First layer issues-Extrusion volume dropping on first layer?

-

For a while I have been having issues with first layer when printing models that have a large surface area on the first layer.

The bed is pretty flat and the print starts out well and as the first layer progresses the bottom infill does not stick well.

I went through the normal debugging with Z Probe, bed leveling etc. Things I have tried that did not make a difference.

- Rebuilt the Z-axis to make sure nothing is loose.

- Switched between BL-Tocuh and SuperPinda

- Printed with Mesh Bed Leveling ON and OFF

- Switched between using TWO Z Motors and ONE

- Tried PrusaSlicer and Simplify3D

- Tried with Pressure Advance ON and OFF

- Tried a few different filaments

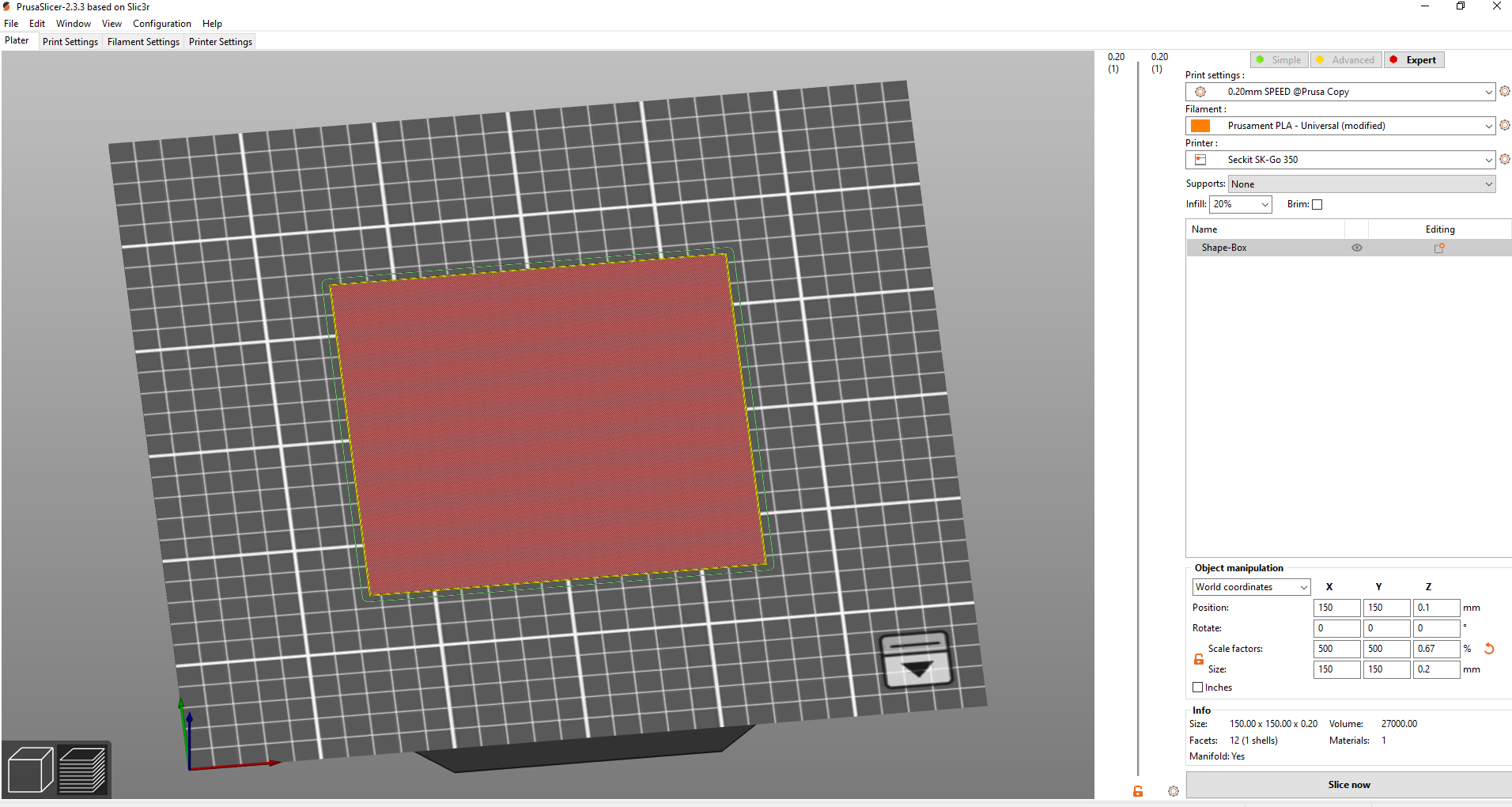

When nothing seemed to solve it I tried a few different infill patterns that go in different directions, this was to make sure the issue is not with bed leveling. The model is just a rectangle with 0.2mm height and printed with PLA

I tried

- Monotonic infill (goes from Right to Left)

- Concentric (outside to inside)

- Hilbert curve (starts out bottom left and moves through the layer and end bottom right)

With these infill patterns the issue seemed to be with extrusion "slowing down" as the first layer progresses, since the gaps in infill increase by the end of first layer.

So I replaced the extruder stepper motor and made sure the Bondtech Extruder is setup correctly.Still the issue persists. So I am kind of lost on what the next steps are to debug this issue.

I have attached a photo with two printouts of the first layer (Monotonic and Hilbert infill style)

With the Hilbert curve style the layer sticks well all through, and there are no bumps to touch, but at the end of the layer the gap between the fractals ends has increased a lot.Is there something else I can monitor during the print to check on extrusion.

-

The thing that helped me the most with first layer adhesion was slow speed -15 mm/s.

I use plain old "rectilinear" infill for all surface layers.

I have no idea what those infill types are.

I've never experienced any sort of extruder slow down so I have no idea what might be causing it.

Fredeick

-

@fcwilt Adhesion is not a problem, and the first layer speed is slow 20mm/s.

Monotonic is just rectilinear if there are no other patterns in the first layer.I used Hilbert Curve for the first time because I wanted to make the infill start from left side and go to right to make sure this is not an issue with bed leveling.

-

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

@fcwilt Adhesion is not a problem, and the first layer speed is slow 20mm/s.

Monotonic is just rectilinear if there are no other patterns in the first layer.I used Hilbert Curve for the first time because I wanted to make the infill start from left side and go to right to make sure this is not an issue with bed leveling.

When you tried mesh compensation did you create the height map with the bed hot? That can make a big difference.

When I start a print I pre-heat the bed for 15 mins.

Frederick

-

@fcwilt Yup. I ran about 25 test with all the tweaks I mentioned, and most of the time I kept the bed hot when just changing config.g, etc.

For any hardware change I let the bed heat for a while, not 15 min, but around 5.

-

I posted your files using the </> tag.

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Mon Feb 17 2020 22:28:24 GMT-0500 (Eastern Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"SKGo" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ;Set PanelDue 7i M575 P1 B57600 S1 ; Drives M584 X0 Y1 Z2:4 E3 ; set drive mapping (dual Z on driver 2 and 4) ;M584 X0 Y1 Z2 E3 ; set drive mapping M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes backwards ;Z Leadscrew locations M671 X-10:310 Y150:150 S5 ;left, Right S5 is the max correction - measure your own offsets, to the bolt for the yoke of each leadscrew M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation ;motor currents M906 X1100 Y1100 Z1100 E800 I60 ; LDO LDO-42STH40-1684MAC ZZZ Motor Currents (mA). 2.375A is peak of 1.68A RMS, 1.9A is 80% of 2.375A ; set motor currents (mA) and motor idle factor in ; ; Accelerations M201 X4000 Y4000 ; Accelerations (mm/s^2) M201 Z1000 ; LDO ZZZ Acceleration M201 E1500.00 ; Extruder acceleration (mm/s^2) ; M203 X24000.00 Y24000.00 Z900.00 E3600.00 ; set maximum speeds (mm/min) M566 X1000.00 Y1000.00 Z300 E1500.00 ; set maximum instantaneous speed changes (mm/min) ;M92 X200.00 Y200.00 Z1600.00 E830 ; set steps per mm M92 X200.00 Y200.00 Z800.00 E415 ; set steps per mm M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X305 Y302 Z340 S0 ; set axis maxima ; Endstops M574 X1 Y1 S3 ; set X endstops to use motor stall M574 Z1 S2 ; set z-Probe ; Z-Probe PINDA M574 Z1 S2 ; Set endstops controlled by probe M558 P5 C"^zprobe.in" I1 H0.7 F800 T6000 A20 S0.03 ; PINDA ;M308 S2 P"e1_temp" A"PINDA" Y"thermistor" T100000 B3950 ;thermistor on the PINDA G31 P500 X0 Y-27 Z2.23 ;yellow sheet ; set Z probe trigger value, offset of 0 in X and -27 in Y and trigger height M557 X5:290 Y5:270 S20 ; define mesh grid ; Z-Probe BLTouch ;M574 Z1 S2 ; Set endstops controlled by probe ;M558 P9 C"^zprobe.in" H4 F150 T8000 ;M950 S0 C"exp.heater3" ;G31 P25 X23 Y0 Z3.485 ; set Z probe trigger value, offset of -22 in X and 0 in Y and trigger height (Slice 0.4) ;G31 P25 X23 Y0 Z3.196 ; set Z probe trigger value, offset of -22 in X and 0 in Y and trigger height (E3D 0.8) ;M557 X10:295 Y10:295 S20 ; define mesh grid ;Filament sensor M591 D0 P5 C"e0stop" R100:350 E10.0 S1 ; Duet3D laser sensor for extruder drive 0, connected to endstop input 3 (E0), tolerance 100 to 350%, 10mm comparison length, Enabled ; Bed Heater M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 A191.5 C435.9 D4.3 V24.3 B0 ; disable bang-bang mode for bed heater and set PID autotune PWM values ; Extruder Heater ;M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as Hemera thermistor on pin e0temp M308 S1 P"e0temp" Y"thermistor" T500000 B4723 C1.196220e-7 M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S440 ; set temperature limit for heater 1 to 390C ; Fans M950 F0 C"fan0" ;Q200 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ; M950 F1 C"fan2" Q15000 ; create fan 1 on pin fan1 and set its frequency M106 P1 S0.7 H1 ;L200 X250 H1 T60:140 ; set fan 1 value. Thermostatic control is turned on. Min speed of 120 as 60 deg, and max speed for 200 (255 is 100%) at 140+degrees ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M501 ; Load config-override.g ; Miscellaneous T0 ; select first toolM561 ; clear any existing bed transform G28 ; home M558 H1 G30 P0 X15 Y150 Z-99999 ; probe near a leadscrew, half way along Y axis G30 P1 X285 Y150 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors ;do it again G30 P0 X15 Y150 Z-99999 ; probe near a leadscrew, half way along Y axis G30 P1 X285 Y150 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors ;finally home Z again at the center of the bed G1 X150 Y177 F6000 G30 ;single z probe -

When you create or load the height map are you first setting the Z=0 datum using G30?

Frederick

-

@fcwilt Yes, in bed.g, at the end, there is a G30 at the center on the bed. The mesh leveling happens after bed.g is run.

-

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

@fcwilt Yes, in bed.g, at the end, there is a G30 at the center on the bed. The mesh leveling happens after bed.g is run.

Have you tried upping the extrusion multiplier using M221 or the DWC slider control?

Frederick

-

Calibrate your extruder and tune your extrusion multiplier.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

I wouldn't use hilbert curve as an indicator of first layer quality. It's not really a suitable pattern for first layer with all the direction changes. The extrusion could become so slow that the filament starts to cook in the hotend.

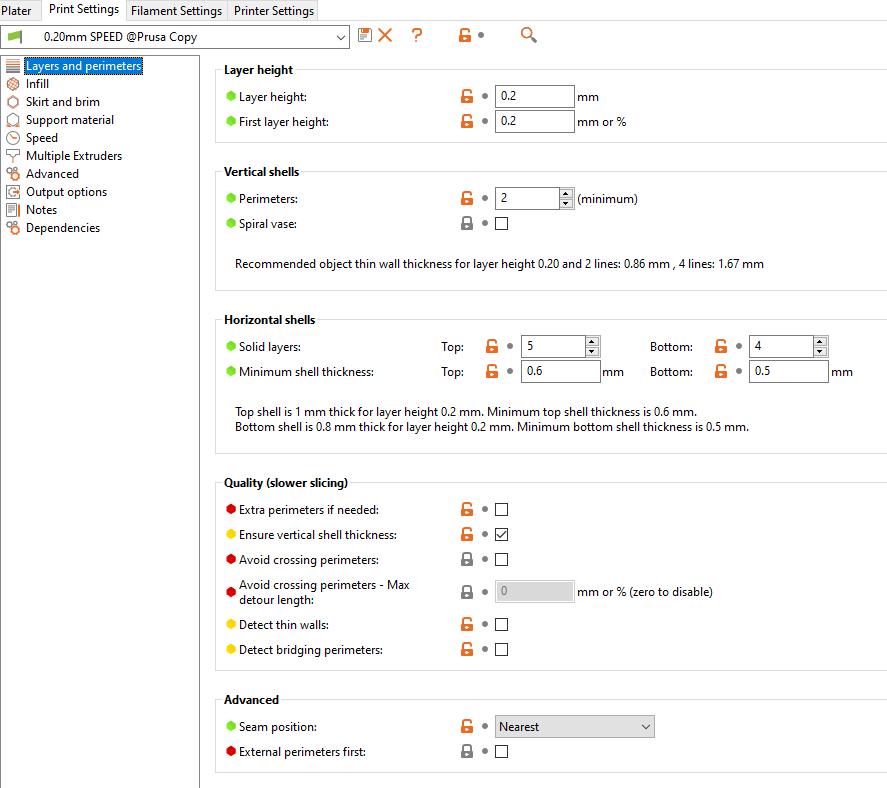

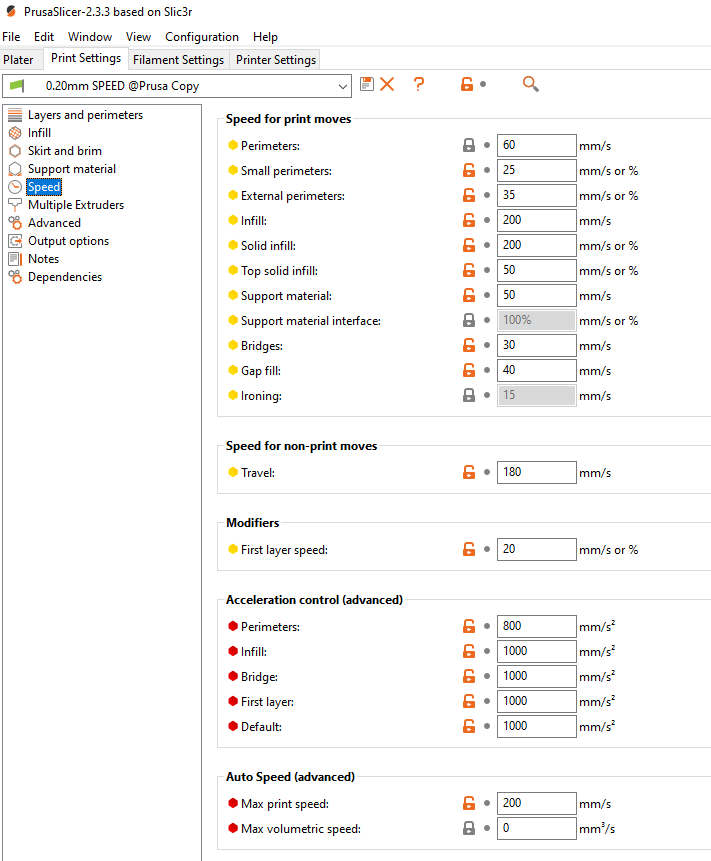

Show us your slicer settings. Upload a sliced gcode file.

-

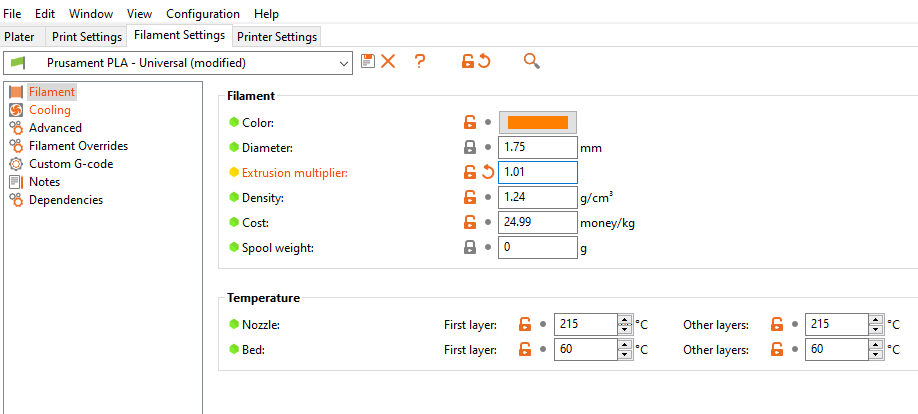

@phaedrux Calibrated the Esteps and extrusion multiplier. ESteps did not change, the extrusion multiplier changed by 0.01, so went from 1 -> 1.01.

Still the issue persists.

Running a few more tests it looks like an issue with Z distance between bed and nozzle increasing as the first layer progresses.

On a 150x150mm square print with reclinear infill the layer stops sticking halfway through the layer, I then reduced the distance using baby step, and kept doing that as the print stops sticking again. At the end of the layer I had to move the nozzle closer by 0.2mm (-0.2)!!!. That is a lot.

I tried heating bed for 15 min before starting print/probing to see if thermal expansion is somehow involved. But that did not help and the print still did not stick halfway through.

Next heated the bed for a while and then ran mesh bed leveling. Then moved the head to various points on the bed with a piece of paper under it to see if the nozzle is close to the bed. And the paper is being gripped by the nozzle correctly. If I raise the bed by 0.2mm the paper does not grip. So the moving the bed using the bed using the Dashboard is maintaining the nozzle distance correctly.

Attaching the gcode of the file I used, and slicer settings.

150x150_center_0.2mm_PLA__50m.gcodeAlso adding the height map, it is pretty level in the middle of the bed.

-

Instead of a large flat full infill print try something like this STL instead.

-

@rkaronde

Do you see skipped steps for the Z-axis?

That's the only explanation, why it keeps gripping the paper when moved manually, but building up a gap when it does mesh levelling -

Printed without an issue.

The lines are pretty well stuck to the bed, and I could see the Z motors move when printing near the bump in the front part of the bed. -

@o_lampe I have not heard any skipping, not sure if there is any way to measure the skipping.

Also in the middle of the bed the Z motors don't actually have to move since the bed is pretty flat. I also marked the Z motor pulley with a Sharpie and it does not move from the initial position printing infill in the center of the bed.

This is a CoreXY with bed moving up/down, so if Z is stable then I would think the X gantry is somehow moving up (not sure how that can happen). I also did the bedlevel_nozzel print suggested by Phaedrux and that stuck well all through.

The reason I am trying large flat full infill print as test is because I ran into this issue when printing large footprint models/STLs and got into debugging.

I am going to recheck for any mechanical issues.

-

@rkaronde silly question time... you don't have any PLA parts supporting your hot bed that are warping under heat/load during the print are you? When I first started printing ABS on my printer I spent days trying to figure out why my z offset ket changing before realised my bed supports had basically melted...

-

@engikeneer Fair question.

Except for the cooling duct and PINDA holder this printer does not use any plastic parts, it is all metal.

https://seckit3dp.design/kit/sk-go2-essential

-

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

The reason I am trying large flat full infill print as test is because I ran into this issue when printing large footprint models/STLs and got into debugging.

This may be more of an extrusion or cooling issue then.

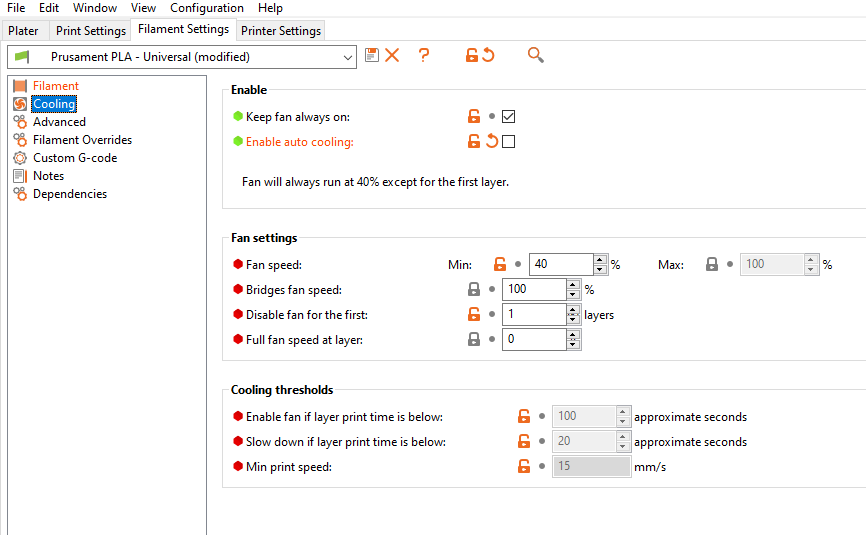

Can you confirm the fan is off for the first layer?

Have you tried upping the first layer hotend and bed temp a bit? Maybe 65c bed, 225c nozzle?

What is your first layer extrusion width?

-

@phaedrux Yes the cooling fan is OFF for the first layer

The first layer extrusion width is 0.42mm (nozzle is 0.4mm), should I try a different extrusion width?

I will try upping the temps.

Thanks

-

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

@phaedrux Yes the cooling fan is OFF for the first layer

The first layer extrusion width is 0.42mm (nozzle is 0.4mm), should I try a different extrusion width?

I will try upping the temps.

Thanks

What is your first layer speed

What is the first layer height as opposed to the normal layer height?

Thanks.

Frederick