Hollow shaft extruder

-

due to the continued interest in hollow shaft extruders, @tombrazier and I had a chat with Jason from LDO about a ready made hollow shaft extruder for VDE. We are currently gauging interest in production of some samples.

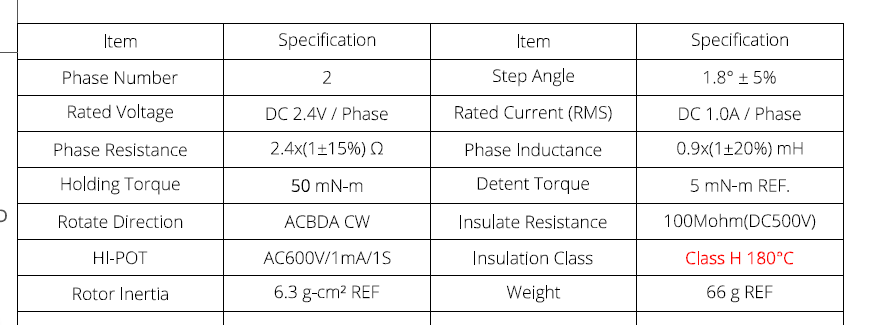

These are the planned motor specs. The weight is with a 1m wire, actual motor weight is closer to 50g as far as I understand

If anyone is interested in getting one or two, please get in touch with me so we can organize a group order.

-

@breed VDE-Tom-9.1mm_backtoback.step

And the FreeCAD parametric model (well, several models including the back to back one): VDE-Tom.FCStd

-

This post is deleted! -

-

@oliof I figured out, that my NEMA14 steppers have a thicker middle part on the shaft. So it isn't possible to replace the shaft with a 5x1mm stainless tube.

OTOH I'm so happy with my BLDC extruder, that I won't spend money on a LDO stepper.I'm happy to supply resin printed carriers, unless @tombrazier has also found a better source in UK?

The bearings didn't arrive yet, so I can't tell if the carrier needs subtile changes. -

@oliof said in Hollow shaft extruder:

If anyone is interested in getting one or two, please get in touch with me so we can organize a group order.

I'd be interested, I need a compact extrusion solution that I can embed in a much more complex print head. I have a hollow shaft stepper I've been playing with, but I'm guessing a closed loop brush less solution will have better performance.

I've only been following the thread superficially so I'd really appreciate if someone in the know could pull together a summary of relevant resources e.g. any cad for printed parts etc, hopefully the resources are Fusion 360 compatible so I can integrate them into my larger assembly.

I have both FDM and resin printers so should be ok to pull something together, albeit I'm maxed out on the day job at the moment so any progress at my end will be relatively slow.

Any thoughts would be much appreciated

All the best.

Barry M -

@breed Cool. Are you Adam, then?

-

@o_lampe You're my only source at the moment. I am interested to see the difference between SLA and FDM. I find the latter works really well but it looks like the SLA print has higher resolution.

-

@CNCModeller said in Hollow shaft extruder:

I have a hollow shaft stepper I've been playing with, but I'm guessing a closed loop brush less solution will have better performance.

The BLDC version is not as compact and lightweight as the stepper because it needs a sensor and separate MCU&driver. I have a working unit with a Waveshare rp2040-zero and sFOC-mini. But the magnetic sensor doesn't work with the hollow shaft concept.

The AMT103-V is expensive and heavy. There is a lighter AMT102-V which could be interesting. But there is yet no design that fits the VDE-100 extruder.

I haven't bought any of these, because the 20€ shipping fee puts me off.

There are optical encoders too, but they need an enclosure...

The dice are still rollingIf you don't want to wait, you should go for a LDO hollow shaft stepper.

-

@o_lampe thanks for the feedback, I'll stick with the stepper for now then.

I have ring based (CNC lathe spindle) magnetic encoders working on other prototypes but you are correct in that the additional mass for the sensor changes the equation.

Will keep an eye on what's happening here all the same.

I'm not timescale sensitive as the day job is really demanding at the moment, just trying to keep up with relevant community developments.

Many thanks

Barry M -

I pushed myself over the edge and ordered an PD30 optical disk encoder with 512ppr.

The wiring and tech-specs are a bit confusing as usual. I hope it's an ABI type... -

@tombrazier Yep. I don't think I linked that correctly.

-

The bearings arrived and I made a big batch of both carrier versions.

It works nice and smooth spinning it by hand.

It's too early to review the threeBB. I'll let him do some weightlifting soon.

The carriers in the background are freebies for guinee pigs (a small donation for stamps and envelops is welcome) . They come without bearings tho.

PM me for detailsI'll send five of each to @tombrazier, so users in UK may ask him...unless he wants to keep them all for himself

He might also be able to tell us more about the grinding process.

-

@o_lampe What did the weight end up?

-

@breed I don't know if my scale would even notice it. Tom weighted his with 5grams.

I'll add an BLDC adapter and motor carrier for the smartEffector first. -

@o_lampe said in Hollow shaft extruder:

He might also be able to tell us more about the grinding process.

My video shows how to do it with any old sanding disk or belt sander on just one side of the flange. The same method is easily adaptable for use with a Dremel cutting disk to grind both sides of the flange.

-

@tombrazier I was more concerned about the required diameter of the flange? In your video, you used very tight tolerances.

-

@o_lampe Wich Resin did you use?

The Temperatur near the Extruders is about 60 °C, sometimes higher.

Thats why I ´m a little bit worried about fixturing the skrews in the plastic.May be I can try it with Formlabs dental materials.

This is a very nice Project - sorry about my english

Gruß zero K

-

@zero-K I'm using ABS-like which has a very high glass temperature. The Sherpa-Mini is made of it too and it works on my delta printer with NEMA14 stepper for about a year and hasn't shown signs of softening.

The BLDC motor doesn't even get warm because of sineWave FOC and a clever current control. -

@o_lampe Thank you for your answer.

Phrozens Resin is cheap compared with them of our Formlabs printers.

I think, a foreign Resin can not be allowed in our Printers and post processing - not only because of bio compatibility - may be too - adjusting the parameters of Laser. For private use, some risk.I will try it first with "Surgical Guide" - Only for testing I have sterilized parts out of this Resin 10 times 20 min at 134°C. I like this Resin very much. If a first try lasts 100 h printing, it would be a nice result because its quite brittle.

3D-printing is not my job - its like play ground and hobby.

I would let you know.

Gruß, zero K