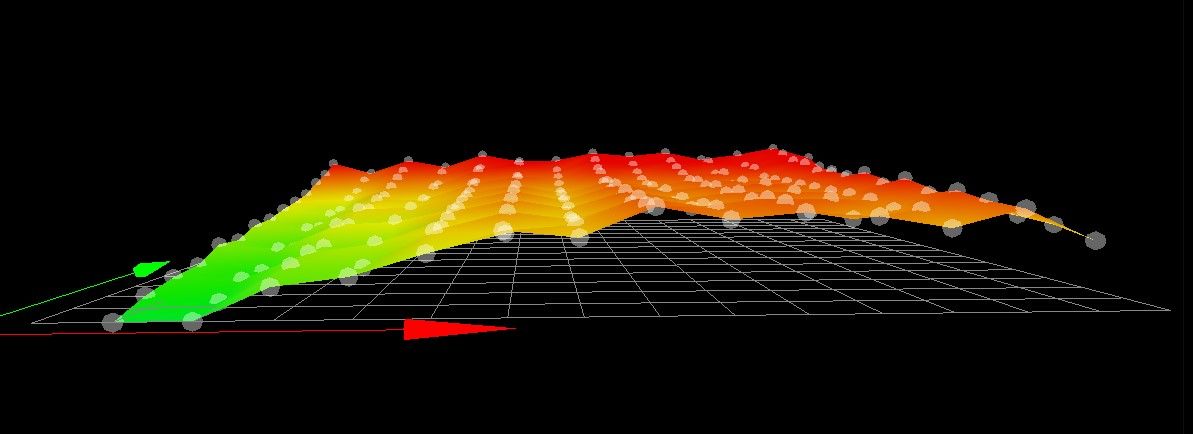

Triangular wave and print area

-

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

there are default values from the configurator.

a quick google shows the motors seem to be 1,68 A motors

so you are running way to little current. try 1300

-

The motors are Quimat Nema 17 Stepper Motor 1.7 A 0.59 Nm 84 oz.in 47mm

-

@Leblond said in Triangular wave and print area:

1.7 A

so running them at 75% rounding to nearest 100 is 1300.

-

ok I took them to 1.3 and I'm doing the test again later

-

25/10/2020, 20:56:11 G32 bed probe heights: 0.198 0.195 0.195 0.198 0.195 0.200 0.195 0.200 0.192 0.195, mean 0.196, deviation from mean 0.002

25/10/2020, 20:55:37 G32 bed probe heights: 0.183 0.180 0.180 0.183 0.183 0.183 0.183 0.180 0.180 0.183, mean 0.181, deviation from mean 0.001

25/10/2020, 20:55:04 G32 bed probe heights: 0.183 0.178 0.173 0.170 0.178 0.173 0.173 0.178 0.178 0.173, mean 0.175, deviation from mean 0.004

25/10/2020, 20:54:31 M98 P"0:/macros/Calibrazione a punto singolo/Calibrazione x 10"

G32 bed probe heights: 0.195 0.192 0.192 0.195 0.192 0.195 0.195 0.195 0.188 0.195, mean 0.194, deviation from mean 0.002 -

I'm retrying cold-meshing the plate to see if we've made any improvements

-

-

no improvement

-

it seems to be very consistent.

can you turn the glass 90 degrees?

-

Is the X carriage on wheels?

I'm not familiar with the printer and can't tell from the photos I've seen,

Almost looks like an eccentric wheel causing the nozzle to rise & fall with each rotation -

-

Yes, the trolley is on rails and has eccentrics

-

I've had the same problem once , it was the x axis wheels and stopped the ripple with linear rails , but I guess getting better would have fixed it too.

-

@Veti yes I have already tried to rotate it 90 degrees, but no improvement

-

@peter247 in practice they had?

-

@Leblond said in Triangular wave and print area:

Yes, the trolley is on rails and has eccentrics

I don't think he's talking about eccentric nuts to adjust wheel tension, I think he means the wheel itself may be out of round.

Is the spacing between the peaks equivalent to a full rotation of the wheel?

-

@Phaedrux ok, but I tried to move it manually without the belt to see if it was free and so it was, do you think the bearings need to be changed?

-

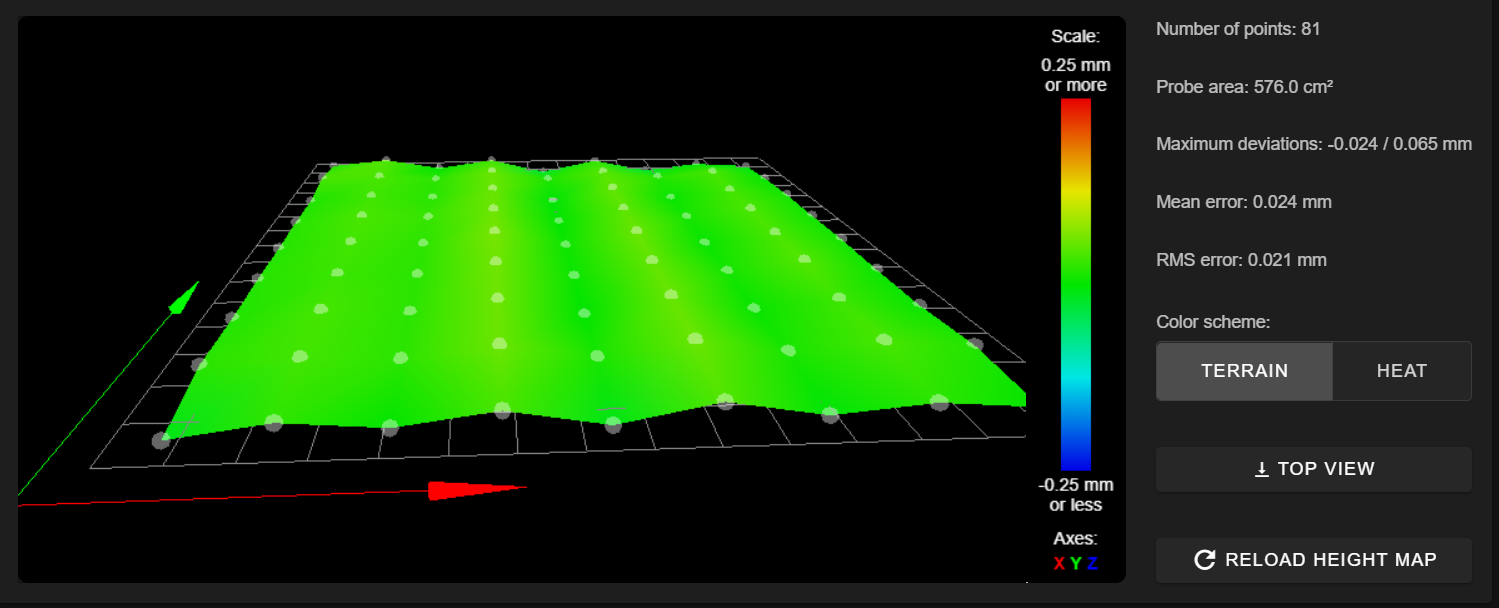

Well the real question is does mesh compensation work to produce a good first layer?

Do a test print once with mesh enabled and another with it disabled. You should be able to tell if the mesh is accurate or not.

-

@Phaedrux ok I will try in the meantime I disassembled the x axis turned the bearings

"just to give it a try while I was waiting for some advice from you" and now I've reassembled it and put it back to making a cold mesh to see if anything has changed, then I'll try to print to see if the mesh works or not, tomorrow I will post the results with and without mesh, for the moment thanks @Phaedrux. -

@Phaedrux looking at the graphic mesh and checking the coordinates of X which are spaced by 20mm, in 60mm the wheel should make a full turn, I did a free test: I lowered the probe stem I raised the Z axis until it touches the flat, at this point I moved the X axis by 60mm and about 30mm it raised and then lowered in the remaining 30mm, you know you were right the bearings are gone