Zaribo / Prusa i3 MK3s - Duet 2 WiFi - RRF 3.11

-

Zaribo/Prusa i3 MK3s - Duet 2 WiFi - RRF 3.11

This is a dump from my GitHub. I figured people in search of doing similar to their i3 MK3s might have a better chance finding it here.

! Wiring guide: Duet2-compressed.pdf

! Always look here for latest revisions of all code and settings: My GitHubHardware changes from stock MK3s:

Note: The config.g file contains notes to facilitate easy adaptation to stock Prusa MK3s.

-

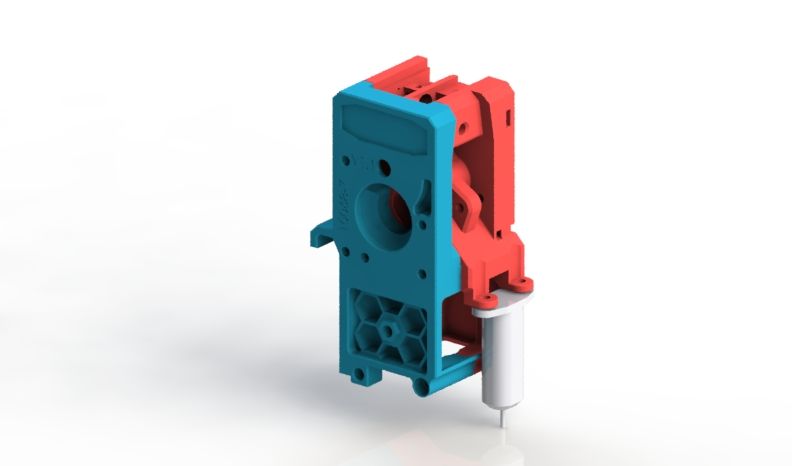

Bondtech Mosquito Extruder

-

0.9 Stepper motors on X & Y axis

-

Duet WiFi

-

Zaribo 10mm Upgrade

-

PanelDue 5i

-

PT1000 hotend thermistor

-

BLTouch v3.1

What do those hardware changes mean for your config?

What do those hardware changes mean for your config? Motors, microstepping resolution, and steps/mm.

Motors, microstepping resolution, and steps/mm.

Unless you have the same setup as referenced above, you may have to change the microstepping resolution and the steps per millimeter located in the 'config.g' file. To retrieve your current machine's configuration, issue a M503 command in the terminal connected to the running printer. Pay attention to the microstepping assigned to the axis as that can change your steps per millimeter. Read through the /sys/config.g file comments and make the applicable changes as needed. More about this can be read here: https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors, here: https://www.linearmotiontips.com/microstepping-basics/, and here: https://blog.prusaprinters.org/calculator3416/. Once you have changed/verified the motor settings, review the networking top portion of the file. When completed, copy all the files located in the 'sys', 'macros', and 'filaments' directory over to your sd-card. The 'www' and 'gcode' folder are present in the repository for reference and should not be needed to copy over to the sd-card in normal circumstances. More can be read about sd-card here: https://duet3d.dozuki.com/Wiki/SDCard, more can be read about macros here: https://duet3d.dozuki.com/Wiki/Macros.

Once you have changed/verified the motor settings, review the networking top portion of the file. When completed, copy all the files located in the 'sys', 'macros', and 'filaments' directory over to your sd-card. The 'www' and 'gcode' folder are present in the repository for reference and should not be needed to copy over to the sd-card in normal circumstances. More can be read about sd-card here: https://duet3d.dozuki.com/Wiki/SDCard, more can be read about macros here: https://duet3d.dozuki.com/Wiki/Macros. Sensorless Homing / Stallguard sensitivity.

Sensorless Homing / Stallguard sensitivity.

The TMC2660 drivers used on the Duet WiFi support the stallGuard feature. This feature allows the driver to detect motor stalls under some circumstances. Stall detection may be useful for detecting when a motor has skipped steps due to the nozzle hitting an obstruction, and for homing the printer without using endstop switches.

As the given configuration files were authored while using 0.9 degree stepper motors on the X and Y axis, you may need to adjust your stallguard sensitivity and sensorless homing. For stallguard sensitivity, look for the "M915" in the current-sense-homing.g and current-sense-normal.g files. Read the full documentation here: https://duet3d.dozuki.com/Wiki/Stall_detection_and_sensorless_homing. Use the included Macros for filament handling.

Use the included Macros for filament handling.

To make filament loading, unloading, and changing the most straightforward and simplistic possible evolution, I have made a macro set that is readily accessible from the PanelDue. To take full advantage of the duet filament system you will need to make the system filaments PLA, PETG, ABS, and PC. This will allow you to have custom instructions for each different filament, by adding such to the filament's config.g file. !Note: Based on my current macro version, it is required that each filament's load.g and unload.g remain empty. Placing code into these files will make these macro fail.

"Set Filament Type" asks what type filament you are going to use; PLA, PETg, ABS, or PC. Based on the selection, this macro rewrites the "Heat Nozzle" macro to heat the nozzle for the selected filament type. !Note: This macro only has to be executed once for the given filament type change as it's settings are nonvolatile, regardless of reset or power off. !Note: The script will not let you change the filament type while filament is loaded.

"Filament Handling" is for any filament unloading, loading, and changing regardless of the printer's state, printing or not. This macro will load, unload, and change filament based on two conditions; whether it detects filament is currently loaded or not, and if a print is in progress or not. !Note: The logic function in the macro retrieves the current status of the filament sensor to base the perceived desired action to enact. If your printer's filament is currently empty and you intend to load filament, please do not place it into the extruder until requested to do so by the macro. Else the macro will determine that filament is loaded and that you desire to unload filament, instead of load.

"Heat Nozzle" is created by the "Set Filament Type" macro and can be selected to heat the hotend to the set temperature for the last chosen filament type. You do not need to run this to change filament, the "Filament Handling" macro automatically runs this macro to perform the heating of the hotend to carry out the filament handling, whether it be loading, unloading, or changing.Print flow events:

When initiating a print, the following sequence of events occur in this order.

/sys/start.g is the first codeset that starts at the beginning of each print. This contains the generic processes that apply to all filament types. From this codeset, the fillament's config.g is called.

/filaments/PETG/config.g is the second codeset that get initiated from the "M703" command in the "start.g" file. As written in this example, we are set to use the PETG "config.g" file, located in the "filaments/PETG" directory. This contains the gcode commands that are particular to PETG filament type.

Slicer's Start GCode is the last bit of codeset to be executed before the object's sliced gcode starts. This contains the settings particulr to the actual print and the exact PETG filament loaded. This would be your 'fine' settings, where PETG/config.g could be considered your 'medium' settings, and start.g would be the 'rough' - performing evaluations to get the printer ready.

The part's actual gcode made by the slicer.

Slicer's End GCode follows the printed object's gcode. This codeset lets the duet know that the print is finished which calls

/sys/stop.g, the very last codeset that is executed. This last part commonly shutdowns heaters, retracts a bit of filament, and positions the machine to easily retrieve the printed part.Additional notes:

Electrically independent Z motors: On printers, such as MK3, which uses two Z motors to raise/lower the bed or gantry, you can have the firmware probe the bed and adjust the motors individually to eliminate tilt. The auto calibration uses a least squares algorithm that minimises the sum of the height errors. The deviation before and expected deviation after calibration is reported. Run G32 to initiate the process. Read the full documentation here: https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors.

Electrically independent Z motors: On printers, such as MK3, which uses two Z motors to raise/lower the bed or gantry, you can have the firmware probe the bed and adjust the motors individually to eliminate tilt. The auto calibration uses a least squares algorithm that minimises the sum of the height errors. The deviation before and expected deviation after calibration is reported. Run G32 to initiate the process. Read the full documentation here: https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors. PINDA v2: Pinda version 2 is upgraded from the previous version in that it now has an integrated thermistor, which this configuration electrically ties to thermistor E1 on the duet. Pinda temperature compensation has to be mitigated via g-code macro but will be handled via integrated function within the duet firmware shortly. Read @Argo's posting in the Duet forums: https://forum.duet3d.com/topic/16972/pinda-2-probe-with-temperature-compensation?_=1593546022132.

PINDA v2: Pinda version 2 is upgraded from the previous version in that it now has an integrated thermistor, which this configuration electrically ties to thermistor E1 on the duet. Pinda temperature compensation has to be mitigated via g-code macro but will be handled via integrated function within the duet firmware shortly. Read @Argo's posting in the Duet forums: https://forum.duet3d.com/topic/16972/pinda-2-probe-with-temperature-compensation?_=1593546022132. BLTouch v3.1: The config.g has comment sections for using this probe and the wiring guide covers the electrical installation of the BLTouch v3.1 in the last few pages. Read the full documentation here: https://duet3d.dozuki.com/Wiki/Connecting_a_Z_probe

BLTouch v3.1: The config.g has comment sections for using this probe and the wiring guide covers the electrical installation of the BLTouch v3.1 in the last few pages. Read the full documentation here: https://duet3d.dozuki.com/Wiki/Connecting_a_Z_probeExample start gcode for ideaMaker Slicer:

; ideaMaker Start G-Code ; Set nozzle and bed to the specific temperatures declared within this slicer M140 S{temperature_heatbed} ; set bed temp M104 S{temperature_extruder1} ; set extruder temp M116 ; wait for all temperatures ; Run macro to print primeline at a 'randomized' Y positon from -1.1 to -2.9 M98 P"0:/sys/primeLine.g" ; primeline macro ; Set pressure advance M572 D0 S0.07 ; set pressure advanceExample end gcode for ideaMaker Slicer:

; ideaMaker End G-Code M400 ; Make sure all moves are complete M0 ; Stop everything and run sys/stop.gExample start gcode for Simplify3D Slicer:

; Simplify3D Start G-Code ; Set nozzle and bed to the specific temperatures declared within this slicer M140 S[bed0_temperature] ; set bed temp M104 S[extruder0_temperature] ; set extruder temp M116 ; wait for all temperatures ; Run macro to print primeline at a 'randomized' Y positon from -1.1 to -2.9 M98 P"0:/sys/primeLine.g" ; primeline macro ; Set pressure advance M572 D0 S0.07 ; set pressure advanceExample end gcode for Simplify3D Slicer:

; Simplify3D End G-Code M400 ; Make sure all moves are complete M0Example start gcode for Prusa Slicer:

; PrusaSlicer Start G-Code: ; Set nozzle and bed to the specific temperatures declared within this slicer M140 S[first_layer_bed_temperature] ; set bed temp M104 S[first_layer_temperature] ; set extruder temp M116 ; wait for all temperatures ; Run macro to print primeline at a 'randomized' Y positon from -1.1 to -2.9 M98 P"0:/sys/primeLine.g" ; primeline macro ; Set pressure advance M572 D0 S0.07 ; set pressure advanceExample end gcode for Prusa Slicer:

; PrusaSlicer End G-Code M400 ; Make sure all moves are complete M0 ; Stop everything and run sys/stop.g*It is highly recommend to read through the very detailed Duet Wiki pages at https://duet3d.dozuki.com. RepRapFirmware supported G-code reference can be found here https://duet3d.dozuki.com/Wiki/Gcode#main.

-

-

DUET System (sd-card contents) files follow:

0:/sys/

bed.g - v08/04/20

; 0:/sys/bed.g ; Called to perform automatic bed compensation via G32 M561 ; Clear any bed transform G28 ; Home while iterations <=2 ; Perform 3 passes G30 P0 X25 Y107 Z-99999 ; Probe near a leadscrew, half way along Y axis G30 P1 X235 Y107 Z-99999 S2 ; Probe near a leadscrew and calibrate 2 motors G90 ; Set to Absolute Positioning G1 X100 ; Move to center G30 ; Probe the bed at the current XY position M400 ; Finish moves, clear buffer while move.calibration.initial.deviation >= 0.002 ; perform additional tramming if previous deviation was over 0.002mm if iterations = 5 ; Perform 5 addition checks, if needed M300 S3000 P500 ; Sound alert, required deviation could not be achieved abort "!!! ABORTED !!! Failed to achieve < 0.002 deviation. Current deviation is " ^ move.calibration.initial.deviation ^ "mm." G30 P0 X25 Y107 Z-99999 ; Probe near a leadscrew, half way along Y axis G30 P1 X235 Y107 Z-99999 S2 ; Probe near a leadscrew and calibrate 2 motors G90 ; Set to Absolute Positioning G1 X100 ; Move to center G30 ; Probe the bed at the current XY position M400 ; Finish moves, clear buffer echo "Gantry deviation of " ^ move.calibration.initial.deviation ^ "mm obtained." G1 Z8 ; Raise head 8mm to ensure it is above the Z probe trigger heightcancel.g - v08/04/20

; 0:/sys/cancel.g ; called when a print is canceled after a pause. M83 ; Makes the extruder interpret extrusion values as relative positions M104 S-273 ; turn off hotend M140 S-273 ; turn off heatbed M107 ; turn off fan G1 F1000.0 ; set feed rate G1 E-2 ; retract 2mm M18 YXE ; unlock X, Y, E axisconfig.g - v08/04/20

; 0:/sys/config.g ; Configuration file for MK3s Duet WiFi, firmware version 3.11 ; Go to https://github.com/rkolbi/RRF-machine-config-files/blob/master/Prusa%20MK3s/Duet-MK3s.pdf ; for corresponding wiring information. ; General preferences G90 ; Send absolute coordinates M83 ; Relative extruder moves M550 P"ZMK3-BMGm" ; Set printer name ; Network M551 P"3D" ; Set password M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disabled FTP M586 P2 S0 ; Disabled Telnet M575 P1 S1 B38400 ; Enable support for PanelDue ; Drive Mappings S0 = backwards, S1 = forwards M569 P0 S1 ; Drive 0 goes forwards: X Axis M569 P1 S1 ; Drive 1 goes forwards: Y Axis M569 P2 S1 ; Drive 2 goes forwards: Z Axis M569 P3 S0 ; Drive 3 goes backwards: E Axis (Bondtech BMGm) M569 P4 S1 ; Drive 4 goes forwards: Z Axis (at E1) ; Motor Configuration ; !!! For stock motors, use the following as a starting point: ; M906 X620.00 Y620.00 Z560.00 E650.00 I10. ; Set motor currents (mA) and motor idle factor in percent ; M350 X16 Y16 Z16 I1 ; Microstepping with interpolation ; M350 E32 I0 ; Microstepping without interpolation ; M92 X100.00 Y100.00 Z400.00 E280.00 ; Steps per mm ; !!! Also note that you should edit the current-sense-homing.g file and increase current to 50 on X and Y, 100 on Z. ; !!! M913 X20 Y20 Z60 ---> M913 X50 Y50 Z100 M350 X16 Y16 E16 Z16 I1 ; Configure microstepping with interpolation M92 X200.00 Y200.00 Z400.00 E415.00 ; Set steps per mm M566 X480.00 Y480.00 Z24.00 E1500.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z750.00 E1500.00 ; Set maximum speeds (mm/min) M201 X2500.00 Y2500.00 Z1000.00 E5000.00 ; Set accelerations (mm/s^2) M906 X1340.00 Y1600.00 Z650.00 E650.00 I10 ; Set initial motor currents (mA) and motor idle factor in percent M84 S30 ; Set idle timeout ; Motor remapping for dual Z and axis Limits M584 X0 Y1 Z2:4 E3 ; two Z motors connected to driver outputs Z and E1 M671 X-37:287 Y0:0 S10 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis M208 X0:250 Y-4:215 Z-0.1:205 ; X carriage moves from 0 to 250, Y bed goes from 0 to 210 M564 H0 ; allow unhomed movement ; Endstops for each Axis M574 X1 S3 ; Set endstops controlled by motor load detection M574 Y1 S3 ; Set endstops controlled by motor load detection ; Stallgaurd Sensitivy M98 P"current-sense-normal.g" ; Current and Sensitivity for normal routine ; Z-Probe Settings for BLTouch M558 P9 C"^zprobe.in" H5 F600 T5000 ; BLTouch, connected to Z probe IN pin M950 S0 C"exp.heater3" ; BLTouch, create servo/gpio 0 on heater 3 pin on expansion G31 P1000 X22.8 Y3.8 Z1.24 ; BLTouch, Z offset with MICRO SWISS NOZZLE M574 Z1 S2 ; Set endstops controlled by probe M557 X25:235 Y10:195 P9 ; Define mesh grid for probing ; Z-Probe Setting for PINDA v2 ; 1 - If using PindaV2, Remove above M558 & M950 lines, replace with the following M558 & M308 line ; 2 - Uncomment one of the Z-Offsets below, follow the wiki guide steps to get the proper Z-offset for your printer ; 3 - Comment out the 2 BLTouch lines in the homez and homeall files ; ; M558 P5 C"^zprobe.in" I1 H1 F1000 T6000 A20 S0.005 ; Prusa PindaV2 ; M308 S2 P"e1_temp" A"Pinda V2" Y"thermistor" T100000 B3950 ; Prusa PindaV2 ; ; Z-Offsets - Read here: https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe ; G31 P1000 X23 Y5 Z0.985 ; PEI Sheet (Prusa) Offset Spool3D Tungsten Carbide ; G31 P1000 X23 Y5 Z0.440 ; PEI Sheet (Prusa) Offset MICRO SWISS NOZZLE ; G31 P1000 X23 Y5 Z1.285 ; Textured Sheet (Prusa) Offset MICRO SWISS NOZZLE ; G31 P1000 X23 Y5 Z0.64 ; Textured Sheet (thekkiinngg) Offset MICRO SWISS NOZZLE ; Heatbed Heaters and Thermistor Bed M308 S0 P"bed_temp" Y"thermistor" A"Build Plate" T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 0 Bed M950 H0 C"bedheat" T0 ; Creates Bed Heater M307 H0 A117.2 C337.4 D9.1 S1.00 V24.0 B0 ; Bed PID Calibration - updated 01AUG2020 M140 H0 ; Bed uses Heater 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C Bed ; Filament Sensor M591 D0 P2 C"e0stop" S1 ; Filament Runout Sensor ; HotEnd Heaters and Thermistor HotEnd ; !!! Use this line for stock thermisotr: M308 S1 P"e0_temp" Y"thermistor" A"Nozzle" T100000 B4725 R4700 ; Set thermistor + ADC parameters for heater 1 HotEnd M308 S1 P"e0_temp" Y"pt1000" A"Mosquito" ; Set extruder thermistor for PT1000 M950 H1 C"e0heat" T1 ; Create HotEnd Heater M307 H1 A444.4 C181.6 D3.9 S1.00 V24.1 B0 ; Hotend PID Calibration - updated 01AUG2020 M143 H1 S285 ; Set temperature limit for heater 1 to 285C HotEnd M302 S190 R190 ; Allow cold extrudes, S-Minimum extrusion temperature, R-Minimum retraction temperature ; Fans M950 F1 C"Fan1" Q250 ; Creates HOTEND Fan M106 P1 T45 S255 H1 ; HOTEND Fan Settings M950 F0 C"Fan0" Q250 ; Creates PARTS COOLING FAN M106 P0 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off PARTS COOLING FAN ; The following lines are for auto case fan control, attached to 'fan2' header on duet board M308 S4 Y"drivers" A"TMC2660" ; Case fan - configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet ; !!! Reports 0C when there is no warning, 100C if any driver reports over-temperature ; !!! warning , and 150C if any driver reports over temperature shutdown M308 S3 Y"mcu-temp" A"Duet2Wifi" ; Case fan - configure sensor 3 as thermistor on pin e1temp for left stepper M950 F2 C"fan2" Q100 ; Case fan - create fan 2 on pin fan2 and set its frequency M106 P2 H4:3 L0.15 X1 B0.3 T40:70 ; Case fan - set fan 2 value M912 P0 S-5.5 ; MCU Temp calibration - default reads 7.5c higher than ambient ; Tools M563 P0 D0 H1 F0 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C T0 ; Set Tool 0 active ; Relase X, Y, and E axis M18 YXE ; Unlock X, Y, and E axiscurrent-sense-homing.g - v08/04/20

; 0:/sys/current-sense-homing.g ; Current and Sensitivity for homing routines M915 X S2 F0 H400 R0 ; Set X axis Sensitivity M915 Y S2 F0 H400 R0 ; Set y axis Sensitivity M913 X20 Y20 Z60 ; set X Y Z motors to X% of their normal currentcurrent-sense-normal.g - v08/04/20

; 0:/sys/current-sense-normal.g ; Current and Sensitivity for normal routine M913 X100 Y100 Z100 ; set X Y Z motors to 100% of their normal current M915 X S3 F0 H200 R0 ; Set X axis Sensitivity M915 Y S3 F0 H200 R0 ; Set y axis Sensitivitydeployprobe.g - v08/04/20

; 0:/sys/deployprobe.g ; called to deploy a physical Z probe M280 P0 S10 ; deploy BLTouch -

filament-change.g - v08/04/20

; 0:/sys/filament-change.g ; called when a print from SD card runs out of filament M25 G91 ; Relative Positioning G1 Z20 F360 ; Raise Z G90 ; Absolute Values G1 X200 Y0 F6000 ; Parking Position M300 S800 P8000 ; play beep sound M98 P"0:/macros/Filament Handling" ; unload and load filament using macro M400 ; clear moves M291 P"Press OK to recommence print." R"Filament Handling" S2 M98 P"0:/macros/Heat Nozzle" ; Get nozzle hot and continue printfilaments.csv - v08/04/20

RepRapFirmware filament assignment file v1 generated at 2020-08-01 15:01 extruder,filament 0,PETGfilaset - v08/04/20

T0 M702 T0 M701 S"PETG"homeall.g - v08/04/20

; 0:/sys/homeall.g ; home x, y, and z axis M98 P"current-sense-homing.g" ; Current and Sensitivity for homing routines ; !!! If using Pinda, comment-out the following two lines M280 P0 S160 ; BLTouch, alarm release G4 P100 ; BLTouch, delay for release command G91 ; relative positioning G1 Z3 F800 H2 ; lift Z relative to current position ; HOME X G1 H0 X5 F1000 ; move slowly away G1 H1 X-255 F3000 ; move quickly to X endstop G1 H0 X5 F1000 ; move slowly away G1 H1 X-255 F3000 ; move quickly to X endstop, second check ; HOME Y G1 H0 Y5 F1000 ; move slowly away G1 H1 Y-215 F3000 ; move quickly to Y endstop G1 H0 Y5 F1000 ; move slowly away G1 H1 Y-215 F3000 ; move quickly to Y endstops, second check ; HOME Z G1 H2 Z2 F2600 ; raise head 2mm to ensure it is above the Z probe trigger height G90 ; back to absolute mode G1 X15 Y15 F6000 ; go to first probe point G30 ; home Z by probing the bed G90 ; absolute positioning G1 H0 Z5 F400 ; lift Z relative to current position M98 P"current-sense-normal.g" ; Current and Sensitivity for normal routinehomex.g - v08/04/20

; 0:/sys/homex.g ; home the x axis M98 P"current-sense-homing.g" ; Current and Sensitivity for homing routines G91 ; relative positioning G1 Z3 F800 H2 ; lift Z relative to current position G1 H0 X5 F1000 ; move slowly away G1 H1 X-255 F3000 ; move quickly to X endstop G1 H0 X5 F1000 ; move slowly away G1 H1 X-255 F3000 ; move quickly to X endstop, second check G1 Z-3 F800 H2 ; place Z back to starting position M98 P"current-sense-normal.g" ; Current and Sensitivity for normal routinehomey.g - v08/04/20

; 0:/sys/homey.g ; home the y axis M98 P"current-sense-homing.g" ; Current and Sensitivity for homing routines G91 ; relative positioning G1 Z3 F800 H2 ; lift Z relative to current position G1 H0 Y5 F1000 ; move slowly away G1 H1 Y-215 F3000 ; move quickly to Y endstop G1 H0 Y5 F1000 ; move slowly away G1 H1 Y-215 F3000 ; move quickly to Y endstop, second check G1 Z-3 F800 H2 ; place Z back to starting position M98 P"current-sense-normal.g" ; Current and Sensitivity for normal routinehomez.g - v08/04/20

; 0:/sys/homez.g ; home the z axis M98 P"current-sense-homing.g" ; Current and Sensitivity for homing routines ; !!! If using Pinda, comment-out the following two lines M280 P0 S160 ; BLTouch, alarm release G4 P100 ; BLTouch, delay for release command G91 ; relative positioning G1 H0 Z3 F6000 ; lift Z relative to current position G90 ; absolute positioning G1 X15 Y15 F6000 ; go to first probe point G30 ; home Z by probing the bed G90 ; absolute positioning G1 H0 Z5 F400 ; lift Z relative to current position M98 P"current-sense-normal.g" ; Current and Sensitivity for normal routinepause.g - v08/04/20

; 0:/sys/pause.g ; called when a print from SD card is paused M120 ; Push the state of the machine onto a stack if sensors.filamentMonitors[0].filamentPresent = false G1 E-3 F3000 ; if filament has run out, retract 6mm of filament M83 ; relative extruder moves G1 E-3 F3000 ; retract 3mm of filament G91 ; Relative Positioning G1 Z10 F360 ; Raise Z G90 ; Absolute Values G1 X10 Y0 F6000 ; Parking Position M300 S80 P2000 ; play beep soundprimeline.g - v08/04/20

; 0:/sys/primeline.g ; Print prime-line at a 'randomized' Y positon from -1.1 to -2.9 G1 X0 Z0.6 Y{-2+(0.1*(floor(10*(cos(sqrt(sensors.analog[0].lastReading * state.upTime))))))} F3000.0; G92 E0.0 ; set E position to 0 G1 Z0.2 X100.0 E30.0 F1000.0 ; prime line G92 E0.0 ; set E position to 0 M400 ; finish all current moves / clear the bufferresume.g - v08/05/20

; 0:/sys/resume.g ; called before a print from SD card is resumed G1 E3 F400 ; extract 3mm of filament G1 R1 X0 Y0 Z5 ; go back to the last print position with Z 5mm above G1 R1 Z0 ; go to Z position of the last print move M121 ; Recover the last state pushed onto the stackretractprobe.g - v08/04/20

; 0:/sys/retractprobe.g ; called to retract a physical Z probe M280 P0 S90 ; retract BLTouchsleep.g - v08/04/20

; 0:/sys/sleep.g ; called when M1 (Sleep) is being processed M104 S-273 ; turn off hotend M140 S-273 ; turn off heatbed M107 ; turn off fan M18 XEZY ; unlock all axisstart.g - v08/04/20

; 0:/sys/start.g ; Executed before each print - BEFORE ANY SLICER CODE IS RAN ;M280 P0 S160 ; BLTouch, alarm release ;G4 P100 ; BLTouch, delay for release command M572 D0 S0.0 ; clear pressure advance M703 ; Execute loaded filement's config.g G28 ; Home all ; if using BLTouch probe, use the following line: G1 Z100 ; Last chance to check nozzle cleanliness ; if using Pinda type probe, use the following line to place probe center of bed to heat the probe ;G1 Z5 X100 Y100 ; Place nozzle center of bed, 5mm up M220 S100 ; Set speed factor back to 100% in case it was changed M221 S100 ; Set extrusion factor back to 100% in case it was changed M290 R0 S0 ; Clear babystepping M106 S0 ; Turn part cooling blower off if it is on M116 ; wait for all temperatures G32 ; Level bed G29 ; Bed mesh G90 ; Absolute Positioning M83 ; Extruder relative mode M98 P"0:/sys/current-sense-normal.g" ; Ensure that motor currents and sense are set for printing G1 X0 Y0 Z2 ; Final position before slicer's temp is reached and primeline is printed. ; The primeline macro is executed by the slicer gcode to enable direct printing ; of the primeline at the objects temp and to immediately print the object ; following primeline completion. ; Slicer generated gcode takes it away from herestop.g - v08/04/20

; 0:/sys/stop.g ; called when M0 (Stop) is run (e.g. when a print from SD card is cancelled) M83 ; Set extruder to relative mode M106 S255 ; Turn fan fully on M104 S-273 ; Turn off hotend M140 S-273 ; Turn off heatbed G1 F1000.0 ; Set feed rate G1 E-2.5 ; Retract 2.5mm G1 X0 Y215 Z205 F1000 ; Place nozzle to left side, build plate to front, Z at top M400 ; Clear queue M107 ; Turn off fan M18 YXE ; Unlock X, Y, and E axis ; Play a triumphant tune to celebrate a successful print. G4 S1 M300 P250 S750 G4 P251 M300 P200 S1250 G4 P201 M300 P250 S750 G4 P251 M300 P200 S1250 G4 P201 M300 P250 S2500 G4 P251 M300 P150 S2000 G4 P151 M300 P150 S2500 G4 P151 M300 P350 S3700 G4 P351 M4000:/macros/

Filament Handling - v08/04/20

; 0:/macros/Filament Handling ; Macro used for all filament handling evolutions if state.status != "processing" ; Printer is not currently printing! if sensors.filamentMonitors[0].filamentPresent = true ; Filament is detected, currently loaded M291 P"Press OK to begin filament UNLOADING, else press CANCEL to exit." R"Filament Handling" S3 M291 P"Please wait while the nozzle is being heated." T5 M98 P"0:/macros/Heat Nozzle" ; Heat nozzle to predetermined temp M291 P"Ready for filament unloading. Gently pull filament and press OK." R"Filament Handling" S2 M291 P"Retracting filament..." T5 ; Display another message G1 E-150 F5000 ; Retract filament M400 ; Wait for the moves to finish T0 M702 ; Select tool 0, set filament is unloaded M104 S-273 ; Turn off hotend M140 S-273 ; Turn off heatbed M98 P"0:/macros/Filament Handling"; run again ; Now that filament is unloaded, lets ask to load filament else M291 P"Press OK to begin filament LOADING, else press CANCEL to exit." R"Filament Handling" S3 M291 P"Please wait while the nozzle is being heated." T5 M98 P"0:/macros/Heat Nozzle" ; Heat nozzle to predetermined temp M291 P"Ready for filament loading. Insert filament and press OK." R"Filament Handling" S2 M291 P"Feeding filament..." T5 ; Display new message G1 E150 F450 ; Feed 150mm of filament at 600mm/min G1 E20 F100 ; Feed 20mm of filament at 100mm/min G4 P1000 ; Wait one second G1 E-1 F1800 ; Retract 10mm of filament at 1800mm/min M400 ; Wait for moves to complete M98 P"0:/sys/filaset" ; Set system filament type M400 ; Wait for moves to complete M104 S-273 ; Turn off hotend M140 S-273 ; Turn off heatbed else M291 P"Press OK to begin filament CHANGE, else press CANCEL to exit." R"Filament Handling" S3 M98 P"0:/sys/filament-change.g" ; Call filament-change.g M24 ; Start/resume SD printHeat Nozzle - v08/04/20

; 0:/macros/Heat Nozzle ; Heat nozzle to set temp M291 R"Filament Handling" P"Heating nozzle for PETg, please wait." S0 T5 T0 ; Select Tool 0 M109 S230 ; set temp to 230c and waitSet Filament Type - v08/04/20

; 0:/macros/Set Filament Type ; Macro used to set system's loaded filament type if sensors.filamentMonitors[0].filamentPresent = false ; if filament is loaded then reject action to change filament type M291 P{"System filament is currently set to " ^ move.extruders[0].filament ^ ". Press OK to change filament type, else press CANCEL to exit."} R"Filament Handling" S3 ; Set PLA temp M28 "0:/macros/Heat Nozzle" ; Begin writing to SD card file M291 R"Filament Handling" P"Heating nozzle for PLA, please wait." S0 T5 T0 ; Activate Hotend M109 S200 ; set temp to 200c and wait M29 ; Stop writing to SD card M28 "0:/sys/filaset" ; Begin writing to SD card file T0 M702 ; Set system filament as UNLOADED T0 M701 S"PLA" ; Set system filament as PLA M29 ; Stop writing to SD card M291 S3 R"Filament Handling" P"Filament type currently set to PLA. Press cancel to save this selection or OK to proceed to next filament type." ; Set PETg temp M28 "0:/macros/Heat Nozzle" ; Begin writing to SD card file M291 R"Filament Handling" P"Heating nozzle for PETg, please wait." S0 T5 T0 ; Activate Hotend M109 S230 ; set temp to 230c and wait M29 ; Stop writing to SD card M28 "0:/sys/filaset" ; Begin writing to SD card file T0 M702 ; Set system filament as UNLOADED T0 M701 S"PETG" ; Set system filament as PETG M29 ; Stop writing to SD card M291 S3 R"Filament Handling" P"Filament type currently set to PETg. Press cancel to save this selection or OK to proceed to next filament type." ; Set ABS temp M28 "0:/macros/Heat Nozzle" ; Begin writing to SD card file M291 R"Filament Handling" P"Heating nozzle for ABS, please wait." S0 T5 T0 ; Activate Hotend M109 S250 ; set temp to 250c and wait M29 ; Stop writing to SD card M28 "0:/sys/filaset" ; Begin writing to SD card file T0 M702 ; Set system filament as UNLOADED T0 M701 S"ABS" ; Set system filament as ABS M29 ; Stop writing to SD card M291 S3 R"Filament Handling" P"Filament type currently set to ABS. Press cancel to save this selection or OK to proceed to next filament type." ; Set PC temp M28 "0:/macros/Heat Nozzle" ; Begin writing to SD card file M291 R"Filament Handling" P"Heating nozzle for PC, please wait." S0 T5 T0 ; Activate Hotend M109 S270 ; set temp to 270c and wait M29 ; Stop writing to SD card M28 "0:/sys/filaset" ; Begin writing to SD card file T0 M702 ; Set system filament as UNLOADED T0 M701 S"PC" ; Set system filament as PC M29 ; Stop writing to SD card M291 S3 R"Filament Handling" P"Filament type currently set to PC. Press cancel to save this selection or OK to proceed to next filament type." else M291 S3 R"Filament Handling" P"Filament is currently loaded. Please unload filament before changing filament type." -

0:/filaments/ABS/

config.g - v08/04/20

; 0:/filaments/ABS/config.g ; Macro use to set 'basic' setting for filament type M300 S1000 P200 G4 P500 M300 S3000 P300 ; play some tones M140 S75 ; set bed temp M104 S150 ; set extruder warm-up temp ; active temp set from slicer gcode ; Insert additional filament specific settings hereload.g - v08/04/20

; LEAVE EMPTYunload.g - v08/04/20

; LEAVE EMPTY0:/filaments/PC/

config.g - v08/04/20

; 0:/filaments/PC/config.g ; Macro use to set 'basic' setting for filament type M300 S1000 P200 G4 P500 M300 S3000 P300 ; play some tones M140 S75 ; set bed temp M104 S150 ; set extruder warm-up temp ; active temp set from slicer gcode ; Insert additional filament specific settings hereload.g - v08/04/20

; LEAVE EMPTYunload.g - v08/04/20

; LEAVE EMPTY0:/filaments/PETG/

config.g - v08/04/20

; 0:/filaments/PETG/config.g ; Macro use to set 'basic' setting for filament type M300 S1000 P200 G4 P500 M300 S3000 P300 ; play some tones M140 S75 ; set bed temp M104 S150 ; set extruder warm-up temp ; active temp set from slicer gcode ; Insert additional filament specific settings hereload.g - v08/04/20

; LEAVE EMPTYunload.g - v08/04/20

; LEAVE EMPTY0:/filaments/PLA/

config.g - v08/04/20

; 0:/filaments/PLA/config.g ; Macro use to set 'basic' setting for filament type M300 S1000 P200 G4 P500 M300 S3000 P300 ; play some tones M140 S65 ; set bed temp M104 S150 ; set extruder warm-up temp ; active temp set from slicer gcode ; Insert additional filament specific settings hereload.g - v08/04/20

; LEAVE EMPTYunload.g - v08/04/20

; LEAVE EMPTY -

Updated primeline:

; 0:/sys/primeline.g ; Print prime-line at a 'randomized' Y position from -1.1 to -2.9 ; Charge! tune M400 G4 S1 M300 P200 S523.25 G4 P200 M300 P200 S659.25 G4 P200 M300 P200 S739.99 G4 P250 M300 P285 S880.00 G4 P450 M300 P285 S880.00 G4 P285 M300 P625 S1108.73 G4 S1 M400 G1 X0 Z0.6 Y{-2+(0.1*(floor(10*(cos(sqrt(sensors.analog[0].lastReading * state.upTime))))))} F3000.0; G92 E0.0 ; Reset extrusion distance G1 E8 ; Purge Bubble G1 X60.0 E11.0 F1000.0 ; intro line G1 X120.0 E16.0 F1000.0 ; intro line G92 E0.0 ; Reset extrusion distance M400 ; Finish all current moves / clear the buffer -

I added a new macro, Hotmesh.

"Hotmesh" preforms bed a mesh probing routine with a heat stabilized bed. This macro will heat the bed based on the currently set system filament type, wait 5 minutes for the bed temperature to stabilize, and then perform mesh probe. Once initiated, the nozzle will rise to 150mm and then lower 15mm for every 30 seconds elapsed - about 5 minutes in total. Once the nozzle is at the bed, the mesh probing cycle will commence.; 0:/macros/hotmesh.g ; Called to perform automatic heated bedmesh compensation T0 ; Ensure tool is selected M703 ; Heat bed to set temp based off current system filament type M104 S-273 ; Turn off hotend M106 S0 ; Turn part cooling blower off if it is on M291 P{"Performing bed heatup per " ^ move.extruders[0].filament ^ " profile. This process will take approximately 6 minutes."} R"Hotmesh" S0 T10 G28 ; Home G1 X100 Y100 ; Place nozzle center of bed ; Give 5 minutes for stabilization G91 ; Set to Rel Positioning while iterations <=9 ; Perform 10 passes G1 Z15 ; Move Z 15mm up G4 S0.5 ; Wait .5 seconds M116 ; Wait for all temperatures M291 P"Bed temperature at setpoint. Please wait 5 minutes for stabilization, Z indicates countdown." R"Hotmesh" S0 T10 ; Start countdown - use Z as indicator while iterations <=9 ; Perform 10 passes G4 S30 ; Wait 30 seconds G1 Z-15 ; Move Z 15mm down G90 ; Set to Absolute Positioning M291 P"Performing homing, gantry alignment, and mesh probing. Please wait." R"Hotmesh" S0 T10 G32 ; Home and Level gantry M400 ; Clear queue G29 ; Perfrom bed mesh M104 S-273 ; Turn off hotend M140 S-273 ; Turn off heatbed M291 P"Hotmesh complete. Hotend and Heatbed are turned off. Performing final homing routine. Please wait." R"Hotmesh" S0 T10 G28 ; Home -

Alternative setup to load bedmesh from the system's set filament type directory, and if start.g fails load the file (because it doesn't exist) it will create one.

Alternative Hotmesh.g:

This saves the heightmap to the system's set filament type directory (0:/filaments/PETG/heightmap.csv); 0:/macros/hotmesh.g ; Called to perform automatic heated bedmesh compensation ; Alternative Hotmesh.g - This saves the heightmap to the system's set filament's type directory (0:/filaments/PETG/heightmap.csv) if state.status = "processing" ; Printer is currently printing! M99 ; Abort this macro T0 ; Ensure tool is selected M703 ; Heat bed to set temp based off current system filament type M104 S-273 ; Turn off hotend M106 S0 ; Turn part cooling blower off if it is on M291 P{"Performing bed heatup per " ^ move.extruders[0].filament ^ " profile. This process will take approximately 6 minutes."} R"Hotmesh" S0 T10 G28 ; Home G1 X100 Y100 ; Place nozzle center of bed ; Give 5 minutes for stabilization G91 ; Set to Rel Positioning while iterations <=9 ; Perform 10 passes G1 Z15 F300 ; Move Z 15mm up G4 S0.5 ; Wait .5 seconds M116 ; Wait for all temperatures M291 P"Bed temperature at setpoint. Please wait 5 minutes for stabilization, Z indicates countdown." R"Hotmesh" S0 T10 ; Start countdown - use Z as indicator while iterations <=9 ; Perform 10 passes G4 S30 ; Wait 30 seconds G1 Z-15 F300 ; Move Z 15mm down G90 ; Set to Absolute Positioning M291 P"Performing homing, gantry alignment, and mesh probing. Please wait." R"Hotmesh" S0 T10 G32 ; Home and Level gantry M400 ; Clear queue G29 ; Perfrom bed mesh G29 S3 [P{"0:/filaments/" ^ move.extruders[0].filament ^ "/heightmap.csv"}] ; Save heightmap.csv to filament type's directory M104 S-273 ; Turn off hotend M140 S-273 ; Turn off heatbed M291 P"Hotmesh complete. Hotend and Heatbed are turned off. Performing final homing routine. Please wait." R"Hotmesh" S0 T10 G28 ; Home M18 ; Free allAlternative Start.g:

Alternative Start.g - This loads the heightmap from the system's set filament type directory (0:/filaments/PETG/heightmap.csv), if the heightmap does not exist, create one, and then save in the filament's directory.; 0:/sys/start.g ; Executed before each print - BEFORE ANY SLICER CODE IS RAN ; Alternative Start.g - This loads the heightmap from the system's set filament ; type directory (0:/filaments/PETG/heightmap.csv), if the heightmap does not ; exist, create one, and then save in the filament's directory. T0 ; Ensure tool is selected ;M280 P0 S160 ; BLTouch, alarm release ;G4 P100 ; BLTouch, delay for the release command M572 D0 S0.0 ; clear pressure advance M220 S100 ; Set speed factor back to 100% in case it was changed M221 S100 ; Set extrusion factor back to 100% in case it was changed M290 R0 S0 ; Clear babystepping M106 S0 ; Turn part cooling blower off if it is on M703 ; Execute loaded filament's config.g G28 ; Home all ;G1 Z5 X100 Y100 ; [PINDA] Place nozzle center of bed, 5mm up G1 Z160 F300 ; [BLTouch] Last chance to check nozzle cleanliness M300 S4000 P100 G4 P200 M300 S4000 P100 ; Give a double beep M116 ; wait for all temperatures M300 S4000 P100 ; Give a single beep ; [BLTouch] Start countdown - use Z as indicator G91 ; [BLTouch] Set to Relative Positioning while iterations <=9 ; [BLTouch] Perform 10 passes G4 S12 ; [BLTouch] Wait 12 seconds G1 Z-15 F300 ; [BLTouch] Move Z 15mm down G90 ; [BLTouch] Set to Absolute Positioning ;G4 S120 ; [PINDA] wait additional 2 minutes for the bed to stabilize G32 ; Level bed G29 S1 [P{"0:/filaments/" ^ move.extruders[0].filament ^ "/heightmap.csv"}] ; Load bed mesh for the system's set filament type if result > 1 ; If file doesn't exist, perform mesh and save G29 ; Perform mesh now G29 S3 [P{"0:/filaments/" ^ move.extruders[0].filament ^ "/heightmap.csv"}] ; Save heightmap.csv to filament type's directory M400 ; Finish all current moves / clear the buffer G90 ; Absolute Positioning M83 ; Extruder relative mode M98 P"0:/sys/current-sense-normal.g" ; Ensure that motor currents and sense are set for printing G1 X0 Y0 Z2 ; Final position before slicer's temp is reached and primeline is printed. ; The primeline macro is executed by the slicer gcode to enable direct printing ; of the primeline at the objects temp and to immediately print the object ; following primeline completion. ; Slicer generated gcode takes it away from here -

Latest README: README.pdf

Latest sd-card dump: README above contains dump.

Latest wiring guide: Duet2.pdf

Archive file containing the full set of sd-card files, wiring guide, readme, and ideaMaker example profile set.The next meaningful revision of my files will most likely occur once variables are enabled within the gcode macros.

If you find any issues or have any suggestions please let me know so I can take the appropriate actions and make this a better guide/code for the public.

Many thanks Duet forum people!

Cheers,

Kolbi -

Thanks for the excellent reference examples.

Also just a heads up it looks like the forum software or copy paste error is inserting some random

{1}to your blocks. -

@Phaedrux Thanks much!

I saw the {1} and tried to get rid of them but for some reason, it didn't work.

I did attach my dump-list.pdf so people could view it there also - I keep this one updated too.I'll give it a shot once I get some time this evening. Do you know what causes them?

Cheers,

Kolbi -

@Kolbi said in Zaribo / Prusa i3 MK3s - Duet 2 WiFi - RRF 3.11:

Do you know what causes them?

They seem to show up on line breaks within the code blocks for some reason. It's a forum issue.

-

@Phaedrux said in Zaribo / Prusa i3 MK3s - Duet 2 WiFi - RRF 3.11:

show up on line breaks within the code blocks

Ah! Just add a space after a line break and that gets rid of it.

-

Good to know!

-

@Phaedrux said in Zaribo / Prusa i3 MK3s - Duet 2 WiFi - RRF 3.11:

They seem to show up on line breaks within the code blocks for some reason. It's a forum issue.

not for all types of code interestingly enough, but haven't experimented with the complete list of language highlighting.

-

Updated stop.g, focused on getting rid of spider web / hair like stringing from nozzle while leaving nothing on nozzle.

; 0:/sys/stop.g ; called when M0 (Stop) is run (e.g. when a print from SD card is cancelled) M83 ; Set extruder to relative mode M106 S255 ; Turn fan fully on M572 D0 S0.0 ; clear pressure advance M220 S100 ; Set speed factor back to 100% in case it was changed M221 S100 ; Set extrusion factor back to 100% in case it was changed G1 E-2 ; Retract 2mm M104 S-273 ; Turn off hotend M140 S-273 ; Turn off heatbed G1 F1000.0 ; Set feed rate M98 P"current-sense-homing.g" ; Adjust current and sensitivity for homing routines ; Let cool and wiggle for bit to reduce end stringing M300 S4000 P100 G4 P200 M300 S4000 P100 ; Give a double beep G91 ; Set to Relative Positioning G1 Z2 F400 ; Move Z up 3mm ; Start countdown - use X/Y as indicators of counting while iterations <=9 ; Perform 10 passes G4 S6 ; Wait 6 seconds G1 X1 Y1 F1000 ; Wiggle +1mm G4 S6 ; Wait 6 seconds G1 Z0.5 X-1 Y-1 F1000 ; Wiggle -1mm, Z +0.5 G90 ; Set to Absolute Positioning G1 X220 Y205 Z205 F1000 ; Place nozzle to the right side, build plate to front, Z at top M400 ; Clear queue M107 ; Turn off fan M18 YXE ; Unlock X, Y, and E axis ; Play a triumphant tune to celebrate a successful print. G4 S1 M300 P250 S750 G4 P251 M300 P200 S1250 G4 P201 M300 P250 S750 G4 P251 M300 P200 S1250 G4 P201 M300 P250 S2500 G4 P251 M300 P150 S2000 G4 P151 M300 P150 S2500 G4 P151 M300 P350 S3700 G4 P351 M400 -

Attached modified BMGm-BLTouch.

Offsets at X22.8, Y3.8, Z1.32.10068-6 Prusa Housing Rear MK3s MosquitoV1.4.STL 10068-7 Prusa Housing Front MK3s MosquitoV1.4.STL

-

Forgot the bltouch wire cover.

bltouch-wirecover.STL*The front and back parts require threaded inserts.

-

undefined jdebuhr referenced this topic 9 May 2022, 02:44

undefined jdebuhr referenced this topic 9 May 2022, 02:44

-

undefined T3P3Tony unpinned this topic 27 Sept 2022, 11:24

undefined T3P3Tony unpinned this topic 27 Sept 2022, 11:24

-

Hello @Kolbi do you have an enclosure for Duet wifi that mount to the printer ? I’d love to have an STL if you mind sharing

-

@e4d Sorry, It's been a while and I don't have that on my latest laptop. I'll give a search on my home server when I get a chance to see if I may have backed it up.

But, give a look at the caribou github - variants from duet 2 and 3mini exist.

https://github.com/Caribou3d/CaribouCartesian/tree/master/STL/01_full-kits/Frame/DuetHope that helps!