Anybody wants a stepper motor analyzer?

-

@th0mpy said in Anybody wants a stepper motor analyzer?:

@zapta It seems that either 3.3v or 5v work just fine. The limits are just a little different.

Good to know. Thanks. Yes, 3.3 will cause saturation for +/-5.75A @400mv/A but we don't need that full range, and it is specified for 3.3V for the other ranges.

-

So that the prototype housing of the AWD Stepper Motor Analyzer fits quite well, just adjust a few small things.

-

@dogma2k said in Anybody wants a stepper motor analyzer?:

AWD Stepper Motor Analyze

Wow! That's a nice design.

-

Hey everyone, I have a new batch of sensors being delivered early next week. If you're interested hit me up via chat.

-

The final case is finally ready. I also installed a FlowMeter. Everything fits in and the lid even closes.

If you like, you can download the STEP file

-

@dogma2k , looks very impressive. If you can, please post here a picture with all screen on, it will be even more cool.

-

@zapta

Unfortunately only provisionally because I don't have my 5V transformer an Arduino Uno yet

-

@zapta

Can the analyzer be switched on and off during operation? Because you can / should only disconnect the motors without electrical voltage. Or does it matter here because the input and output always have continuity and the measurements are only picked up in parallel? -

@dogma2k, the electronics and the stepper circuit are isolated from each other so it's safe to turn 5V power on/off even when the printer is working. It will not damage the electronic and the print will continue with no interruption.

-

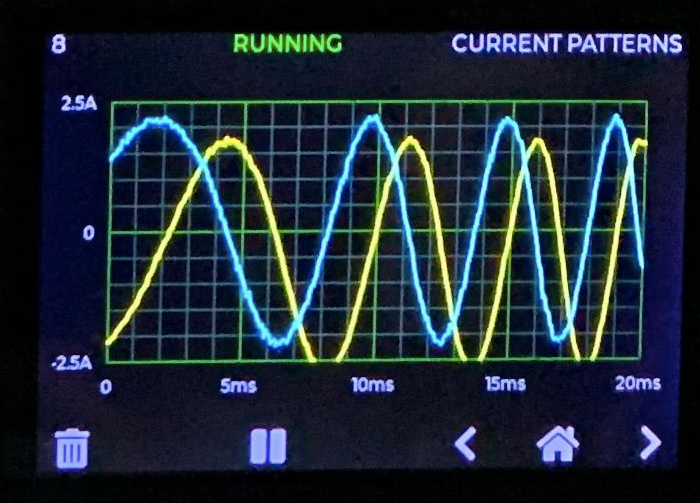

The analyzer is finally running after I had to remove the display again because the soldering points of the connector had pushed through the metal frame of the display and always caused a short circuit

Thanks for the nice toy

-

@dogma2k said in Anybody wants a stepper motor analyzer?:

the soldering points of the connector had pushed through the metal frame of the display and always caused a short circuit

Wow! Looks awesome. I am glad that this didn't cause a permanent damage. I maintain the insulation by

-

Using an insulated 10mm width double tape on the back of the PCB, at the marked areas. E.g. https://www.amazon.com/Adhesive-10mmx25mx0-25mm-Thermally-Conductive-Computer/dp/B075FRPXQ5 . I also apply it between the PCB and the PICO, just in case.

-

Pre cutting the servo connectors pins such that they don't protrude at the back of the connector. This is the trimming jig I use https://github.com/zapta/simple_stepper_motor_analyzer/blob/main/3d/connector_trim_jig.stl

BTW, it should be ok to connect multiple analyzers to the same servo since the sensors serial resistance is very low.

-

-

@dogma2k, the current readings seem have have offset. You may want to reset it in the Settings screen with the motor disconnected (that is, zero current).

-

@zapta said in Anybody wants a stepper motor analyzer?:

- Using an insulated 10mm width double tape on the back of the PCB, at the marked areas. E.g. https://www.amazon.com/Adhesive-10mmx25mx0-25mm-Thermally-Conductive-Computer/dp/B075FRPXQ5 . I also apply it between the PCB and the PICO, just in case.

I had double-sided tape in between. Wasn't enough

https://www.amazon.de/gp/product/B08YJK6L1T/ref=ppx_yo_dt_b_asin_title_o07_s00?ie=UTF8&psc=1

It didn't matter, it went well, it was just fun to find the fault ...- Pre cutting the servo connectors pins such that they don't protrude at the back of the connector. This is the trimming jig I use https://github.com/zapta/simple_stepper_motor_analyzer/blob/main/3d/connector_trim_jig.stl

That would probably have been the best had I done that

BTW, it should be ok to connect multiple analyzers to the same servo since the sensors serial resistance is very low.

Even more? I already need 4 pieces because I have 2x X steppers and 2x Y steppers.

The small OLED is also not yet in operation for the filament flow meter, because I haven't had time to get the Arduino UNO readyI still have a problem that as soon as the motors are working, the display does not react at all or almost not at all.

If the motors are switched off with M84 then you can use the display properly.

How come that -

@dogma2k said in Anybody wants a stepper motor analyzer?:

I still have a problem that as soon as the motors are working, the display does not react at all or almost not at all

Can you explain what what you mean? Chan you change pages? Do you see any reading on the main page?

Per my previous post, it seems that your sensors need zero calibration. This is done in the Settings page (accessible from the main page) with the motor disconnected.

-

@zapta said in Anybody wants a stepper motor analyzer?:

@dogma2k said in Anybody wants a stepper motor analyzer?:

I still have a problem that as soon as the motors are working, the display does not react at all or almost not at all

Can you explain what what you mean? Chan you change pages?

Would you have to recognize property in the two videos what I mean (if not, I'll make better ones)

If no stepper has been used, I can switch through the menus, as soon as the stepper has moved once, the displays can no longer be operated.I'll do the zeroing with disconnected stepper afterwards when I'm back.

-

@dogma2k I had this issue on my first analyzer I boiled it down to a couple things.

As @zapta mentions, if you don't cut the pins there may just enough bite into the back of the LCD which shorts things out. I pulled the connectors out, recut, and used some 3M VHB to secure the LCDs.

Finally, double check the castellated pins on the PICO and make sure they're solid. If you used a thicker adhesive behind the PICO it might prevent good connections.

-

@th0mpy said in Anybody wants a stepper motor analyzer?:

@dogma2k I had this issue on my first analyzer I boiled it down to a couple things.

How can you reduce the choice, I really don't have a clue about it yet.

I took the APPLICATION.uf2 file from the temp directory on github, was it wrong?Finally, double check the castellated pins on the PICO and make sure they're solid. If you used a thicker adhesive behind the PICO it might prevent good connections.

Now the analyzers just don't run properly when the steppers are moving.

So it is more as if the Pico does not have enough power to process the incoming data quickly enough -

@dogma2k ,

-

Do you have the same problem on all four analyzer or just a few?

-

If you power the analyzers from a power supply on your printer, I suggest, as an experiment, to power one of them from a regular USB 5V charger and see if the problem persists.

-

-

Hey

Is it possible to indicate layer shifts with this analyser?

Richard -

@gruna-studio, that a good question. I guess it depends on the cause. E.g.

Intermittent wiring connection - It detects idling and electrical stepping error events so will probably detect.

Low current/torque due to an high speed - it will probably diagnose it in the current vs speed histogram page.

Mechanical binding - I am not sure about that. May need to research how that condition is reflected on the electrical signals. Also, the analyzer measures only current, monitoring also the stepper voltage may help here.