Vertical lines vs. geared extruders

-

@ajdtreyd said in Vertical lines vs. geared extruders:

If you want to determine if it's the extruder then do several test prints changing ONLY the extrusion width. This way the motion system does exactly the same thing every time, but the extruder is moving filament faster as the EW increases. If it's the extruder, the period of your sine wave will decrease (or if you prefer, the frequency will increase) as the extrusion rate increases. If the sine wave stays the same the issue is somewhere in the motion system.

I had the vertical line artifact on my delta in the past and resolved it by replacing the smooth bearing idlers and belt with genuine Gates belt and toothed idlers.

Of course once those artifacts were gone I was able to see the next set of subtler artifacts. And on it goes ...You would have to make large changes in flow to have observable changes in drive gear speed.

-

Stumbled recently upon this video that claim that the meshing of the two gears of dual gear drives creates extrusion artifacts.

-

He did say he was observing that sine wave pattern in "microscopic pictures". I assume he meant he had taken the pics through a microscope and not that the pics themselves were microscopic. Anyway, I assume he has the means to distinguish those small changes (a microscope) and the simple, quick test would be worth doing if only to eliminate the extruder.

-

@ajdtreyd said in Vertical lines vs. geared extruders:

He did say he was observing that sine wave pattern in "microscopic pictures". I assume he meant he had taken the pics through a microscope and not that the pics themselves were microscopic. Anyway, I assume he has the means to distinguish those small changes (a microscope) and the simple, quick test would be worth doing if only to eliminate the extruder.

Fair point.... and especially if it was a single wall print, you could definitely run a pretty large flow modifier without consequence.

-

@zapta read up a few posts we've been discussing that.

I've confirmed a very faint wood grain pattern on my printer with bondtech gears and non-bowden extruder.

-

rq3 at has a couple threads on an extruder he built that is very light and propels the filament by rolling threads into it. See:

https://reprap.org/forum/read.php?424,883786

and

https://reprap.org/forum/read.php?424,885022,885049 -

i have yet to see any "perfect" extruder drive , all current extruders have drawbacks .

i think the current best would be to use large (like lgx) hobbed gear without the dual drive .this extruder looked interesting

https://www.youtube.com/watch?v=OVhw3XlrDuYbut mechanical tolerances on it need to be perfect .

i have stratasys fortus machine at work and it is also generating extrusion artifacts .

-

@hackinistrator at 49 seconds into the video there's a close-up of the print that seems to have the same vertical lines we've been talking about here (or maybe they are defined by the segment length in the STL file?).

-

@mrehorstdmd Looks a bit like STL segmentation to me.

-

On my printer, I see faint vertical lines on the sides of a printed test cube, but only in the Y direction, not the X, so suspect printer frame deflection/ringing in the Y axis.

Are you guys seeing the patterns being discussed irrespective of print direction? If it really is an extruder issue, print direction would not matter. If it does, then frame stiffness may be contributing.

-

@bot I replaced the belt even though it was only very slightly frayed.

The vertical artifact didn't go away, but may have faded some. But the flatness of my walls improved pretty significantly. So I think you're right that belts need to be replaced more frequently than it seems. It really made a difference. Just not the one I was looking for. But it's still good.

-

@donstauffer I think I need to try the same thing! Thanks for the feedback.

-

@phaedrux Im unfortunately having that issue on straight walls. so I can confirm its not STL deresolution. honestly pulling my hair out trying to find out why I get vertical lines so blatant on straight walls.

-

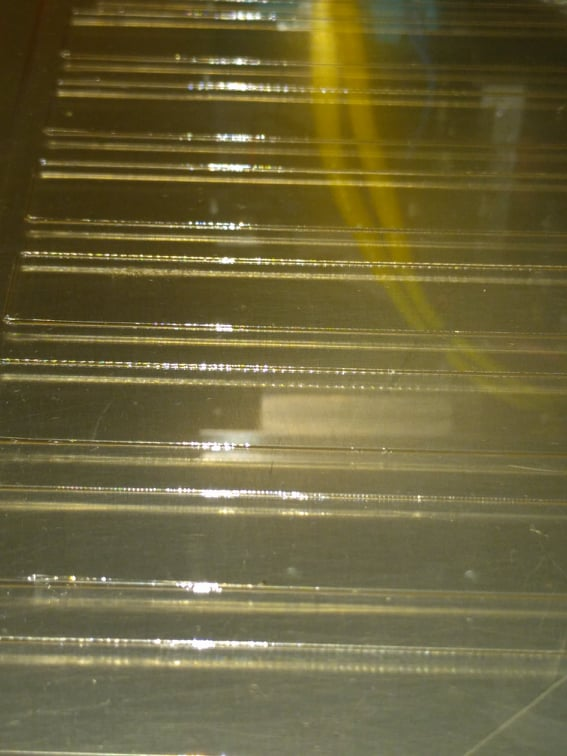

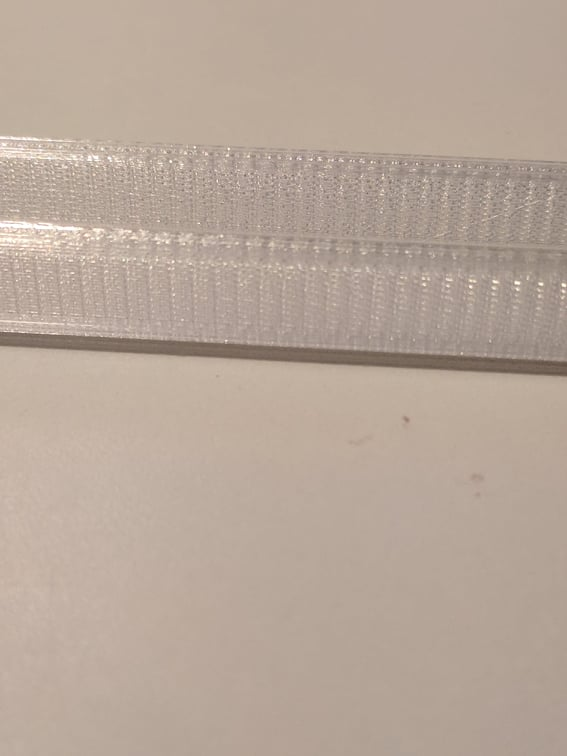

This is a first layer, in Hatchbox transparent PETG, printed at 12 mm/sec, showing the vertical artifact. I have now replaced all hot end parts and all movement parts, with the only exception being the linear rails, which are smooth as silk. I have not been able to solve this problem, at all, but I have concluded it is not likely to be a mechanical problem.

-

Another remarkable example in transparent PETG, printed at about 45 mm/sec:

-

-

@donstauffer

those lines are pretty impressive.

I can't see what the printdirection was, but I guess it was "left-right"? Otherwise it indicates your nozzle isn't exactly true to the bed and more filament is squished to one side then the other..The cross section would look like a seesaw -

@donstauffer

some math wizard should be able to calculate what part of the equation is synchron with that line distance.

We'd need to calculate the amount of extrusion ( layer height, layerwidth, nozzle) and correlate it with the extruder drive train.

Is it a wobbling drive gear or a current control issue of the stepper driver or what? -

@donstauffer I think you have missed out on a large part of this thread. See from here: https://forum.duet3d.com/post/240216

Watch these two videos, particularly the second one:

https://www.youtube.com/watch?v=dL6u0UwPJOQ

https://www.youtube.com/watch?v=32dTLRNIYmwPrint this object and see if you get the 'woodgrain' effect: https://mihaidesigns.com/pages/inconsistent-extrusion-test

If you get the woodgrain effect, then you'll know if the issue is the extruder. If the lines line up, it's something in your X and Y movement.

If you do get a woodgrain effect, he explains calculating the extrusion distance between artefacts in the second video from about 1:50, which can help pinpoint what's causing the issue. It looks like you have 13 artefacts in 20mm, which is quite a lot shorter than the extruder gear cogging issue, but depends on extrusion width. It may be the extruder motor full step distance, or the extruder gear teeth distance. Maybe post the response to M115 and config.g, too.

Ian

-

@o_lampe I don't really understand. It's symmetrical, so it doesn't matter what the print direction was.