Trying to remove tiny holes/gaps on layers...

-

Under extrusion seems likely. Possibly unstable hotend temps.

PID tune the hotend and bed heaters, re calibrate the extruder.

-

@JoergS5 @Phaedrux

Hiccups seem to be gone now. RanM122every few mins during the print. Each time the following was returned:Hiccups: 0(0).I re-calibrated the extruder (updated

M92 E118.68).I re-ran PID tune for the hotend.

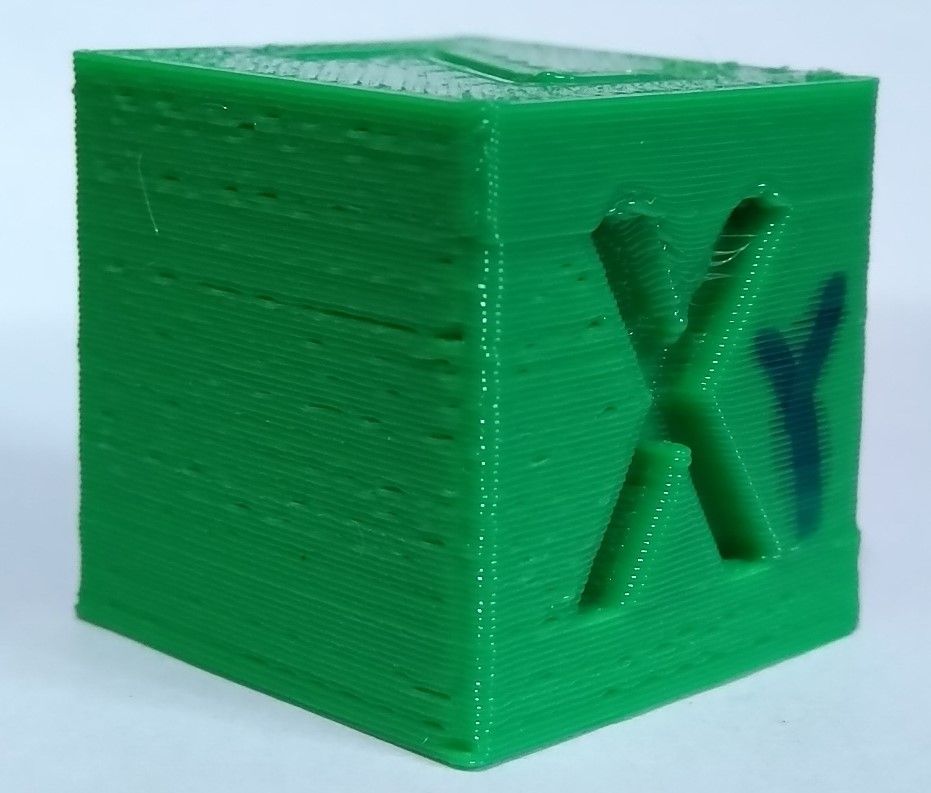

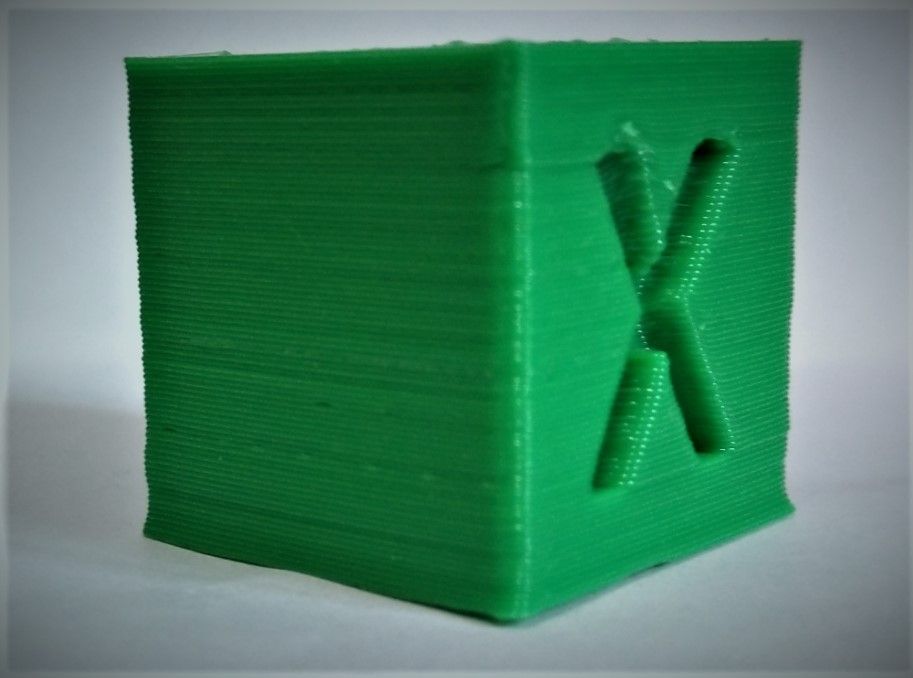

I then rotated the STL file and re-printed it (see below). The gaps seem to be in the exact same place as the non rotated prints.

-

@skezo I am not a specialist to handle filament (PETG) problems and cannot help further. But there are many users here who have a lot of experience.

To get the attraction of PETG specialist, you could rename the title of this thread to include PETG. The title has a display problem with the and symbol anyway.

-

I think your retraction speed is way too high, try 70mm/s.

-

-

try few other slicers and compare results

-

-

@skezo Is it only happen with PETG? Could be it has too much moisture in it?

-

Are you running the part cooling fan too high for PETG?

Do you have different filament to test with?

Even though you've tuned the extruder can you also try increasing the extrusion factor to see if the gaps are reduced?

-

Setting the extrusion factor to 0.95 or above removes the gaps but when I run the extrusion multiplier calibration that value I get is 0.86 (this prints the walls at the correct width but has under extrusion). How can I balance extrusion with accuracy?

-

Filling the proper extrusion volume is a combination of the amount of plastic coming out of the nozzle and the distance from the nozzle to the surface being printed on. If the Z axis steps per mm is slightly off you could have a greater gap than expected leading to the appearance of underextrusion.

@skezo said in Trying to remove tiny holes/gaps on layers...:

but when I run the extrusion multiplier calibration

How exactly are you doing that?

-

If I set the extrusion multiplier to 0.86 I can see the nozzle laying beads of filament on some layers (see below image). Which is what I think is causing the gaps in the calibration cube.

For extrusion multiplier calibration I have been printing 40mm cube in vase mode and 40 mm cube with a single vertical perimeter. Then measuring the wall thickness with calipers.

Extrusion multiplier = Old Extrusion Multiplier * (Expected Thickness/Measured Thickness)

-

Perhaps give this calibration method a try.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

What is the filament path like? Does the filament feed smoothly or is there friction and resistance?