Is my extruder set up properly?

-

Hi all,

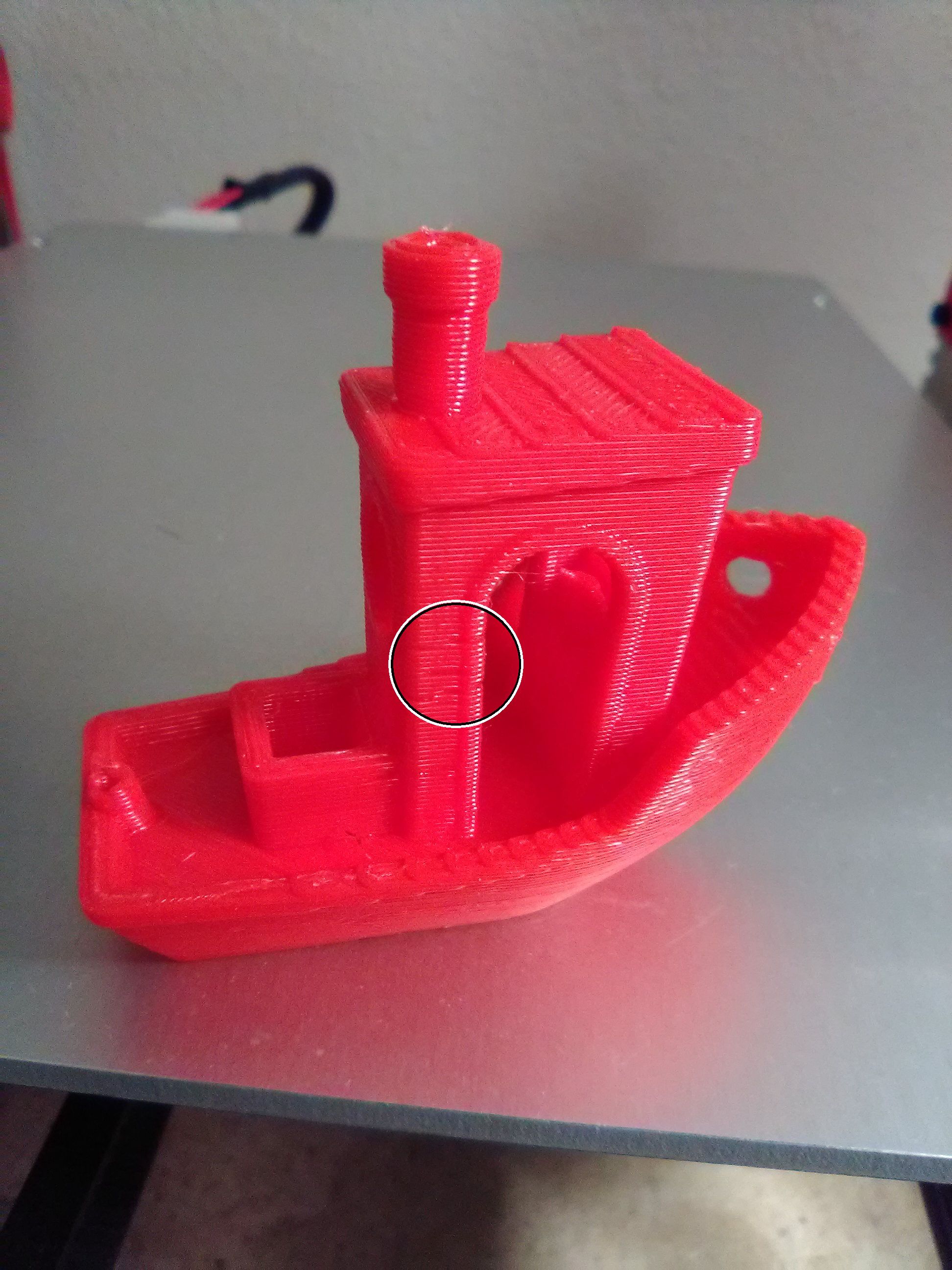

I'm getting intermittent voids in my horizontal layers, around 2-3 mm long and occasional popping sounds from the extruder. Could it be my extruder setup? I plugged in my numbers to dc42's "choosing a stepper" formulas when i set up everything and i think it's okay but I'm not sure. I thought maybe it was the PLA filament so i dried it for 24 hours in a dehydrator but it didn't help. I've also tried varying the hotend temperature from 200-225.

My printer is a duet 2 wifi, 24v AM8 with 0.9 degree steppers.

Thank you for reading this.

Here's my config.g

Firmware Name: RepRapFirmware for Duet 2 WiFi/Ethernet Firmware Electronics: Duet WiFi 1.02 or later Firmware Version: 2.01(RTOS) (2018-07-26b2) WiFi Server Version: 1.21 Web Interface Version: 1.21.2-dc42Extruder stepper part number: 17HM15-0904S

stepper spec sheet.pdf

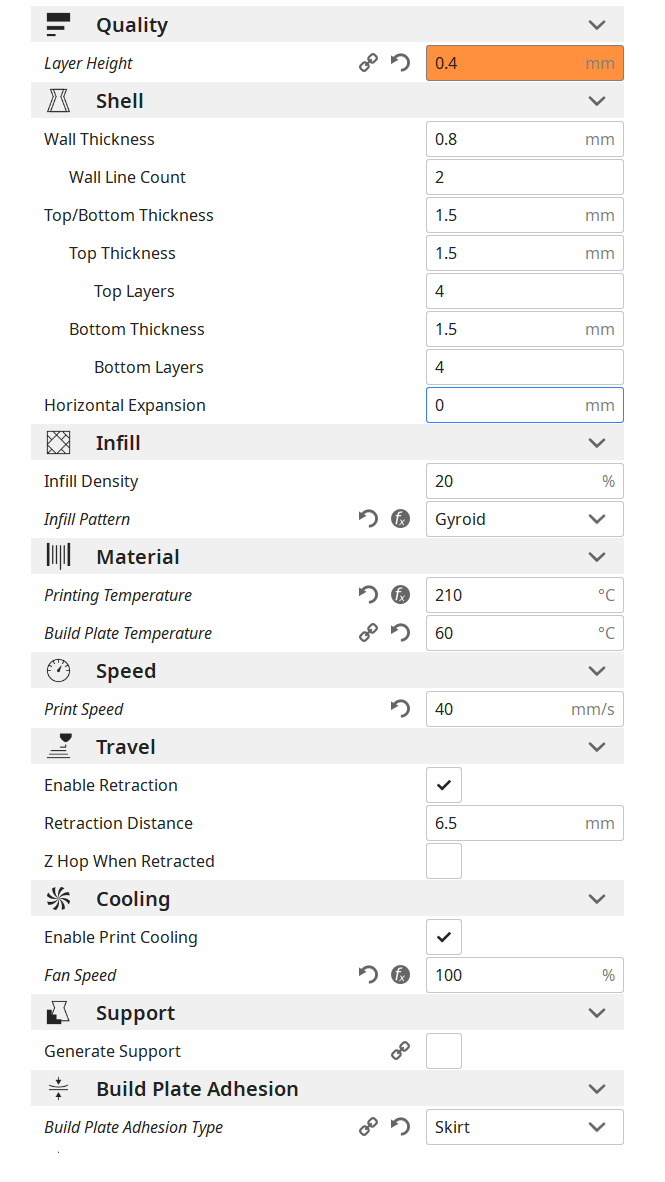

PullOutTorque.pdfHere are my Cura settings:

Alternate link to cura settings -

@gibbeth said in Is my extruder set up properly?:

Could it be my extruder setup?

What is your extruder setup? Bowden? Direct? 6.5mm retraction could be too much, or maybe it's not enough? We don't have enough information to say.

-

Popping is usually a sign of wet filament.

Maybe think about trying some other filament if you have some?Other than that, its generally a good looking benchy

-

@jay_s_uk said in Is my extruder set up properly?:

Popping is usually a sign of wet filament.

Maybe think about trying some other filament if you have some?Other than that, its generally a good looking benchy

Agreed.

Popping sounds are little steam explosions that rip the layer apart. They can be cause by

- wet filament - try drying it before using it or use an inline dryer for your prints

- too much retraction - I found that when retracting too much I get ambient air pulled into the nozzle, that will produce the same effect a few millimeters after the start of a new line.

Good looking benchy indeed

-

What is your extruder setup?

It's direct.

too much retraction - I found that when retracting too much I get ambient air pulled into the nozzle, that will produce the same effect a few millimeters after the start of a new line

6.5mm retraction could be too much

I changed to 1mm retraction and that seems to have solved it. Thanks for your help!

Good looking benchy indeed

Other than that, its generally a good looking benchy

Thank you

-

Glad it worked.

I found there is a pretty universal rule of thumb for retractions:

0.5-2.5 mm + 1% of bowden tube length

For direct drive there is no bowden part so you are just left with 0.5-2.5mm (found that even at 2.5 mm you can see popping)

For bowden drive on e.g. 500mm bowden tube you end up with 0.5-2.5mm + 5mm -> often in the 6.5mm range

Also found that its true for wether you run a V6 style hotend or a Volcano. Despite some online suggestions that a Volcano should have longer retractions because of its longer meltzone. Above 2mm even Volcanos will start popping because in the end its not about the top of the melting zone, but the bottom of the nozzle.

Once you pull up the filament past 1-2mm you get air into the melting chamber, that violently overheats once re-primed. -

@fxstein somewhat offtopic nit-pick, but "direct drive" and "direct" are two different things. "Direct drive" usually means an ungeared extruder (while I am nit-picking, I'll nitpick on myself and mention that this should be "filament feeder", with the opposite being geared extruder (like Bondtech or Hemera). The "direct" versus "Bowden" (no drive) are really "short distance" vs "long distance" (between filament feeder and hotend).

-

@oliof said in Is my extruder set up properly?:

@fxstein somewhat offtopic nit-pick, but "direct drive" and "direct" are two different things. "Direct drive" usually means an ungeared extruder (while I am nit-picking, I'll nitpick on myself and mention that this should be "filament feeder", with the opposite being geared extruder (like Bondtech or Hemera). The "direct" versus "Bowden" (no drive) are really "short distance" vs "long distance" (between filament feeder and hotend).

I know exactly what you mean. We - no I am are butchering a bunch of terms. Guilty as charged. Having said so, the vast majority will understand the meaning of it - might even be less confused than when we speak more precisely.