Help me I think my endstops stopped

-

@adalton5683 that looks fine, nothing I can see as being wrong.

So are you saying that testing with M119 that they don't change from not stopped to stopped when triggered?

You may want to install the endstops plugin to make it easier to test them https://github.com/Duet3D/DSF-Plugins/releases -

@jay_s_uk

yeah they show not stopped set to S0 and they show no-endstop when set to S1 -

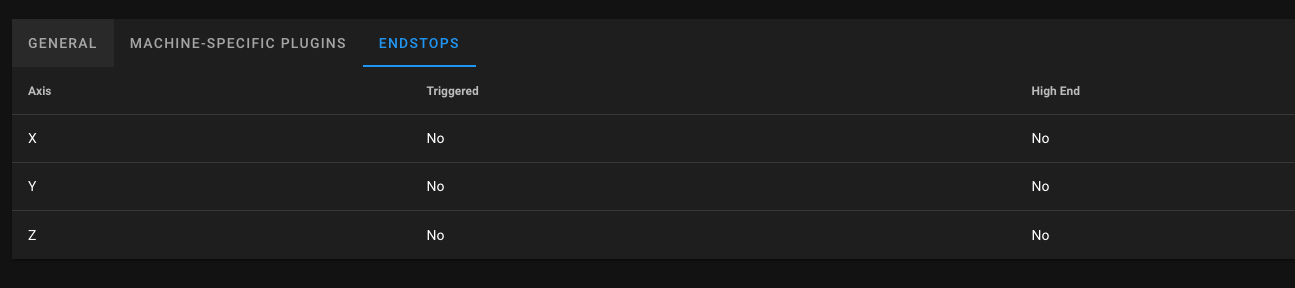

@adalton5683 Installed the plugin

when I hit the X or Y endstop the plugin shows no change. Both columns say no for all axes.

-

@adalton5683![ ]

)

) -

@adalton5683 @adalton5683 and it stays like that when either are activated.

-

@adalton5683 I would go through and check your wiring. If you have a multimeter, check that the endstop resistance changes when triggered. There's very little you can do to break the endstop inputs of the board

-

Does the board you are using have LEDs on the endstop inputs like the Duet2?

If so, make sure they switch from lit to unlit when you click the endswitches.

-

@alankilian said in Help me I think my endstops stopped:

If so, make sure they switch from lit to unlit when you click the endswitches.

they won't always go lit to unlit if normally open (will go unlit to lit when pressed)

-

Yeah, I just meant sometimes they are lit and sometimes they are unlit.

Sorry, I should have said "toggle" instead of "click"

It's hard to get it right.Also, @adalton5683 HERE is a page where someone did something similar.

It's a long page, and the endstops are at the end. -

@alankilian

Yeah I had already looked at this page when I had trouble setting up my bl touch but I found that issue.The reason I think it is hardware is I have base from the confit tool setup on normal end stops from my ender. So the setup and settings should not mess with it. I

So unless there is somehow a jumper or something that can auto change its spot or something code wise that I could have put in that changes and output bus then I think I have fried my output 5 and 6.

One thing I am thinking is maybe a piece of the stranded wires got in somewhere from making the valve terms. But I can’t find any.I’m an electrical engineer but I’m not super electronics heavy in specialty so I get uncomfortable when it’s needed to probe into a board with metal. I’ve got the grounding and anti static equipment thought and I think that’s what it’s going to come to.

Does anyone know anything about what I should be seeing on those two inputs and how they should behave electrically? When I get off work today I’m going to meter all the pins and see what they do on actuation.

-

Is it possible to swap my end stops to other connectors and then reassign? I did just a basic setup so I have some free pins, just don’t know which will work.

-

First thing is to test your switches.

Can you post images of the wires on the switch and the wires in the connector on the Duet board?

It looks like the Duet Mini 5+ does not have endstop LEDs, so that's no help to you.

If we know what kind of endstop switch you are using and how they are wired into your board that will help.

-

-

OK, are those are regular normally-closed or normally-open switches or are they optical-interruptor type switches?

Do you have a Volt/Ohm meter you can use to test them?

-

@alankilian theyre the basic 1923 switch. The switch is able to be wired to NO or NC so what I have it on rn is the outside rails which is C and NC so im setup normally closed. Do you know what voltage im supposed to be seeing cross the two leads of the switch if its operating right with setting S1?

-

also since its a mechanical switch idk how possible it is to fry it that easy. id say the board is probably more easily broke than a mechanical switch. theres literally just traces and the lil box spring switch.

for giggle and shts im gonna go ahead and order a few new switches. but have them be inductive switches.

-

@adalton5683 IO_1 and IO_0 are also similar and it looks like theyre on a different buss. I think im going to swap out the molexes for 5 pin ones and move them over there. that should tell me if 5 and 6 are blown. from the docs they only can take 30V. I def didnt put more than on them or whatever that goes to them so idk how that happened if so.

ill check back in 15 with if I caught the board on fire yet or not.

-

@adalton5683 So.... I noticed also that my Zhigh endstop isnt working either. idk wth is going on.

I swapped over to IO_0 and IO_1 for the endstops and reconnected and they are still no go. I ran back through the config.json and reassigned them and rebooted.

nada

any help would be amazing. I cant really wrap my head around the idea that 2 seperate busses (or at least I think it is) IO_5/6 and IO_0/1/2 are both toast. Buuu my BL touch on IO_4 is still happily working.

are any of you guys people that know the actual circuit diagram like how th eauxiliares are routed, protected etc. like say it overloaded does that go back to the fuze or just poof?

do I have options to hook up to if I smoked the IO bus? aaaaand well I already bought another board im just really sad about it I really expected more out of the resillency of this board from all the hype on them and I cant even get it to a first print. And im an electrical engineer(who sucks at circuits) but still this shouldnt be this hard. or fail electrically out of nowhere.

-

So ......

I had that Z highend endstop wired up right and was checking it. well I think it may have been wire wrong and it was taking that entire bus to ground. only with the 3.3 v so no harm no foul and thus I swapped the wire and now im working on all endstops.

god I hate circuit analysis. Give me PLCs and controls all day over this. haha I wanna design and pay people to put it together.

BUT... now to the reason I actually started this thread. (no it wasnt the endstops that happened right when I was posting so I edited.

My issue: My bed is all outta wack like orient-wise. Ive went through how to get a mesh bed to work and it always fails or doesnt generate a mesh.

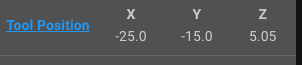

Here is my coordinates when my nozzle is perfectly over the bottom left of my bed and

ignore z height its perfect with however I set up my probe offset.(2.5 I think)

But when I go to the opposite end of the bed MAX(X,Y,Z) I get only to

heres my config.g

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Tue Jan 25 2022 20:05:51 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"bEnder vE3D" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes backwards M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X60.00 Y60.00 Z409.00 E409.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E2500.00 ; set accelerations (mm/s^2) M906 X600 Y600 Z750 E1200 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X235 Y235 Z250 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io0.in M574 Y1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"io3.out" ; create servo pin 0 for BLTouch M558 P9 C"io3.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-55 Y10 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X20:200 Y20:200 S20 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T9880 B4185 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S0.70 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C ; Fans M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency M106 P0 C"PartCool" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 C"HotEnd" S1 H1 T60 ; set fan 1 name and value. Thermostatic control is turned on M950 F2 C"out5" Q500 ; create fan 2 on pin out5 and set its frequency M106 P2 C"CaseFan" S1 H1:0 T60 ; set fan 2 name and value. Thermostatic control is turned on ; Tools M563 P0 S"HotEnd" D0 H1 F0 ; define tool 0 G10 P0 X-25 Y-30 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M574 Z2 S1 P"io2.in" ; configure active-high endstop for high end on Z ;M204 P600 T2000 ; Set accelerations (mm/s^2) for print and travel moves ;M912 P0 S-13 ; CPU temperature calibration ;M572 D0 S0.35 ; Pressure Advance ;M207 S6.5 R0.0 F4800 T4800 Z0.0 ; Retraction ;M280 P0 S160 ; Clear any alarms M402 ; retract pin just in case ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 ; select first tool -

Where is the nozzle when the endstops are actually hit?

If the nozzle is off the bed edge then you can set the axis minimum to a negative value such that 0,0 is right at the corner of the bed.

But I don't understand how you have negative values at the bottom left corner if your endstops are at min and set the axis to 0.