Issues with pressure advance since RRF 3.4

-

@argo said in Issues with pressure advance since RRF 3.4:

Because it’s a very good indicator to rate infill quality. At the end PA is a compromise between infill and perimeter quality.

Can you explain how you think PA affects the intersection of infill lines printed at steady-state speed?

-

When I switched to RRF 3.4 (beta) I also installed a Duet 1LC toolboard. So my conclusion was it has something to do with RRF 3.4 as I did not think the toolboard had something to do with it. So I compared an old print (without toolboard) and RRF 3.3 with a print that I made with RRF 3.4 (+ Duet 1LC).

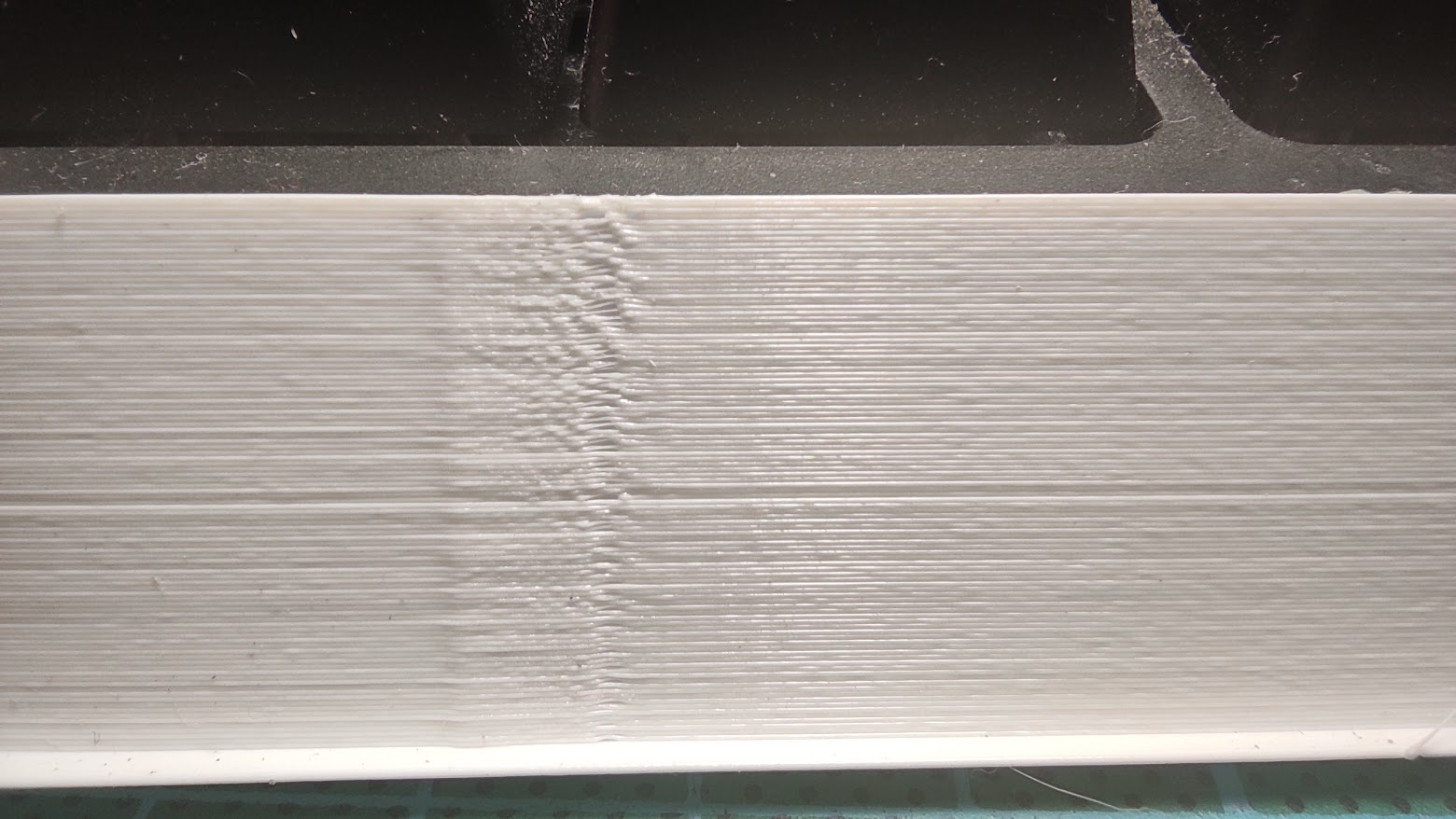

Both printed with RRF 3.3 and RRF 3.4 with the toolboard installed:

Difference is only marginal between both FW versions. My suspicious for now is the CAN toolboard.

@CCS86

Just print a small rectangle object with any filament and double the PA value you usually use. Infill lines won't connect with walls and also not within each other when using "Grid" filament type. Images from test prints are already in this thread from me. -

@argo said in Issues with pressure advance since RRF 3.4:

@CCS86

Just print a small rectangle object with any filament and double the PA value you usually use. Infill lines won't connect with walls and also not within each other when using "Grid" filament type. Images from test prints are already in this thread from me.Connect to the walls sure, because there are direction changes there, where PA is active. But, grid intersections some number of millimeters from a wall should not be affected.

-

-

I am having several issues with PA too.... The test using the python script have bulges AND under extrusion even on very high values of PA.

Here an example for PLA from 0.5 to 0.9 - The bulge NEVER disappear even when the under extrusion after starts to show.In the past there always a clear transition where the slow segments had the same width and no under extrusion after.

Also I simply cannot find a value of PA + Retract that lead to good results. It starts to to cause excessive retraction and blocking issues much before solving any oozing.

I reviewed all my hardware looking for possible issues and after finding this thread I think it is related.

It is very severe with small details and curved surfaces (like round small posts for retraction tuning) it is so severe that sometimes and entire layer is mission while others spurts excessive material. For straight lines - like a small cube walls - only the bulge is apparent and the under extrusion after the bulge for higher PA.

I had not updated my board for a long time and the issues started after the update to 3.4 - I do not remember what older version I had before.

But the issues are the same: Excess extrusion even with very high PA with under extrusion right after for higher PA. I had not of these issues before.

I will test 3.4.2 now and then roll back to 3.3 and repeat the Python script test to compare.

-

Ok... No differences at all from the same gcode from PA 0.5 to 1.3 with 3.3 and 3.4.2

-

@brunofporto How bout 3.2?

-

@brunofporto Are you using a toolboard, or other can-fd board to control the extruder?

-

@phaedrux I'll try!

-

@gloomyandy Nope. Duet 2 Ethernet v1.02 (the one before the on board fuses).

-

@brunofporto said in Issues with pressure advance since RRF 3.4:

Here an example for PLA from 0.5 to 0.9 - The bulge NEVER disappear even when the under extrusion after starts to show.

I'm looking forward to seeing your comparative results for RRF 3.3 and 3.4.2.

How long is the Bowden tube between the extruder drive and the hot end?

-

Small update for RRF 3.4.2. (stable) release.

PA was set to 0.052, printing PLA.

LDO Orbiter 2 extruder

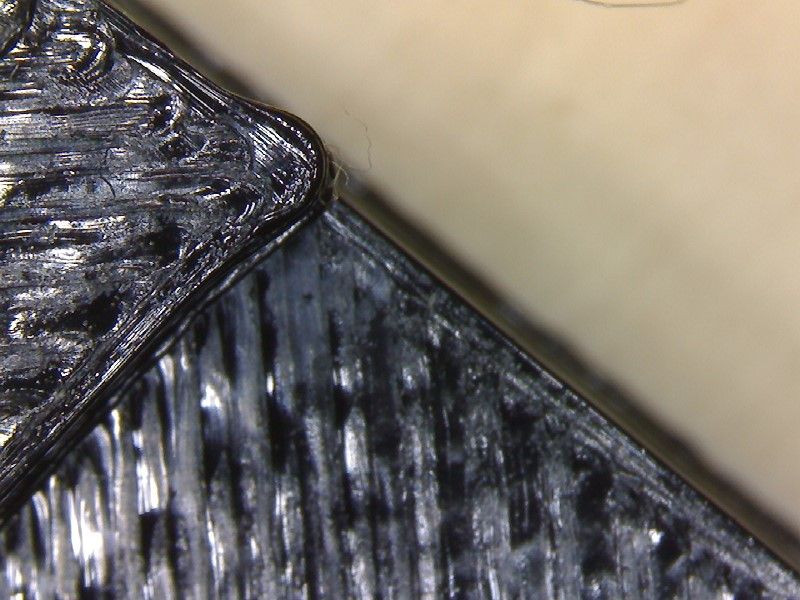

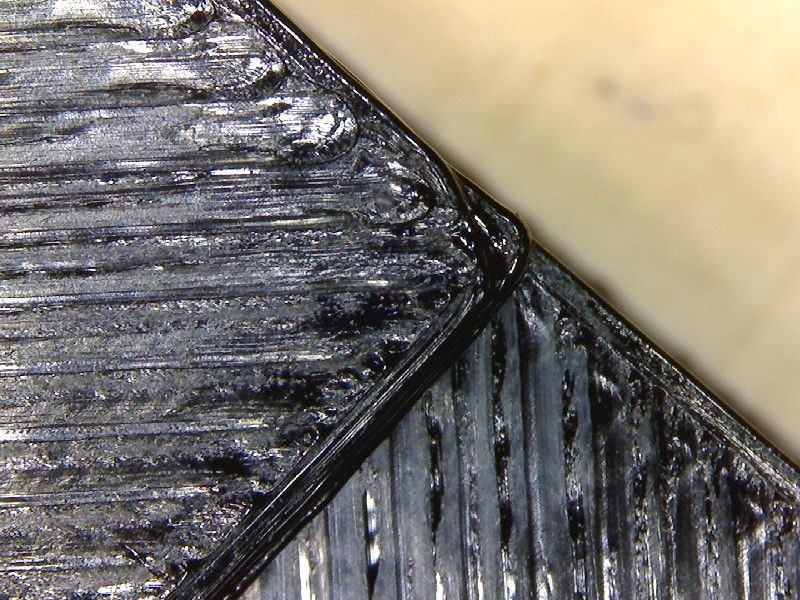

Input shaper ZVDD used (M593 P"zvdd" F40.5 S0.03)New test object (from a duet_rrf Voron channel user) to demonstrate the created overhang by the bulging corner which you can see when you flip it over:

-

@argo I'm not totally sure what it is we are looking at here. Can you post a picture that shows the full object partially from the side (rather than directly above) so we can get a better idea about the test print you have used?

-

Here's the object from another perspective. Imo it's a rather good test to see the actual material that overshoots when flipping the object. In my last post, when viewing the second picture in full screen you can see overshooting edge.

Second picture from last posting but cropped so you can see what I mean:

Unfortunately the bulging makes the printer unusable for me atm because I can only print round objects. For now the printer stays at RRF so I can share test prints when a new FW version gets released but I plan to move to Klipper in the near future (when I find the free time) if the issue remains.

Also the stl:

bulgecheck.stl -

@argo most slicers have a parameter to set the degree of overlap between infill and perimeters. What slicer are you using, and what overlap parameter?

-

I tried following slicers: Prusa Slicer, Super Slicer, Ideamaker and tried infill/perimeter overlap between 10% and 25%.

-

Think i have the same problem with corners.

My System :

Hardware:- Duet 3 6HC

- Duet 3 Tool Board 1LC

- Orbiter 2 Extruder

Firmware 3.4.3

SuperSlicer:

PA 0.2 on PETG

-

Tbh I'm not expecting a fix anymore. Too few are having issues and I understand that a problem that can't be reproduced is not fixable...

-

@argo I have it too

-

I think i found my problem

I used the wrong parameter.

SET_PRESSURE_ADVANCE ADVANCE=0.2M572 D0 S0.13