Tips to mitigate vertical artifacting Duet 2 Wifi

-

@sebkritikel said in Tips to mitigate vertical artifacting Duet 2 Wifi:

[...]

I've done that on my machine, and it works quite well (albeit the assembly stackup can get pricy quick!). Must carefully select parts based on all the appropriate parameters.

That is awesome! I'm glad to hear. How did the bearings fit into the stepped holes? Not much of a press fit, but an "aligned fit?" Where they won't go in unless they're straight, but they aren't firmly held in place?

Something to look out for is there is an issue on Misumi's site it seems, where you cannot select all the options on the left side (for example, with the Gates MR2 page, the "T" parameter does not show up. As an example, filling out all the available options can give you "GPA30MR2090-A-Y4-Q6-R6-S3", so copying and pasting that P/N with the addition of "-T3" into the search pulls up a real part.

I encountered exactly that issue but was too lazy to re-figure out how to get around those problems. With how shiny they made their website lately, the user experience hasn't improved much lol.

For this case, do we want GT2/GT3 (Gates MR) or the 2GT series?

Looking at 2GT

Looks like something like 26teeth would match the 16mm OD (16.04mm OD, 16.55 PD). However the max 'shaft' hole for this size is 6mm, and the max counterbore is 8mm. However, it looks like the site gets stuck at GPA26GT2060-A-Y6, and we cannot configure past that.I forgot about the 16 mm OD specification. That indeed will limit the geometry. I was also looking at 9 mm width, which perhaps could also change available specifications. With A shape and 9 mm belt, I was able to select Y in the range of up to 21 mm or so. The Y is confusing, though -- it's the shaft bore diameter. The stepped bore is greater.

Oh, and yeah we want the "MR2" listing. Misumi does have some other type listed under 2GT or some such, and they are said to be compatible by Misumi reps. Dunno. The MR2 has more options, IIRC.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

@Phaedrux The max speed test is interesting. Started at lower speeds. As it got faster the ringing increased, the artifact stayed the same.

Since you've still got a lot of ringing I'd try to find a print speed you want to use (based on the layer height and width you want to use) to maximize the flow rate of the hotend, and then find a jerk and accel combo that eliminates the ringing. Then any remaining artifacts will be a lot easier to see and isolate.

Finding max flow rate: https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s177

-

@theruttmeister said in Tips to mitigate vertical artifacting Duet 2 Wifi:

@sebkritikel said in Tips to mitigate vertical artifacting Duet 2 Wifi:

For this case, do we want GT2/GT3 (Gates MR) or the 2GT series?

Looking at 2GTThose are essentially all the same thing. Gates powergrip. GT is the early version, GT2 being a newer stronger belt design, GT3 being the newest (2GT being either GT in 2mm pitch, or GT2 written oddly). They come in anything from 1 to 14mm pitch (with 2mm being the most common in 3D printing).

The tooth profile and the pulleys are all same for a given pitch. Its only the belt construction that changed as far as I know.For Gates GT2 VS GT3, you are correct - tooth profile is identical, GT2 pulleys and GT3 pulleys are identical. The GT3 belt is somewhat thicker on the backside.

GT2 is not 2GT, and GT3 is not 3GT - Gates GT3 belts used in Stratasys printers (Dimension series, etc) is not the same tooth profile when discussing Gates Unitta 2GT (sold by e3d for example), nor the 2GT (or 3GT) series sold by Misumi. GT2 vs GT3 does not correlate to 2mm or 3mm pitch, like you said - MR2, MR3, does correlate to pitch however. Gates GT2/GT3, be it MR2, MR3, MR5, etc, is not directly compatible with 2GT, 3GT, etc. What "Gates" you get from SDP/SI, Misumi, is not what you get from e3d.

Hilariously Misumi put out a blog post to talk about some of the differences, but frankly they did a bad job at it: https://blog.misumiusa.com/youve-got-the-power-mr-vs-gt/

Many people (including lovely Amazon and Aliexpress sellers) use 2GT and GT2 interchangeably (and often will throw MXL and whatnot in there as well).

-

@bot said in Tips to mitigate vertical artifacting Duet 2 Wifi:

That is awesome! I'm glad to hear. How did the bearings fit into the stepped holes? Not much of a press fit, but an "aligned fit?" Where they won't go in unless they're straight, but they aren't firmly held in place?

Exactly as you say! With the h7 hole, more of an aligned fit vs a press fit.

I encountered exactly that issue but was too lazy to re-figure out how to get around those problems. With how shiny they made their website lately, the user experience hasn't improved much lol.

I forgot about the 16 mm OD specification. That indeed will limit the geometry. I was also looking at 9 mm width, which perhaps could also change available specifications. With A shape and 9 mm belt, I was able to select Y in the range of up to 21 mm or so. The Y is confusing, though -- it's the shaft bore diameter. The stepped bore is greater.

Oh, and yeah we want the "MR2" listing. Misumi does have some other type listed under 2GT or some such, and they are said to be compatible by Misumi reps. Dunno. The MR2 has more options, IIRC.

Reading this stuff really bugs me out haha, I need to reach out to one of their reps re: 2GT, 3GT VS Gates MR. I'm pretty sure that, if Chris is using anything from e3d (2GT), Chris will need to stick with 2GT, vs Gates MR (even though MR has more options!).

-

@sebkritikel Dude... yeah I just read your reply and saw that blog post -- WTF. It's so confusing. I've got MR2 drive pulleys and 2GT idlers because a Misumi rep told me that this combination would work. And it seems to work pretty damn well but I almost want to try converting the idlers to MR2 to see how it is. My belts are also MR2.

I wasn't aware that the Unitta/E3D stuff is much different, but thankfully I have no desire to mix and match anyway.

-

@sebkritikel Here are the results of the pyramid. It breaks the strait lines into more of a gradient.

-

@sebkritikel said

Hilariously Misumi put out a blog post to talk about some of the differences, but frankly they did a bad job at it: https://blog.misumiusa.com/youve-got-the-power-mr-vs-gt/

They are different! [proceed to not explain the differences at all]

Thanks Misumi!

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

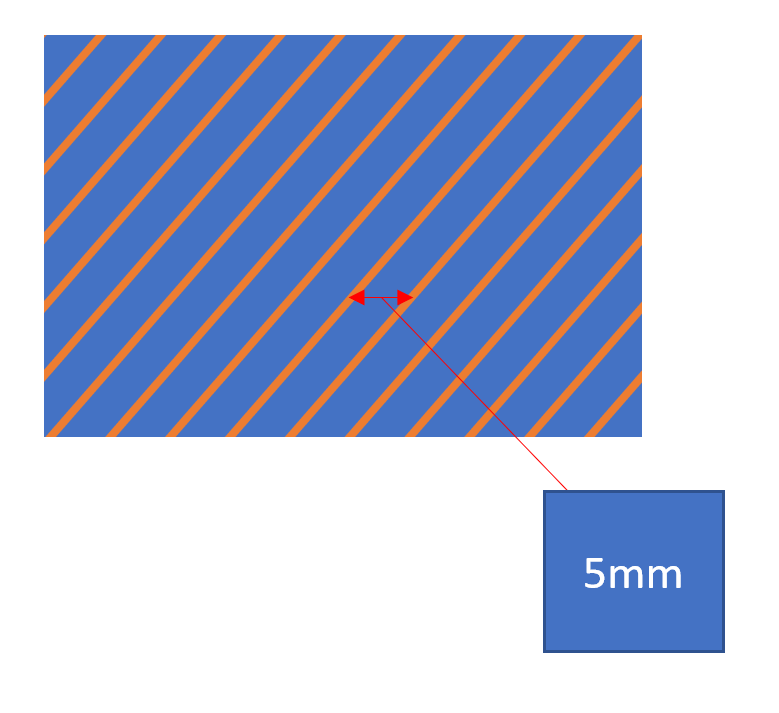

@sebkritikel Here are the results of the pyramid. It breaks the strait lines into more of a gradient.

Hi Chris, apologies for the delay in response. Not quite the result I was expecting, but I think its along the same vein. The repeating "diagonal" lines in a constant-cross section print, and the gradient in the "pyramid" print do suggest some sort of eccentricity or issue with the extruder.

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

More pic of the stripes. Reminds me of old school A4988 candy strips. snip

In these pictures, where the pattern is much more obvious, you can measure the error period, and eventually verify if the error occurs only after a complete revolution of a specific part of the extruder - stepper, a gear, etc.

Example measurement.

-

@theruttmeister said in Tips to mitigate vertical artifacting Duet 2 Wifi:

@sebkritikel said

Hilariously Misumi put out a blog post to talk about some of the differences, but frankly they did a bad job at it: https://blog.misumiusa.com/youve-got-the-power-mr-vs-gt/

They are different! [proceed to not explain the differences at all]

Thanks Misumi!

hahahaha

@bot said in Tips to mitigate vertical artifacting Duet 2 Wifi:

@sebkritikel Dude... yeah I just read your reply and saw that blog post -- WTF. It's so confusing. I've got MR2 drive pulleys and 2GT idlers because a Misumi rep told me that this combination would work. And it seems to work pretty damn well but I almost want to try converting the idlers to MR2 to see how it is. My belts are also MR2.

I wasn't aware that the Unitta/E3D stuff is much different, but thankfully I have no desire to mix and match anyway.

In your setup.... the 2GT idlers, if they truly are different, probably work fine. I could imagine significant issues if you were to mix MR2 and 2GT pulleys in a transmission or gearing setup.

For what its worth, all my belts from SDP/SI and Misumi say "POWERGRIP" instead of "POWER GRIP", have their country of MFG on there (USA, UK, and JAPAN), and the part numbers on the belts take me straight to official Gates (USA) catalogs for the GT series stuff.

More investigation is needed.

-

I got fed up with something retraction related in Simply3d. So I did some test prints in Kisslicer and Cura (cura definitely has some odd quirks when it comes retraction though...) and the diagonal cross hatch lines that plagued me are smooth as silk in the Cura prints. So I just wanted to put the reminder to rule out slicer quirks occasionally when hunting this down.

-

@sebkritikel I now have a Bondtech BMG and mosquito installed. The artifacts appear to be the same, but I will run another pyramid to see if there are any changes.

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

I now have a Bondtech BMG and mosquito installed.

Same stepper?

-

@brotherchris said in Tips to mitigate vertical artifacting Duet 2 Wifi:

@sebkritikel I now have a Bondtech BMG and mosquito installed. The artifacts appear to be the same, but I will run another pyramid to see if there are any changes.

Thats a bummer to hear.

Is it the same stepper motor on the extruder?beat me to it!Some other testing steps... the goal of course is to not waste filament, but sometimes we need to

- If you do the same print (same exact GCODE file) multiple times in a row - print, remove, restart, repeat - are the patterns in the exact same spot(s), or does it vary print to print?

- Can you do a medium-small box - 40mm x 40mm x 40mm perhaps? Both with infill, and another print with only one or two walls? If it happens to both (I know you said it does previously) can you take more images, measure the horizontal distance (period), and try and measure the slope of the artifact, and upload the GCODE file?

-

@sebkritikel said in Tips to mitigate vertical artifacting Duet 2 Wifi:

Some other testing steps... the goal of course is to not waste filament, but sometimes we need to

i think filament is the least of his problem

it will make for an interesting video to watch in the end.how many times have you disassembled and reassembled the belt with its idlers by now?

-

@Phaedrux Different stepper. I might try the other E driver though.

-

@brotherchris

i know you want to reveal your project once its ready, but a picture of the belt and its path might help to think of more things that could be causing this. -

@Veti No worries on that. It's kind of a mess at the moment, but here are some shots of the stuff that matters.

-

-

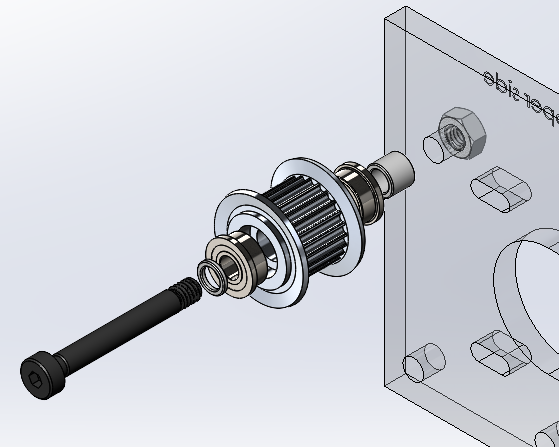

Looking at the long spans on the belts remind me of another issue I had (I run a delta though). The constant tension on the motors eventually affected the bearings in the motors. I eventually replaced the motors, but I also added in thrust bearings* between the pulley and the motor, so any lateral pull on the motor shaft is limited by the pulley pushing down on the thrust bearing against the motor. Granted the motors were also like 7 years old so they did good. Still, I'd at least consider these since they are easy to replace, inexpensive, and they worked great for me removing a visible deflection in the motor shaft when the belts were tightened. Tuning after that I tuned for better jerk and accel, but that could have been the motor model changing. Still, these did have noticeable improvement on the hash pattern for the old motors before I replaced them, but the artifacts were not fully resolved until I changed slicers. I had to format my computer recently and didn't deem those pictures as worthy of backup....heh.. and it's kind of hard to describe how it changed to a kind of fainter or less pronounced but crisper or finer lines at the same time.

*- https://www.amazon.com/gp/product/B07QKKYKR8/ -

taking the last picture as a reference.

the belt at the top motor is angled and goes from the bottom path to the top path. that could be the cause of those artefacts. the belt would be constantly pushed upwards on the pulley.

looking at the bottom motor. here the belts are not parallel. this will cause dimensional inaccuracies. the belt path creates a triangle where the belt moved is longer than the axis movement it causes.

That part of the belt path and the one on the x axis has to be parallel to the extrusions.