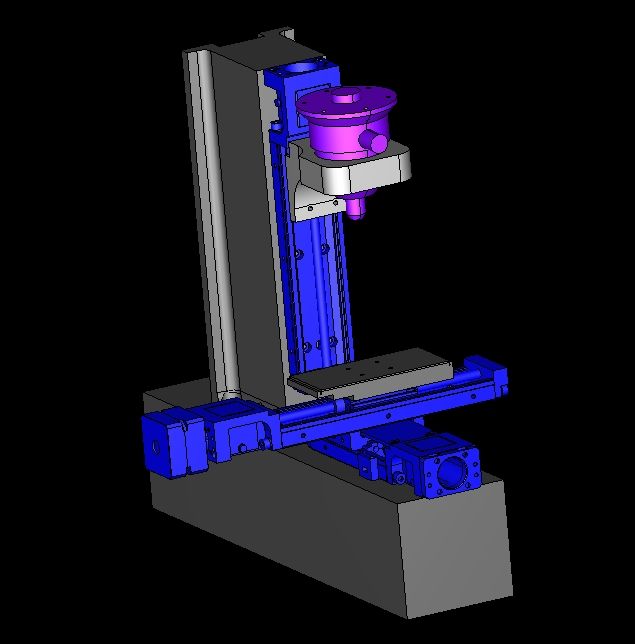

Duet controlled micro mill

-

@3DPMicro This build looks really great! Is there any chance I could take a peak at a BOM or exploded view? I've been wanting to build something like this for machining watch cases / main plates but I haven't found the time.

Thanks!

-k -

@kzamani said in Duet controlled micro mill:

@3DPMicro This build looks really great! Is there any chance I could take a peak at a BOM or exploded view? I've been wanting to build something like this for machining watch cases / main plates but I haven't found the time.

Thanks!

-kI didnt create a BOM because it was fairly simple. Each axis is a self contained Misumi linear actuator. They are designed to stack to create a cartesian motion system. Mine are LX2001-100 (38mm travel) for the Y axis and LX2001-150 (88mm travel) for X, Z axis'. All are 1mm lead ball screws "P" precision grade for no backlash. The LX2005 would still provide high resolution (5mm lead ball screws) with .9 nema 17 steppers and afford faster rapids. Mine are 1.8 nema 14's on the X and Y and a .9 nema 17 on the Z. LX25's or 30's would also be a good choice as well as THK/NSK equivalents. The frame is made from 3" square steel bar machined to 75mm square. There is a decent amount of machine work to get them in a suitable state for a square and accurate CNC machine. I surface ground the critical surfaces but that isnt totally necessary. I also designed in some versatility to allow longer Y travel and separate linear rails and ball screw for the Z axis. End stops are OMRON E2EC-CR5C1 proximity switches which are deadly accurate.

If you want to duplicate exactly what I did I will put the CAD model up.

This temporary solution for keeping the machine clean has worked well so I doubt I'll change it

-

@3dpmicro Sorry to reply to this old thread but I find this build to be awesome, so simple yet super high precision, I wonder if is posible to see a video of it in action? I am a watchmaker student doing research for building a cnc mill and this one has to be the best approach I have ever seen, thanks in advance!

-

The Duet 2, with regularily updated FW has been flawless through many projects over the last few years guiding this little mill. I have the same confidence in it as any of the professional grade machines I run at work.

I thought if it could be tripped up the g code for 3d maching the .5mm radii on this part would do it. Resolving moves as small as 100nm for the inside corners there was no indication of lost steps or rounding errors (the floating point goes that low?) over the 8 parts that were made. Pretty cool

https://youtu.be/27_E8RawCyQ

There were 0 hiccups and 0 errors but underruns showed 0,0,4. What does that mean? -

@3DPMicro said in Duet controlled micro mill:

rounding errors (the floating point goes that low?

float is built by three parts: the sign, then the digits with 7 to 8 digits precision (the 7 to 8 digits of the 10 base decimal system) and an exponent with high range (1e-38 to 1e38), so it doesn't make a difference between mm or nm. Most values will be rounded.

For your 0,0,4 underrun message, I searched the code. in DDARing.cpp Diagnostics() is the code, the three variables are

numLookaheadUnderruns, numPrepareUnderruns, numNoMoveUnderrunsIn DDARing.h are some explanations about the meaning:

unsigned int numNoMoveUnderruns; // How many times we wanted a new move but there were noneso this seems to be not a serious error. I am not sure about the reason, but I can think of rounding errors or queue not being filled fast enough.

-

@JoergS5 thanks for the explanation and feedback. I wont concern myself with it but will monitor it for the sake of better understanding what might effect it

-

659-resized.jpg) !

659-resized.jpg) !

-

-

very nice! ...what is it?

-

@Phaedrux Its a retractable ID badge holder that goes on your belt with places to attach a zip drive and random number generator dongle. Grade 5 Titanium, Delrin and spring steel

Made on a wire EDM, Duet 2 controlled Lathe and my Duet 2 controlled micro mill -

I was going to guess fishing reel.

-

@3DPMicro said in Duet controlled micro mill:

Its a retractable ID badge holder that goes on your belt with places to attach a zip drive and random number generator dongle. Grade 5 Titanium, Delrin and spring steel

Made on a wire EDM, Duet 2 controlled Lathe and my Duet 2 controlled micro millI thought that it is an accurate scale, with compliant parts left and right, the big wheel being the indicator.

Nice quality!!

-

I can see it being a real hard guess

The dies to form the springs were finish machined on the mill with a .5mm ball endmill, too.

https://youtu.be/27zb8gcqGPA?si=suV_zfw9h41iTjDT

I posted this above already but this is what the part was for https://youtu.be/27_E8RawCyQ?si=GDXWU7Ujmx36qK8a -

undefined 3DPMicro referenced this topic

undefined 3DPMicro referenced this topic