Tips to mitigate vertical artifacting Duet 2 Wifi

-

@Veti Yeah, that kind of sucks. I have been looking for alternatives all morning, but 5mm bore is about my only option. I really didn't want to go down that small. I am determined to find some sort of work around.

-

what quality are your F623zz ? for a corexy they should be ABEC-3 or above.

-

i am going to test these myself once they arrive.

https://www.aliexpress.com/item/4000040551804.html

but i dont have high hopes -

@Veti I am actually using F688ZZ. Not sure the grade.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

F688ZZ

closest thing i can find is

https://www.aliexpress.com/item/32961265334.html

but its 6mm bore -

@Veti I am trying 16 tooth idlers like this on my kossel delta, but have bought some 6x2.5x3mm bore bearings, and pressed 3 into each idler. You clamp the idler firmly (not possible with the original 2 bearing idlers), but you need 3mm bore washers that are 4.5mm diameter to do this. Will be interesting to see if they last longer.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

@Veti Yeah, that kind of sucks. I have been looking for alternatives all morning, but 5mm bore is about my only option. I really didn't want to go down that small. I am determined to find some sort of work around.

It seems you think 5mm is too small. Why do you think that is so?

Thanks.

Frederick

-

@fcwilt It's not that I think it's too small, I just wanted a little larger hardware on this setup.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

I need to find some toothed pullies that will fit my setup.

I was able to do a few belt twists to run the smooth side of the belt over my flanged bearings. When I tried toothed idlers there was still a lot of ridges. I think the small 16T idlers are just too tight of a bend for the teeth to mesh smoothly. I was able to have the belt twists on the fixed length sections between the motor and the rear idlers.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

It's not that I think it's too small, I just wanted a little larger hardware on this setup.

ok then here you go.

https://www.aliexpress.com/item/32961693003.html

its 8mm bore.

but the diameter is larger than the F688ZZ -

@Phaedrux Run a test with a belt twist now.

-

@Veti Nice find, I am going to grab some for testing.

-

@Phaedrux Still confused, the belt flip didn't change anything.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

@Phaedrux Still confused, the belt flip didn't change anything.

Well that's one more thing to cross off the list and leaves stepper artifacts. I wonder if it's related to the exoslide movement? Is there more or less resistance to motion with it?

Were you able to print a test that varied the speed over a range to try and see if there is a speed which doesn't excite the artifacts?

-

What I.D. would you prefer for a toothed idler? Also, what effective O.D. are you aiming for? (to keep the belts aligned)

I agree it's too hard to find the right idlers, but Misumi has a few options I could try and find something for you.

-

@bot Most of the bearing are 8mm ID and 16 OD. I have 2 that are 8mm ID 12mm OD, 1 in each path to help with clearance.

-

@Phaedrux The max speed test is interesting. Started at lower speeds. As it got faster the ringing increased, the artifact stayed the same.

-

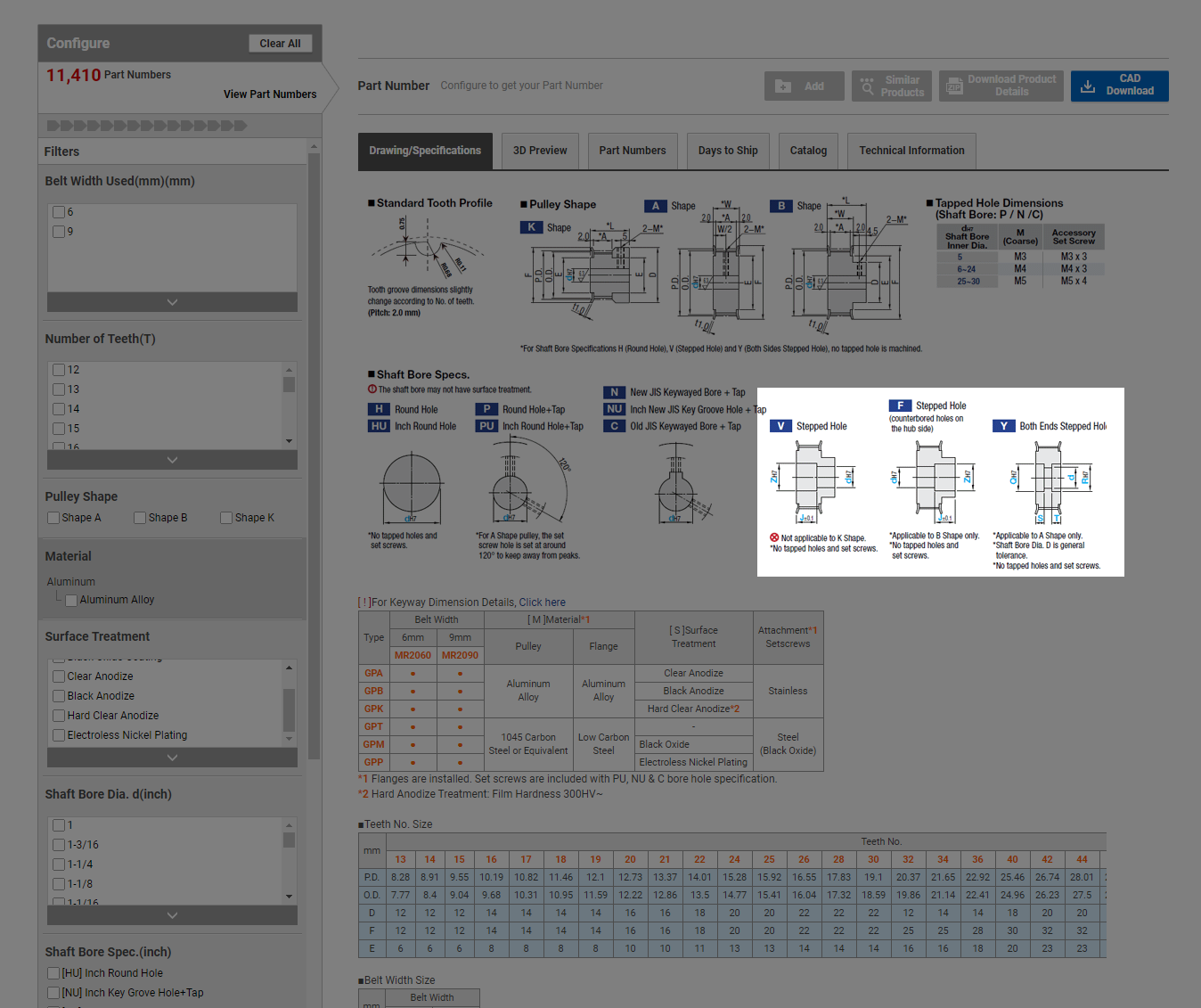

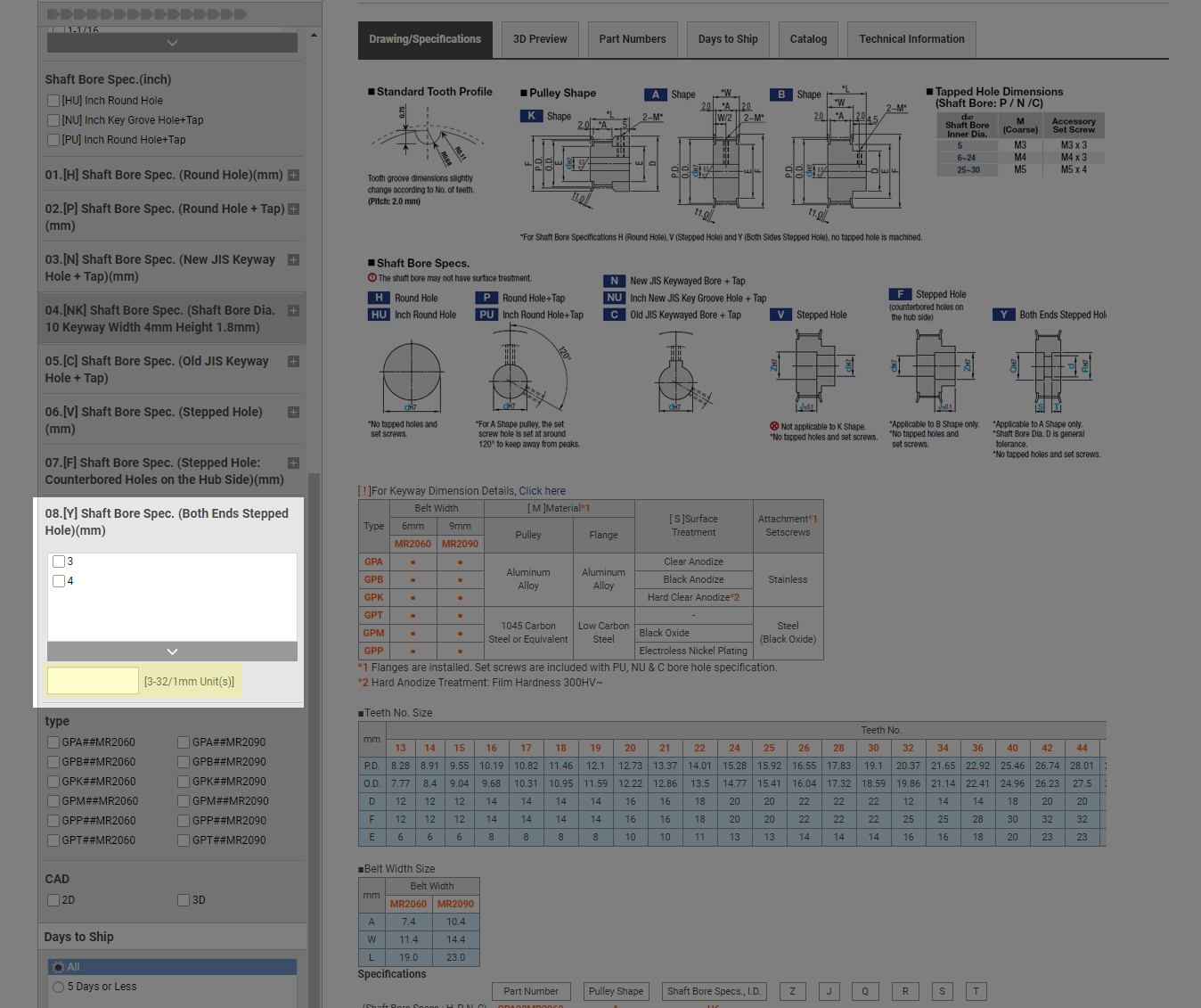

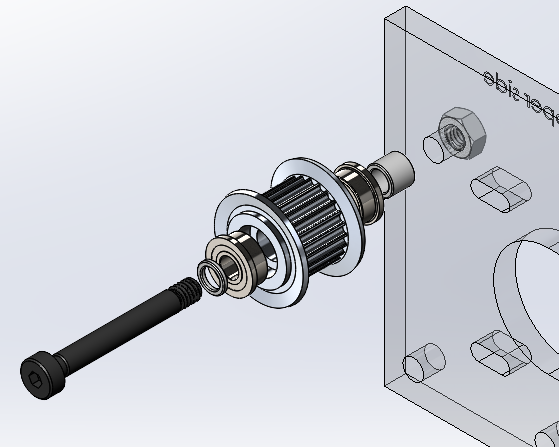

Well, I wasn't able to find any ready-to-go off-the-shelf idlers from Misumi (that are more than 5 or 6 mm), but I've always wanted to try using one of their customizable pulleys for idlers: See info here.

You can choose a wide range of sizes of pulley there, and you can get stepped holes made which should allow for easy placement of bearings. They have a variety of options and you can have the stepped hole sized how you wish. See:

[Edit: this photo is slightly misleading, there are more options to configure to get a full part number. Still playing around with it

]

] -

@bot said in Tips to mitigate vertical artifacting Duet 2 Wifi:

Well, I wasn't able to find any ready-to-go off-the-shelf idlers from Misumi (that are more than 5 or 6 mm), but I've always wanted to try using one of their customizable pulleys for idlers: See info here.

You can choose a wide range of sizes of pulley there, and you can get stepped holes made which should allow for easy placement of bearings. They have a variety of options and you can have the stepped hole sized how you wish. See:

snip

[Edit: this photo is slightly misleading, there are more options to configure to get a full part number. Still playing around with it

]

]I've done that on my machine, and it works quite well (albeit the assembly stackup can get pricy quick!). Must carefully select parts based on all the appropriate parameters.

Something to look out for is there is an issue on Misumi's site it seems, where you cannot select all the options on the left side (for example, with the Gates MR2 page, the "T" parameter does not show up. As an example, filling out all the available options can give you "GPA30MR2090-A-Y4-Q6-R6-S3", so copying and pasting that P/N with the addition of "-T3" into the search pulls up a real part.

For this case, do we want GT2/GT3 (Gates MR) or the 2GT series?

Looking at 2GT

Looks like something like 26teeth would match the 16mm OD (16.04mm OD, 16.55 PD). However the max 'shaft' hole for this size is 6mm, and the max counterbore is 8mm. However, it looks like the site gets stuck at GPA26GT2060-A-Y6, and we cannot configure past that. -

@brotherchris this happens with thin wall (one or two wall/perimeter only) prints correct (I'm sure the answer is yes, but I want to ask). What you could do, to see if it is an extruder issue, is print a hollow square pyramid (maybe with the top cut off) or cone. Probably should keep the print speed consistent throughout the print. What this should, I think, test, is if the "candy stripes" will maintain the same pattern (straight diagonals) or change style, by varying the layer cross section as height increases. I think that, if it is an extruder issue, the diagonal artifacts will turn into curves.

Horrible PowerPoint diagram - what is happening now

What I would expect to happen (not exactly haha)