Auto pressure advance turning by hotend pressure

-

@Charlie Yes prusa has implemented it

-

@Charlie would a mouse optical sensor work to monitor filament

-

@Richard-F that's the simple runout switch that you find on many printers. There are other filament failures you'd want to catch.

-

@penguinya Do you have a link to this? I havent seen anything about it.

-

@Richard-F It would absolutely work. Ive seen a few systems using this, and Ive used it myself in the past. I know the Duet supports it, though Id recommend looking around to see how others have implemented it. (eg: using printed levers to contact the filament instead of the switch lever contacting the filament directly)

-

@Charlie Thanks

-

@Richard-F Youre welcome. Happy Printing!

-

-

-

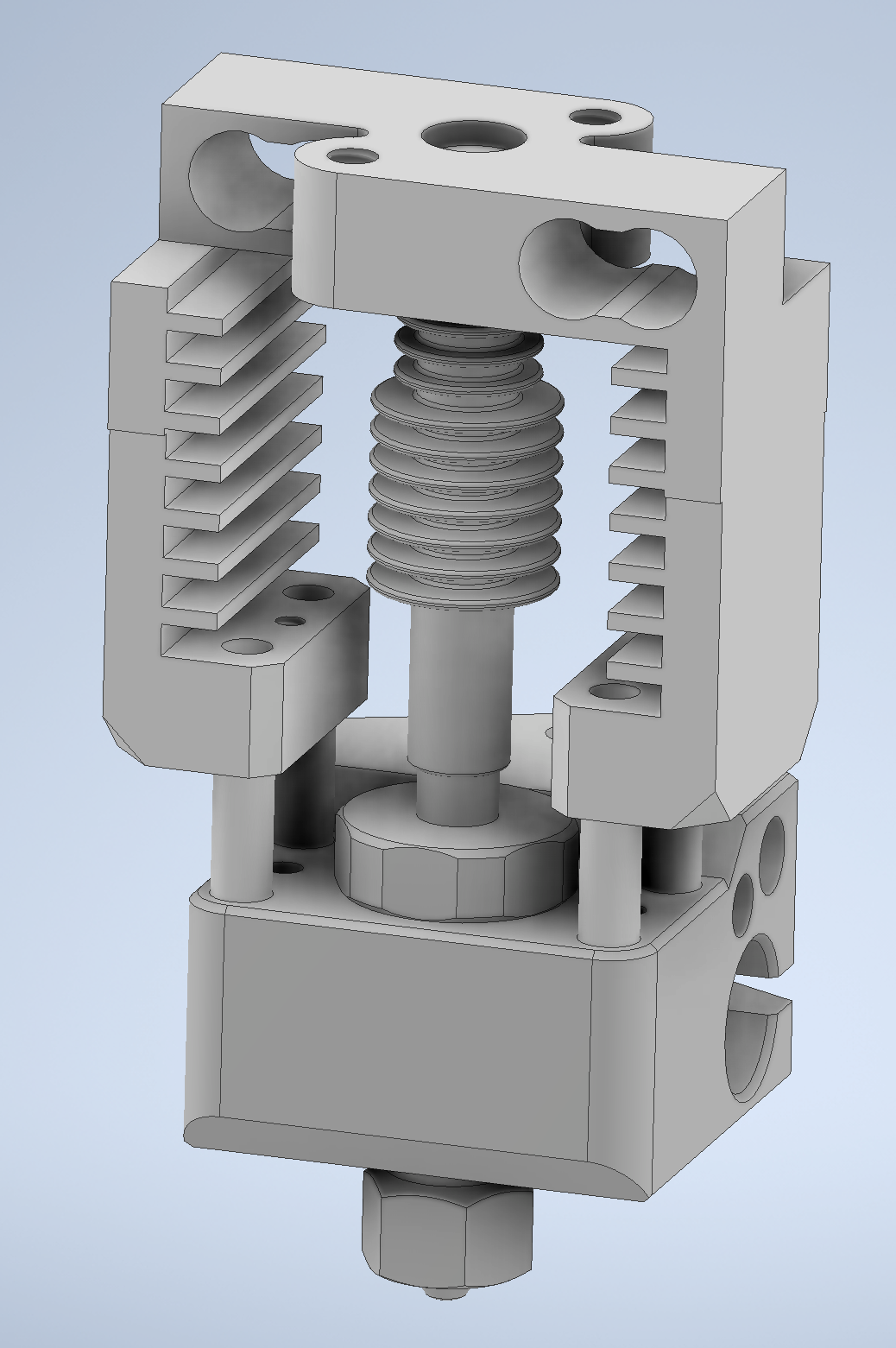

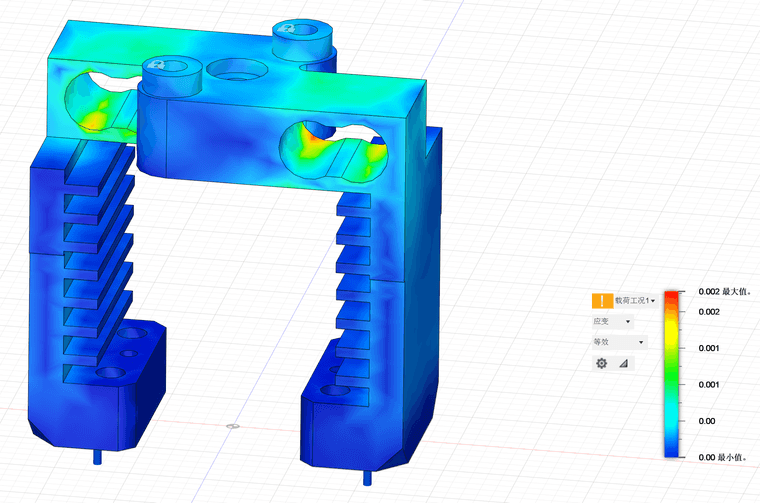

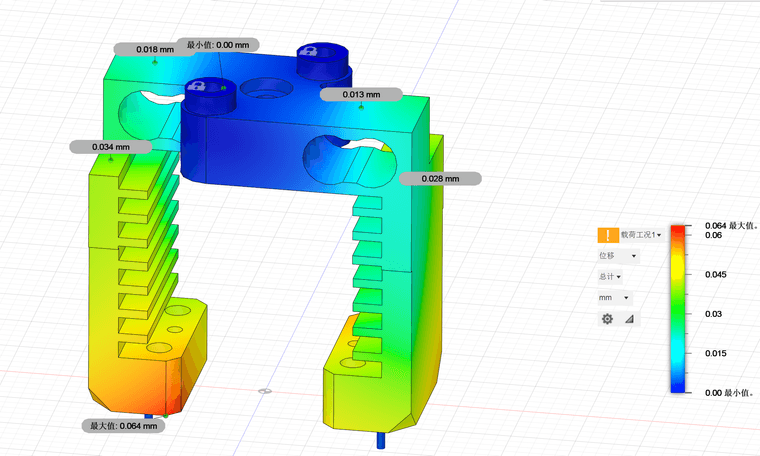

@penguinya I love it! I'm assuming that the geometry near the top is to allow for deflection that can be measured using a strain gage.

Random thought though. Would it be necessary to constrain it some other way to prevent loads from being transmitted from the model being printed to the load cell? Like, if you do a travel move, and the nozzle skips along the top of the print, it will transfer load to the load cell. Perhaps this can be mitigated in firmware (by not taking measurements unless its actively extruding) or filtering out certain frequencies.

-

@Charlie According to the simulation results, the impact on printing is unobservable.

Aluminum 6061, 100N force

-

-

@penguinya Cool work! And apologies if I was unclear, but I was thinking that the print itself may induce feedback that may skew how the strain is being determined. Not that the reduced material would affect print quality. But again, that may be able to be filtered out.

-

@penguinya Yes, it's operating on Prusa MK4 and XL, but I had to turn it off on my machine because it was falsely triggering on the first layers when they had low layer height. I suspect that there might need to be some exception incorporated for those circumstances.

They have described it in these release notes.

-

@T3P3Tony I have a meeting a super long time ago with the trinamics team, it was the time were they were just launching their drivers. They made to me a presentation, where they showed me on a screen how sensitive was their torque detection on a common nema17 motor. I clearly rememnber thatn even a very soft touch to the motor axis using my finger, was being detected by the driver and shown on screen.

This is basically the stall detection capabilities.

I have a long no started idea to try to tune the 5160 drivers on the extruder to be able to detect a change on pressure change while extruding. I managed to do something (not finished) but woulkd it be possible for you to access directly thjrough firmware the driver data and detect these torque changes?

This would be my idea on how to do it with your actual hardware. I think It would be possible, trinamics offers its API of their drivers to work on such features too. -

undefined PenguinAkiko referenced this topic 24 May 2024, 05:15