IDEX CoreXY, With Only 2 Motors.

-

@o_lampe said in IDEX CoreXY, With Only 2 Motors.:

I'm trying to find a way to switch the locks without servos.

Just by moving against the far end of the printer, both carriers would simultanously push a springloaded switch, that toggles their lock/unlock hooks. Not sure yet, how to do this but it's thereYou know what, I have done some finger paintings on my phone in bed, which I am not quite prepared to publish haha, but I think this may actually be possible. I will sketch something better in the morning

-

@RichardDuke said in IDEX CoreXY, With Only 2 Motors.:

@o_lampe said in IDEX CoreXY, With Only 2 Motors.:

I'm trying to find a way to switch the locks without servos.

Just by moving against the far end of the printer, both carriers would simultanously push a springloaded switch, that toggles their lock/unlock hooks. Not sure yet, how to do this but it's thereYou know what, I have done some finger paintings on my phone in bed, which I am not quite prepared to publish haha, but I think this may actually be possible. I will sketch something better in the morning

Keep your hands over the blanket they say

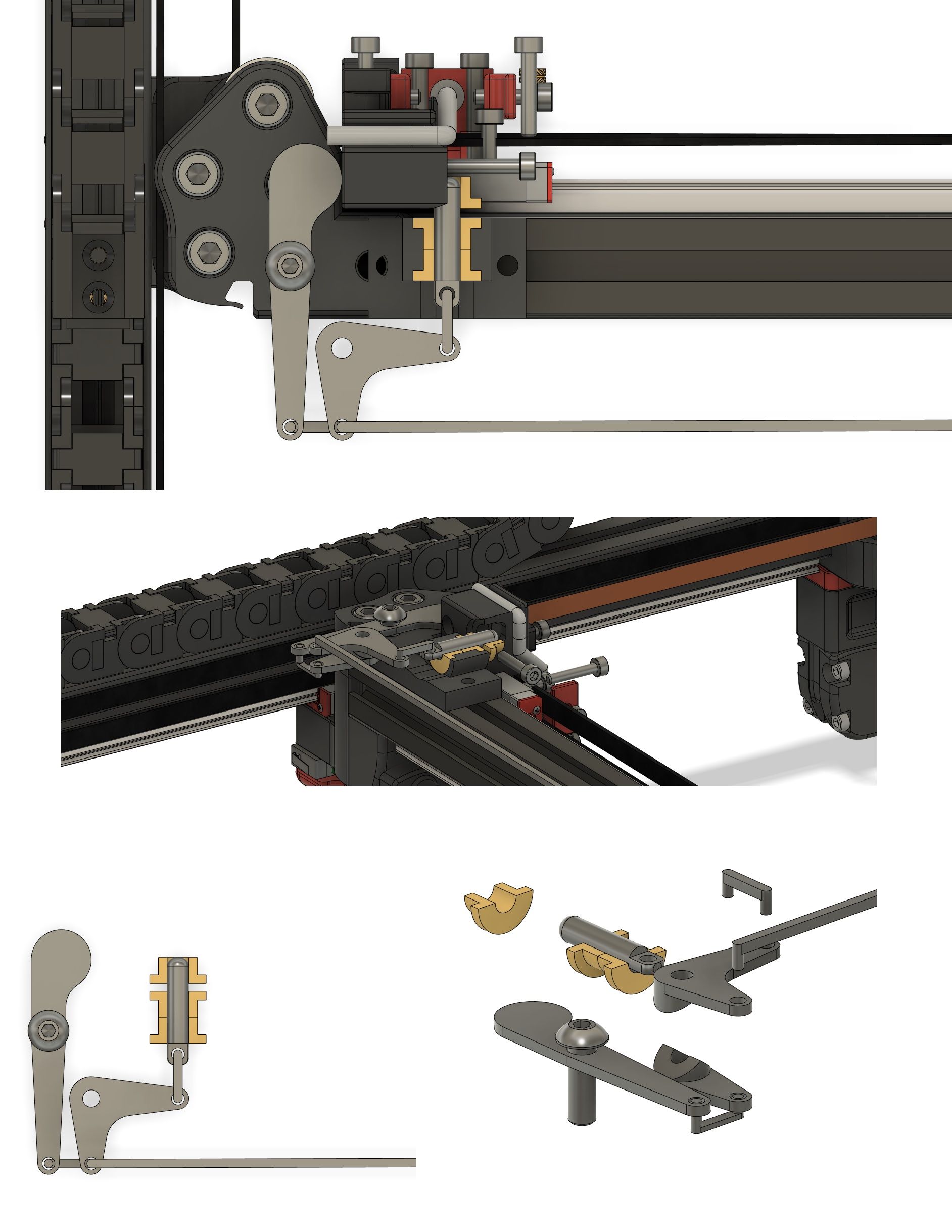

Here's a first design to play with. Needs some beefing up, but the springloaded steelball snaps the switch nicely from one side to the other. And the springload is not important for the lock, just to make sure it stays in place.

I agree with the need for absolute locking. My idea is to add another (strong) spring that pushes the carrier against the hook. I already found the place for the spring in my design, but have no spring that fits.

The parking procedure is:- move the carrier against the limit and a bit beyond

- move the whole beam towards the far end of the printer

- toggle the lock(s) by pushing the switch into the toggler (not designed yet)

- change the kinematics and continue printing

-

@3DPrintingWorld said in IDEX CoreXY, With Only 2 Motors.:

I'm not sure I understand the purpose of locking the carriages to save a stepper.

I believe most Duets sold are Duet_2 with 5 steppers. Only with this solution we have the chance to add a second independent extruder. (I'm sick of trying to get my dual nozzle chimera running)

And it's not a crippled IDEX; their usual usecase is: one extruder parked, the other working. (not that you said, it's crippled)Copy-mode with two extruder running has the same issues as a dual nozzle extruder: one nozzle is scraping off the print, because the mesh bed leveling works for one nozzle only.

@RichardDuke Just for the record: with both carriers held in a fixed distance and the kinematics set as CoreXY, we could do the copy-mode too. (with the same issues as above)

-

@o_lampe I agree, saving a driver would be a advantage on a single board if the servo's can also fit on that board and you only have one Z motor.

Copy mode works amazing on my printer, I ran copy mode 24/7 from Thanskgiving to Christmas to keep up with orders. I would suggest you look at the Copperhead if building a IDEX. The heat sink clamps on the heat break opposed to set screws, so its very easy to set.

-

@o_lampe said in IDEX CoreXY, With Only 2 Motors.:

I believe most Duets sold are Duet_2 with 5 steppers. Only with this solution we have the chance to add a second independent extruder.

You could use an external stepper driver connected to the Duet 2 expansion port.

For simple and small these work well:

Frederick

-

@fcwilt I know, there are other options. That's why I wrote only in Italic. I like the pragmatic approach and work with "what I have". And the challenge of the switching lock may help me with my toolchanger idea as well.

-

@o_lampe said in IDEX CoreXY, With Only 2 Motors.:

That's why I wrote only in Italic...

That was too subtle for me.

I like the pragmatic approach...

I prefer the simple approach.

Good luck.

Frederick

-

check how "proper printing" did it , pretty amazing .

https://www.youtube.com/watch?v=OBB5WuhNhWk -

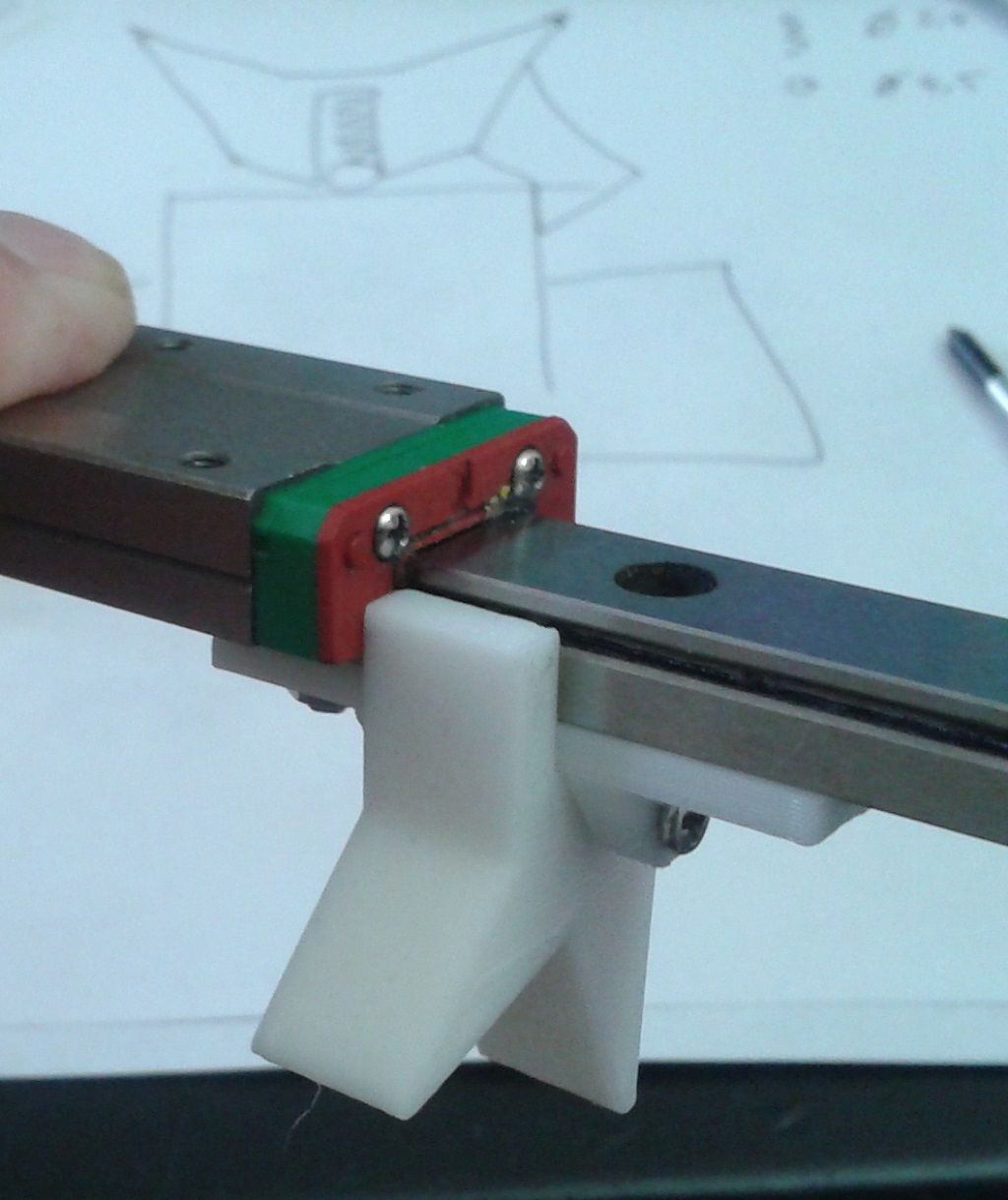

Alrighty, been a busy day, haven’t had much chance to ponder things, but here is my rough idea. It needs a lot more refinement and maybe it can be simplified further but hopefully this is good enough to portray the idea.

There is a brass bush in the carriage where a piece of linear rod can be inserted into to lock it in place.

The far left arm is actuated by the carriage moving to the park position. The secondary idler arm is similar to a servo saver, two seperate arms cut with a v groove allowing the lower arm that’s connected to the carriage actuator to rotate, while the upper arm connected to the locking pin stays in place until the lock pin meets the carriage hole, and snaps into place. A long connecting rod is attached to a mirrored assembly at the other end. Once the lock pin snaps into the parked carriage, it is released simultaneously at the other end.

-

@RichardDuke

If that would work, it had a great advantage over my idea. The beam wouldn't have to travel to the far end, but switch carriers where it is.

But there is one thing, I have doubts. A Servo Saver would store a certain amount of energy, before it can move the pin in the brass bush.

The energy would release, the very moment when the pin fits in the bushing. But at the same time, it tries to pull out the other pin from the bushing. This is only possible by twisting the other Servo Saver because the other side is still locked.

Assuming both Servo Savers have the same spring tension applied, where does the extra energy come from? In my mind, both Servo Savers would stop in the middle, where the forces are equal.

Another point is the push action of the long connecting rod. That's never a good idea, but can be modified to a pull action with a different arm-setup.I hope, I'm wrong. Let's find out by building a Proof_of_Concept thing.

Is there a way to avoid printing the Servo Saver V-grooves? -

@o_lampe ahh yes your right about the energy thing at both ends, it will be equal so it will probably bind up and freeze. But I think it can be altered to accomodate. It is a little bit of a complex system though, electric servos are sounding pretty good at the moment haha

-

Nice graphics!

Do you do that sort of work professionally?

Frederick

-

looks like solidworks to me

-

@RichardDuke said in IDEX CoreXY, With Only 2 Motors.:

@o_lampe ahh yes your right about the energy thing at both ends, it will be equal so it will probably bind up and freeze. But I think it can be altered to accomodate. It is a little bit of a complex system though, electric servos are sounding pretty good at the moment haha

My design also failed. Because it has to be symetric in both directions, it doesn't push the switch over the hump.

I watched some videos (for kids) Subject: How a ballpen works. Ran them in slowmotion to see every bit of it. There is a trick how to overcome our dilemma. But I don't see the light yet. Some kind of rotating excenter...a triangle if you will. Let me sleep over it, I have best ideas when I wake up.BTW: Did you know it took 66 engineers to invent the ballpen 1965?

-

A pin in a hole requires clearance, any slop is going to cause the active extruder to overtravel when changing direction which would give the same effect as ringing.

I would consider a tapered pin, or a wedge would be better. Then you don't have to worry about vertical alignment. However a tapered pin or wedge might require a spring because otherwise it would be hard on your servo.

-

@fcwilt said in IDEX CoreXY, With Only 2 Motors.:

Nice graphics!

I believe he is using Voron's stp files.

-

@fcwilt said in IDEX CoreXY, With Only 2 Motors.:

Nice graphics!

Do you do that sort of work professionally?

Frederick

These are the Voron .step files. Someone has put a lot of work into creating them with all the correct colours. I am just building on it in Fusion 360.

I guess you could call what I do a profession haha. I quit my job in the Automotive trade to pursue my 3D printing business from what started out as a hobby 7 years or so ago. I mostly focus on engineering related 3d printing, but the bulk of what I print is PLA investment casting patterns (I dont do the castings, just supply the patterns). Before you ask, yes we print a lot of cool sh!t that gets cast in metal, but I generally cant share most of it. But one of the coolest ones was this public sculpture, all of the spheres and the bendy straw collars were 3d printed and investment cast in bronze, the straight pipe is off the shelf. We went big straight out the gate as this was the first thing we ever investment cast with 3d printing.

Another cool one was this motorbike Cylinder head. Any my ugly mug holding the very intricate printed pattern.

-

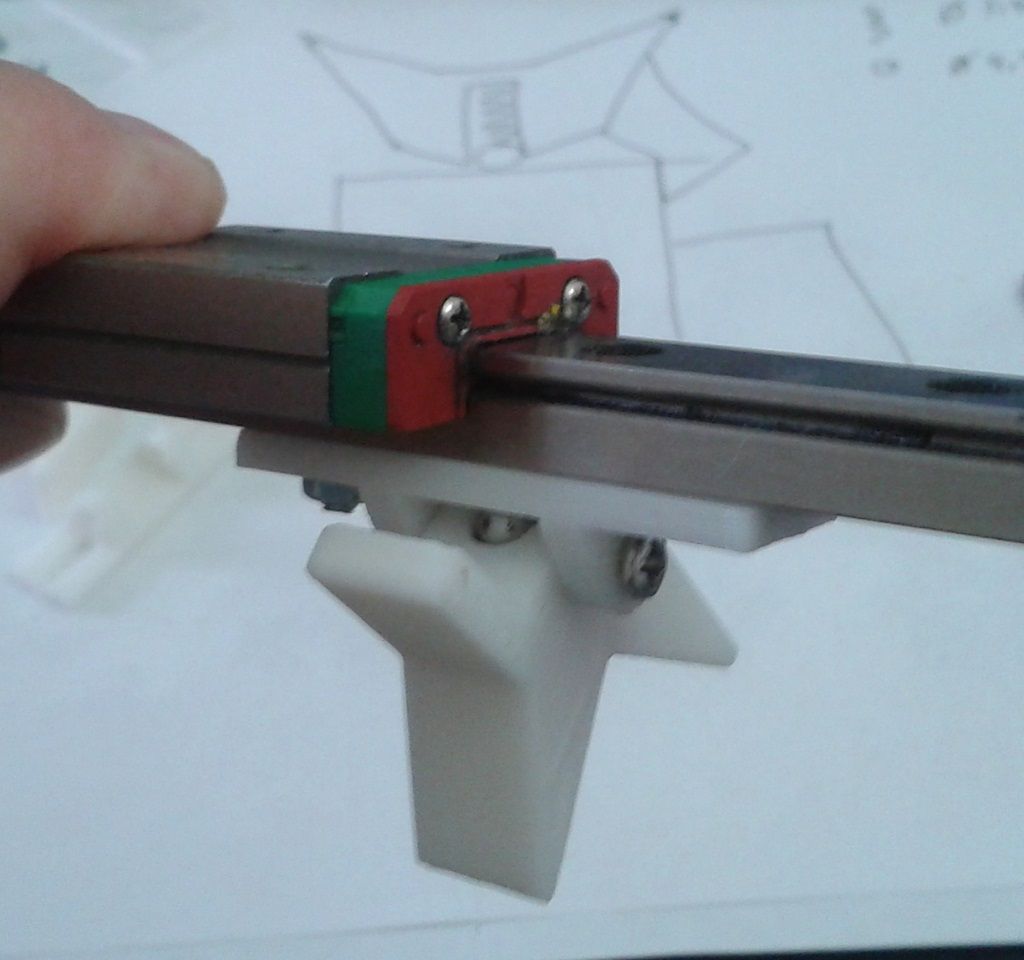

I've found a way to add a spring between locked carrier and the beams end.

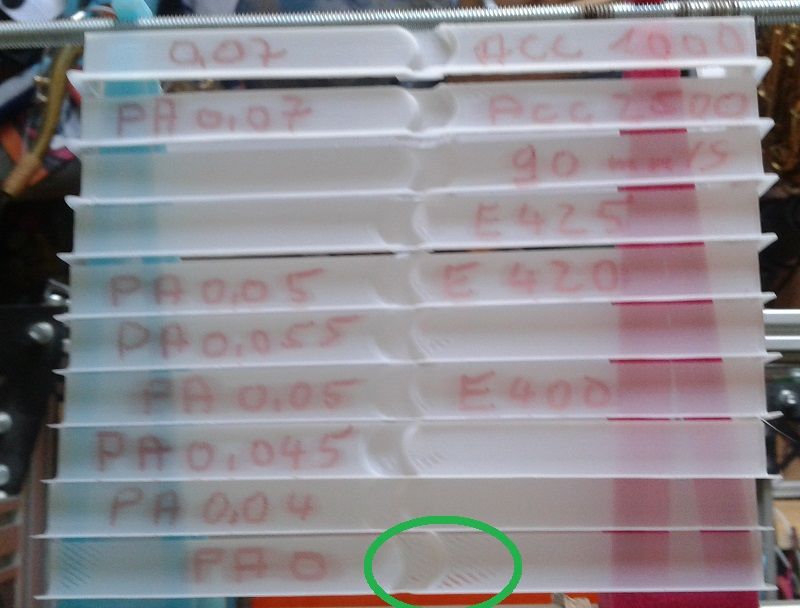

I made some ringing single-wall testprints with upto 90mm/s and acc. 2500mm/s^2, but there was no ringing or overshooting.

I saw other creepy stuff, but that's another thread. Just a little glimps...

"PA" means pressure advance.

-

@RichardDuke

I dreamt about printing a mold to make silicone-rubber tracks for a garden truck, but now I want a radial engine-modell cast in aluminum. (Bronce is easier to cast?) -

I think, I'll put my brain on the real task and get the toolchanging to work.

For now I'll use a servo mounted on the far side to switch the locks. No added weight, and easy to implement.

I will also redesign the switches. No spring/ball but a piece of PTFE tube will execute both tasks. That will make the whole switch thinner.