Vertical lines vs. geared extruders

-

@ccs86 lets say the the gear mesh is perfect - no backlash .

in this case , why do you think that only primary gear is driving ?

both spin at the same speed , it does not matter which one is directly connected to the motor .

in ideal world and perfect filament torque will be split 50/50 in this case . -

@hackinistrator said in Vertical lines vs. geared extruders:

@ccs86 lets say the the gear mesh is perfect - no backlash .

in this case , why do you think that only primary gear is driving ?

both spin at the same speed , it does not matter which one is directly connected to the motor .

in ideal world and perfect filament torque will be split 50/50 in this case .Read my post again.

-

@ccs86

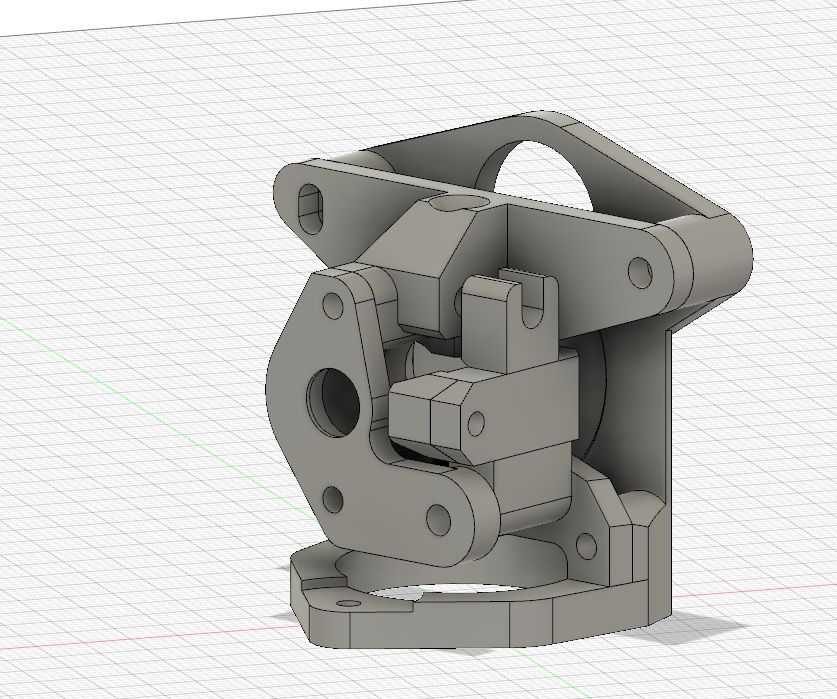

I've changed my 'Sherpa Mini Clone' to adjustable gears as you proposed. Will test it today...also allowed my stepper to be adjustable with the spur gear. That wasn't possible before, because the center hole wasn't oval.

I also beefed up a few strategic points, but that's not the point here.

-

@o_lampe HI!

How did it work?

-

@zabana

Surprisingly well!

I have some ringing, I try to dampen with input shaping, but that's another thread.

In the meantime I print at 90-100mm/s and 300-400mm/s travel speed. The result is 'sharper' than the same parts printed on my CoreXY. (shorter belts?)

I have an idea, how to drop the motor about 20mm to improve effector stability. But, that's again another thread. -

@o_lampe your sherpa mini clone reminds me of the superfly extruder and the Sailfin extruder... a lot of minimalized setups around now.

-

-

-

this guy is doing great analysis of this issue

https://www.youtube.com/watch?v=dL6u0UwPJOQit looks like he also thinks (like me) that this comes from direct drive dual gear extruders . i'm waiting for the next vid to see his conclusion .

-

@hackinistrator Interesting video. I suppose we have to wait for the second video to find out why this is caused by what he says it is? I was watching with captions on and no sound, so maybe I missed some type of evidence that was presented?

Not an attack. The theory seems quite plausible, I'm just genuinely curious as to if any more info is out there or in the video that I missed.

-

@hackinistrator said in Vertical lines vs. geared extruders:

this guy is doing great analysis of this issue

https://www.youtube.com/watch?v=dL6u0UwPJOQit looks like he also thinks (like me) that this comes from direct drive dual gear extruders . i'm waiting for the next vid to see his conclusion .

Wow.

He has done an amazing amount work - interesting stuff - this shows that being obsessed can be a good thing - at least for the rest of us.

I'm currently only using Zesty Nimble v1.x remote drive extruders, with a variety of hot ends, and I am quite happy with the results.

Sometimes I get faint diagonal lines but to see them I need a flashlight has he has done.

Be interested to see if he finds the "ultimate" solution to this problem.

I'm waiting on v3 of the Nimble which is supposed to deal with the diagonal lines - only time will tell.

Frederick

-

@hackinistrator I printed the slanted recommended test print and I see the wood pattern! I also have a bondtech dual drive wheel setup.

My theory would be that it is a slight non-concentricity of the drive wheel. However, the YouTuber suggests that turning one of the wheels around so the gears don't mesh resolves the issue. This seems odd to me, because the gears on my machine are not closely meshed. There is a LOT of movement before the gear teeth touch. I would have thought this basically removed their influence from anything, unless the filament grinded or something and the wheel slipped and had to turn the other one, instead of the other one merely idling along.

I digress. I'm interested to see this next video! I wonder if grinding off the gear teeth from the bondtech wheels would help. I have never felt the gears were beneficial. I just liked having two toothed drive gears. IMO, the idler is a difficult part to source otherwise. Plain bearing? Meh. I'm just rambling.

-

@bot The follow up video is now available

-

@skrotz Yes I saw that. I agree with the conclusion that the "wood grain" pattern is being caused by the gear teeth meshing. I'm gonna grind mine off and see if it makes extrusion smoother.

-

Interesting videos. New gear design required. I had the thought of using two motors to drive in unison but that comes with it's own issues.

-

I guess I don't feel so out of date for still running a single gear titan aero like a pleeb.

-

I have tried a few of the test prints from the videos. I have been unable to get the “wood grain” pattern to show up with an LGX extruder(pleased about that).

I’m going to try a few different parameters to see if I can excite it in some way because it’s a dual drive and I would expect similar results in some form or fashion.

-

I just printed "rectangular 2 recommended.stl" using recommended settings and reported my results with photos through the survey page linked in the video description. I have a genuine Bondtech BMG suspended with a 140mm bowden on my delta and I see no such artifacts. Perhaps I got lucky with my BMG unit or maybe the bowden is long enough to compensate (though my usual retraction is under 2mm).

Perhaps this is an issue of stacking tolerances leading to problems in some setups. -

@alex-cr

the LGX is the one with the bigger diameter gears?

I suspect they made them bigger, also to have better bearings for the gears.

The usual barrel bearing and the super small main bearings might have an influence on the lack off smoothness of extrusion, too? -

@ajdtreyd

bowden wont show those problems , it is masking it .its a combination of things , bondtech style drive + short filament path .

i have V6 style heatsink that was cut in half (to shorten filament path) , after cutting the pattern or "inconsistent extrusion" became much worse .