Orbiter 2 extruder mounting for Smart effector with Magball arms

-

Just to add that I have updated the orbiter 2 mount, posted at https://www.thingiverse.com/thing:5402227

I have made small changes including thickening the top mount and extruder mount, and kept the 55 mm magball spacing. I have recently started using a revo micro extruder, so have included a part cooling duct for that.

The revo seems to have a higher melt rate than the v6 I was using previously, so I have been able to print at 250mm/sec, with 300mm/sec travel speed, with very good results. -

@fred-y though about exactly that multiple times. Problem is that it's pointless with 55mm magball spacing as you need some real nasty vertical offset and tilt to jot collide with the arms which then puts a lot of direct force onto the hotend itself.

-

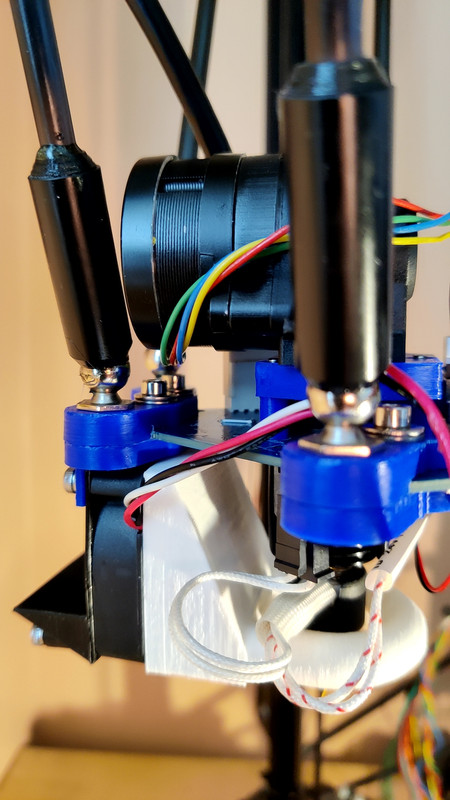

@bberger I find that the 55mm spacing (which I wanted to use to avoid changes to carriages) works well with a 12mm extension - the extruder can be horizontal (filament path vertical). Here is my setup in the furthest -Y position, where the arms are closest to the extruder motor.

The gap between the extruder platform and the top of the hotend is about 1mm:

, giving the shortest possible filament path. I would have thought that as the downward force during extrusion is symetrically distrubuted, the strain on the effector/hotend should not be a problem.

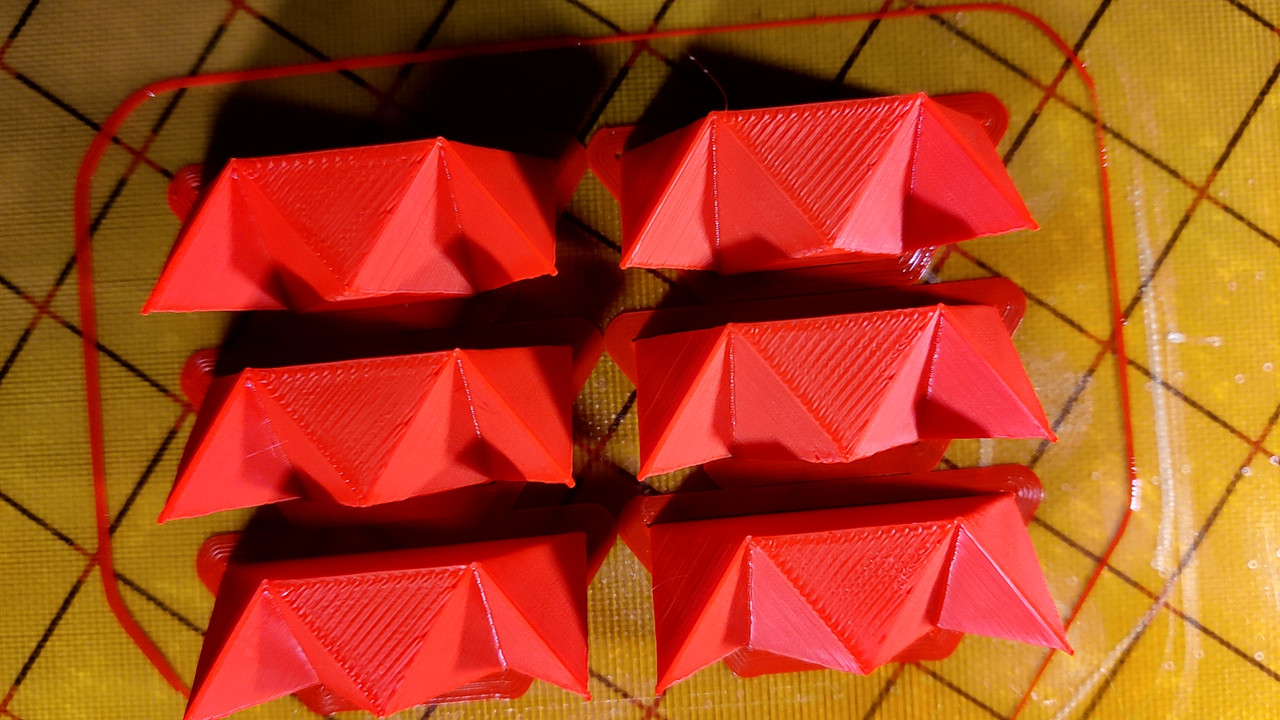

, giving the shortest possible filament path. I would have thought that as the downward force during extrusion is symetrically distrubuted, the strain on the effector/hotend should not be a problem.These puzzle pieces, which are about 40mm long and 14mm high, were printed at 250mm/sec, with 300mm/sec travel.

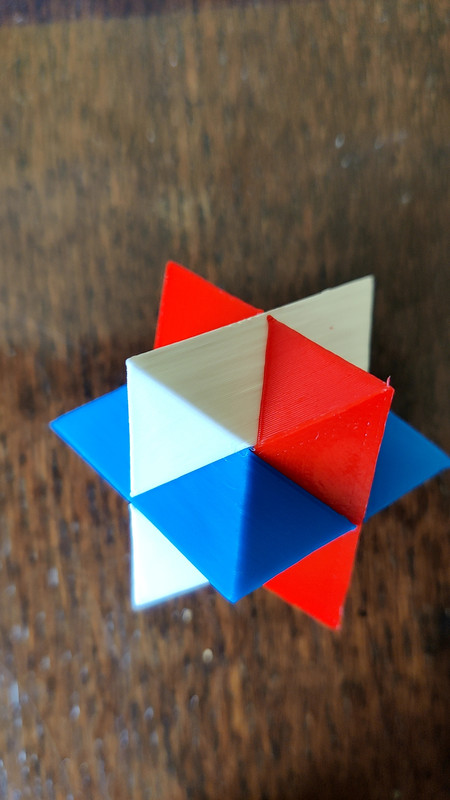

The pieces fit together to make and Escher solid:

We have just had a jubilee here in the UK - hence the red white and blue. The pieces have to be very precise to fit together with no gaps. -

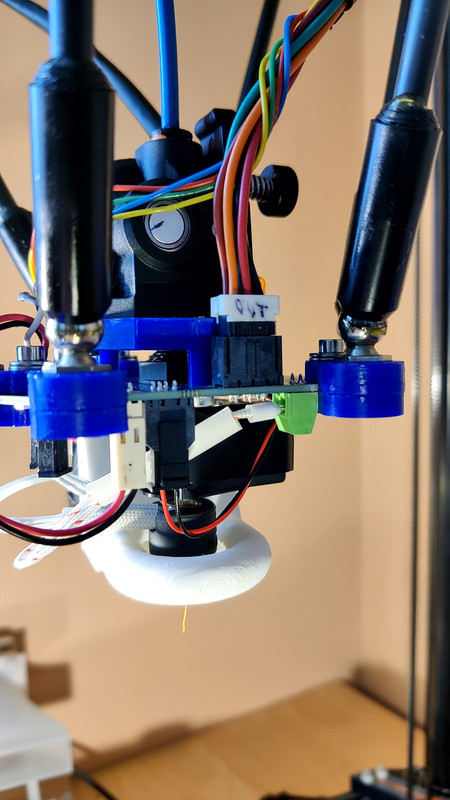

@fred-y Thanks for this idea - it seems to work. I made this:

using the two holes on the motor side of the extruder. This leaves a nice gap on the molex connector side for the plug to fit properly.

This is how it looks in situ:

I am using the default sensitivity on a v3 smart effector, and found that it needed an extra -0.04 on the probe offset. Seems to work well though - a 19 point G32 gave a 0.010 fit.

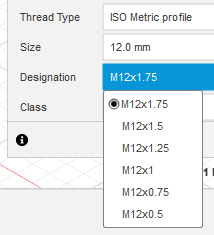

The mount pictured was printed with the new setup - I was fine tuning the thread diameter - 12.3mm was good for me. I havent pushed the new setup yet - seems promising though.

-

@adrian52 That's really nice!

You've done exactly what I was thinking about, I'm happy to know it works.I will definitively spend a little bit of time on Fusion360 this week to try something for the LGX Lite on either my SR or Predator.

What is pitch of the thread on the heatsink?

-

@fred-y Its 1.5mm.

You do need to be able to rotate your hot end - would be difficult with a v6 where the heater block really has to be aligned with the part cooling fan -

@adrian52 said in Orbiter 2 extruder mounting for Smart effector with Magball arms:

@fred-y Its 1.5mm.

You do need to be able to rotate your hot end - would be difficult with a v6 where the heater block really has to be aligned with the part cooling fanIt actually depends. The earlier versions that shipped with the metal nut had a fine pitch..

-

@adrian52 Wow! Looks solid. Is this design available for download somewhere? Or is it an "alpha" version?

-

I have this on my Big Delta.

-

Does any of you have a view as to how much the size of the Smart Effector should be increased to allow the Orbiter 2 to be mounted directly on it?

-

@dc42

Will you want to keep 55mm c/c on balls or go a bit wider there also? -

@tecno said in Orbiter 2 extruder mounting for Smart effector with Magball arms:

@dc42

Will you want to keep 55mm c/c on balls or go a bit wider there also?Go wider.

-

Good, like that approach a lot. You should also have a look at Phaetus 4-screw mounting of the hotend.

-

@dc42 yes, definitely look at supporting mounting a dragon or dragonfly hotend

-

-

This is my take for direct extruder sherpa mini

[url=https://ibb.co/jh3q5yK][img]https://i.ibb.co/zsPC5Xc/20220717-113347.jpg[/img][/url]

[url=https://ibb.co/3Mvh1hX][img]https://i.ibb.co/P9MCxCp/20220717-113353.jpg[/img][/url]

[url=https://ibb.co/HGjsNyM][img]https://i.ibb.co/r5VSbhL/20220717-113358.jpg[/img][/url]

[url=https://usefulwebtool.com/math-keyboard]subscript in math[/url] -

This post is deleted! -

@vapvap I have just added it to the thingiverse thing 5402227

-

@dc42 I find an extra 12mm allows the orbiter 2 to be mounted horizontally with a minimal vertical filament path between extruder and hotend, whilst maintaining the 55mm arm separation. I find the 55mm separation works well - you don't have to modify carriages, and the performance seems fine. I have been printing at 250mm/sec, with travel at 300mm/sec.

-

@adrian52 Thanks a lot.

What plastic do you use/recommend for this part?