Five bar Parallel SCARA print area problem

-

@rutku G1 X10 means you want to go to a position a bit right (right in the sense of X-Axis direction) of the homing position. This would mean you have to rotate the actuators to an angle smaller 30 degree. This is not allowed (C parameter 30 limit, and your current endstop type).

After homing, please try G1 X-10 first several times to get away from the homing position. Maybe you have to move Y a bit at the same time at the beginning, like G1 X-10 Y10

...limited movements. X 200 -> 185~ Y 29 -> 78

makes sense: the print area is in the diminishing X, and bigger actuator angles mean the hotend moves to a higher Y.Depending on your hardware,

M350 X128 Y128 I1

may be a too high microstepping value. You can check whether you get lost steps by making some movements, then calling M122 and look at the hiccups value. A high number would mean you loose steps. Often 16 microsteps are used, M350 X16 Y16 I1 -

@joergs5 Hi, I did what you said. However, I'm getting the same mistake again. In the output of debug ThetaL: 249.5 ThetaR: 69.45.

config.g

M350 X16 Y16 I1 ;S3 ; Configure microstepping with interpolation M669 K9 L1 X-95:95 Y0:0 P130:130 D186:186:0:0 B30:30 A15:165:0:360:0:360 C-90:270:-90:270 M92 X115.555556 Y115.555556 ; Set steps per mmDebug Output

getInverse not cantilevered proximalL:130.00 distalL:186.00 xOrigL:-95.00 yOrigL:0.00 x_0:0.00 y_0:0.00 getTheta getIntersec firstRadius: 130.00 secondRadius: 186.00 firstX: -95.00 firstY: 0.00 secondX: 0.00 secondY: 0.00 getTheta use: 2 x2: -140.64 y2: -121.73 thetaB: 249.45 x1: -140.64 y1: 121.73 thetaA: 110.55 getInverse not cantilevered proximalR:130.00 distalR:186.00 xOrigR:95.00 yOrigR:0.00 x_0:0.00 y_0:0.00 getTheta getIntersec firstRadius: 130.00 secondRadius: 186.00 firstX: 95.00 firstY: 0.00 secondX: 0.00 secondY: 0.00 getTheta use: 2 x2: 140.64 y2: 121.73 thetaB: 69.45 x1: 140.64 y1: -121.73 thetaA: 290.55 getInverse cachedInvalid 0 => cachedX0:0.00 cachedY0:0.00 cachedX1:0.00 cachedY1:0.00 cachedXL:-140.64 cachedYL:-121.73 cachedXR:140.64 cachedYR:121.73 cachedThetaR:69.45 cachedXR:140.64 cachedYR:121.73 cachedThetaL:249.45 cachedXL:-140.64 cachedYL:-121.73 getInverse => cachedInvalid:0 x_0:0.00 y_0:0.00 xL:-140.64 yL:-121.73 thetaL:249.45 xR:140.64 yR:121.73 thetaR:69.45 x1:0.00 y1:0.00 constraintsOK->cachedInvalid:0 actuatorAngleLMin:-90.00<0 && thetaL:249.45>actuatorAngleLMax:270.00 constraintsOK->cachedInvalid:0 thetaL:249.45 < actuatorAngleLMin:-90.00 || thetaL:249.45 > actuatorAngleLMax:270.00 return false constraintsOK->cachedInvalid:0 actuatorAngleRMin:-90.00<0 && thetaR:69.45>actuatorAngleRMax:270.00 constraintsOK->cachedInvalid:0 thetaR:69.45 < actuatorAngleRMin:-90.00 || thetaR:69.45 > actuatorAngleRMax:270.00 return false constraintsOK->cachedInvalid:0 headAngle:180.00 < headAngleMin:15.00 || headAngle:180.00 > headAngleMax:165.00 isnan(headAngle):0 return false -

@rutku said in Five bar Parallel SCARA print area problem:

=> Please comment out the G0 Y0 Y0 line at the end of the homing file, so the values when the endstops are triggered can be controlled.

Then start Duet, and run the homing file. Both endstops must be triggered. Please report M114.

ThetaL and ThetaR should be 30 each at the homing position.

I suspect that the G0 X0 Y0, which is at the end of the homing file, is not reachable. My documentation in https://duet3d.dozuki.com/Guide/Five+Bar+Parallel+SCARA/24#s92 is only a draft of the printable area.

ThetaL: 249.5 (= 180 + 69.5) ThetaR: 69.45.

mean the both arms are nearly in opposite positions, and singularity example 1 of my explanation above is met:

-

@joergs5 How could it be? I have printed almost all values in the FiveBarScaraKinematics.cpp file. I am adding all my settings and outputs again. I am adding the video of the process steps.

config.g

; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M552 S1 ; Turn network on M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Enable FTP M586 P2 S0 ; Enable Telnet ; Drives M569 P0 S1 ; Drive 0 (X) goes forwards M569 P1 S1 ; Drive 1 (Y) goes forwards ;M569 P2 S1 ; Drive 2 (Z) goes forwards ;M569 P3 S1 ; Drive 3 (E0) goes forwards M584 X0 Y1 ; set drive mapping M350 X16 Y16 I1 ;S3 ; Configure microstepping with interpolation M669 K9 L1 X-95:95 Y0:0 P130:130 D210:210:0:0 B30:30 A15:165:0:360:0:360 C-90:270:-90:270 M92 X115.555556 Y115.555556 ; Set steps per mm M203 X10000 Y10000 ; maximum speeds mm/minute M566 X15 Y15 ; Set maximum instantaneous speed changes (mm/min) M201 X40 Y40 ; Set accelerations (mm/s^2) M906 X1200 Y1200 ; Set motor currents (mA) and motor idle factor in per cent M84 S0 ; Set idle timeout ; Axis Limits M208 X-1000:1000 Y-1000:1000 ; set axis minima and maxima ; Endstops M574 X1 S1 P"xstop" ; X min active high endstop switch M574 Y1 S1 P"ystop" ; Y min active high endstop switch ;M574 Z0 S1 P"zstop" ; Z min active high endstop switchhome5barscara.g

G91 ; relative positioning G1 H1 X100 Y300 F900 ; move quickly to endstop and stop there (first pass) G1 H1 X300 F900 G1 H1 Y300 F900 G1 H2 X-2 Y-2 F900 ; go back a few degrees G1 H1 X100 F90 ; move slowly to endstop once more (second pass) G1 H1 Y100 F90 ; move slowly to endstop once more (second pass) G1 H2 X-5 Y-5 F900 ; go back a few degrees G92 Z0 G90 ; absolute positioning G0 X0 Y0 ; move to a reasonable positionoutputs:

m115 FIRMWARE_NAME: RepRapFirmware for STM32F4 based Boards FIRMWARE_VERSION: 3.2.2_2 ELECTRONICS: STM32F4 FIRMWARE_DATE: 2021-05-02 ok WiFi module is connected to access point Utku, IP address 192.168.1.3 MotorStepsToCartesian => thetaL:224.27=MotorPosX:25916.00/StepsPermmX:115.56 MotorStepsToCartesian => thetaR:224.27=MotorPosY:3467.00/StepsPermmY:115.56 getForwad->getIntersec(distalL:210.00,distalR:210.00,xL:-188.08,yL:-90.75,xR:207.58,yR:65.01) getIntersec firstRadius: 210.00 secondRadius: 210.00 firstX: -188.08 firstY: -90.75 secondX: 207.58 secondY: 65.01 MotorStepsToCartesian => MachinePosX:nan MachinePosY:nan XYZ_AXES:3 numVisibleAxes:3 MotorStepsToCartesian => thetaL:224.27=MotorPosX:25916.00/StepsPermmX:115.56 MotorStepsToCartesian => thetaR:224.27=MotorPosY:3467.00/StepsPermmY:115.56 getForwad->getIntersec(distalL:210.00,distalR:210.00,xL:-188.08,yL:-90.75,xR:207.58,yR:65.01) getIntersec firstRadius: 210.00 secondRadius: 210.00 firstX: -188.08 firstY: -90.75 secondX: 207.58 secondY: 65.01 MotorStepsToCartesian => MachinePosX:nan MachinePosY:nan XYZ_AXES:3 numVisibleAxes:3 MotorStepsToCartesian => thetaL:30.00=MotorPosX:3467.00/StepsPermmX:115.56 MotorStepsToCartesian => thetaR:30.00=MotorPosY:3467.00/StepsPermmY:115.56 getForwad->getIntersec(distalL:210.00,distalR:210.00,xL:17.58,yL:65.01,xR:207.58,yR:65.01) getIntersec firstRadius: 210.00 secondRadius: 210.00 firstX: 17.58 firstY: 65.01 secondX: 207.58 secondY: 65.01 MotorStepsToCartesian => MachinePosX:112.58 MachinePosY:252.29 XYZ_AXES:3 numVisibleAxes:3 MotorStepsToCartesian => thetaL:30.00=MotorPosX:3467.00/StepsPermmX:115.56 MotorStepsToCartesian => thetaR:30.00=MotorPosY:3467.00/StepsPermmY:115.56 getForwad->getIntersec(distalL:210.00,distalR:210.00,xL:17.58,yL:65.01,xR:207.58,yR:65.01) getIntersec firstRadius: 210.00 secondRadius: 210.00 firstX: 17.58 firstY: 65.01 secondX: 207.58 secondY: 65.01 MotorStepsToCartesian => MachinePosX:112.58 MachinePosY:252.29 XYZ_AXES:3 numVisibleAxes:3 MotorStepsToCartesian => thetaL:30.00=MotorPosX:3467.00/StepsPermmX:115.56 MotorStepsToCartesian => thetaR:30.00=MotorPosY:3467.00/StepsPermmY:115.56 getForwad->getIntersec(distalL:210.00,distalR:210.00,xL:17.58,yL:65.01,xR:207.58,yR:65.01) getIntersec firstRadius: 210.00 secondRadius: 210.00 firstX: 17.58 firstY: 65.01 secondX: 207.58 secondY: 65.01 MotorStepsToCartesian => MachinePosX:112.58 MachinePosY:252.29 XYZ_AXES:3 numVisibleAxes:3 MotorStepsToCartesian => thetaL:28.00=MotorPosX:3236.00/StepsPermmX:115.56 MotorStepsToCartesian => thetaR:28.00=MotorPosY:3236.00/StepsPermmY:115.56 getForwad->getIntersec(distalL:210.00,distalR:210.00,xL:19.78,yL:61.04,xR:209.78,yR:61.04) getIntersec firstRadius: 210.00 secondRadius: 210.00 firstX: 19.78 firstY: 61.04 secondX: 209.78 secondY: 61.04 MotorStepsToCartesian => MachinePosX:114.78 MachinePosY:248.32 XYZ_AXES:3 numVisibleAxes:3 MotorStepsToCartesian => thetaL:28.00=MotorPosX:3236.00/StepsPermmX:115.56 MotorStepsToCartesian => thetaR:28.00=MotorPosY:3236.00/StepsPermmY:115.56 getForwad->getIntersec(distalL:210.00,distalR:210.00,xL:19.78,yL:61.04,xR:209.78,yR:61.04) getIntersec firstRadius: 210.00 secondRadius: 210.00 firstX: 19.78 firstY: 61.04 secondX: 209.78 secondY: 61.04 MotorStepsToCartesian => MachinePosX:114.78 MachinePosY:248.32 XYZ_AXES:3 numVisibleAxes:3 MotorStepsToCartesian => thetaL:30.00=MotorPosX:3467.00/StepsPermmX:115.56 MotorStepsToCartesian => thetaR:30.00=MotorPosY:3236.00/StepsPermmY:115.56 getForwad->getIntersec(distalL:210.00,distalR:210.00,xL:17.58,yL:65.01,xR:209.78,yR:61.04) getIntersec firstRadius: 210.00 secondRadius: 210.00 firstX: 17.58 firstY: 65.01 secondX: 209.78 secondY: 61.04 MotorStepsToCartesian => MachinePosX:117.53 MachinePosY:249.69 XYZ_AXES:3 numVisibleAxes:3 MotorStepsToCartesian => thetaL:30.00=MotorPosX:3467.00/StepsPermmX:115.56 MotorStepsToCartesian => thetaR:30.00=MotorPosY:3236.00/StepsPermmY:115.56 getForwad->getIntersec(distalL:210.00,distalR:210.00,xL:17.58,yL:65.01,xR:209.78,yR:61.04) getIntersec firstRadius: 210.00 secondRadius: 210.00 firstX: 17.58 firstY: 65.01 secondX: 209.78 secondY: 61.04 MotorStepsToCartesian => MachinePosX:117.53 MachinePosY:249.69 XYZ_AXES:3 numVisibleAxes:3 MotorStepsToCartesian => thetaL:30.00=MotorPosX:3467.00/StepsPermmX:115.56 MotorStepsToCartesian => thetaR:30.00=MotorPosY:3467.00/StepsPermmY:115.56 getForwad->getIntersec(distalL:210.00,distalR:210.00,xL:17.58,yL:65.01,xR:207.58,yR:65.01) getIntersec firstRadius: 210.00 secondRadius: 210.00 firstX: 17.58 firstY: 65.01 secondX: 207.58 secondY: 65.01 MotorStepsToCartesian => MachinePosX:112.58 MachinePosY:252.29 XYZ_AXES:3 numVisibleAxes:3 MotorStepsToCartesian => thetaL:30.00=MotorPosX:3467.00/StepsPermmX:115.56 MotorStepsToCartesian => thetaR:30.00=MotorPosY:3467.00/StepsPermmY:115.56 getForwad->getIntersec(distalL:210.00,distalR:210.00,xL:17.58,yL:65.01,xR:207.58,yR:65.01) getIntersec firstRadius: 210.00 secondRadius: 210.00 firstX: 17.58 firstY: 65.01 secondX: 207.58 secondY: 65.01 MotorStepsToCartesian => MachinePosX:112.58 MachinePosY:252.29 XYZ_AXES:3 numVisibleAxes:3 MotorStepsToCartesian => thetaL:25.00=MotorPosX:2889.00/StepsPermmX:115.56 MotorStepsToCartesian => thetaR:25.00=MotorPosY:2889.00/StepsPermmY:115.56 getForwad->getIntersec(distalL:210.00,distalR:210.00,xL:22.82,yL:54.94,xR:212.82,yR:54.94) getIntersec firstRadius: 210.00 secondRadius: 210.00 firstX: 22.82 firstY: 54.94 secondX: 212.82 secondY: 54.94 MotorStepsToCartesian => MachinePosX:117.82 MachinePosY:242.23 XYZ_AXES:3 numVisibleAxes:3 constraintsOK->cachedInvalid:0 cachedX0:0.00 cachedY0:0.00 getInverse not cantilevered proximalL:130.00 distalL:210.00 xOrigL:-95.00 yOrigL:0.00 x_0:117.82 y_0:242.23 getTheta getIntersec firstRadius: 130.00 secondRadius: 210.00 firstX: -95.00 firstY: 0.00 secondX: 117.82 secondY: 242.23 getTheta use: 2 x2: 22.82 y2: 54.94 thetaB: 25.00 x1: -55.68 y1: 123.91 thetaA: 72.39 getInverse not cantilevered proximalR:130.00 distalR:210.00 xOrigR:95.00 yOrigR:0.00 x_0:117.82 y_0:242.23 getTheta getIntersec firstRadius: 130.00 secondRadius: 210.00 firstX: 95.00 firstY: 0.00 secondX: 117.82 secondY: 242.23 getTheta use: 2 x2: 212.82 y2: 54.94 thetaB: 25.00 x1: -10.49 y1: 75.98 thetaA: 144.24 getInverse cachedInvalid 0 => cachedX0:117.82 cachedY0:242.23 cachedX1:117.82 cachedY1:242.23 cachedXL:22.82 cachedYL:54.94 cachedXR:212.82 cachedYR:54.94 cachedThetaR:25.00 cachedXR:212.82 cachedYR:54.94 cachedThetaL:25.00 cachedXL:22.82 cachedYL:54.94 getInverse => cachedInvalid:0 x_0:117.82 y_0:242.23 xL:22.82 yL:54.94 thetaL:25.00 xR:212.82 yR:54.94 thetaR:25.00 x1:117.82 y1:242.23 constraintsOK->cachedInvalid:0 actuatorAngleLMin:-90.00<0 && thetaL:25.00>actuatorAngleLMax:270.00 constraintsOK->cachedInvalid:0 thetaL:25.00 < actuatorAngleLMin:-90.00 || thetaL:25.00 > actuatorAngleLMax:270.00 return false constraintsOK->cachedInvalid:0 actuatorAngleRMin:-90.00<0 && thetaR:25.00>actuatorAngleRMax:270.00 constraintsOK->cachedInvalid:0 thetaR:25.00 < actuatorAngleRMin:-90.00 || thetaR:25.00 > actuatorAngleRMax:270.00 return false constraintsOK->cachedInvalid:0 headAngle:53.79 < headAngleMin:15.00 || headAngle:53.79 > headAngleMax:165.00 isnan(headAngle):0 return false constraintsOK->cachedInvalid:0 angleProxDistL:218.10 < proxDistLAngleMin:0.00 || angleProxDistL:218.10 > proxDistLAngleMax:360.00 isnan(angleProxDistL):0 return false constraintsOK->cachedInvalid:0 angleProxDistR:271.90 < proxDistRAngleMin:0.00 || angleProxDistR:271.90 > proxDistRAngleMax:360.00 isnan(angleProxDistR):0 return false constraintsOK->cachedInvalid:0 cachedX0:117.82 cachedY0:242.23 CartesianToMotorSteps => motorPosX = cachedThetaL:25.00 * stespPermm[X_AXIS]115.56 motorPosY = cachedThetaR:25.00 * stepsPermm[Y_AXIS]115.56 CartesianToMotorSteps => machinePos[0]:117.82 machinePos[1]:242.23 motorPosX:0.00 motorPosY:115.56 CartesianToMotorSteps => XYZ_AXES:3 numVisibleAxes:3 constraintsOK->cachedInvalid:0 cachedX0:117.82 cachedY0:242.23 CartesianToMotorSteps => motorPosX = cachedThetaL:25.00 * stespPermm[X_AXIS]115.56 motorPosY = cachedThetaR:25.00 * stepsPermm[Y_AXIS]115.56 CartesianToMotorSteps => machinePos[0]:117.82 machinePos[1]:242.23 motorPosX:0.00 motorPosY:115.56 CartesianToMotorSteps => XYZ_AXES:3 numVisibleAxes:3 constraintsOK->cachedInvalid:0 cachedX0:117.82 cachedY0:242.23 getInverse not cantilevered proximalL:130.00 distalL:210.00 xOrigL:-95.00 yOrigL:0.00 x_0:0.00 y_0:0.00 getTheta getIntersec firstRadius: 130.00 secondRadius: 210.00 firstX: -95.00 firstY: 0.00 secondX: 0.00 secondY: 0.00 getTheta use: 2 x2: -190.66 y2: -88.03 thetaB: 222.62 x1: -190.66 y1: 88.03 thetaA: 137.38 getInverse not cantilevered proximalR:130.00 distalR:210.00 xOrigR:95.00 yOrigR:0.00 x_0:0.00 y_0:0.00 getTheta getIntersec firstRadius: 130.00 secondRadius: 210.00 firstX: 95.00 firstY: 0.00 secondX: 0.00 secondY: 0.00 getTheta use: 2 x2: 190.66 y2: 88.03 thetaB: 42.62 x1: 190.66 y1: -88.03 thetaA: 317.38 getInverse cachedInvalid 0 => cachedX0:0.00 cachedY0:0.00 cachedX1:0.00 cachedY1:0.00 cachedXL:-190.66 cachedYL:-88.03 cachedXR:190.66 cachedYR:88.03 cachedThetaR:42.62 cachedXR:190.66 cachedYR:88.03 cachedThetaL:222.62 cachedXL:-190.66 cachedYL:-88.03 getInverse => cachedInvalid:0 x_0:0.00 y_0:0.00 xL:-190.66 yL:-88.03 thetaL:222.62 xR:190.66 yR:88.03 thetaR:42.62 x1:0.00 y1:0.00 constraintsOK->cachedInvalid:0 actuatorAngleLMin:-90.00<0 && thetaL:222.62>actuatorAngleLMax:270.00 constraintsOK->cachedInvalid:0 thetaL:222.62 < actuatorAngleLMin:-90.00 || thetaL:222.62 > actuatorAngleLMax:270.00 return false constraintsOK->cachedInvalid:0 actuatorAngleRMin:-90.00<0 && thetaR:42.62>actuatorAngleRMax:270.00 constraintsOK->cachedInvalid:0 thetaR:42.62 < actuatorAngleRMin:-90.00 || thetaR:42.62 > actuatorAngleRMax:270.00 return false constraintsOK->cachedInvalid:0 headAngle:180.00 < headAngleMin:15.00 || headAngle:180.00 > headAngleMax:165.00 isnan(headAngle):0 return false constraintsOK->cachedInvalid:1 cachedX0:0.00 cachedY0:0.00 getInverse not cantilevered proximalL:130.00 distalL:210.00 xOrigL:-95.00 yOrigL:0.00 x_0:0.00 y_0:0.00 getTheta getIntersec firstRadius: 130.00 secondRadius: 210.00 firstX: -95.00 firstY: 0.00 secondX: 0.00 secondY: 0.00 getTheta use: 2 x2: -190.66 y2: -88.03 thetaB: 222.62 x1: -190.66 y1: 88.03 thetaA: 137.38 getInverse not cantilevered proximalR:130.00 distalR:210.00 xOrigR:95.00 yOrigR:0.00 x_0:0.00 y_0:0.00 getTheta getIntersec firstRadius: 130.00 secondRadius: 210.00 firstX: 95.00 firstY: 0.00 secondX: 0.00 secondY: 0.00 getTheta use: 2 x2: 190.66 y2: 88.03 thetaB: 42.62 x1: 190.66 y1: -88.03 thetaA: 317.38 getInverse cachedInvalid 0 => cachedX0:0.00 cachedY0:0.00 cachedX1:0.00 cachedY1:0.00 cachedXL:-190.66 cachedYL:-88.03 cachedXR:190.66 cachedYR:88.03 cachedThetaR:42.62 cachedXR:190.66 cachedYR:88.03 cachedThetaL:222.62 cachedXL:-190.66 cachedYL:-88.03 getInverse => cachedInvalid:0 x_0:0.00 y_0:0.00 xL:-190.66 yL:-88.03 thetaL:222.62 xR:190.66 yR:88.03 thetaR:42.62 x1:0.00 y1:0.00 constraintsOK->cachedInvalid:0 actuatorAngleLMin:-90.00<0 && thetaL:222.62>actuatorAngleLMax:270.00 constraintsOK->cachedInvalid:0 thetaL:222.62 < actuatorAngleLMin:-90.00 || thetaL:222.62 > actuatorAngleLMax:270.00 return false constraintsOK->cachedInvalid:0 actuatorAngleRMin:-90.00<0 && thetaR:42.62>actuatorAngleRMax:270.00 constraintsOK->cachedInvalid:0 thetaR:42.62 < actuatorAngleRMin:-90.00 || thetaR:42.62 > actuatorAngleRMax:270.00 return false constraintsOK->cachedInvalid:0 headAngle:180.00 < headAngleMin:15.00 || headAngle:180.00 > headAngleMax:165.00 isnan(headAngle):0 return falseM114 outputs:

m114 X:117.819 Y:242.226 Z:0.000 E:0.000 E0:0.0 Count 2889 2889 0 Machine 117.819 242.226 0.000 Bed comp 0.000 ok

-

This post is deleted! -

@rutku the values seem to be all ok for me.

Homing works, debug tells that the actuators move back 5 degree to 25 like planned, then trying to move to X0 Y0 is not possible because of restriction of parameter A maximum value:

From https://duet3d.dozuki.com/Guide/Five+Bar+Parallel+SCARA/24#s90 :

Annn:mmm:ppp:qqq:rrr:sss nnn is the minimum angle between the distal arms (constr in the first image) in degrees, mmm the maximum....Your setting is 165 degree maximum angle of distal arms, and X0 Y0 is only reachable with distal arms nearly straight line.

line 131 confirms this check:

constraintsOK->cachedInvalid:0 headAngle:180.00 < headAngleMin:15.00 || headAngle:180.00 > headAngleMax:165.00 isnan(headAngle):0 return false -

@joergs5 Yes! Worked!

Work Mode 1 but the arms worked at different angles. They work in a very limited area. Could it be from the location of the endstops?

config.g

M669 K9 L1 X-95:95 Y0:0 P130:130 D200:200:0:0 B30:30 A0:180:0:360:0:360 C0:270:0:270

-

@rutku your actuators are 190 away (X -95 to X 95), the proximal arms have length 260, distal arms have length 400, so you cannot rotate to the position of horizontal arms 180/0 degree, because the distance of proximal+distance is 190+260 = 450, and your distal arms are not long enough "to close the gap".

Your video starting at 1:16 the angle of the distal arms is again near 180 degree and violates the A max value parameter.(I see you changed A to 180. The limit will be the arm lengths). A "secure" area is when the arms are forward, like 90 degree both.To clarify: you place the endstops at one location and the B parameter must tell the firmware the correct angle for this endstops. Because when you turn on the Duet, he doesn't know at what position the arms and steppers are. Homing has only one task: tell the firmware at which arm/stepper position the endstop is triggered, then set a value. Kinematics like Cartesian/CoreXY set the value of G1 H1 movements to the M208 value, but here it is set to the value of the B parameter.

The procedure I follow when I am not sure where the print area is:

- home with both actuators endstop 30 degree

- move to an area which is "secure" like G1 X-50 Y20 (relative) (or measure where the absolute coordinate is where both proximal arms are 90 degree)

- from there mark where you can move with small G1 in every direction

I assembled a pen as "hotend" and draw on a sheet of paper.

-

@rutku with your position in video at 1:11:

When you try to move X10, this is not possible: you could turn the left arm up (to a lower angle) and right arm to a low one, but this movement crosses the singularity of unprintable area (the 400 too short for the 450). When a G0/G1 move is done, the kinematics checks whether the movement path is reachable the hole path.

BTW: you could reach your destination if you move the hotend to a high Y value first, then approaching the goal. This is a risk later, when printing an object, because reachability depends on where you start. In other words it depends on how the slicer wants to draw the lines. Later for printing it is better to restrict M208 to a safe rectangular print area and print only in this area.

Please see

https://forum.duet3d.com/topic/10409/joergs5-parallel-five-bar-scara/30

for the complex print area, where some areas on the Y0 line or near it is not printable. -

@joergs5 Hello, I did what you said. I set the right arm to 90 degrees and the left arm to 45 degrees. I used optical endstop. It worked great. G0 X0 Y0 position is not wrong?

Is @bondus repository up to date? I tried but there was no change.

config.g

M350 X16 Y16 I1 ;S3 ; Configure microstepping with interpolation M669 K9 L1 X-95:95 Y0:0 P130:130 D200:200:0:0 B45:45 A0:180:0:360:0:360 C-180:270:-180:270 M92 X115.555556 Y115.555556 ; Set steps per mm

-

@rutku G0 X0 Y0 is probably not reachable.

Do you have a question for the debug_output or video?

-

@joergs5 Hi, working mode 1 is selected but the levers like working mode 2 are moving. I made the angle of Constr "0: 180" degrees "15: 165" degrees. Nothing changed. I wanted to show it with video and output.

I wanted to draw 20x20 squares. But very different shape appeared. What is the reason?

Thank you so much for your patience. You have been very helpful.

-

@rutku there must be something wrong with the setup, because your X0 is close to the first wheel, but should be in the middle between the wheels. This change in coordinates produces the curved lines.

Maybe your homing didn't work like before, please check the angles and position when you finished homing (without the last G0 X0 Y0 line).

After homing please try to go to absolute coordinate

G90 G0 X0 Y50

and verify that the position is in the middle between the two big wheels.If you homing angles are correct, but the X0 Y50 is at the wrong place, you can check

- whether the gear ratio and M92 are correctly calculated

- the arm lengths are correct. The length is always from the middle of a hinge to middle of the other hinge

- whether the endstop positions are 45 degree, like is set in config now

-

I followed this thread with great interest, but it got stuck in the middle...are all problems solved?

What was the solution and final layout?I ask, because I look for an excuse to build a fancy Capstan geared drive, either for a SCARA or robot arm.

I'd use Aramid fishing line instead of steel cable and spur and pinion gear hardware from the orbiter/BMG extruder. -

@o_lampe I didn't hear from rutku, but the firmware is ok so far, bondus has made a working scara here: https://hackaday.com/2020/03/18/a-practical-dual-arm-scara-3d-printer/ And if you find a bug, tell me, I'll fix it.

The Capstan is interesting for robot gear also, but 1:30 is difficult to achieve with one stage, because you need a very big wheel. Therefore I use 2 stage gears 1:3 (or 1:2) and 1:10. Please go ahead!

-

@joergs5 @o_lampe

Hi, I didn't get the calibration. I've been dealing with a week calibration but draws the same shapes. @bondus had not shared a detail about calibration. I didn't mean to bother @JoergS5 on that.I didn't understand the "Step Calibration" portion in the file where the bond is shared.

-

@rutku the step calibration in the link mentioned is to calculate the M92 values.

What is the number of teeth of your small and big pulley, is it a standard 200 step stepper and the microstep settingis 16? The goal is to calculate how many steps are needed to rotate by 1 degree. Please tell the numbers, then I will help calculating.

The google calc provided in the link is readonly, but the formula is:

microsteps / stepperdeg * bigwheelteeth / smallwheelteeth

The result is the M92 value.

Example: 16 microsteps, stepper 1.8 degree for one step (= stepper with 200 steps, 360/200 = 1.8), 200 teeth bigwheel, 20 teethsmallwheel => 16/1.8*200/20 = 88.88888 -

microsteps = 128

stepper Degree = 1.8

Teeth bigwheel = 260

Teeth smallwheel = 20M92 = (128/1.8) * (260/20) = 924.444444

square.gcode

G90 G1 X0 Y90 G1 X0 Y140 G1 X50 Y140 G1 X50 Y90 G1 X0 Y90

-

@rutku there are some ideas you can check:

- after your tests, please make M122 and check for hiccups. 128 microsteps could mean you loose steps => correction: I remember you're using hardware which will not report hiccups. You can try to reduce microsteps, but then changing M92 also. You can reduce speed with F parameter (eg G91 G1 H2 X10 F100) also without changing the values and check whether the lines are better then. Reducing speed gives your controller more time to calculate the segments.

- you can verify that your setting are correct by testing:

Home axis 1 to let's say 45 degree (to verify: M669 B first value is 45, arm is at 45 degree position after homing). Make M114 and check the first value of the Count values. This must be M92 value * degree, i.e. 924.4444 * 45 = 41600. Please rotate the axis to example 90 degree (with G91 G1 H2 X90)and make M114 again, the Count value should now be 83200 and the arm should be at 90 degree position.

You can verify additionally the resulting position: verify that the (0,50) position is 5 cm away from your x axis and in the middle of the two wheels. I cannot see it in your image, but the (50,90) and (50,140) must be on the vertical line between the wheels.

Having correct angles is critical for your line precision (straight or curved), so please measure exaclty. I used this idea:

https://forum.duet3d.com/topic/14996/five-bar-parallel-scara-prototypes/10

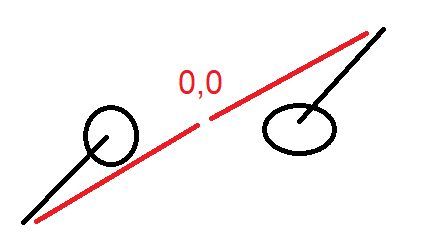

Another thing to check is whether your arms lengtsh are correct, please verify the lengths:

The red lines are the lenghts, from middle of hinge to middle of other hinge. The green line is the starting point of the first line.

-

@joergs5 said in Five bar Parallel SCARA print area problem:

The Capstan is interesting for robot gear also

The good thing about Capstan is, you don't have to print a big wheel with precise teeth. I also had good experience with Aramid line in a non-slipping config. I think it will run really smooth (no tooth-mesh problems)

I should start a new thread about it.