Vertical lines vs. geared extruders

-

@jens55 said in Vertical lines vs. geared extruders:

@ccs86, my BMG LGX uses 405 steps/mm and it has a 3:1 gear reduction build in and I agree that the steps are not easily visible although in a print you might still see an overall pattern. I think an extruder without gear reduction is around 120 or so steps per mm which is considerably coarser than your 709 steps/mm.

Here is my math .... please double check and correct me where/if I have made an error.

1 step = 1/120 mm of 1.75 mm filament

filament is (1.75 /2)^2 x 3.14 = 2.4 mm^3 volume of filament per mm.

Since each step is 1/120mm then each step is 0.02 mm^3 of filament

Printed filament (0.4x0.2) is 0.08 mm^3 volume per mm laid down

So we lay down 4 mm of filament for every full step of the extruder.

At a micro stepping rate of 16 we lay down 0.25 mm of filament or 4 microsteps per mm laid down.

This is certainly visible in itself but you have to keep in mind that each step has a flow curve associated with it which makes the individual steps more visible. Then you put all of this into a largish printed area (let's say 100mm x 100 mm) and even though the eye might have an issue looking at the individual line and see the flaws it is remarkably more accurate to see a pattern in a larger area and you will see this pattern.So to sum it up and even if my math is incorrect, I was going under the assumption of a standard extruder where the motor turns the gear that feeds the filament and you would see the steps. When reduced in a 3:1 gear reduction like the BMG, steps are much less visible. At 709 steps/mm

the end result would be even smoother.I think your math is correct, depending on your microstepping. I am pretty sure that 709 step/mm on the Sherpa mini is considering x16 stepping, not full steps of a 1.8* motor.

-

@hackinistrator said in Vertical lines vs. geared extruders:

i think the bondtech style extruder gears are the main cause for those issues .

the tensioning mechanism on bondtech style extruder effects the backlash . more tension = gears fully engaged . less tensions = gears are separated , causing backlash .

too much tension and you're chewing the filament .What issues?

Backlash in Bondtech gears only affects the idler's ability to drive the filament. Especially at lower flow rates, there is essentially no demand for the idler to drive. Only once the primary gear starts to slip on the filament is the idler gear truly loaded.

-

@ccs86 I agree. Low tension isn’t the problem, it’s high tension that causes cogging issues in the Bondtech-style gears. And as @gloomyandy (I think) pointed out, the lack of torque at some microsteps causes the movement to be delayed, then catches up as the micro stepping gains more torque towards the full step (or wherever there is more torque), which creates a pulsing in the extrusion.

I had a look on the Bondtech website to try and find correct tensioning advice, but couldn’t find any.

Ian

-

@droftarts said in Vertical lines vs. geared extruders:

@ccs86 I agree. Low tension isn’t the problem, it’s high tension that causes cogging issues in the Bondtech-style gears. And as @gloomyandy (I think) pointed out, the lack of torque at some microsteps causes the movement to be delayed, then catches up as the micro stepping gains more torque towards the full step (or wherever there is more torque), which creates a pulsing in the extrusion.

I had a look on the Bondtech website to try and find correct tensioning advice, but couldn’t find any.

Ian

That's a very interesting theory. Basically, regardless of micro-stepping setting, you have a periodic torque output, depending on distance from the closest full step. This would cause a similar (but inverse) plot of positional error of the extruder, given a constant filament force. If this is true, I can only see more mechanical reduction and/or smaller step angle to improve the situation.

-

@ccs86 said in Vertical lines vs. geared extruders:

@hackinistrator said in Vertical lines vs. geared extruders:

i think the bondtech style extruder gears are the main cause for those issues .

the tensioning mechanism on bondtech style extruder effects the backlash . more tension = gears fully engaged . less tensions = gears are separated , causing backlash .

too much tension and you're chewing the filament .What issues?

Backlash in Bondtech gears only affects the idler's ability to drive the filament. Especially at lower flow rates, there is essentially no demand for the idler to drive. Only once the primary gear starts to slip on the filament is the idler gear truly loaded.

you never truly know which side (primary or idler) is actually loaded and driving the filament with this set up .

if gears are fully meshed , it can be that the idler is the one loaded and driving the filament .i dont think its the microstepping torque spread issue , as i already tested extruders with 2 set-ups , one with bondtech style (not original , so there might be quality issues) and one with simple idler .

the simple extruder wins .

even prusa had many quality issues in mk3 since the move to bondtech . -

@hackinistrator said in Vertical lines vs. geared extruders:

you never truly know which side (primary or idler) is actually loaded and driving the filament with this set up .

if gears are fully meshed , it can be that the idler is the one loaded and driving the filament .I don't agree. The primary gear is always driving. Torque input comes in through the primary gear and that gear is always engaged in the filament. How could it not be driving?

The idler gear is always in contact with the filament too. So, it is either out of contact with the main gear and idling, or in contact and also driving.

-

@ccs86 lets say the the gear mesh is perfect - no backlash .

in this case , why do you think that only primary gear is driving ?

both spin at the same speed , it does not matter which one is directly connected to the motor .

in ideal world and perfect filament torque will be split 50/50 in this case . -

@hackinistrator said in Vertical lines vs. geared extruders:

@ccs86 lets say the the gear mesh is perfect - no backlash .

in this case , why do you think that only primary gear is driving ?

both spin at the same speed , it does not matter which one is directly connected to the motor .

in ideal world and perfect filament torque will be split 50/50 in this case .Read my post again.

-

@ccs86

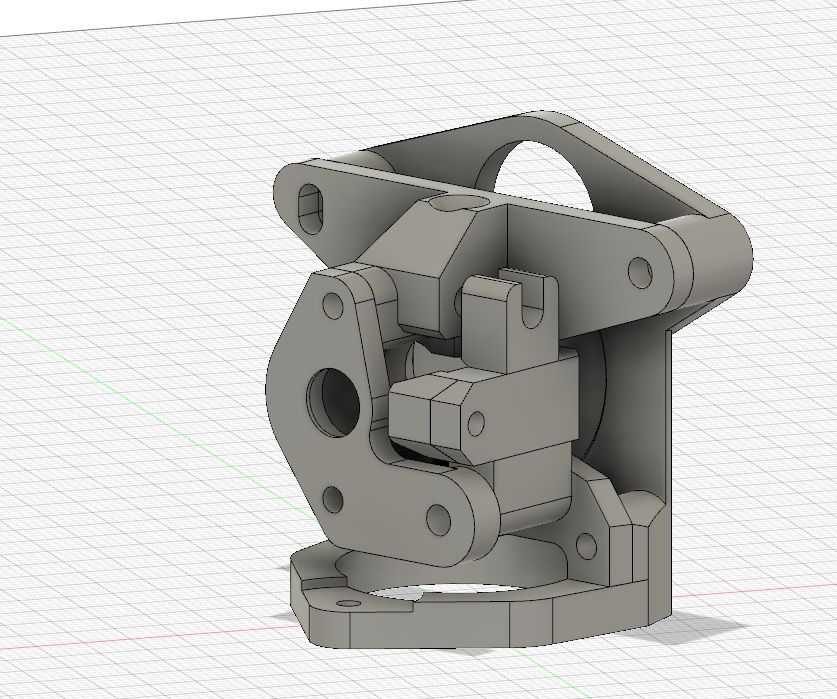

I've changed my 'Sherpa Mini Clone' to adjustable gears as you proposed. Will test it today...also allowed my stepper to be adjustable with the spur gear. That wasn't possible before, because the center hole wasn't oval.

I also beefed up a few strategic points, but that's not the point here.

-

@o_lampe HI!

How did it work?

-

@zabana

Surprisingly well!

I have some ringing, I try to dampen with input shaping, but that's another thread.

In the meantime I print at 90-100mm/s and 300-400mm/s travel speed. The result is 'sharper' than the same parts printed on my CoreXY. (shorter belts?)

I have an idea, how to drop the motor about 20mm to improve effector stability. But, that's again another thread. -

@o_lampe your sherpa mini clone reminds me of the superfly extruder and the Sailfin extruder... a lot of minimalized setups around now.

-

-

-

this guy is doing great analysis of this issue

https://www.youtube.com/watch?v=dL6u0UwPJOQit looks like he also thinks (like me) that this comes from direct drive dual gear extruders . i'm waiting for the next vid to see his conclusion .

-

@hackinistrator Interesting video. I suppose we have to wait for the second video to find out why this is caused by what he says it is? I was watching with captions on and no sound, so maybe I missed some type of evidence that was presented?

Not an attack. The theory seems quite plausible, I'm just genuinely curious as to if any more info is out there or in the video that I missed.

-

@hackinistrator said in Vertical lines vs. geared extruders:

this guy is doing great analysis of this issue

https://www.youtube.com/watch?v=dL6u0UwPJOQit looks like he also thinks (like me) that this comes from direct drive dual gear extruders . i'm waiting for the next vid to see his conclusion .

Wow.

He has done an amazing amount work - interesting stuff - this shows that being obsessed can be a good thing - at least for the rest of us.

I'm currently only using Zesty Nimble v1.x remote drive extruders, with a variety of hot ends, and I am quite happy with the results.

Sometimes I get faint diagonal lines but to see them I need a flashlight has he has done.

Be interested to see if he finds the "ultimate" solution to this problem.

I'm waiting on v3 of the Nimble which is supposed to deal with the diagonal lines - only time will tell.

Frederick

-

@hackinistrator I printed the slanted recommended test print and I see the wood pattern! I also have a bondtech dual drive wheel setup.

My theory would be that it is a slight non-concentricity of the drive wheel. However, the YouTuber suggests that turning one of the wheels around so the gears don't mesh resolves the issue. This seems odd to me, because the gears on my machine are not closely meshed. There is a LOT of movement before the gear teeth touch. I would have thought this basically removed their influence from anything, unless the filament grinded or something and the wheel slipped and had to turn the other one, instead of the other one merely idling along.

I digress. I'm interested to see this next video! I wonder if grinding off the gear teeth from the bondtech wheels would help. I have never felt the gears were beneficial. I just liked having two toothed drive gears. IMO, the idler is a difficult part to source otherwise. Plain bearing? Meh. I'm just rambling.

-

@bot The follow up video is now available

-

@skrotz Yes I saw that. I agree with the conclusion that the "wood grain" pattern is being caused by the gear teeth meshing. I'm gonna grind mine off and see if it makes extrusion smoother.