded in the motor housing."

While the EU branch can get the revised version, they quoted me €80 a piece with a 3 week lead time. Which seems excessive to me sadly

@dc42 said in Delta stepper upgrade - advice welcome:

Unless you are planning a really big delta, I suspect that all this talk about bigger stepper motors and supporting the shaft at additional points is overkill. Just turn the pulleys round (as I think was suggested in the other thread) so that the belts run closer to the face of the motor.

On previous iteration of the machine the pulleys were actually turned around for this very reason and sadly it not suffice. I must admit that I don't really know why they are the 'wrong' way around at the moment, must not have been paying attention when I did the last mod.

On the topic of the stepper size, the delta is quite large I'd say, the rails are 1030 mm long with 500 mm arms.

-

@Nxt-1 I added simple thrust bearings between my pulley and my stepper motors on my delta(I did add some superlube grease to them too).

Ex. https://www.amazon.com/dp/B07QKKYKR8/ref=cm_sw_r_sms_awdb_t1_YWX3EbZQ7GDY0The reason was that I saw a hackaday article where someone used them in lieu of pillow blocks for steppers that had noticeable deflection on the motor shaft. My steppers are about 8 years old and the bearings are starting to show wear so while I save up and decide on new ones I figured I'd try these out too mostly for shits and giggles while I make up my mind.

My results? I did not notice a difference in print quality or indications in my bed level/mapping (was around 0.014 +/-0.004 there's a one step backlash I can't find the source of shrug). I can tension the belts significantly more with minimal shaft deflection, and no obvious negative indications. I was able to increase my acceleration and jerk settings a good deal higher (in running direct drive on my delta right now so I can't eliminate it completely) with equivalent ringing to the before. Whether that's directly attributed to the tension change i haven't tested. I do feel that my motors would have had a longer lifespan if I had used these from the start though.

-

@lord-binky said in Delta stepper upgrade - advice welcome:

@Nxt-1 I added simple thrust bearings between my pulley and my stepper motors on my delta(I did add some superlube grease to them too).

Ex. https://www.amazon.com/dp/B07QKKYKR8/ref=cm_sw_r_sms_awdb_t1_YWX3EbZQ7GDY0The reason was that I saw a hackaday article where someone used them in lieu of pillow blocks for steppers that had noticeable deflection on the motor shaft. My steppers are about 8 years old and the bearings are starting to show wear so while I save up and decide on new ones I figured I'd try these out too mostly for shits and giggles while I make up my mind.

Unless I am misunderstanding, I do not really see how a thrust bearing would be beneficial. Thrust bearings are used to deal with pure axial loads and are very good at that. However, in our scenario we need to deal with pure radial load as a result of the belt tension.

That is why I opted for needle bearings in my design (for which I will provide pictures in the upcoming months). These bearings excel at dealing with radial load (and completely lacking axial load capabilities).

EDIT: Do not get me wrong, I have not actually tested my new motor mount brackets so I cannot provide actual results. I am confident that if the goal is dealing with the loads on the axle due to belt tension, roller/needle bearings or at least ball bearings are the way to go.

-

@Nxt-1 When sandwiched together the pulley is pressing the bearing against the motor body. Its fairly constrained between the pulley, shaft, and motor so its mostly horizontal forces from the pulley trying to tilit and the pulling force of the belt keeps the forces on one side so it isn't like we are spinning an imbalanced load around the shaft. So for our speeds at least and the cost of the bearings I'd consider it worth it to consider them a consumable if they hold up as long as my belts do. I agree there are better bearings, but for no additional supporting elements these have worked great for me and thought worth throwing out.