leadscrew vs ballscrew

-

So Now that i solved my extruder problem by switching to a bondtech bmg-x2 , him now looking to fix the last problem i have on my machine , which is a Z pattern every 1mm caused by my not so straight 8mm leadscrew , ive tried to straighten it but since it 850mm long it not easy to do , and i always fear because of the length and weight of 3d printed object that it will unfortunately always bent/flex causing problem on the z axis

either i give another try to another cheap leadscrew hoping to get a straighter one or go for a Ball Screw SFU1204 900mm long .

Any opinion or suggestion ?

here a link to my machine : https://forum.duet3d.com/topic/17999/the-mean-machine?_=1606370045182

-

best would be a belt driven system

-

yes belt driven would be best to elimination z wobble.

but ball screws are very good as well.

you might also be able to adjust your design to use this

https://de.aliexpress.com/item/4001120210864.html -

@PCR any exemple of that you kinda made me curious about that

i could definitively put a belt were the current leadscrew is without changing much to the printer itself

-

@Dad003

the most prominent printer with belt driven design is the voron 2.4

https://vorondesign.com/voron2.4 -

you have very long leadscrews, I find that it's very difficult to source straight medium quality leadscrews longer than 300mm. You may try with 10mm leadscrews that are relatively easy to find.

It is important that you hold the leadscrew tight on the bottom (near the motor). The weight should not lay on the motor shaft but on the motor bracket. I'd suggest you to use flex couplers and be sure that the motor shaft and the leadscrew don't touch each other (leave 1mm gap) or put a ballbearing between the two (so you get a little axial freeway).

Ballscrews are definitely an options but a little more complicated to setup and low quality ballscrew is not better than low quality leadscrew... but I guess you are getting 12mm ballscrews so that should help.

As others have already said the alternative would be using belts, that is something I also wanted to try (I have 50cm leadscrews) but I'm not experienced enough to tell the kind of issues you may end up with.

-

i might give a try to a belt design , my current stepper motor is a .9 degree 60mm nema 17 , the question is even with a 3/1 ratio with pulley and belt will that be enough to power the axis ?

here some of the spec of that stepper motor :

Rated Voltage: 2.8V DC

Rated Current: 2.0 A/Phase DC

Resistance/phase @ 20°C : 1.4 Ω/phase

Inductance: 2.8 mH +/- 20%

Holding Torque: 0.6 N.m (6.1 kg.cm)

Insulation Resistance: >100 MΩ (DC 500V)need a bit of help to figure out what the max load

how about a planetary gearbox on a stepper motor ?

-

@Dad003 IMO lead screws are just fine for the Z axis. Ball screws are over kill because they are designed for use in higher speed, lower friction applications - not what we need for the Z axis of a 3D printer. It's also difficult to find ball screws with a fine enough lead - something we do need for the Z axis. For that length, I would consider using 10mm rather than 8mm (but with a lead of 2mm). The reason being that with 850mm length, an 8mm diameter screws can "whip" when driven at higher speeds such as a long homing move (I know from experience because I use 8mm x 900mm long screws on my machine) .

-

@Dad003 said in leadscrew vs ballscrew:

how about a planetary gearbox on a stepper motor ?

did you check out the voron design? they build a 5:1 gear reduction for each z axis.

-

My printer has a 700 mm long, belt-lifted Z axis. It uses a 30:1 worm gear reducer that stops the bed from moving when the Z motor power is cut- you don't need to worry about brakes to stop the bed from slamming into the bottom of the printer. The motor and gearbox come as a unit, so you don't have to mess around (much). It uses a keyed 8mm shaft (that's the messing around part). It has a NEMA23 motor driven directly by the Duet board driver. I run the motor at about 1A and it still has plenty of grunt to lift the 3.5 kg bed plus 4 kg of print. Top speed is 15 mm/sec in my printer.

The printer doesn't use any auto leveling and Z=0 is set by an optical endstop and screw. The bed is on a kinematic mount and it stays level once set manually using the manual bed leveling assist built into RRF. I don't have to adjust it, ever, unless I take apart the Z axis to make a modification (last time was maybe 8 months ago).

Here's the worm gear drive:

https://www.ebay.com/itm/Rino-Motorized-Rotary-Table-Stage-CNC-4th-Axis-Sherline-Milling-Engraver-Router/191714031261?epid=711126295&hash=item2ca30bf69d:g:A7UAAOSwPhdVB2f0Some pictures

[UMMD Z axis ](https://drive.google.com/file/d/17K20nkb95RXOf_OFrKNdmo2UW4CKLLPX/view?usp=sharing, https://drive.google.com/file/d/1FRbF3AvW42yLIC7u1Vhlc_W56gK6790Q/view?usp=sharing, https://drive.google.com/file/d/1p1Pav9lCuDMh7R7oA3b6llfytrZws9__/view?usp=sharing) -

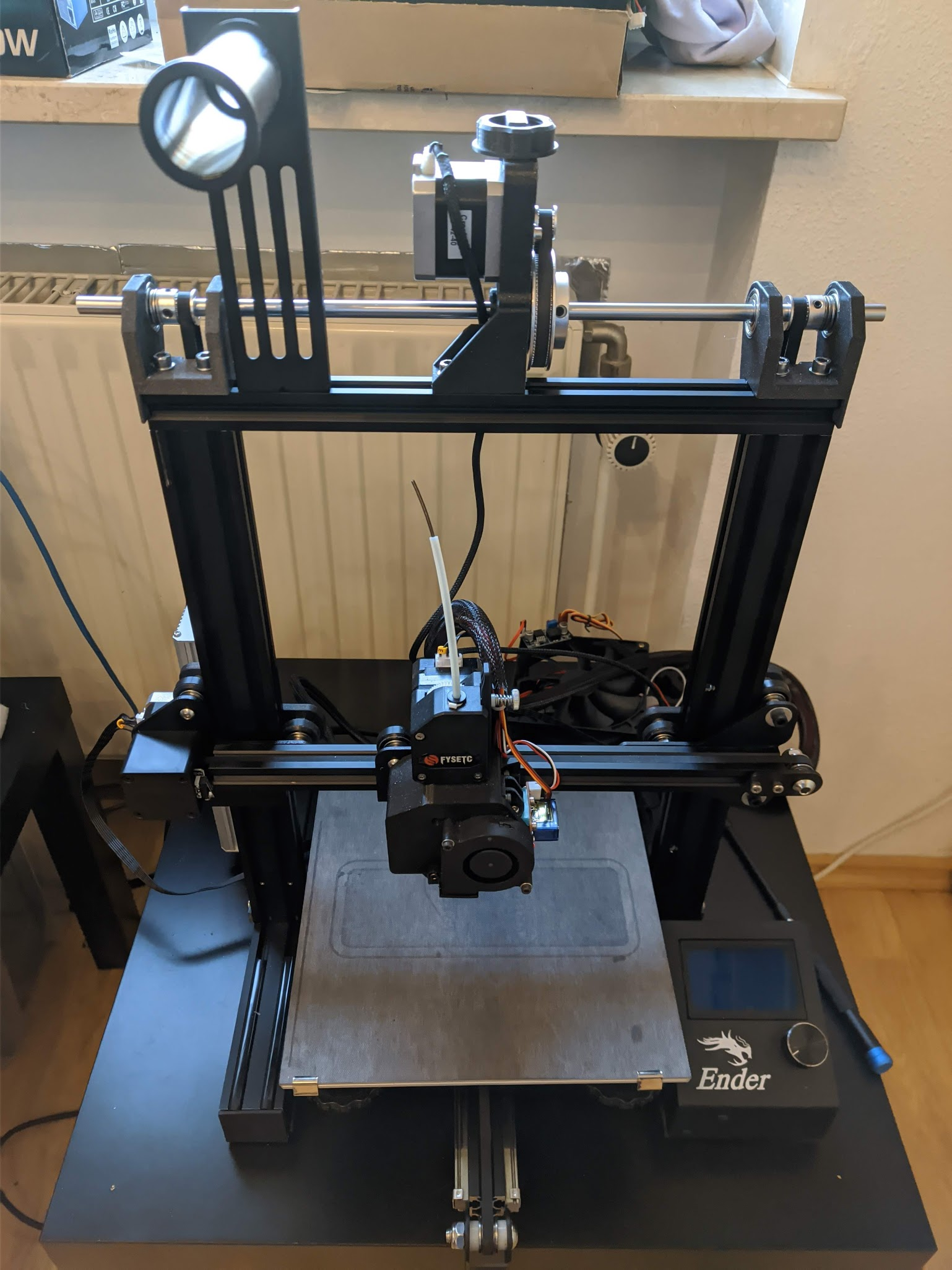

i just converted my ender 3 to belt driven

-

Buy quality parts. Not cheap parts.

-

@Veti Do you have a part list and files for it?

-

https://github.com/kevinakasam/BeltDrivenEnder3

i modified the setup a bit. i used the metal toothed pulley instead of the printed one. because of that i needed to raise the height by about 5mm.

-

@Dad003 I tried cheap, used, super cheap and high quality 1605 ballscrews and they were all better (even the cheap-used) than high-quality acme leadscrew, and next-level stuff compared to PRC delivered acme leadscrews. Now, high quality acme screws are usually good enough for Z but if you can afford and have room to place ballscrews - they are worth it :). Now I never tried any of these small ones like 1204, 1605 is the smallest one I ever tried but I guess small ones are decent. The only important issue with any of the cnc movable parts from PRC - you have to open the nuts, remove all the bearings, clean all the bearings and the nut, check if you have "not shiny" bearings and replace them - ideally, replace ALL bearings with decent ones from hardware store (they are cheap), clean, "wash" (W60 is ideal imho for that), lubricate again with proper lubricant.

belt driven Z is great option but have it's own set of drawbacks... if you introduce gearing to get precision and torque those gearing need to be super high quality or it will introduce worse issues that what you started with

-

@matt3o said in leadscrew vs ballscrew:

you have very long leadscrews, I find that it's very difficult to source straight medium quality leadscrews longer than 300mm. You may try with 10mm leadscrews that are relatively easy to find.

10mm dia with a 2mm lead/pitch, works well.

Ian @deckingman has a nice video covering lead screws if you want a little education.

As for sourcing straight lead screws dont even try to, a pair of roller v blocks, a dial indicator and a heat source then straighten to whatever tolerance you wish.

I got a set of 600mm long ones to under a thou of run out in about 15 minutes on each one

-

@CaLviNx said in leadscrew vs ballscrew:

10mm dia with a 2mm lead/pitch, works well.

@omni replaced his on D9 with 10x2 acme and they came pretty darn straight and work awesome

I got a set of 600mm long ones to under a thou of run out in about 15 minutes on each one

how the ^#%$^#&^%# you do it

... I tried to straighten few 8x2 40cm and more I tried worse they got

... I tried to straighten few 8x2 40cm and more I tried worse they got

-

find the high spot with the dial indicator, heat the high spot with a pencil torch, cold quench with a wet cloth, simple, mind you i have a few years of experience of straightening hydraulic rods offshore.

-

@CaLviNx said in leadscrew vs ballscrew:

Ian @deckingman has a nice video covering lead screws if you want a little education.

For the sake of completeness, here is a link to the aforementioned video https://www.youtube.com/watch?v=o_0xdrKUYVU

-

@CaLviNx said in leadscrew vs ballscrew:

find the high spot with the dial indicator, heat the high spot with a pencil torch, cold quench with a wet cloth, simple, mind you i have a few years of experience of straightening hydraulic rods offshore.

I tried that technique too (using proxxon butane torch) ... same as with "pressing it between two blocks" .. I'm just not made for that

..

..