Bug? In Retraction and Movement Junction

-

Can you show a comparison photo of the results of those settings and the print from the PrusaMini?

-

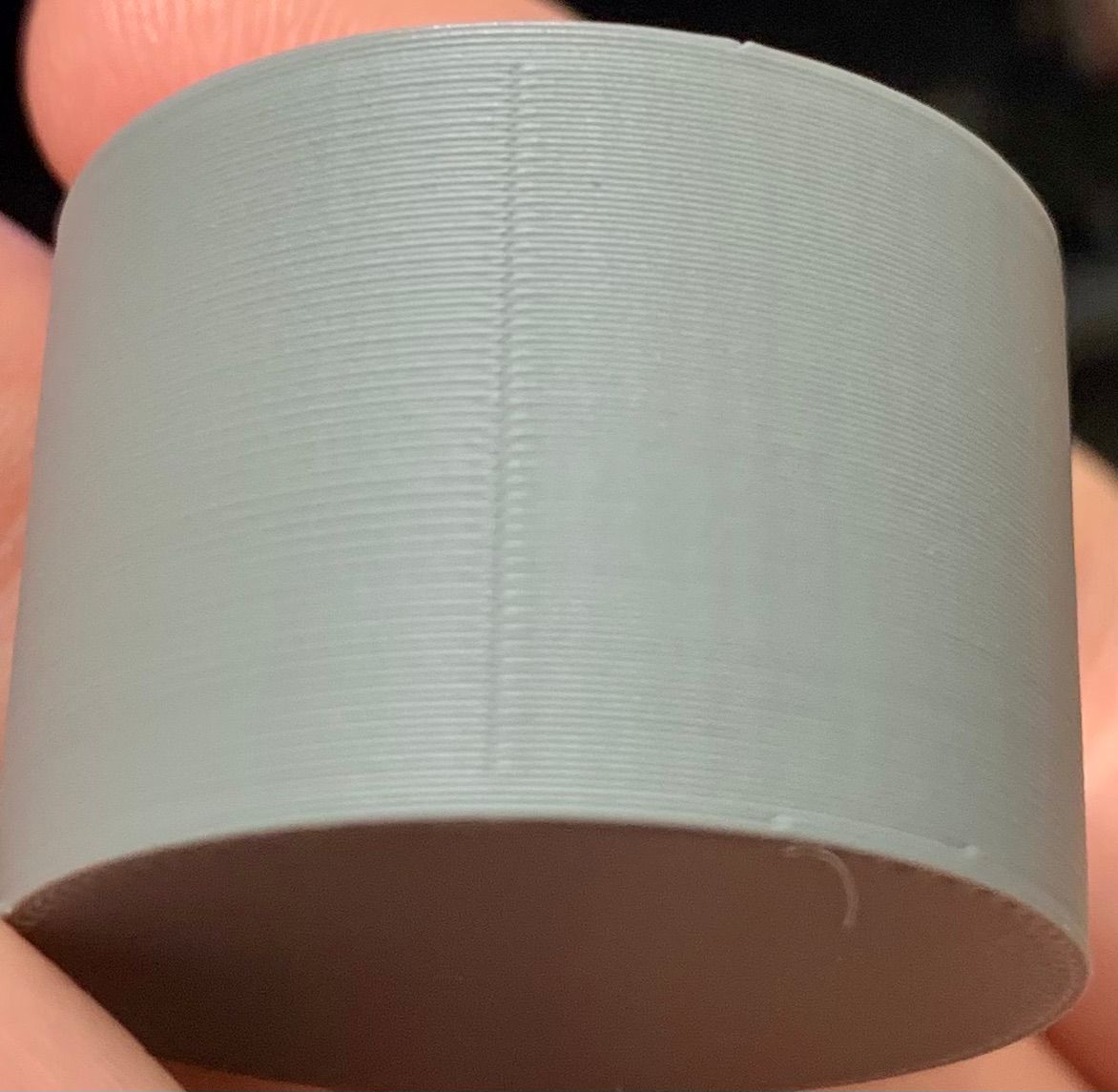

That was posted above already, but here it is.

Grey was RRF

Red was Prusa Mini

-

currently my only running machine is a modified prusa mk2 . still using marlin .

if i'm using retraction , its easy to tune the seam to be a bulge or a void . invisible seam is impossible .

i dont see how its not tunable with rrf , same way it is with marlin .

i will try to connect it to duet board and compare. -

@jatmn having finished another bit of detailed investigation i am now looking at this. The video and pictures are helpful, along with the detailed description.

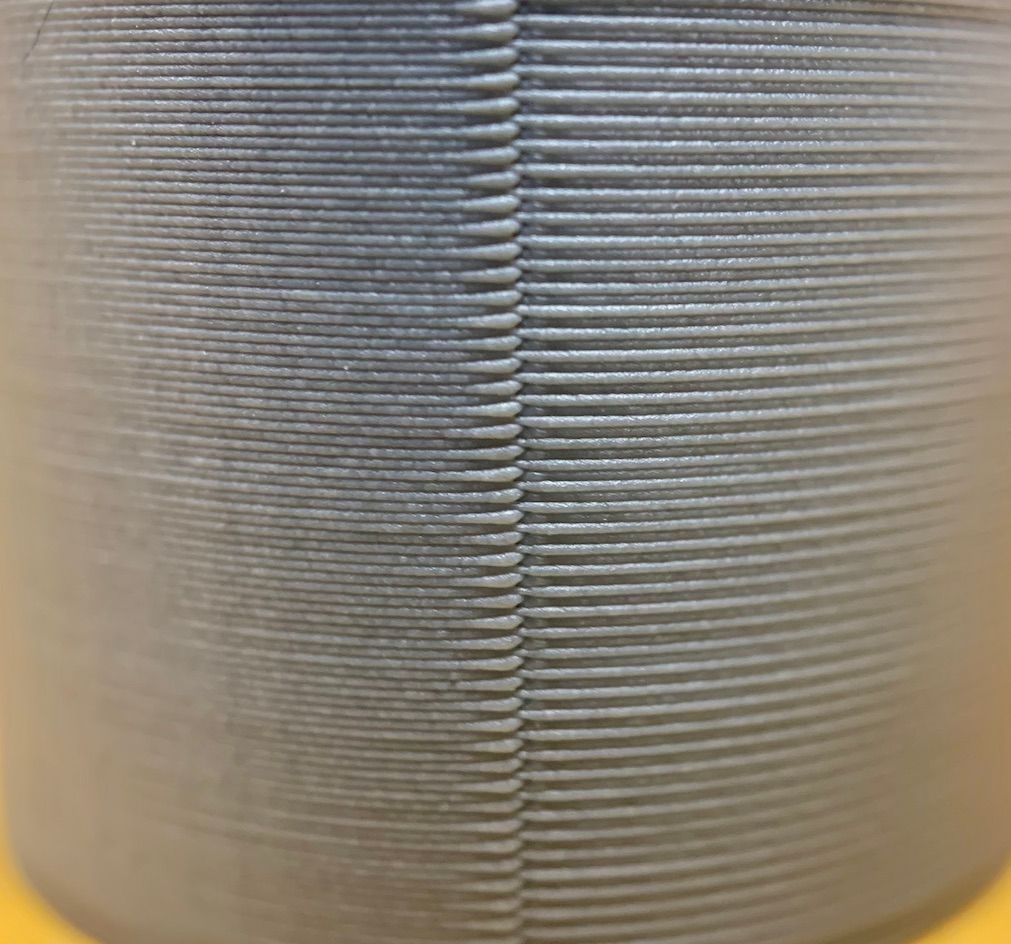

Is it a fair to say in summary the key difference in that on a Z seam there is a "bulge then gap" effect, where as the mini/marlin printed part is something of a gap with no bulge?

Will look to recreate this using your posted gcode and settings, although i don't have an identical machine - should be able to get close.

-

@T3P3Tony That is correct a "bulge than gap" and in my tests pressure advance has more effect on the gap and start point and less of an effect on the stop (bulge). Values high enough to affect the bulge result usually in a significant gap (actually a hole all the way thru) and under extruded start point.

-

@jatmn thanks, I am going to be testing without PA initially to help rule that out.

-

For what it's worth - I also have been experiencing less-than-optimal seam performance as well, similar series of troubleshooting steps, PA tuning, jerk/speed/accel adjustments, slicer tweaks, slicer changes, hardware updates, and the like on 3.2 (and earlier betas) I do not use aligned seam, so the bulges are everywhere and are just tiny zits.

I haven't changed my jerk policy yet and will change that to see if it resolves, but I eagerly anticipate the results from the work you all are doing.

-

@jatmn Just as an update I did a number of cylinder prints here on a delta and e3d toolchanger. I can see a similar seam presentation as you showed with some variation between slicers (Cura, ideamaker, Prusa slicer) but not enough to be conclusive. I also tried the latest beta firmware and spent a not entirely fruitful time with pressure advance settings.. I ended up ordering a well regarded small printer that does not run RRF to use as a comparison machine. It will be interesting to set it up with both control options and run the same gcode through to see what changes.

-

I'm having quite the similar printer, Bondtech extruder, Bear frame and so on with Duet 3 Mini 5+ and RRF 3.3b2.

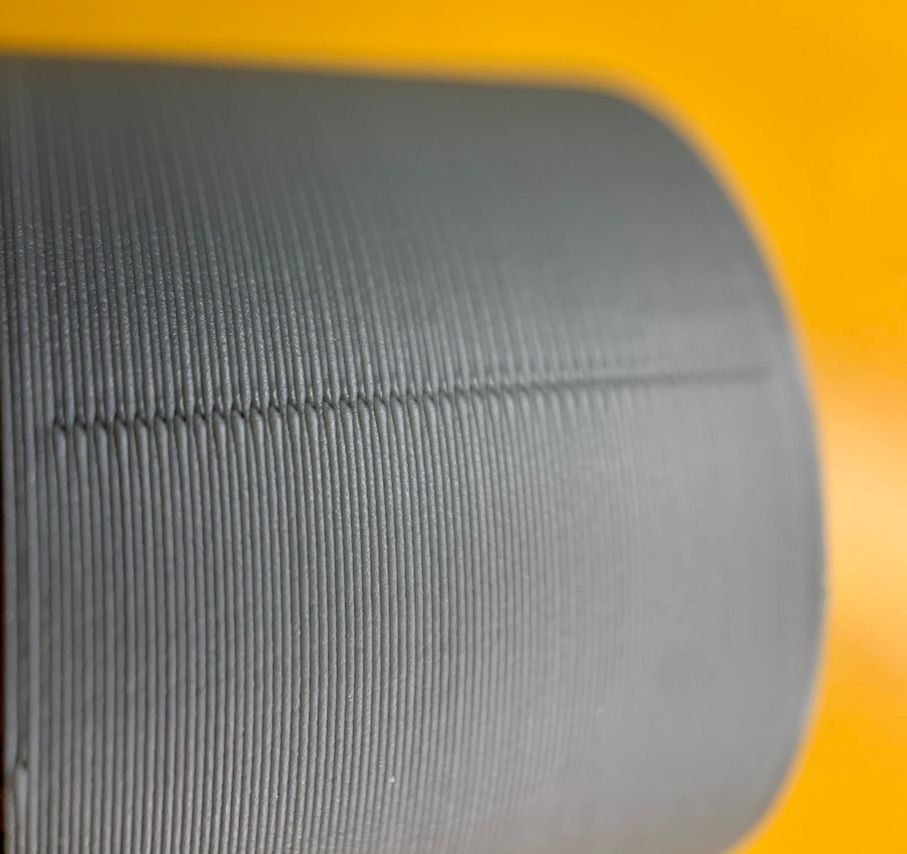

So I also did a test cylinder and like to share my results. Printed in PLA with PA set to 0.056.

-

@Argo Perfect!

-

It looks like the seam is showing "bulges" only on alternate layers.

IF that is what is happening how are you doing that?

Thanks.

Frederick

-

It looks like it's alternating the layer seam.

-

You are right, it's alternating the layer seam.

I've made another picture closer to the print where you can see this more clearly.

I'm using SuperSlicer (inofficial branch of PrusaSlicer):

-

Anyone still has this issue? Was there a resolution? I might have something similar but I'm still testing.

How about you @jatmn?