3d Benchy Question

-

I'd try these changes.

M203 E6000

M566 E3000 P1

M201 Z200 E3000These changes would make your extruder and z axis a bit more responsive. M566 P1 enables jerk between all move types which basically makes transitions to and from travel moves a bit quicker, which can help on those blobs on the surface.

Now might also be a good time to tube retraction and pressure advance.

I know your axis are fairly large and slow, so conservative jerk and accel on the X and Y are understandable. But you may still want to play with that a bit to see what you can get away with.

These macro files can help in live tuning things.

-

@phaedrux

When the current print finishes i will upload these changes. However, what did you mean by its time to tube retraction?? -

tune! Not Tube.. sorry.

-

@wingtip what is the printing order per layer? I’m not familiar with S3D, but you can change it on other slicers. It can help overhangs if you print inner perimeter before outer perimeter. But can negatively effect the dimensions, as outer perimeter can be pushed out further if overextruding.

Ian

-

@droftarts

in S3D its called outline direction and the options are outside-in, or inside- out.

Mine is defaulted to inside-out.The print i had going last night finally finished. I will implement some of the changes suggested in the thread now for the next print. Its very close to being dialed in. The part last night came out great and was dimensionally accurate. It had very few minor defects that doesn't affect the usability of the part at all.

Will make the changes and post the results.

-

@wingtip said in 3d Benchy Question:

Nozzle-.3

Are you going to be using a 0.3mm nozzle long term? Seems an odd choice for such a large printer?

-

@phaedrux

I was planning on using it for detail... i care more about detail than speed. However, when i plugged in my model i built this printer for into S3D, I was quite shocked at the print time. It was like 13 days! Soooo I will more than likely break it into sections.Here is another benchy i just finished after making some of the adjustments suggested. I also turned the benchy 90 deg to aid in the cooler nozzle hitting the bow. Those first tests again were with zylatec black petg, this is matterhackers white petg. Also older filament and white isnt the easiest to print in.

-

13 days... wow. You'd be surprised the detail you can get from a 0.6mm nozzle. Unless you're printing minis with very fine features.

-

@phaedrux

can you even run a .6 on a v6 or would i have to switch to a volcano, which means also making another new part cooler and a new bl touch bracket.... uggg lol -

@wingtip I run a 0.6 on a V6 titan aero. No problem. 10 to 12 cubic mm per sec of flow without issue. Gets me 60-70mm/s and 0.3 layer heights.

-

@phaedrux

using your numbers i plugged them in to see what the time difference would be.. holy cow.. 300 hours to 55 lol.... but im worried about the detail ... i want to take this finished part and make a fiberglass mold... the .3 nozzle parts when printed look fine for the detail.... a .6 though i worry.. can you post some pics of some .6 nozzle prints??? Cause the print time does look wayyyy better.. Other wise im going to have to split this down to more manageable print times. -

If you're making a mold I doubt you'll be transferring features with 0.3mm accuracy anyway? Can you share an example of what you're trying to ultimately print?

Examples of 0.6mm prints: https://forum.duet3d.com/topic/5282/my-custom-d-bot/2

I chose 0.6 because it maximizes the flow rate potential of the V6 and has a good balance of speed to detail. And it's a lot easier to tune than a volcano with a larger nozzle, that's for sure.

-

-

@wingtip

Let me rephrase that... its not so much transferring details but it makes for less filling and sanding for smooth surfaces where there are no details... there will still be the panel lines and indentations for holes to be drilled etc... -

Well then it would depend on where you need the resolution. A small nozzle will only help on thin features or top surface X/Y details like text or slightly sharper corners. You can still use smaller layer heights with a 0.6 nozzle and still save a lot of time. I use 0.15 as my detail layer height. 0.2 ends up looking quite good as well.

Looking at the photos in that album I don't see much that would really benefit from a 0.3 nozzle.

-

Well after looking at my stash of nozzles i had .2's, .3's, .4's, .5's, NO .6's, and had .8's. So I installed a .5 nozzle, set the layer height to .25, the speed up to 60 and thought i'd try a benchy first.

It wasnt long before i started noticing problems. The first thing i noticed was the increased layer height was high enough that my probe was extremely close to the print. Any boogers at all and it was catching on the probe if i didnt catch them and cut them away.

Once the first layer was down and the speed really kicked in i kept an eye on the nozzle temp and sure enough it was dropping. I backed the fan down without slowing the speed for now. the temp stopped dropping but wasn't climbing either but i let it keep printing... As the print got higher the probe was dragging more and more often and eventually i just stopped the print for fear of breaking it. Problem is my bl touch cant go any higher without printing a different bracket perhaps. So is there a way to adjust the probe slightly further up into the bl touch housing???

Otherwise the print was looking pretty impressive till it started dragging through the layers. My brain needs a rest lol.

-

That looks pretty over extruded, but maybe it's just from PETG and too little time between layers. The benchy isn't a very good analogue for what you'll actually be printing. The short layer times means the layers don't have time to cool, so you get lots of curling. Try printing 2 or 3 benchies at the same time. The increased layer time will allow the layers to solidify.

Or start printing your actual models that you'll eventually be printing. You'll learn a lot more from that.

Doesn't hurt to go through another extruder calibration either.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165

-

@phaedrux

The probe is still extremely close to the print... i really wish i could raise it more somehow.Printed your extrusion test. went as low as .92 but ended up back at 1.0.

Im going to bed, will jack with this more later tomorrow evening.

-

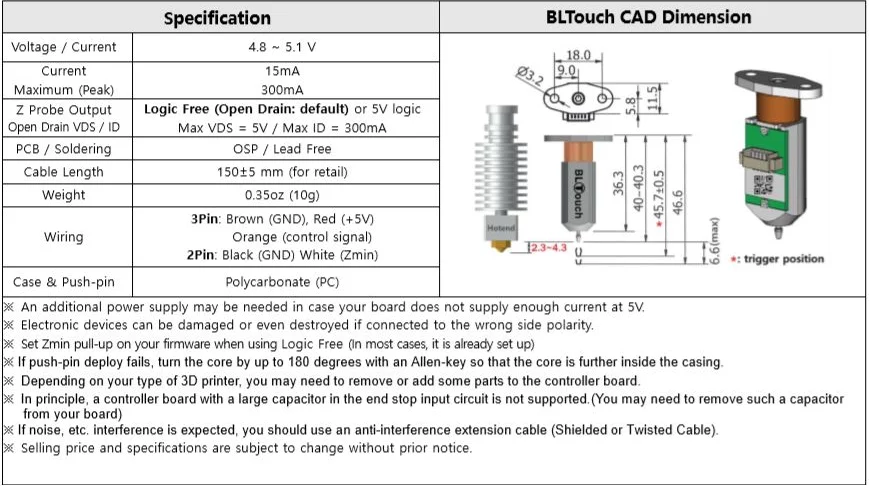

@wingtip I think you must have your bltouch mounted at the wrong height... for the V3, it should be 2.3 to 4.3mm above the nozzle height. (think the V2 was ~3mm?)

-

@engikeneer

That may very well be... the bracket im using was just from thingiverse.