CR-10+Bondtech+Silicon Bed 450W+Microswiss...Help

-

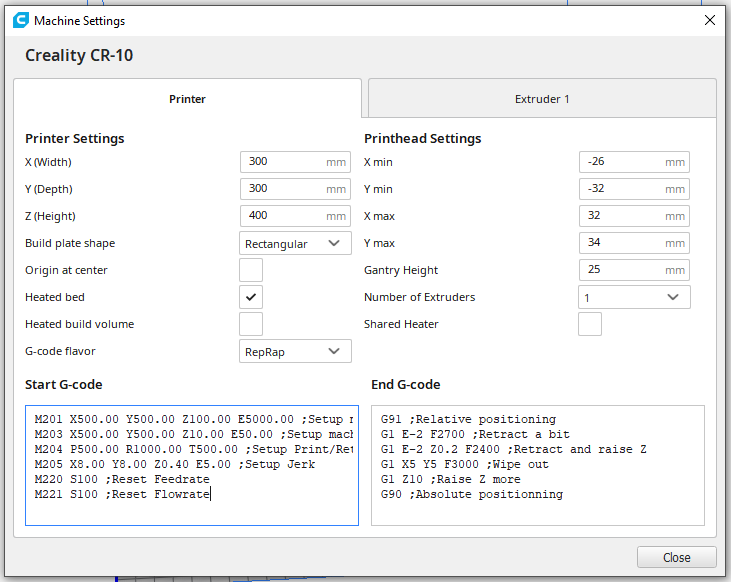

@Hélder-Rocha it's in the start gcode section for the printer profile in Cura.

Google Cura start gcode if you can't find it.

When you're there you can also change the end gcode to move the print head up and away from the print.

Can you control the part cooling fan with the slider in dwc?

-

@Hélder-Rocha said in CR-10+Bondtech+Silicon Bed 450W+Microswiss...Help:

2-At the end of the printing, the extruder stays on top of the printed object.

Change your "stop.g" and tell the printer there what to do after the print.

My look like that:

M400 ; Finish move queue G91 ; Relative positioning G1 E-20 ; Retract filament 20mm M104 S0 ; Extruder heater off M140 S0 ; Bed heater off ;M106 S255 ; Fan at 100 to cool nozzle and bed M220 S100 ; Set speed factor back to 100% in case it was changed M221 S100 ; Set extrusion factor back to 100% in case it was changed G1 Z15 ; raise nozzle 15mm from printed part G1 Y255 F3000 ; Drive the bed forward -

If you want to use stop.g on the duet rather than the end gcode in cura, you need to add M0 in the end gcode in cura otherwise stop.g won't get called

-

Hi guys, fist of all, thankyou very much for the help. Im sorry but the last few days ive been working out and has been impossible for me to check this forum.

Chriss, the end of my g.code for a test cube on cura is like this:

;TIME_ELAPSED:2011.898237

G1 F2700 E-3

M140 S0

M82 ;absolute extrusion mode

M107

G91 ;Relative positioning

G1 E-2 F2700 ;Retract a bit

G1 E-2 Z0.2 F2400 ;Retract and raise Z

G1 X5 Y5 F3000 ;Wipe out

G1 Z10 ;Raise Z more

G90 ;Absolute positionningG1 X0 Y300 ;Present print

M106 S0 ;Turn-off fan

M104 S0 ;Turn-off hotend

M140 S0 ;Turn-off bedM84 X Y E ;Disable all steppers but Z

M83 ;relative extrusion mode

M104 S0

;End of Gcode

;SETTING_3 {"extruder_quality": ["[general]\nversion = 4\nname = Dynamic Quali

;SETTING_3 ty #2\ndefinition = creality_cr10\n\n[metadata]\nquality_type = a

;SETTING_3 daptive\nposition = 0\ntype = quality_changes\n\n[values]\ncoast

;SETTING_3 ing_enable = True\nmaterial_print_temperature = 220\nretraction_amo

;SETTING_3 unt = 3\nretraction_extrusion_window = 6\nspeed_print = 60\n\n"],

;SETTING_3 "global_quality": "[general]\nversion = 4\nname = Dynamic Quality

;SETTING_3 #2\ndefinition = creality_base\n\n[metadata]\nquality_type = adap

;SETTING_3 tive\ntype = quality_changes\n\n[values]\n\n"}However, the printer doesnt do nothing, and it stays stoped on top of the print.

As Jay_s_uk said, is it possible to for a conflit between this G.code from cura and a Stop.G on the duet? If it is, i cant find that stop.g in the duet config!Phaedrux, "Can you control the part cooling fan with the slider in dwc?" i cant even make the fan tests with the macros i have, but, for the momment, thats not a problem. The speed is what is troubelling me for now.

Sorry for my gramatics...

Best regards -

Phaedrux describes stop.g here:

https://forum.duet3d.com/topic/6760/stop-g/2I think that you do not have the "M0" in your endcode in your slicer.

You can test your code fist by adding it the the endcode of your slicer for testing.

You can test your code fist by adding it the the endcode of your slicer for testing.Cheers, Chriss

-

Tks Chriss.

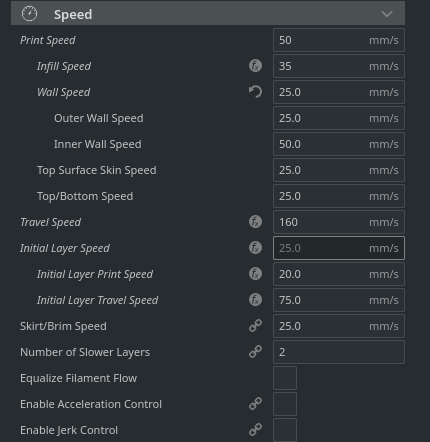

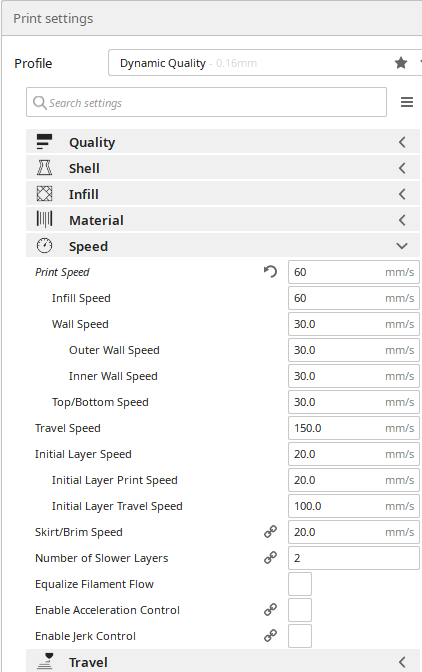

How you know, when we find ourselfs a bit lost, we have to solve one problem at the time. For now, i wold like to find what is making my printer so slow. On the web panel i find the speed between 8 and 12 mm/sec. I have Cura 4.6.1 and g.code is reprap flavor. Do you know how can i make the printing faster? -

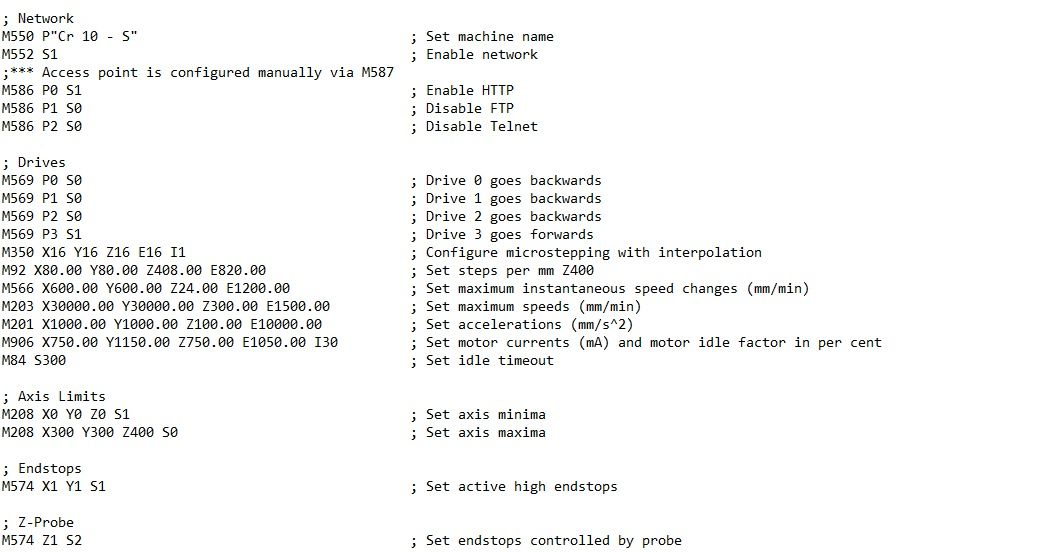

This is my inicial g.code on the machine settings. However, in my cnfig is like this:

-

M201 and M203 are complitly different!

-

I know how you feel.. I struggle with my CR10 a lot too. That blood thing behaves very strange but I have lost my motivation to debug that further. I will continue on mine after this weekend.

M201 and M203 "must" be different. M203 set the maximum speed you printer can go. The acceleration (M201) is more the latency the head have when it accelerates. I would recommend to read the docu, it describes it better than I can.

For your speed problem: Did you checked your speed setting in the cura profile?

Mine look like that:

Use them as reference only please! I work on them at the moment and my setup in guaranteed not very good. But I can tell you that this settings result in acceptable print speeds.

Here is my current setup for the steppers:

M350 E16 I1 ; Chriss - with interpolation M350 X16 Y16 Z16 I1 ; Chriss - configure microstepping with interpolation M92 X80.00 Y80.16 Z400.00 E431.06 ; Chriss - set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00 ; Chriss - set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z800.00 E1200.00 ; Chriss - set maximum speeds (mm/min) Z180 M201 X500.00 Y500.00 Z20.00 E250.00 ; Chriss - set accelerations (mm/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeoutCheers, Chriss

-

@Hélder-Rocha Remove the lines from the cura start gcode section. Your profile has inserted a bunch of speed settings that are overriding your config.g.

-

@Chriss my speed on cura looks like this:

-

@Phaedrux , those lines you are talking about are those from the g.code in the object i want to print, or can i erase the complet start g.code in the printer settings in cura?

-

Remove at least the M20X lines... They override .. Well as Phaedrux said....

-

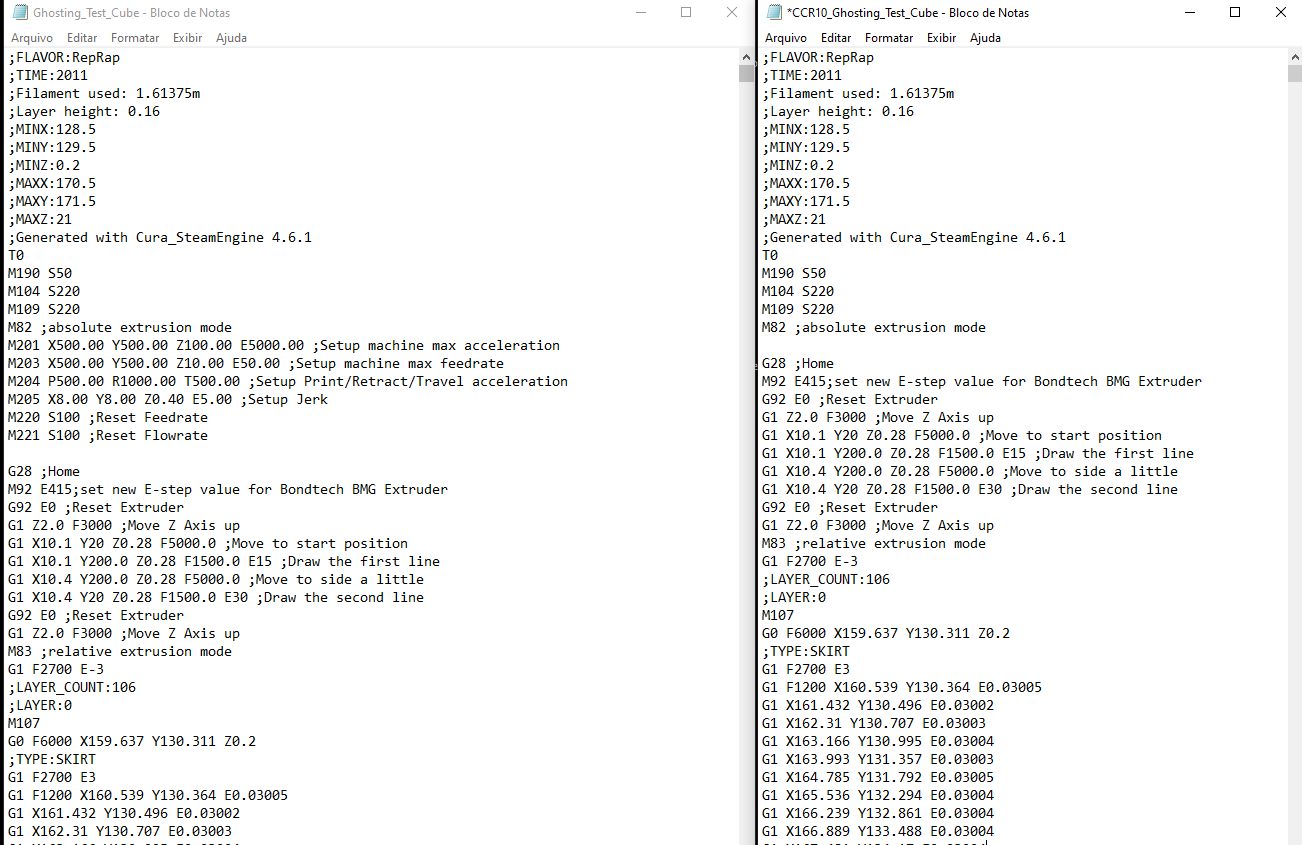

Well, in the next image i have 2 g.codes. one with the start gcode from cura and the other with out it.... will the second work?

-

@Hélder-Rocha

Looks Good to me. As long as you keep the M20x in the config.g. There must me at least one place where you set some limits which should match your hardware and other settings. -

@Chriss i beleave is there! Looks good?

Going now downstairs to the garage and try it

; Drives

M569 P0 S0 ; Drive 0 goes backwards

M569 P1 S0 ; Drive 1 goes backwards

M569 P2 S0 ; Drive 2 goes backwards

M569 P3 S1 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z408.00 E820.00 ; Set steps per mm Z400

M566 X600.00 Y600.00 Z24.00 E1200.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y30000.00 Z300.00 E1500.00 ; Set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z100.00 E10000.00 ; Set accelerations (mm/s^2)

M906 X750.00 Y1150.00 Z750.00 E1050.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S300 ; Set idle timeout

-

YESSSSSSSSSSSSSSSSSS... speed is normal now. Tks a lot guys... are you ready for the next problem i have? eh eh

Allright... my config for homeall with the bltouch. Is the original one, not replica. Is the smart bltouch 2020.

But first one question: i heve seen in some toturials that we should make a cut with a knife, because of the 3.3 v power or something like that!!! Is it needed to be done on this bltouch?My config next:

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v2 on Wed Dec 26 2018 13:31:24 GMT+0000 (Hora padrão da Europa Ocidental)

G91 ; relative positioning

G1 Z5 F6000 S2 ; lift Z relative to current position

M98 Pdeployprobe.g ; deploy mechanical Z probe

G1 S1 X-305 Y-305 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 X5 Y5 F6000 ; go back a few mm

G1 S1 X-305 Y-305 F360 ; move slowly to X and Y axis endstops once more (second pass)

G90 ; absolute positioning

G1 X200 Y150 F6000 ; go to first bed probe point and home Z

G30 ; home Z by probing the bed; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 S2 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioningM98 Pretractprobe.g ; retract mechanical Z probe

Ok... at the momment, i have the bltouch installed, but i am doing the home return with endstops swich. But first i tried this config and what apenned is that the printer does the x and y, but doesnt come down to make the measures!

Any sugestions?

-

No you don't have to cut any trace now.

Please post you config.g as text.

-

@Phaedrux Good morning, sorry at the time i went to bed. My config is like this:

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Wed Dec 26 2018 13:31:24 GMT+0000 (Hora padrão da Europa Ocidental); General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P2 ; Set firmware compatibility to look like Marlin; Network

M550 P"Cr 10 - S" ; Set machine name

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S0 ; Drive 0 goes backwards

M569 P1 S0 ; Drive 1 goes backwards

M569 P2 S0 ; Drive 2 goes backwards

M569 P3 S1 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z408.00 E820.00 ; Set steps per mm Z400

M566 X600.00 Y600.00 Z24.00 E1200.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y30000.00 Z300.00 E1500.00 ; Set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z100.00 E10000.00 ; Set accelerations (mm/s^2)

M906 X750.00 Y1150.00 Z750.00 E1050.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S300 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X300 Y300 Z400 S0 ; Set axis maxima; Endstops

M574 X1 Y1 S1 ; Set active high endstops; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M558 P9 H5 F120 T6000 A5 S0.02 ; Set Z probe type to bltouch and the dive height + speeds

G31 P25 X-40 Y-10 Z1.20 ; Set Z probe trigger value, offset and trigger height

M557 X50:250 Y50:250 S50 ; Define mesh grid; Heaters

M305 P0 T100000 B3950 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S290 ; Set temperature limit for heater 1 to 290C; Fans

M106 P0 S0 I0 F30 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S0.5 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S0 I0 F500 H-1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic power saving

M911 S22 R23 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss; Custom settings are not configured

M912 P0 S-1 ; calibrate MCU Temp; pressure advance

M572 D0 S0.3 ; pressure advance; Miscellaneous

M501 ; Load saved parameters from non-volatile memory -

@Hélder-Rocha said in CR-10+Bondtech+Silicon Bed 450W+Microswiss...Help:

M98 Pdeployprobe.g ; deploy mechanical Z probe

M98 Pretractprobe.g ; retract mechanical Z probeRemove those parts from your homing file. You don't need to control the pin manually. It should deploy automatically with G30.

Please test M401 and M402 to deploy and retract the probe, and post your retractprobe.g and deployprobe.g files.

Also check your config-override.g file and look for an M307 H3 command that could be over writing your M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch