input shaping and printer feet

-

With input shaping being on the verge of release, I have a question regarding the stability of the frame and how soft the feet are.

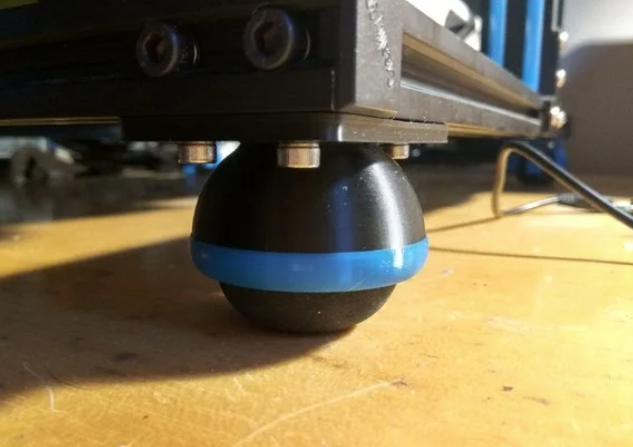

My printer is pretty big and very sturdy. I started on duet2 and had some resonance issues so installed squash ball feet. They are very soft and give great isolation, but they are so soft that the printer frame moves slightly on large fast moves. There's no twisting of the frame or print quality issues.

When tuning input shaping, is this movement going to give false results?

From what I understand, we only want to measure resonance in the print head. If the whole frame is moving the accelerometer will pick this up too. -

Only way to know for sure is to measure it twice, once with and without the feet.

-

When I do input shaping I do it with as rigid of a surface as possible to bounce off of to get the true frame impact.

this will definitely impact results, unless there are multiple accelerometers to determine what the delta is between frame->nozzle.

Do both tests to confirm yourself tho.

-

You can try doing the measurement with the sensor attached to the frame and see what kind of resonance you get. Possibly it will be at a much lower frequency that the input shaper will not care about.

-

@luke-slaboratory IMO, the frame on most printers is not what contributes much to ringing. If it does, then it's quite a spindly frame.

I think the belts and the motor itself (being held in place by magnetism, so, springy) are what cause the ringing. This is based on the frequencies that may be excited in the frames of 3D printers -- they are usually significantly higher than we see in ringing. I'm not personally sure if there is a direct correlation between excited resonant frequencies and the frequency of the ripples in the ringing on the print, but it seems that way.

-

So since a lot of the ringing seems to be from the stepper motors, why are we not using servo's ?

-

@jens55 I think there are many good reasons that we are not yet there. Obviously, there is cost. Then, there is complexity. But they also have their own problems. Hunting can cause print artifacts, among other things. They don't hold a single position as well as steppers, IIRC.

I'm no expert these are just ideas I remember hearing.

-

@bot, I am no expert either but I do know that every substantial piece of CNC equipment out there uses servo's to power them. Part of that is speed and power but if there was an issue with hunting or other issues, they would not be used in every commercial piece of equipment.

Cost is indeed an issue, steppers are the cheapest way for low power applications. Things swing the other way once you get to a high power requirement.

Complexity in tuning a servo loop is most certainly an issue but isn't going to be an insurmountable issue to the folks hanging out here (they are certainly not feasible for the average consumer / 3D hobbyist) -

No, I agree!

The accelerometer on the frame was to see what is extra about the head shaking on systems that are damped and allowed to freely wobble - IE, in the context of the toolhead to the rest of the room, it will be shaking alot more if its on a damped ball or a soft foam than if it was rigidly affixed to the floor, but by using the damping, it will be vibrating alot less in the context of toolhead to the bed - The extra accelerometer on the frame was merely to subtract out the total machine shaking and to isolate only the undesirable vibrations that affect actual print quality

-

@luke-slaboratory that's actually really cool. When I get around to playing with accelerometers I might have to try that out.

-

Yeah - https://drive.google.com/file/d/1QePf8ESv3j3wUwLrDP3FBE8x0FJYt_Bv/view?usp=sharing

The accelerometer data I get from this thing (which is damped on the feet) is garbage, but not damping it produces terrible prints. Who would have thought? XD

-

...what should people do with 'flying extruders'? Fix their extruders during accel-tests or run it as_is?

I believe the same answer also applies to damped feet.

IMHO you want to damp the resulting frequency of the whole system? -

@o_lampe said in input shaping and printer feet:

...what should people do with 'flying extruders'? Fix their extruders during accel-tests or run it as_is?

I believe the same answer also applies to damped feet.

IMHO you want to damp the resulting frequency of the whole system?What matters is ringing of the nozzle relative to the bed. So you need to use an accelerometer mounted as close to the nozzle as you reasonably can, for example on the hot end mount. If the bed is likely to be ringing too, for example because the machine is a bed slinger or it is constrained by a wobbly frame, then you should also take readings with an accelerometer mounted on the bed.

-

@dc42 Yep! Exactly what I did - the video attached was a damped machine, the whole frame vibrates as one and it produces beautiful prints because there is low (at least for a bedslinger) ringing between the bed and the nozzle.

-

@dc42 I wonder if there is some merit in using two accelerometers for input shaping? One attached to the bed, and one attached to the hotend. Then the actual trace you care about to drive input shaping is the difference between them?

I'm not sure if it is as simple as subtracting one trace from the other in the frequency domain or is it more complex...? -

@engikeneer said in input shaping and printer feet:

@dc42 I wonder if there is some merit in using two accelerometers for input shaping? One attached to the bed, and one attached to the hotend. Then the actual trace you care about to drive input shaping is the difference between them?

I'm not sure if it is as simple as subtracting one trace from the other in the frequency domain or is it more complex...?Running simultaneous capture of one accelerometer on the print head and one on the bed, then summing the data, sure seems like the most accurate way to characterize the behavior we care about.

-

@engikeneer said in input shaping and printer feet:

@dc42 I wonder if there is some merit in using two accelerometers for input shaping? One attached to the bed, and one attached to the hotend. Then the actual trace you care about to drive input shaping is the difference between them?

I'm not sure if it is as simple as subtracting one trace from the other in the frequency domain or is it more complex...?Ideally, yes. However, the bed and the print head are likely to ring at different frequencies, so I doubt that it makes much difference.