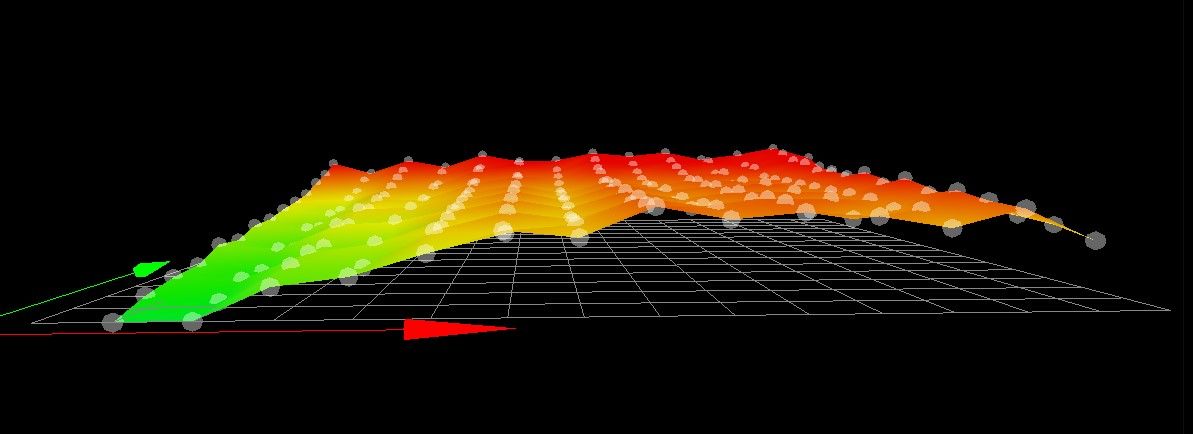

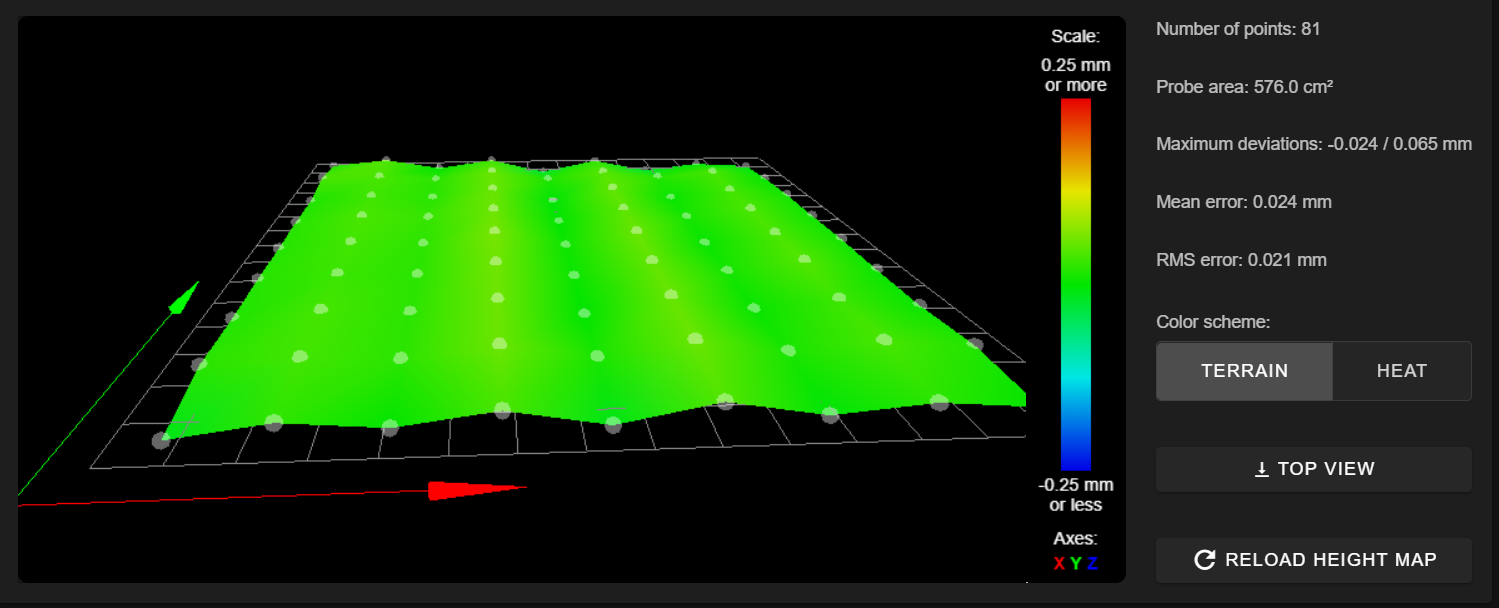

Triangular wave and print area

-

ok, I'll call you hawkeye, correct and take the test again

-

25/10/2020, 19:37:22 G32 bed probe heights: 0.190 0.198 0.195 0.195 0.192 0.192 0.190 0.195 0.188 0.192, mean 0.193, deviation from mean 0.003

25/10/2020, 19:36:52 G32 bed probe heights: 0.195 0.195 0.192 0.202 0.212 0.208 0.205 0.200 0.200 0.198, mean 0.201, deviation from mean 0.006

25/10/2020, 19:36:22 G32 bed probe heights: 0.188 0.178 0.178 0.178 0.178 0.178 0.173 0.178 0.183 0.180, mean 0.179, deviation from mean 0.004

25/10/2020, 19:35:52 M98 P"0:/macros/Calibrazione a punto singolo/Calibrazione x 10"

G32 bed probe heights: 0.190 0.192 0.192 0.195 0.190 0.185 0.190 0.188 0.188 0.190, mean 0.190, deviation from mean 0.003 -

ok that looks good.

now do the test again, grab the hotend carriage and turn on clockwise and anticlockwise between probes. dont force it but do it gently.

after that do it again trying to rotate it forwards and backwards.

-

in practice I take the trolley and manually try to move it and then I do the tests again, did I understand correctly?

-

@Leblond

yes. we are looking for backlash in the assembly. movement could cause the assembly to rotate and cause the result you are seeing. -

25/10/2020, 19:57:24 G32 bed probe heights: 0.192 0.195 0.190 0.192 0.192 0.192 0.190 0.190 0.190 0.190, mean 0.191, deviation from mean 0.002

25/10/2020, 19:56:50 G32 bed probe heights: 0.183 0.185 0.180 0.185 0.185 0.183 0.183 0.183 0.185 0.183, mean 0.183, deviation from mean 0.002

25/10/2020, 19:56:17 G32 bed probe heights: 0.168 0.168 0.168 0.173 0.170 0.165 0.170 0.170 0.170 0.170, mean 0.169, deviation from mean 0.002

25/10/2020, 19:55:43 M98 P"0:/macros/Calibrazione a punto singolo/Calibrazione x 10"

G32 bed probe heights: 0.183 0.185 0.183 0.185 0.185 0.185 0.183 0.185 0.185 0.183, mean 0.184, deviation from mean 0.001 -

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

there are default values from the configurator.

a quick google shows the motors seem to be 1,68 A motors

so you are running way to little current. try 1300

-

The motors are Quimat Nema 17 Stepper Motor 1.7 A 0.59 Nm 84 oz.in 47mm

-

@Leblond said in Triangular wave and print area:

1.7 A

so running them at 75% rounding to nearest 100 is 1300.

-

ok I took them to 1.3 and I'm doing the test again later

-

25/10/2020, 20:56:11 G32 bed probe heights: 0.198 0.195 0.195 0.198 0.195 0.200 0.195 0.200 0.192 0.195, mean 0.196, deviation from mean 0.002

25/10/2020, 20:55:37 G32 bed probe heights: 0.183 0.180 0.180 0.183 0.183 0.183 0.183 0.180 0.180 0.183, mean 0.181, deviation from mean 0.001

25/10/2020, 20:55:04 G32 bed probe heights: 0.183 0.178 0.173 0.170 0.178 0.173 0.173 0.178 0.178 0.173, mean 0.175, deviation from mean 0.004

25/10/2020, 20:54:31 M98 P"0:/macros/Calibrazione a punto singolo/Calibrazione x 10"

G32 bed probe heights: 0.195 0.192 0.192 0.195 0.192 0.195 0.195 0.195 0.188 0.195, mean 0.194, deviation from mean 0.002 -

I'm retrying cold-meshing the plate to see if we've made any improvements

-

-

no improvement

-

it seems to be very consistent.

can you turn the glass 90 degrees?

-

Is the X carriage on wheels?

I'm not familiar with the printer and can't tell from the photos I've seen,

Almost looks like an eccentric wheel causing the nozzle to rise & fall with each rotation -

-

Yes, the trolley is on rails and has eccentrics

-

I've had the same problem once , it was the x axis wheels and stopped the ripple with linear rails , but I guess getting better would have fixed it too.

-

@Veti yes I have already tried to rotate it 90 degrees, but no improvement