Verifying mesh levelling

-

@phaedrux said in Verifying mesh levelling:

@marp said in Verifying mesh levelling:

the tilt macro calls bedscrews.g which just checks the four corners with G30 and adjusts it.

How many points are you using in your mesh? For such a large bed you should be using as many as possible which is up to 441.

How many times are you doing the tilt correction?

We typically do a 400 point mesh.

The bed tilt calibrations runs up to 6 times to dial in.

-

@bstump said in Verifying mesh levelling:

Frederick

Can you share your bed.g and mesh.g

Both of my files are more complicated then they need to be to perform their basic functions - I have included features primarily of use when getting the printer initially dialed in.

Here is my bed.g - it references a number of .G files to perform needed actions - the names indicate what is done.

M98 P"homeALL_verify.g" M98 P"probe_config.g" ; --- prepare to level bed --- ; M671: Define positions pf manual bed levelling screws or Z leadscrews ; Xnn:nn:nn... list of between 2 and 4 X coordinates of the leadscrews that drive the Z axis or the bed levelling screws ; Ynn:nn:nn... list of between 2 and 4 Y coordinates of the leadscrews that drive the Z axis or the bed levelling screws ; Snn maximum correction allowed for each leadscrew in mm (optional, default 1.0) ; Pnnn pitch of the bed levelling screws (not used when bed levelling using independently-driven leadscrews). Defaults to 0.5mm which is correct for M3 bed levelling screws ; Fnn fudge factor, default 1.0 M671 X-180:0:180 Y-65:130:-65 S3 ; positions of ball studs M291 R"Leveling bed" P"Please wait..." T0 ; --- level bed leveling --- while true ; run leveling pass ; determine where to probe if {global.g_level_mode} != "4PT" ; --- probe near ball studs --- G30 P0 X-145 Y-65 Z-99999 ; probe near ball stud #1 G30 P1 X0 Y100 Z-99999 ; probe near ball stud #2 G30 P2 X145 Y-65 Z-99999 S3 ; probe near ball stud #3 else ; --- probe near bed corners --- G30 P0 X-140 Y-90 Z-99999 ; LF G30 P1 X-140 Y90 Z-99999 ; LR G30 P2 X140 Y90 Z-99999 ; RR G30 P2 X140 Y-90 Z-99999 S3 ; RF ; check results - exit loop if results are good if move.calibration.initial.deviation < 0.02 break ; check pass limit - abort if pass limit reached if iterations = 5 M291 P"Bed Leveling Aborted" R"Pass Limit Reached" abort "Bed Leveling Aborted - Pass Limit Reached" ; --- finish up --- ; --- set Z=0 datum which can be affected by leveling --- M98 P"center_probe.g" ; position for probing G30 ; do single probe which sets Z to trigger height of Z probe M291 R"Bed leveling complete" P"OK" T0Here is my mesh.g:

if {global.g_map_mode} = "NONE" M291 R"Cannot create height map - Map Mode is set to NONE" P"Cannot continue" S2 T0 abort "Map Mode is set to NONE" M98 P"homeALL_query.g" M98 P"probe_set_z.g" ; set Z=0 datum G32 ; level bed to be safe M208 Y-115:100 ; adjust axis min/max to allow for probe offset if {global.g_map_mode} = "FAST4" M291 R"Creating FAST4 Height Map" P"Please wait..." T0 M557 X-140:140 Y-90:90 P2:2 ; define 4 point mesh for G29 G29 S0 ; do probing G29 S3 P"heightmap_FAST4.csv" ; save file with unique name M291 R"FAST4 Height Map Created" P"OK" T1 elif {global.g_map_mode} = "FAST9" M291 R"Creating FAST9 Height Map" P"Please wait..." T0 M557 X-140:140 Y-90:90 P3:3 ; define 9 point mesh for G29 G29 S0 ; do probing G29 S3 P"heightmap_FAST9.csv" ; save file with unique name M291 R"FAST9 Height Map Created" P"OK" T1 else M291 R"Creating FULL Height Map" P"Please wait..." T0 M557 X-140:140 Y-90:90 P20 ; define FULL mesh for G29 (400 points) G29 S0 ; do probing G29 S3 P"heightmap_FULL.csv" ; save file with unique name M291 R"FULL Height Map Created" P"OK" T1 M208 Y-100:100 ; restore axis min/max to normal G29 S2 ; cancel mesh bed compensation M290 R0 S0 ; cancel baby stepping -

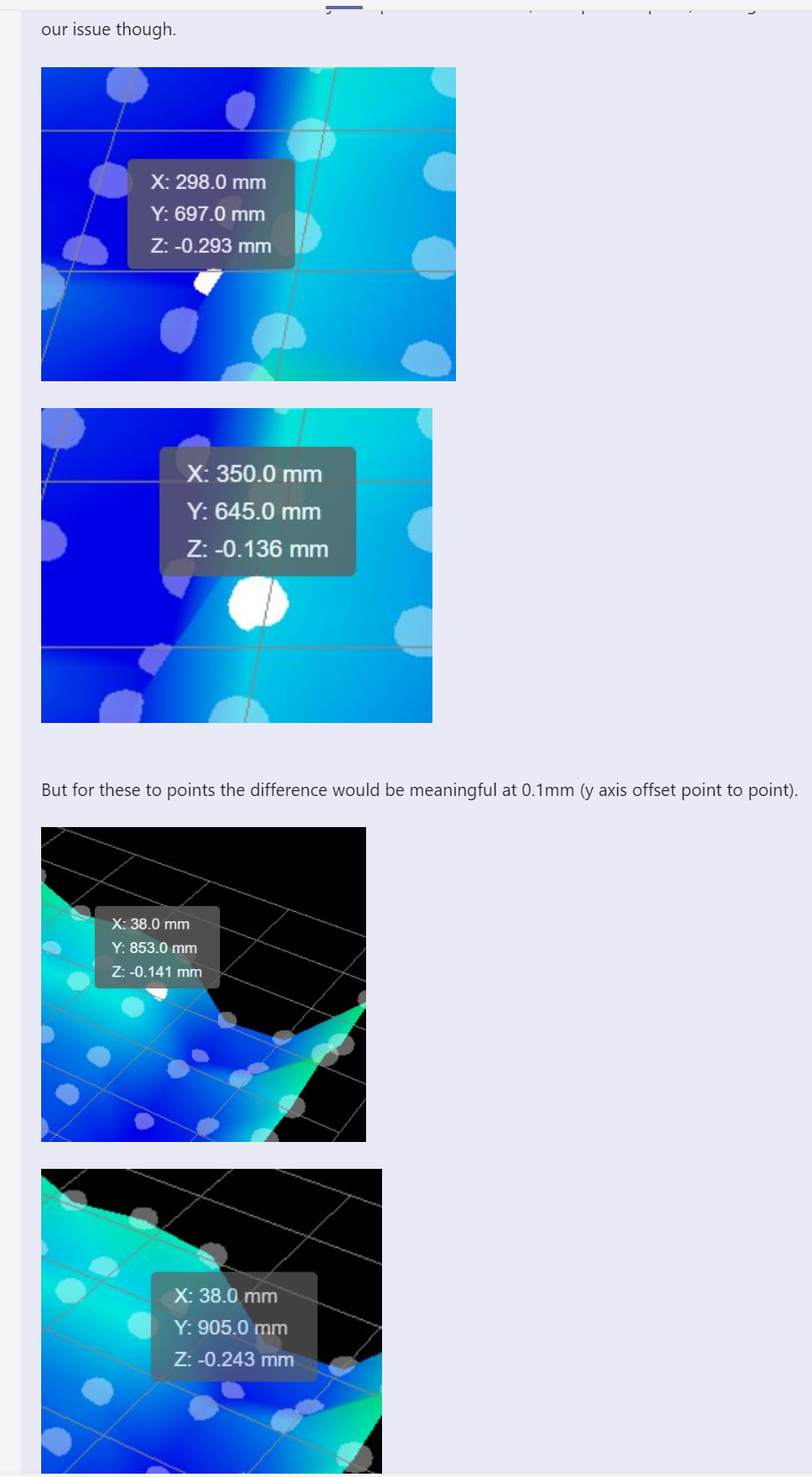

@fcwilt I am wondering if the offset between the probe and the nozzle is correctly compensated for in the bed tilt and mesh compensation. with our duel head extruder the probe sits half way between the tow nozzles in the direction for one axis and the aligned for the other axis . I think the nozzle to probe distance is in the range of 50-75mm. In looking at two side by side probe points in the mesh the probing distance is around 5mm and the difference in mesh height can be 0.1 to 0.16mm. I am thinking our bed adhesion issue may be related to the probe to nozzle distance not being fully adjusted for and the mesh compensation being for a real surface point around 5 mm from where the nozzle is. Depending on where on the bed the nozzle is the adjusted mesh may be up or down from what the mesh says because the mesh is effectively pushed back/front by around 50 mm.

-

If I read the following correctly we say the two nozzles are 52.5mm apart and the probe is X-14 Y21 from the first nozzle. I am having this verified.

; Z-Probe M950 S0 C"duex.e6heat" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H5 F120 T9000 R0.7 ; set Z probe type to bltouch and the dive height + speeds ; heater 7 output used for PWM of BL touch (e6 heat) G31 P500 X-14 Y21 Z1.000 ; Set Z probe trigger value, offset and trigger height(Z-offset) M557 X-14:974 Y21:1009 S52 ; Define mesh grid. 400 Points ;M376 H10 ; Height (mm) over which to taper off the bed compensation M376 H0 ; compensation taper disabled TEST; Tools M563 P0 S"E0 Primary" D0 H1 F0 ; define tool 0, E0 drive, heater 1, fan 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"E1 SEcondary" D1 H2 F1 ; define tool 1 G10 P1 X-0.2 Y52.5 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C -

I think the method to do the offsets is correct, but how can we tell if the mesh compensation take these offsets into account correctly? We are still verifying the numbers.

-

@bstump said in Verifying mesh levelling:

@fcwilt I am wondering if the offset between the probe and the nozzle is correctly compensated for in the bed tilt and mesh compensation

I don't actually understand what you are asking.

Frederick

-

I've never worked with a multi-tool printer.

And I don't find the documentation of G31 very clear in regards to multi-tool printers.

In the absence of any additional information I would set the offsets of the probe to X=0 Y=0 and offsets of each tool relative to the probe.

Testing would reveal if that actually worked.

Frederick

-

@fcwilt said in Verifying mesh levelling:

In the absence of any additional information I would set the offsets of the probe to X=0 Y=0 and offsets of each tool relative to the probe.

You could do that for testing, but I think the default method is to have tool0 be at x0 y0, and the probe for tool 0 offset from that. Tool1 would then have it's offset defined in relation to tool0.

-

@phaedrux said in Verifying mesh levelling:

@fcwilt said in Verifying mesh levelling:

In the absence of any additional information I would set the offsets of the probe to X=0 Y=0 and offsets of each tool relative to the probe.

You could do that for testing, but I think the default method is to have tool0 be at x0 y0, and the probe for tool 0 offset from that. Tool1 would then have it's offset defined in relation to tool0.

That makes sense but I could not find where that is stated.

There is this in the Gode Dictionary for G31:

1X and Y offsets of the Z probe relative to the print head (i.e. the position when the empty tool is selected) can be specified. This allows you to calculate your probe coordinates based on the geometry of the bed, without having to correct them for Z probe X and Y offset.

but I don't know what it is trying to say.

Frederick

-

@fcwilt said in Verifying mesh levelling:

I don't actually understand what you are asking.

There is an offset between the probe and the nozzle. Assuming our offsets are correct, how can we verify that the mesh compensation take this offset correctly into account when applying the mesh compensation? Basically the probe mesh is offset in two directions to the primary nozzle.

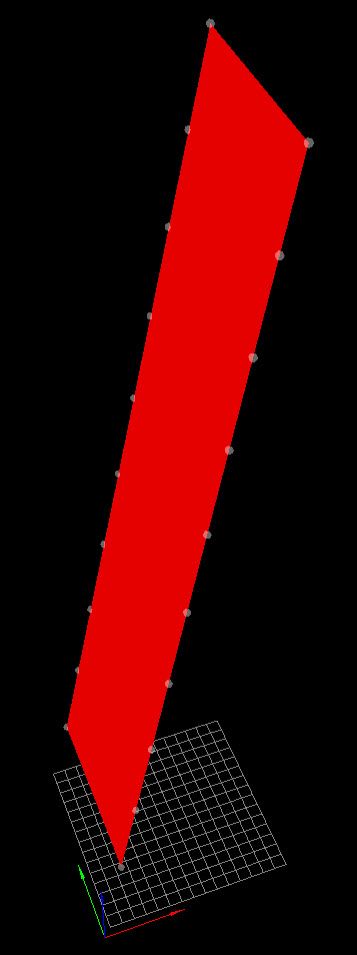

If it takes the offset correctly into account then I would expect the nozzle to follow the mesh contour almost perfectly (given whatever extrapolation method it uses). However if it does not take the offset into account correctly or at all then the applied mesh would be offset from the nozzle and the nozzle would follow an offset contour.

We have a test spiral that covers the bed twice and he pair of lines is 25mm away from the other pair of lines. We see some spots that are nice and some a bit tight and squished, and others that do not adhere and were not proper layer thickness. This leans me to think the whole mesh is offset.

If we compare side by side points (given the large bed that is not easy to level manually) we see between 0.1 and 0.16mm difference in mesh pint heights. If this translates to the nozzle contour that would be great, but It does not. The first pair of points is beside a seam in the plates (three bead plates with 3 separate pieces of PEI. The second pair of points is along one plate.

As I said, I am questioning if the probe to nozzle offsets are correctly applied when the bed mesh is applied and questioning how to check that.

-

I've always assumed they are but it's easy to check.

Here is the text of a height map for testing:

RepRapFirmware height map file v2 generated at 2021-01-01 00:00, min error 0.000, max error 0.00, mean 0.000, deviation 0.000

xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum

0.00,150.00,0.00,150.00,-1.00,15.00,150.00,11,2

0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10

0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10It greatly exaggerates Z errors so you can jog along the X axis and verify the Z adjustments.

Adjust these values as needed to match your printer:

xmin, xmax, ymin, ymax, radius, xspacing, yspacing, xnum, ynum

Create a file heightmap.csv in your system folder with the data above adjusted for your printer.

Enable mesh compensation using this file.

Frederick

-

@fcwilt said in Verifying mesh levelling:

That makes sense but I could not find where that is stated.

I think it's just convention, since you can set whatever you want as the origin and offset anything from anywhere if you want. It really depends on the setup what makes the most sense.

@fcwilt said in Verifying mesh levelling:

1X and Y offsets of the Z probe relative to the print head (i.e. the position when the empty tool is selected) can be specified. This allows you to calculate your probe coordinates based on the geometry of the bed, without having to correct them for Z probe X and Y offset.

but I don't know what it is trying to say.I think it might be talking about tool changer situations where you may have a probe attached to the head itself rather than a tool. I think the E3D tool changer is an example of that. There is a switch on the carriage itself that is used to probe. The tools are all offset from that.

-

@bstump said in Verifying mesh levelling:

If it takes the offset correctly into account then I would expect the nozzle to follow the mesh contour almost perfectly

Yes of course it takes the offset into account. It will adjust for your nozzle not the probe itself. That's why you tell it how far your probe is from the nozzle tip in XYZ.

-

@phaedrux said in Verifying mesh levelling:

@bstump said in Verifying mesh levelling:

If it takes the offset correctly into account then I would expect the nozzle to follow the mesh contour almost perfectly

Yes of course it takes the offset into account. It will adjust for your nozzle not the probe itself. That's why you tell it how far your probe is from the nozzle tip in XYZ.

If it does properly take it into account then we have bigger issues. If it does not take it into account then That would tend to look somewhat like the issues we are seeing.

We did find turning off taper did improve the first layer but not as much as hoped.

-

I thought of a way to prove the nozzle to probe offset is being taken into account correctly.

-

For the first point in the bed tilt probing, mark the bed with a sharpie at the expected probe spot +/-5mm. Likely all 4 corners.

-

Run the tilt macro and see if the probe comes down on the marked spots.

-

Now via the console, send the nozzle to those coordinates and also see if they match up.

-

I suppose I could generate a quick code to print a few loops of a circle at each spot. The sharpie dots should be centered on each circle.

If they all match up then we have some other issues, and we need to figure iut what the issue(s) is(are)

If they do not match up then the probe offset is not being compensated for correctly, and we need to figure out why.

This would not prove the mesh compensation compensates correctly for the probe to nozzle offset, but it is a first step in trusting that it does.

-

-

-

We did my little check and found that the probe offset is compensated for. We also did do some test prints where we turned off Taper and adhesion improved notably. So the questions now are

- Why does the taper adjustment degrade adhesion?

- What is happening in the algorithm that does the taper adjustment that it is not applying a consistent first layer thickness?

** Over 10mm taper ajdustment zone, the per layer adjustment should be ~2% of the needed mesh compensation.

** A pretty small number that should not impact bed adhesion.

Could it be at a mesh point ever 50mm is not enough to properly mesh the bed? Should we try a 900 point mesh vs the 400 point mesh we typically do?

-

@bstump the most mesh points you can have are 441

-

@bstump said in Verifying mesh levelling:

Could it be at a mesh point ever 50mm is not enough to properly mesh the bed?

this is why I suggested doing a mesh of a smaller area of your printer where you will print a part and see if there is improvement.

@bstump said in Verifying mesh levelling:

Why does the taper adjustment degrade adhesion?

It's adsjusting the position less each layer than the measured amount over the distance set for the taper. If you use 10mm, at 5mm height it will have 50% less compensation effect such that by 10mm there is no compensation at all. If you set the taper too low, it will be reducing the compensation too much for what you need.

-

this is why I suggested doing a mesh of a smaller area of your printer where you will print a part and see if there is improvement.

We can try this on the worst area of the bed.

It's adjusting the position less each layer than the measured amount over the distance set for the taper. If you use 10mm, at 5mm height it will have 50% less compensation effect such that by 10mm there is no compensation at all. If you set the taper too low, it will be reducing the compensation too much for what you need.

I can understand at height this being the case, but the very first layer is different with the Taper on vs with the Taper off. I would not expect anything noticeable in the way of a difference between Taper on and Off for the first layer. But there is.