stepper precision

-

That calibration only cancels fixed nonlinearities (and adds stepper imprecision). A slight magnetic short after calibration of changing operating point of the sensor due to temperature is not cancelled.

-

@DaBit said in stepper precision:

That calibration only cancels fixed nonlinearities (and adds stepper imprecision). A slight magnetic short after calibration of changing operating point of the sensor due to temperature is not cancelled.

no clue how these magnet sensors work and what really is the supposed 15 bit precision. I normally deal with optical and mechanical ones, the magnetic ones I used only up to 4bit (for basic rotation)

-

Basically 2 linear magnetic flux sensors oriented with 90 degree rotation. Rotating a magnet over them give a sin and cos signal from which you can calculate the angle.

Works fairly well. But usually not 15-bit well. A resolver would be more accurate.

[edit]

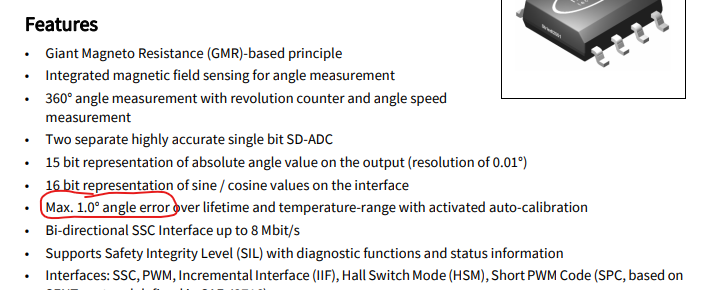

From the datasheet:

[/edit]So that's 8.5 bits of precision. The extra 6.5 bits of resolution come in handy for the servo loop, but that is not precision.

-

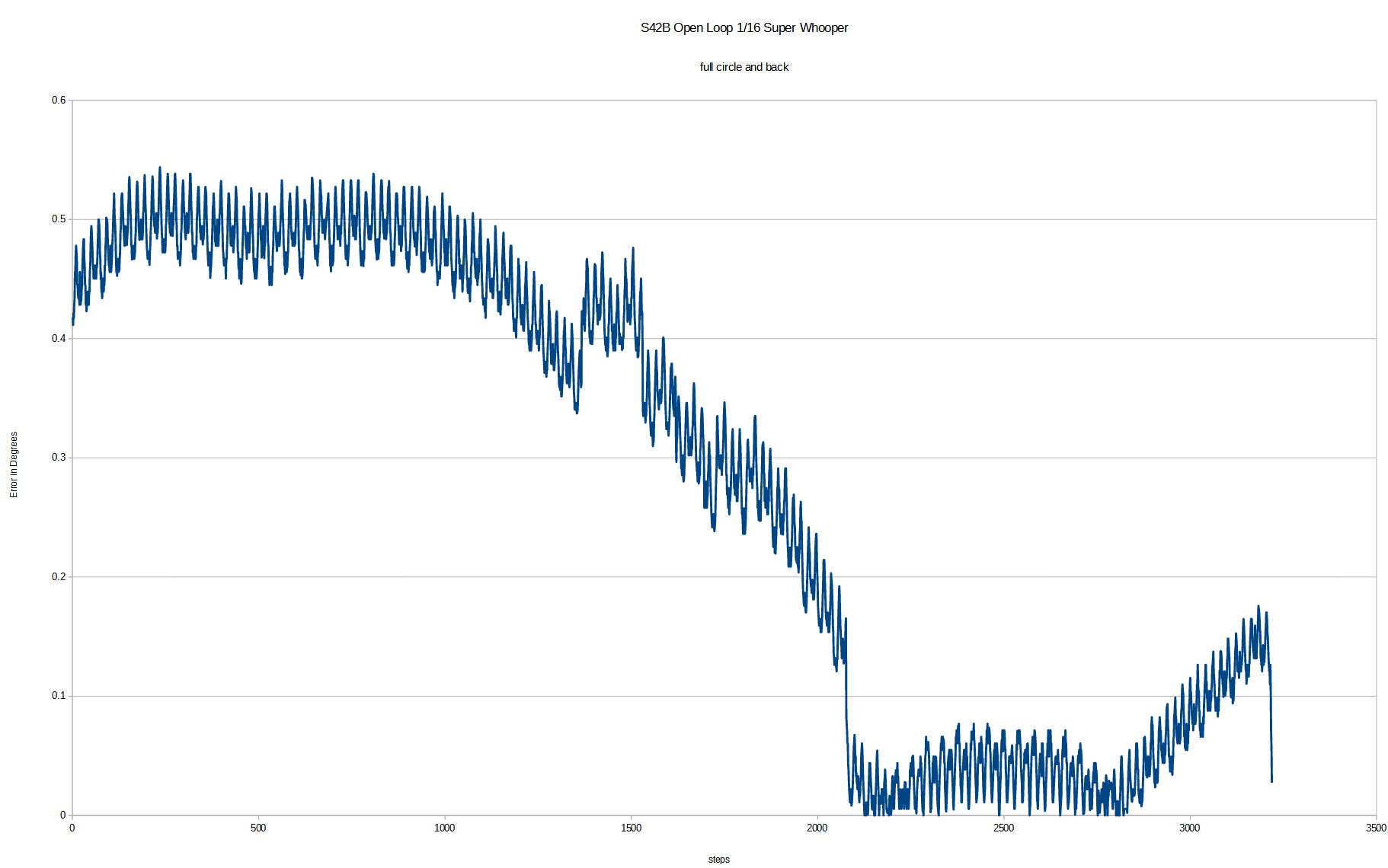

open loop, full circle, S42B

-

in closed loop mode the S42B display show constantly error between -0.04° to +0.04°

closed loop is running "much" colder than open loop and I doubt it's using full current I configured it to use (can't dig out my current probe to test, no way to get to it now)

-

The closed-loop mode of the S42B is not intended to improve accuracy compared to open-loop mode when the motor load is well below the motor's load limit.

It's intended to improve accuracy when the load intermittently exceeds the maximum motor load.

Try your open-loop vs. closed-loop experiment and hold the rotor with something for 10 steps and see how the closed-loop corrects for that once you remove the load and the open loop mode does not correct the error.

THAT'S what the closed-loop mode is for. It might cost you some accuracy in the step-to-step positioning, but you gain the ability to (when the load is lessened) correct for overload conditions and missed-steps.

Open-loop cannot do that.

-

-

@alankilian said in stepper precision:

Try your open-loop vs. closed-loop experiment and hold the rotor with something for 10 steps and see how the closed-loop corrects for that once you remove the load and the open loop mode does not correct the error.

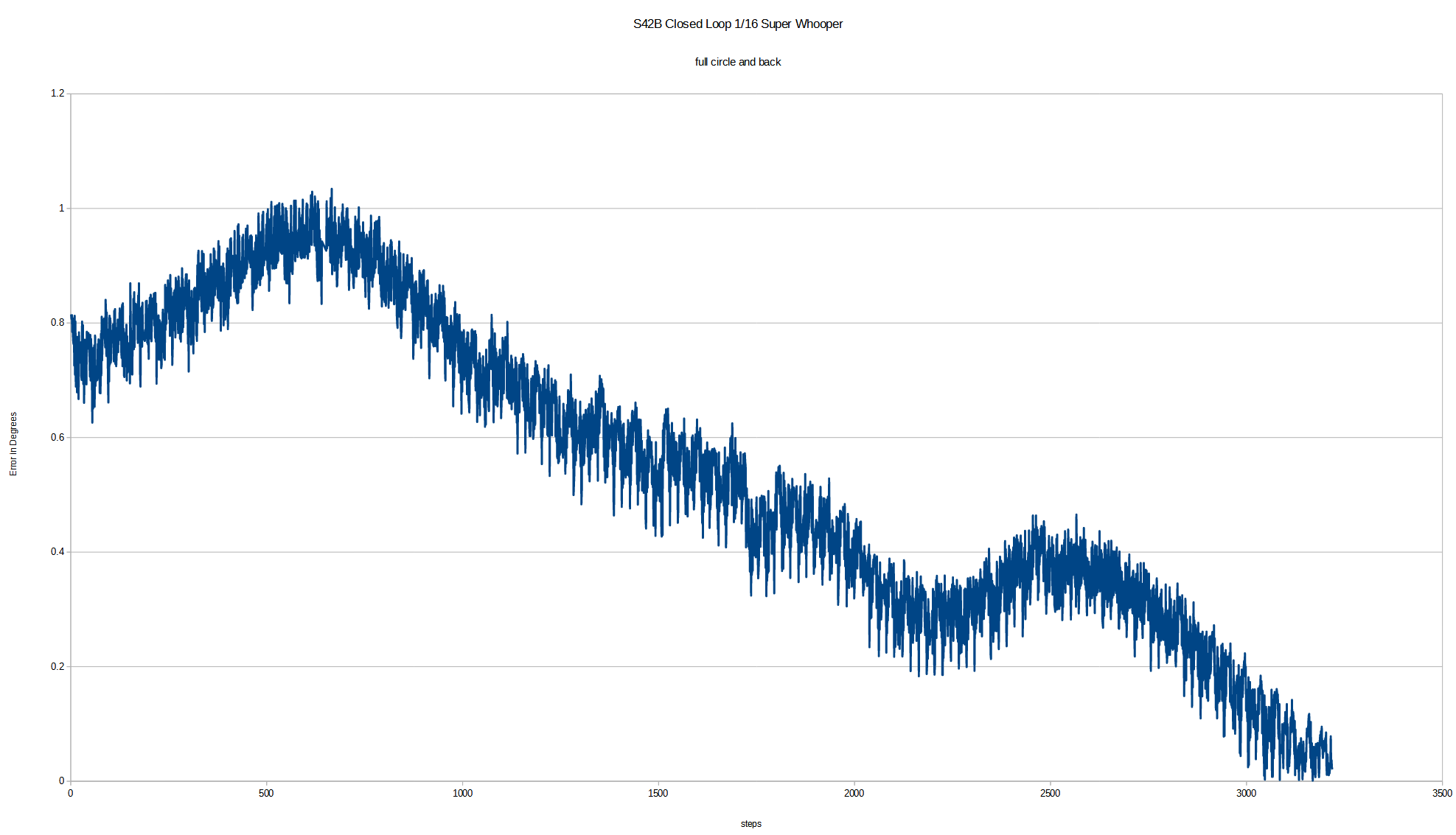

it does correct the missed steps, but it should be also more precise than what I'm seeing

... 1° error !?!? that's more than half a step

... 1° error !?!? that's more than half a stepAnyhow done with S42B, moving on to TMC2208 driver and different motors

-

Would also be cool if someone can reproduce measurements with S42B as this does not require super good/expensive/high resolution encoder, even cheap 1000 lines encoder should be able to see error 0.5° and 1°

-

-

@arhi said in stepper precision:

Anyhow done with S42B, moving on to TMC2208 driver and different motors

Have you done any testing of the "two piece" closed loop systems consisting of a stepper/encoder and separate control unit?

Thanks.

Frederick

-

@fcwilt said in stepper precision:

Have you done any testing of the "two piece" closed loop systems consisting of a stepper/encoder and separate control unit?

Haven't got to it yet, can't find where I put my vallder stepper with encoder and driver combo. Also I wanna finish with few nema17 before I have to use another mount to test the bigger motor

-

-

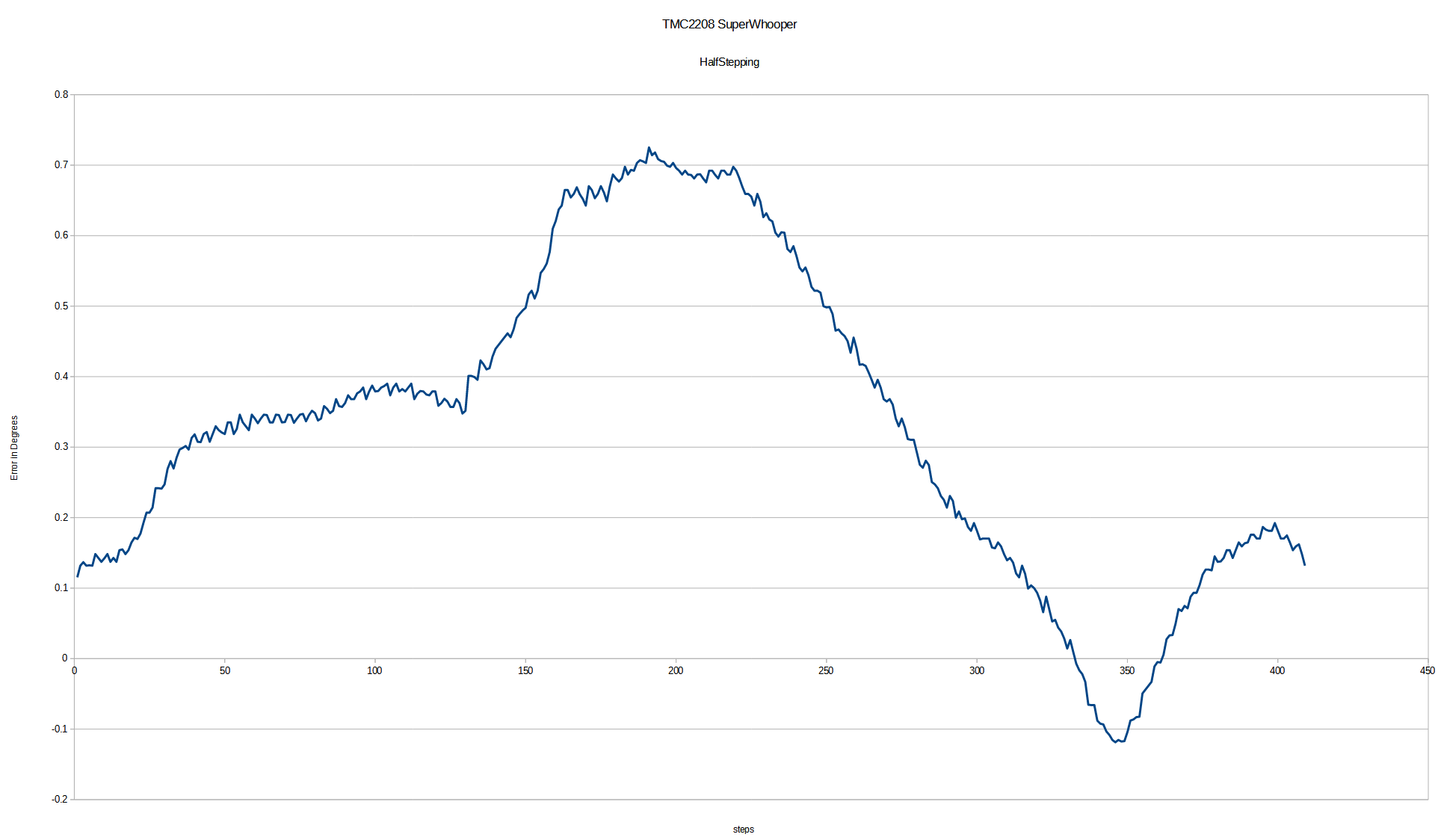

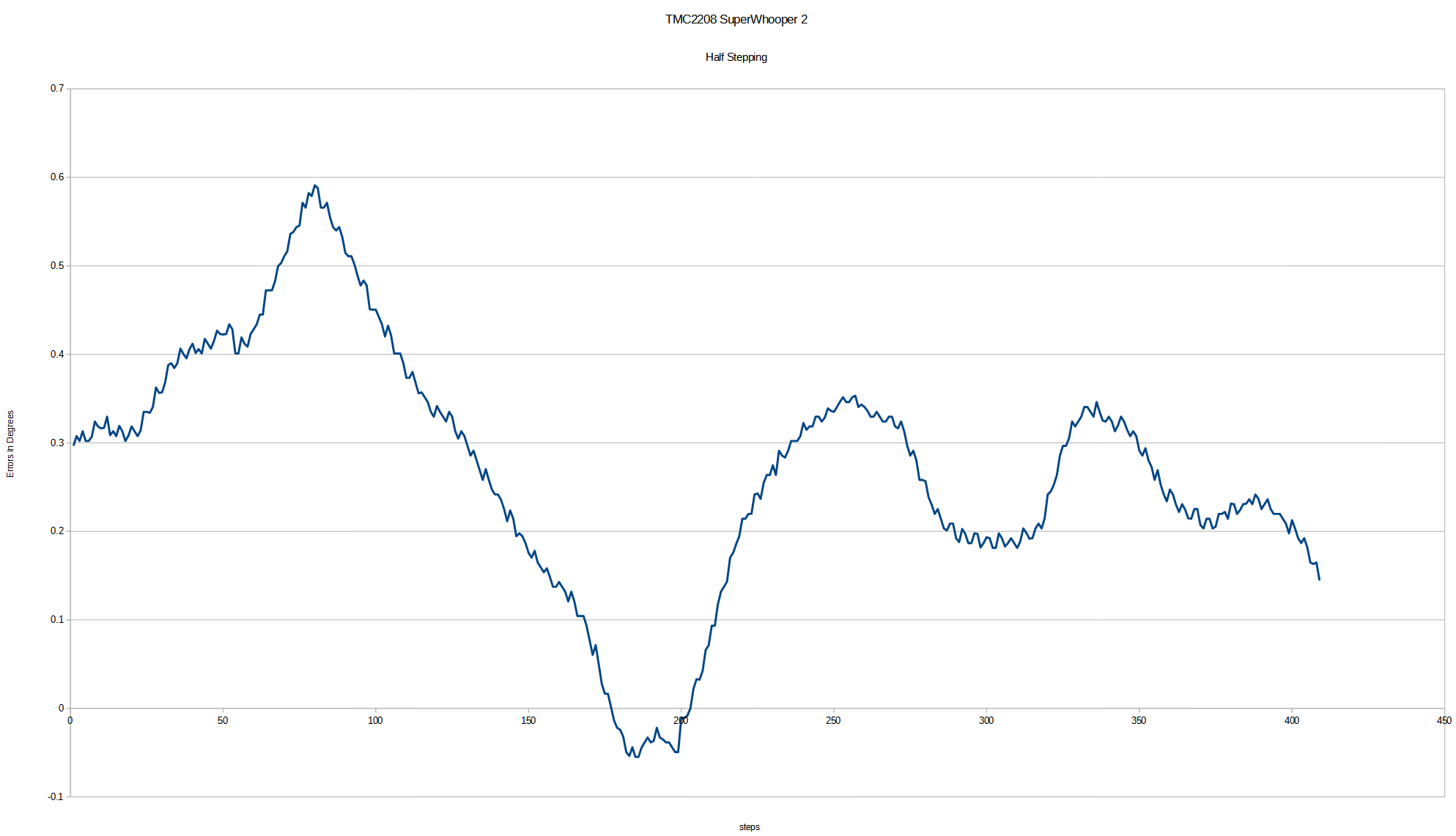

second super whooper

-

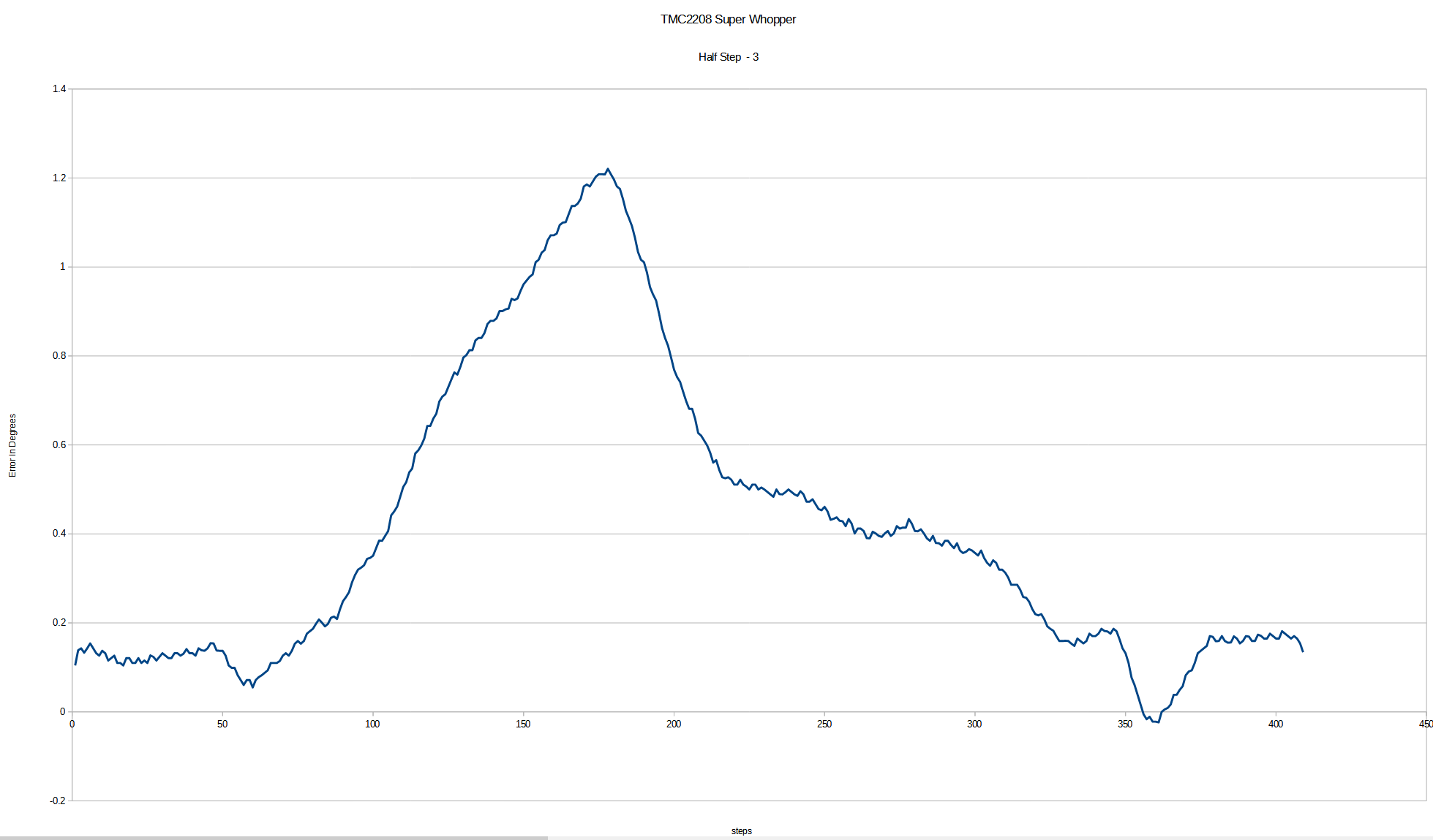

third super whapper motor

-

So, basically, at 180 steps or so the actual vs demanded position deviation of the last motor is more than half a step with the others close to that, with zero load?

That is way worse than what I would have expected...

-

@arhi said in stepper precision:

Haven't got to it yet, can't find where I put my vallder stepper with encoder and driver combo. Also I wanna finish with few nema17 before I have to use another mount to test the bigger motor

That's funny.

A while back I purchased such a system for testing but the project got put on hold as other more important things needed to be done.

And now I cannot find it.

Frederick

-

-

@DaBit said in stepper precision:

That is way worse than what I would have expected...

will have to spend more time looking at all this data, so far I'm running the tests and just showing the error of going forward than backwards. The other data I'm interested is spread of steps going in one direction only, how much off each step is from ideal position but I will do those graphs after I finish all the tests as I need to return this encoder in few days

-

@fcwilt said in stepper precision:

And now I cannot find it.

so you understand my frustration

I'm not used to everything being "in order" and everything "having it's place" but I hate working from "storage", can't find anything, $@^%#^ is getting on my nerves and breaks my concentration too .. and I don't see the end, I doubt my house will be ready before summer