Vertical lines vs. geared extruders

-

@mrehorstdmd Looks a bit like STL segmentation to me.

-

On my printer, I see faint vertical lines on the sides of a printed test cube, but only in the Y direction, not the X, so suspect printer frame deflection/ringing in the Y axis.

Are you guys seeing the patterns being discussed irrespective of print direction? If it really is an extruder issue, print direction would not matter. If it does, then frame stiffness may be contributing.

-

@bot I replaced the belt even though it was only very slightly frayed.

The vertical artifact didn't go away, but may have faded some. But the flatness of my walls improved pretty significantly. So I think you're right that belts need to be replaced more frequently than it seems. It really made a difference. Just not the one I was looking for. But it's still good.

-

@donstauffer I think I need to try the same thing! Thanks for the feedback.

-

@phaedrux Im unfortunately having that issue on straight walls. so I can confirm its not STL deresolution. honestly pulling my hair out trying to find out why I get vertical lines so blatant on straight walls.

-

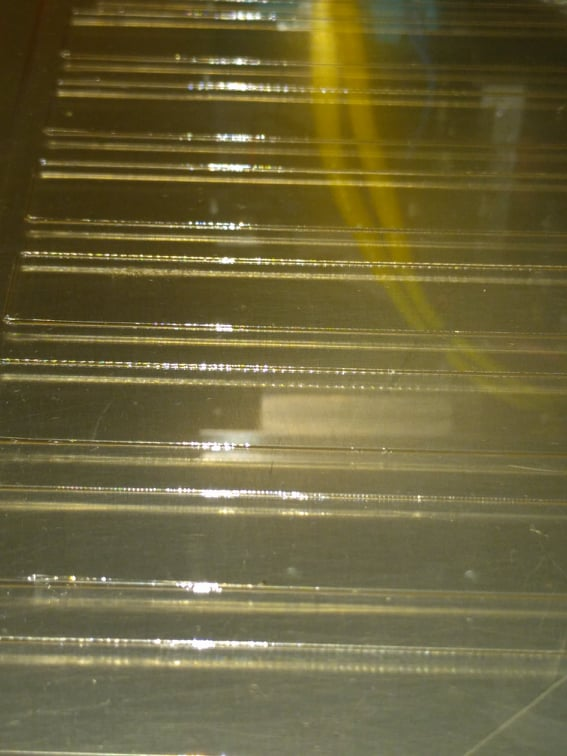

This is a first layer, in Hatchbox transparent PETG, printed at 12 mm/sec, showing the vertical artifact. I have now replaced all hot end parts and all movement parts, with the only exception being the linear rails, which are smooth as silk. I have not been able to solve this problem, at all, but I have concluded it is not likely to be a mechanical problem.

-

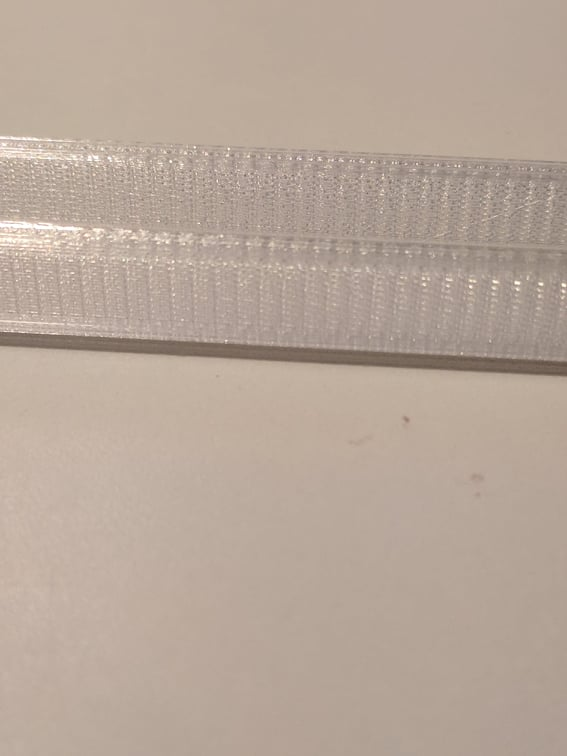

Another remarkable example in transparent PETG, printed at about 45 mm/sec:

-

-

@donstauffer

those lines are pretty impressive.

I can't see what the printdirection was, but I guess it was "left-right"? Otherwise it indicates your nozzle isn't exactly true to the bed and more filament is squished to one side then the other..The cross section would look like a seesaw -

@donstauffer

some math wizard should be able to calculate what part of the equation is synchron with that line distance.

We'd need to calculate the amount of extrusion ( layer height, layerwidth, nozzle) and correlate it with the extruder drive train.

Is it a wobbling drive gear or a current control issue of the stepper driver or what? -

@donstauffer I think you have missed out on a large part of this thread. See from here: https://forum.duet3d.com/post/240216

Watch these two videos, particularly the second one:

https://www.youtube.com/watch?v=dL6u0UwPJOQ

https://www.youtube.com/watch?v=32dTLRNIYmwPrint this object and see if you get the 'woodgrain' effect: https://mihaidesigns.com/pages/inconsistent-extrusion-test

If you get the woodgrain effect, then you'll know if the issue is the extruder. If the lines line up, it's something in your X and Y movement.

If you do get a woodgrain effect, he explains calculating the extrusion distance between artefacts in the second video from about 1:50, which can help pinpoint what's causing the issue. It looks like you have 13 artefacts in 20mm, which is quite a lot shorter than the extruder gear cogging issue, but depends on extrusion width. It may be the extruder motor full step distance, or the extruder gear teeth distance. Maybe post the response to M115 and config.g, too.

Ian

-

@o_lampe I don't really understand. It's symmetrical, so it doesn't matter what the print direction was.

-

@droftarts No, I didn't miss any of this thread, believe me! And I did watch the videos already. He shows the problem is common, but not how to solve it. Also, my problem isn't wood grain. It's nice neat vertical lines.

My conclusion is it can't be extrusion related unless it's firmware or electronics, because the transform from print line to extrusion would be so small. There's nothing that small in the extruder path, not even the ridges in the feed roller of the BMG. So, it's either firmware or electronics (the only way the extrusion could "jiggle" so frequently), or movement.

From what I've found out since, others have had this problem with the Railcore and concluded it was from long belts inherent in the CoreXY architecture. But nobody has any speculation why some people find it hard to detect and others, like me, have it BOLD. It does seem to be the case that certain filaments show it better, with transparent being the most.

Another conclusion some have drawn is that this is NOT a result of resonance, though resonance may make it worse. Rather, they believe it to be a meshing issue between the teeth of the belt and the pulley. But I can't figure out what exactly that would be, or how to fix it. Possibly the 16-tooth stepper pulleys are too small in diameter, but that doesn't seem too likely.

-

@donstauffer said in Vertical lines vs. geared extruders:

Another conclusion some have drawn is that this is NOT a result of resonance, though resonance may make it worse. Rather, they believe it to be a meshing issue between the teeth of the belt and the pulley. But I can't figure out what exactly that would be, or how to fix it. Possibly the 16-tooth stepper pulleys are too small in diameter, but that doesn't seem too likely.

This would be my guess. Possible solutions are to use flat flanged bearings for idlers instead of toothed idlers and flip the belts such that the smooth side rides on the bearing face. This is what I do on my Dbot as I had some pronounced ridges like that originally.

-

I had strong vertical lines like that with overtensioned belts.

(Speaking of belts, I am currently experimenting with a friction extruder, which is helping with the secondary woodgrain pattern that are the result of the hob teeth on hobbed extruders (both dual and single geared in this case. Copy mode comparison with a BMG from my IDEX imminent).

-

@donstauffer

I always ruled out resonance, because it would fade out after a few lines. Alas if the source of ringing would be permanent, it would constantly keep it going. Overstretched belts could be it. On a CoreXY it would show different results at different path-angles.

If it's the extruder gears, a change in layerheight would make a difference. -

@donstauffer Thanks for the reply, it's good to know it's not extrusion related (or at least, that's not obvious!). I did think the 13 artefacts in 20mm made it unlikely to be the extruder effect seen in the videos.

Next question: do you have these artefacts in X and Y directions? On a CoreXY, movements in X move all 8 (or minimum of 8 ) idlers and both motors. Movements in Y move 4 idlers and both motors. Movements diagonally move 6 idlers (4 on the X axis and 2 connected to the moving motor), and that one motor. So if you print an octagonal object, and you only get the artefacts on some faces, you should be able to narrow the problem to specific idlers and/or one motor/pulley.

If you still get artefacts on all faces, I'd look again at your belts, pulleys and toothed idlers, as @Phaedrux suggested. Assuming your pictures show a print in the X or Y direction, and assuming you're using belts with a 2mm tooth pitch, and that your printer is a CoreXY, the 13 artefacts per 20mm means that the belts are actually moving 28mm, so artefacts are about every 1mm.

One explanation could be that your belts are mismatched; there are two Gates belts specification, with Gates USA producing the GT2 and GT3 profiles, while Gates Unitta Asia produce 2GT. I've heard that they are not compatible if you mix them, so make sure you're using pulleys with the same tooth profile as belt tooth profile. The artefacts every 1mm could be the effect of the belt tooth pushing in and then popping out of the pulley, or camming around the pulley (which would also be at half the tooth pitch).

If you could more accurately measure the distance between vertical artefacts than I can from your image (or count how many there are per 10mm), and post your config.g (to show steps per mm etc) that might help narrow down where the problem is.

Ian

-

There's a screw drive extruder here that looks interesting- a bit large and complex, but might be smoother:

https://www.youtube.com/watch?v=OVhw3XlrDuY -

@oliof My belts are most definitely not overtensioned. When I loosened them to do the Air Print tensioning, they didn't bounce at all so I stopped and just left them there. I used to have them at about 50Hz, but now they're much looser.

-

@droftarts All faces, although less at some angles, and at many angles they become a sort of "interference pattern".

I have replaced all belts and pulleys and idlers with new brand name ones. It makes the artifact look really pristine! But didn't reduce it at all.