PETG - Brittle?

-

@deckingman said in PETG - Brittle?:

Highly doped perhaps?

I think it's a different types of additives to the pigments or different pigments, not the ammount of pigment. For e.g. I know that for clothing they will add some "glow in dark" stuff that makes whites brighter under uv and fluo lights (that's why you have to use flash when taking photos of the bride on the wedding even if you have a lot of lux of led light available, as with only led without flash the "white dress" looks gray and does not pop up)

But that's just guess. I'd really love to ask ppl who actually make filament how different they are in making, what do they add to the pellets for each of them but I never seen any of them (filament makers) join in such conversations

-

For completeness my materials are snow white from 3DFilaprint and clear rPETG from filamentive. Very difficult to directly compare due to the colour differences.

I don't think temp is an issue here as I aim for the slight sheen on the part, and keep extrusion rates within recomended for the nozzle. In this case below 10mm3/sec for E3D V6 std with standard 0.4mm nozzle.

-

If anything the shield printing has just encouraged me to shop around a bit. I don't do colour preference much, but like to stick to a constant colour and supplier. I am liking the finish on the grey filamentive rPLA parts ao may look thatbway in the future.

-

Brand new spool and still got issues. Think I will attempt a return unless the purchase was too long ago.

-

@DocTrucker said in PETG - Brittle?:

Brand new spool and still got issues.

Of what and where from DocTrucker? -

@antlestxp said in PETG - Brittle?:

The polymaker polylite is pretty good stuff along with the polymax. My go to is the fillamentum cpe. That stuff is fantastic but you can't leave it out too long.

PC-Max is one of my all time favs, it also doesn't like being left out. I haven't tried Fillamentum CPE, I'll put it on my list to try, thanks! They've changed PC-Max to PolyMax now, FYI.

-

@DocTrucker

PETG and most polyesters are prone to hydrolysis when exposed to heat in presence of water. The ideal moisture content for PETG is below 300 ppm or parts per million (300 mg of water per kilogram of PETG). To make the problem worst, PETG is fairly hygroscopic (It likes to absorb water). Once you remove it from the bag and the dissecants, it will start the absorption process.

The good thing is that the process is reversible. Heating PETG in presence of Desiccants (Silica Gel) at about 70 Celsius (70 x 1.8+32) approx 158F for 10 hs would dry the polymer while preserving its mechanical properties.

However, if the filament was made with wet resin. We could do very little to save it, since the hydrolysis process already occurred before we processed. If you could return it to the manufacturers and get a fresh batch, life can be better.

Good printing -

@Daniel isn't filament going from the nozzle directly into the warm water bath ?! How does that affect the moisture content?

was made with wet resin.

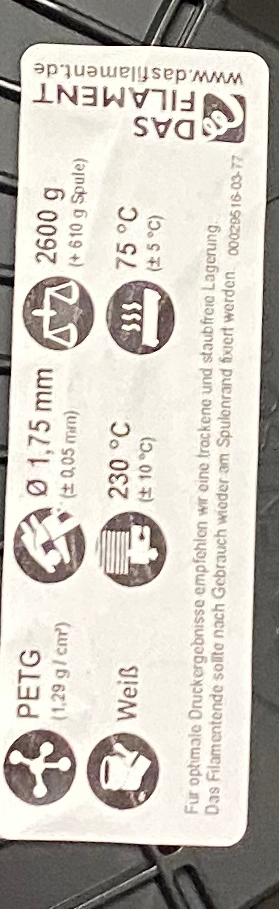

I recently watched some video (trying to figure out what's wrong with this XXL spool of white petg from dasfilament that print at 180C that strings like crazy) about filament making and guy said that the process starts by

- put pellets, additives, pigments into the blender and mix and mix and mix

- put the mixed content into the dryer and dry for at least 2 hours

and went on about if you don't dry for at least 2 hours the filament will be %$#@^&# quality...

I guess everyone making filament knows this and I doubt anyone is crazy enough not to dry the mixture before using up all the time and energy to convert that into filament.

-

@arhi

That is a very good observation. Filaments are made by melting dry polymer in the extruded and pushing them through a die with the proper diameter and then immersed into a water bath to solidify.

The residence time in the bath is enough to chill the filament but not enough to to raise the internal moisture content above 300 ppm.

It takes time to make the moisture diffuse into the polymer. -

@Daniel sounds interesting, I have no clue about how that part of the work is done, never looked much in to it before this issues with dasfilament white petg, so I started looking at the process and if anyone published recipes but info about it all is super scarce. Apart from few videos and few pictures info there's nothing out there. Easier to find a procedure to make extazy or heroin than to make filament

Anyhows looks like the general course of action for any filament is the same - if something fishy, dry it first

-

@arhi

I am attaching a link to a resin vendor for injection molders and other plastic processes containing a table for water content on different polymers as well as a reference on how to measure that.

https://omnexus.specialchem.com/polymer-properties/properties/water-absorption-24-hoursWhat filaments are interested in making?

-

@Daniel thanks. No wish to make filament. I just wanted to understand what happened to the spool I had issues with

( saga is here https://forum.duet3d.com/topic/16111/6mm-e3dv6-stringing-petg-any-ideas?_=1589127397515 it's a XXL role of dasfilament petg white that behave weird imo)

( saga is here https://forum.duet3d.com/topic/16111/6mm-e3dv6-stringing-petg-any-ideas?_=1589127397515 it's a XXL role of dasfilament petg white that behave weird imo) -

@arhi said in PETG - Brittle?:

if something fishy, dry it first

I god a food dehydrator and tried a few time to dry filaments but I can't say I noticed any before/after difference.

-

@PaulHew the filament I'm having issues with is the Snow White PETG filament from 3DFilaprint. Premium own brand. Emailed them for comment last week. Not heard back yet.

-

@DocTrucker said in PETG - Brittle?:

@PaulHew the filament I'm having issues with is the Snow White PETG filament from 3DFilaprint. Premium own brand. Emailed them for comment last week. Not heard back yet.

That's interesting - it was Snow White PET-G (but a different brand) that @arhi was having problems with in a different thread.

-

@deckingman mine is actually called just "white" but it is "whiter" than regular white I have from other brands.

-

If anything there is a slight blue tint to the snow white PETG from 3D Filaprint. They tend to completely hude products on their website when out of stock so can't see any product data sheets to get any hints on who makes it. I was reading somewhere (perhaps here) that the snow white behaves a little like a filled material.

No response from the first email to them. I will try again soon.

-

@DocTrucker said in PETG - Brittle?:

that the snow white behaves a little like a filled material

That's what I believe. Does not need to be called "snow white" but those white filaments that are "whiter" than the rest of them. But that's just a personal feeling I can't quantify it.