nozzle wipe

-

@dc42 said in nozzle wipe:

On a multi-tool printer I suggest the following instead:

Awesome. I gave up on multi tool on the ender5 since e3d ms-tc arrived but still, this is better as I assume a lot of scripts I will use on more printers (as I plan to replace most of my printer boards and unify them to RRF)

-

@deckingman now that you mention "silicone in tube", ages ago I created a heat shield around my old rapman nozzles with silicone for some car gaskets from car parts store that is supposed to be good up to 300C. 250-260C many years later it's still standing so I guess it's usable. I think I seen people use it to mold the heat block socks out of it. Might be interesting to design a mold to create silicone "brush" specifically designed to clean nozzle

-

@arhi I don't see why not. For info, I once made a "sock" for one of my Diamond hot ends using this stuff which is supposedly good for 370 degC https://www.dwrplastics.com/high-temperature-resistant.html. I'd guess something like that would also work if one wanted to make a "brush" from scratch.

-

@deckingman lot of nice molding materials available, unfortunately, not accessible for all of us

.. but this car stuff is available in local shops so ... I'll think about it. I know they have green, red and black. One is I think 300C, other 370C and one is IIRC 700C but I might be wrong will check the shops it's clearly marked on the tube

.. but this car stuff is available in local shops so ... I'll think about it. I know they have green, red and black. One is I think 300C, other 370C and one is IIRC 700C but I might be wrong will check the shops it's clearly marked on the tube

I think bigger issue is "what" to design, what a "perfect" brush for this would look like maybe a "cup", dunno, need to think about it, interesting anyhow

maybe a "cup", dunno, need to think about it, interesting anyhow

-

@CaLviNx said in nozzle wipe:

Why do you feel you need to wipe the nozzle every few layers?

Mostly for PETG. Over time the nozzle collect small pieces that later land on the part.

I also have a Micro Swiss nozzle on order. It supposed to be smooth and 'PETGphobic'. Will see how that one goes.

-

@zapta Slice engineering now use a "plastic repellent coating" on their Vanadium nozzles. I still don't have a working printer so cannot validate just how "plastic repellent" it is though.

-

@deckingman said in nozzle wipe:

@zapta Slice engineering now use a "plastic repellent coating"

I assume it is same "plastic repellent coating" X nozzles from E3D use

I'm not impressed

Maybe I expected too much.

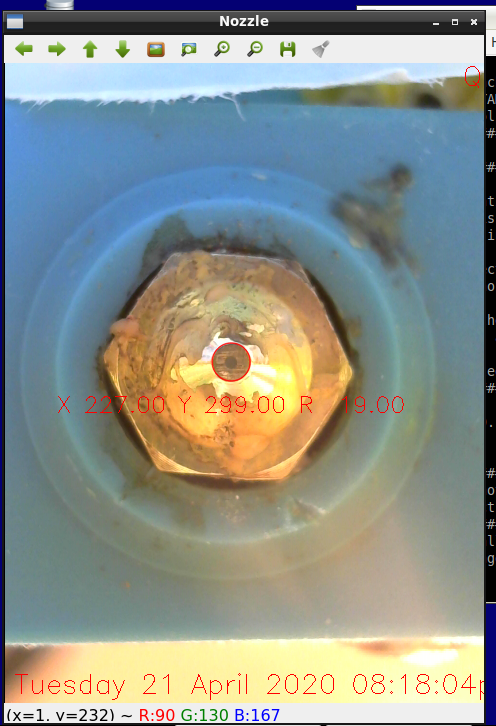

.3mm X nozzle

The "scratches" are from the brass brush

Total printing time - 1 hour PLA + 30min PETG (both blue/greenish so this blue on the nozzle is mix of the two)

impossible to clean cold ... basically I did not notice any difference between this X nozzle and regular brass nozzle

.. no "wow" effect on the top layer, no "wow" layer on the bottom layer... works great just like their normal brass and hardened nozzles but I don't see it's any "better". Replaced it with brass .6mm as .3 is too slow for the stuff I'm printing these days

.. no "wow" effect on the top layer, no "wow" layer on the bottom layer... works great just like their normal brass and hardened nozzles but I don't see it's any "better". Replaced it with brass .6mm as .3 is too slow for the stuff I'm printing these days

-

@zapta I print almost exclusively with petg (das-filament) and after I carry out the initial wipe I don't suffer from build up on the nozzle at all, you might want to optimise your slicer settings if you are finding a buildup on the nozzle, I had to optimise my settings to prevent this too but that was many years ago when I was not that experienced in printing with petg.

-

@arhi said in nozzle wipe:

I assume it is same "plastic repellent coating" X nozzles from E3D use

I wouldn't make that assumption if I were you.

I have a rough idea what Slice Engineering use but I don't know for sure and even if I did, I couldn't divulge that information. I think a fusing process which involves heating the part to around 581 deg C might be involved, but I could be wrong. I have no idea what E3D use except what I've read from their marketing literature.

But I think it would be a mistake to assume that just because one coating from one nozzle manufacturer didn't work for you, that all coatings by all nozzle manufacturers would behave the same. Having said that, as I said before, I can't vouch for the Slice Engineering coating because I haven't been able to test it.

-

@deckingman said in nozzle wipe:

@arhi said in nozzle wipe:

I assume it is same "plastic repellent coating" X nozzles from E3D use

I wouldn't make that assumption if I were you.

It looks exactly the same and I'm pretty sure I heard on some of the videos about mosquito something like "our vanadium nozzle uses same olifobic material as e3d is now using" or something along those lines, but could not find the video... I have no clue what's e3d using neither

Anyhow friend just got his original recently with 5+ nozzles (I think all vanadium coated with this thing) and he just started using them. If not for this police lockout I'd be there with thermal camera already but unfortunately... We'll see in few weeks how will that vanadium looks like

... so far we confirmed that original mosquito has zero issues with PLA (contrary to that damn clone I purchased).

... so far we confirmed that original mosquito has zero issues with PLA (contrary to that damn clone I purchased).But I think it would be a mistake to assume

I always say assumption is mother of all fsckups and when I do assume I'm sure to be clear that I don't "know" but just assume

(actually maybe assume is wrong term here, "suspect" or "almost believe to be" might be more correct)

(actually maybe assume is wrong term here, "suspect" or "almost believe to be" might be more correct) -

@arhi said in nozzle wipe:

X nozzle

The "scratches" are from the brass brushThe brass brush will destroy the X-nozzle coating pretty quickly IIRC.

-

@CaLviNx said in nozzle wipe:

I print almost exclusively with petg (das-filament) and after I carry out the initial wipe I don't suffer from build up on the nozzle at all,

Any suggestion what kind of settings to loo for to avoid buildup? I am using 2mm retraction, 0.95 flow, and 245C. BMG direct extruder + E3D hotend with 0.4mm brass nozzle.

-

First thing is "squish" petg doesn't like being squished into the bed like PLA does. You could be quite alarmed at how much further away from the bed petg likes to be. On my chiron I run a BMG with an e3d nozzle and the retraction on it is all the way upto 5.60mm retraction speed of 40.0mm/s.

I also force retraction between layers (in simplify3d)

-

@arhi said in nozzle wipe:

It looks exactly the same ................

....................I always say assumption is mother of all fsckups and when I do assume I'm sure to be clear that I don't "know" but just assume

(actually maybe assume is wrong term here, "suspect" or "almost believe to be" might be more correct)

(actually maybe assume is wrong term here, "suspect" or "almost believe to be" might be more correct)Sure it might look the same but that's hardly a basis for assuming, "suspecting", or "almost believing" that it is the same. Taking a quick gander at the relative specs, E3D claim a hardness of 60 HRC for their X nozzles while Slice Engineering claim 65 HRC. Given that the Rockwell scale is logarithmic, that's a big difference in hardness even though they "look the same".

One of my neighbours has a cat. It has 4 legs and a tail. My other neighbour also has a pet which has 4 legs and a tail. At night and from a distance they look the same. Do you therefore assume, suspect or almost believe that the other pet must also be a cat? (Hint - one mews the other barks).

Not sure how we ended up here but we've gone way off topic. Nice little chat though......

-

@deckingman said in nozzle wipe:

One of my neighbours has a cat. It has 4 legs and a tail. My other neighbour also has a pet which has 4 legs and a tail. At night and from a distance they look the same. Do you therefore assume, suspect or almost believe that the other pet must also be a cat? (Hint - one mews the other barks).

It's a cat speaking a foreign language ....

-

@arhi I've been using the same hardened steel nozzle heavily for about 2 years now and I've never managed to get it that messy. The little bit that does manage to cake on comes off easy when heated to 80-90c with a pair of pliers. I use a brass brush too. No coating to worry about. In fact, if anything the steel has been seasoned from use with it's own non-stick coating.

-

@deckingman that is a huge difference in hardness so they def. are not same. Dunno if it has to do with the hardness of the underlying material as e3d nozzles are made from something way softer than vanadium :D. Not sure if the rockwell measuring needle can easily measure just the coating (none of the ones I seen could).

We'll see how the slice one will perform

I have one vanadium nozzle (hexagon, their experimental one, was too expensive to produce so they never mass-produced them) and I love it even without any coating so I might be a user soon... also with the clone, while the clone is useless pos that does not work it gave me a good understanding of the size and weight of the mosquito so I'm getting me one as soon as I can.

I have one vanadium nozzle (hexagon, their experimental one, was too expensive to produce so they never mass-produced them) and I love it even without any coating so I might be a user soon... also with the clone, while the clone is useless pos that does not work it gave me a good understanding of the size and weight of the mosquito so I'm getting me one as soon as I can.Back to original discussion, I'm thinking hard about the "design" of the "brush" and I still don't see what would be much better than a simple "plate" to brush over (like what you and @danal are using), anything I came up (stacked arrowheads were kinda max I could throw) can be "simulated" by different path over the simple flat plate so I'll just wait for this to pass and use a flat piece of silicone stripe, till then this sponge will have to do

-

@Phaedrux said in nozzle wipe:

@arhi I've been using the same hardened steel nozzle heavily for about 2 years now and I've never managed to get it that messy.

I have bunch of printers with very clean nozzles too, this is the nozzle I used to "break this printer in", to get extrusion, heights, sensors etc etc dialed in so there was plowing trough overextruded filament more than once

When the printer get dialed in usually nozzle and heatblock only slowly turn black from collecting that abs oil that condenses from abs fumes, or in case of pla/petg they stay super clean

When the printer get dialed in usually nozzle and heatblock only slowly turn black from collecting that abs oil that condenses from abs fumes, or in case of pla/petg they stay super clean

-

Fairly heavily used nozzle, wiped over the strip thingie above for all its life.

-

Much, MUCH older, same wipe for life, this one really needs to be replaced (it was, a few min later) because of the scratching on the "ironing surface" around the actual hole.