Wavy surface problem.

-

@egon-net

2660's aren't the quietest drivers, but it might be worth to check out per-motor register tuning? I'm thinking of the same as I can't seem to get my 60mm LDO motors to be at all quiet, but those are high-inductance.

Could it be full frame resonance? Maybe add some weight to the base and see if that changes the natural freq and quiets it down at slow speeds

-

@luke-slaboratory said in Wavy surface problem.:

@egon-net

2660's aren't the quietest drivers, but it might be worth to check out per-motor register tuning? I'm thinking of the same as I can't seem to get my 60mm LDO motors to be at all quiet, but those are high-inductance.

Could it be full frame resonance? Maybe add some weight to the base and see if that changes the natural freq and quiets it down at slow speeds

My old printer has the TMC2130 drivers IIRC, in spreadCycle mode and just shy of 1A. Can't configure anything else, and they are scary silent (can't hear them out of the enclosure if not moving fast)

My new printer is built like a brick (3060/306060 extrusions bolted directly) and all metal. Maybe being too rigid means any vibration gets amplified by it...

-

My old printer has the TMC2130 drivers IIRC, in spreadCycle mode and just shy of 1A. Can't configure anything else, and they are scary silent (can't hear them out of the enclosure if not moving fast)

My new printer is built like a brick (3060/306060 extrusions bolted directly) and all metal. Maybe being too rigid means any vibration gets amplified by it...

I tried to optmize the TMC parameters with an oscilloscope monitoring the current measuring resistor, but couldn't get any better than default.

-

@egon-net just using extrusion without extra mass+damping definitely will vibe everything extra.

My printers are 2040-4040, and without damping and extra mass are loud from just mechanical vibrations.

-

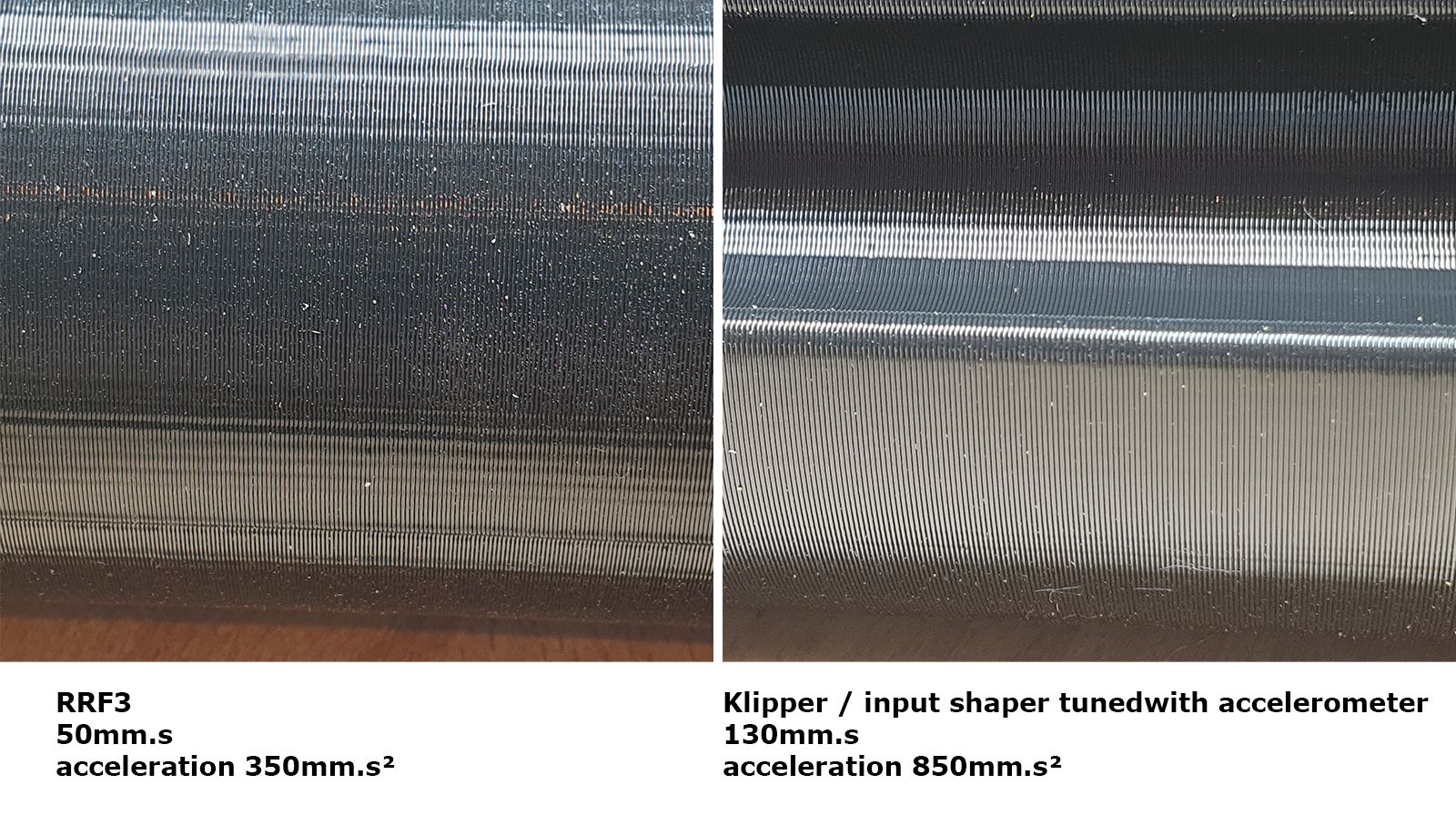

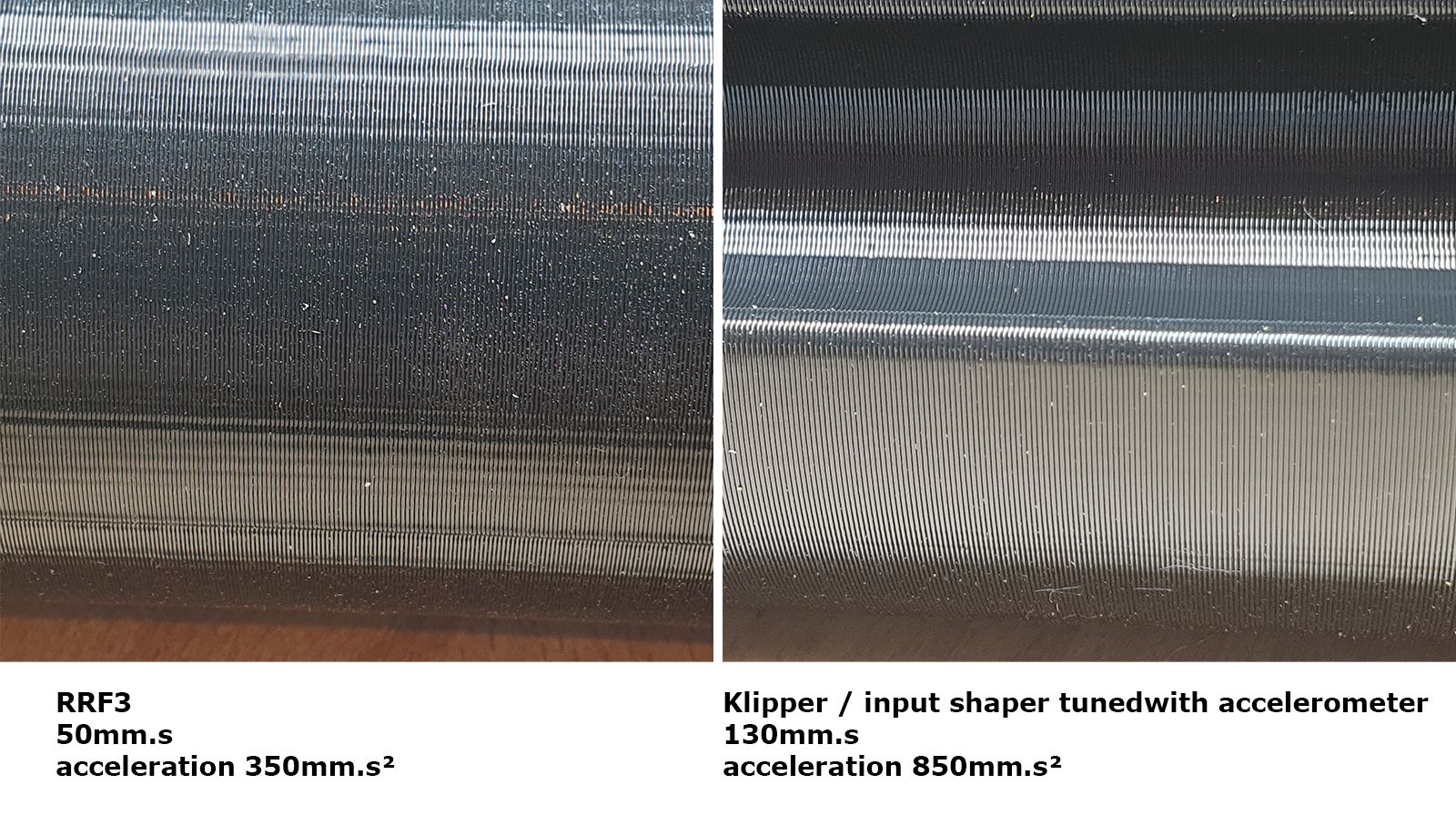

So. I made a picture comparison to be really clear about VFAs, ie very fine artifacts.

(please look at it real size, else moire effect is pronounced)First it's something that you'll only on a carefuly tuned printer. Else it will be "hidden" by other things.

It is super super visible with shiny filaments like petg (or colorfabb ngen in my case).

It looks like very fine tiny vertical "waves", like ghosting, but with a constant amplitude.I still absolutly don't know what produces it exactly.

However, in the picture attached :- both parts sliced from the exact same stl

- both parts sliced with the same slicer profile in prusaslicer, just a lot faster for the klipper test

- settings copied from the duet config when i switched to klipper (i mean no recalibration process)

- pid's were obviously re-made after firmware switch

-

@tpra said in Wavy surface problem.:

So. I made a picture comparison to be really clear about VFAs, ie very fine artifacts.

(please look at it real size, else moire effect is pronounced)First it's something that you'll only on a carefuly tuned printer. Else it will be "hidden" by other things.

It is super super visible with shiny filaments like petg (or colorfabb ngen in my case).

It looks like very fine tiny vertical "waves", like ghosting, but with a constant amplitude.I still absolutly don't know what produces it exactly.

However, in the picture attached :- both parts sliced from the exact same stl

- both parts sliced with the same slicer profile in prusaslicer, just a lot faster for the klipper test

- settings copied from the duet config when i switched to klipper (i mean no recalibration process)

- pid's were obviously re-made after firmware switch

I'd try again with Klipper at 50mm/s2, since I've noticed that VFA is way more noticeable with slower speed, just to be sure.

-

@luke-slaboratory said in Wavy surface problem.:

@egon-net just using extrusion without extra mass+damping definitely will vibe everything extra.

My printers are 2040-4040, and without damping and extra mass are loud from just mechanical vibrations.

It already weights 30+ kg... It's quite tall.

-

@egon-net same quality at low speed. even better actually.

if i don't go faster with rrf it's because it produces too much ghosting but that's another story

anyway klipper produces the same quality from 40 to 130. -

@tpra said in Wavy surface problem.:

@egon-net same quality at low speed. even better actually.

if i don't go faster with rrf it's because it produces too much ghosting but that's another story

anyway klipper produces the same quality from 40 to 130.Can you test Klipper without input shaper? I wonder how much of the quality increase is beacuse of it...

-

@egon-net said in Wavy surface problem.:

Can you test Klipper without input shaper? I wonder how much of the quality increase is beacuse of it...

Sure. as soon as the current print finishes i'll do that.

-

-

@luke-slaboratory said in Wavy surface problem.:

my largest is 622x622x1000, and i still added 30kg of concrete to the base.

shrug

And then you threw it to the river XDD Just joking...

Did u really noticed a decrease in noise/ringing after adding so much extra weight?

-

Suprisingly, yes!

I forget what the numbers were for feeds+speeds, but it made a considerable improvment for $12

-

@luke-slaboratory said in Wavy surface problem.:

Suprisingly, yes!

I forget what the numbers were for feeds+speeds, but it made a considerable improvment for $12

Holy cow! What a difference!

I already have installed an accelerometer, just waiting for the montion planner overhaul with imput shaping in reprapfirmware...

-

@luke-slaboratory So is that improvement from adding the extra mass to the printer?

-

Yessir! Both pictures were me trying to find the worst light where I was, but I fully admit that they're not 1:1 comparative since they weren't taken in the same spot.

-

@luke-slaboratory That's interesting though. Complex things these printers!

-

@tpra Hello. That print result is excellent ! Can you show me a photo how your printer is constructed?

-

@egon-net said in Wavy surface problem.:

@tpra said in Wavy surface problem.:

@egon-net same quality at low speed. even better actually.

if i don't go faster with rrf it's because it produces too much ghosting but that's another story

anyway klipper produces the same quality from 40 to 130.Can you test Klipper without input shaper? I wonder how much of the quality increase is beacuse of it...

I am very curious to see this as well!

Input shaper benefits are pretty well established at this point, and I am anxiously awaiting the feature to roll out for RRF (hopefully supporting my Maestro board). But, I have had a suspicion that something in RRF is driving the steppers in a way that sets up a resonance.

-

@hiroaki said in Wavy surface problem.:

@tpra Hello. That print result is excellent ! Can you show me a photo how your printer is constructed?

Hello, nothing crazy, it's a simple cartesian.

You can find pictures here : https://forum.duet3d.com/topic/21792/my-latest-duet-cartesian-printer

The Z drive has been completly modified since the pictures so it's closer to the one i designed on the funX4. Imho the printer would benefit a lot stronger and heavier frame. That"s why the next one will be a mix of the FunX4 Z and frame + RatRig's vcore3 XY carriage / EVA extruder holder.@ccs86 said in Wavy surface problem.:

I am very curious to see this as well!

Input shaper benefits are pretty well established at this point, and I am anxiously awaiting the feature to roll out for RRF (hopefully supporting my Maestro board). But, I have had a suspicion that something in RRF is driving the steppers in a way that sets up a resonance.

Sorry it took time, i'm printing a no-input-shaper test with the exact same gcode used on the right picture of my comparison, will post results when i'm back at noon.

Tbh i don't think it has anything to do with input shaper. I also have the exact same suspicion as you about "something in RRF is driving the steppers in a way that sets up a resonance".You know what makes me crazy with this ? the problem exists, and it's ignored. I don't even understand that seeing the comparison i posted above, no dev wondered or even asked me more informations.

I mean, it's not like if a guy who just got its first printer said "it's it does not work why???".

I thought the print quality spoke for itself. Clearly not. So why bother ?