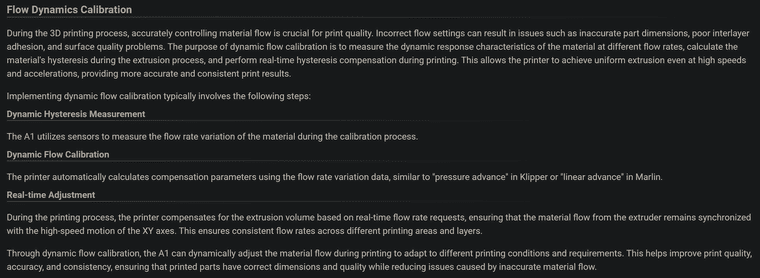

Auto pressure advance turning by hotend pressure

-

@penguinya I think it would be fast enough. Just put a "while true" into daemon.g and then a G4 P50 in the body to execute your script every 50ms. (Edit: this wouldn't actually run that frequent, more like 3-6 times a second)

I don't think pressure advance needs to be adjusted that often, right?

-

@nikscha Bambu Lab tests pa every print, and 50ms really slow, HX711 can reach 80HZ, Prusa using HX717 320HZ, higher the sampling frequency, the more beneficial for auto PA testing.

-

find a better chip for load cell.

CS1237 http://www.asidesigner.com/Files/PartFiles/15315/222/cs1237_datasheet.pdf

spi bus 1.28kHz ADC and PGA -

@nikscha Here is a post about sampling speed

https://forum.duet3d.com/post/251488 -

-

@penguinya The introduction of bambulab confirmed my guess.

-

Correct me if Im wrong, but I feel like this sensor could also be used for filament runout/jam detection as well. Like if the force expected by feeding the filament is not produced, it could indicate that there is some filament error.

-

@Charlie Yes prusa has implemented it

-

@Charlie would a mouse optical sensor work to monitor filament

do we need more than this for a run out trigger

-

@Richard-F that's the simple runout switch that you find on many printers. There are other filament failures you'd want to catch.

-

@penguinya Do you have a link to this? I havent seen anything about it.

-

@Richard-F It would absolutely work. Ive seen a few systems using this, and Ive used it myself in the past. I know the Duet supports it, though Id recommend looking around to see how others have implemented it. (eg: using printed levers to contact the filament instead of the switch lever contacting the filament directly)

-

@Charlie Thanks

-

@Richard-F Youre welcome. Happy Printing!

-

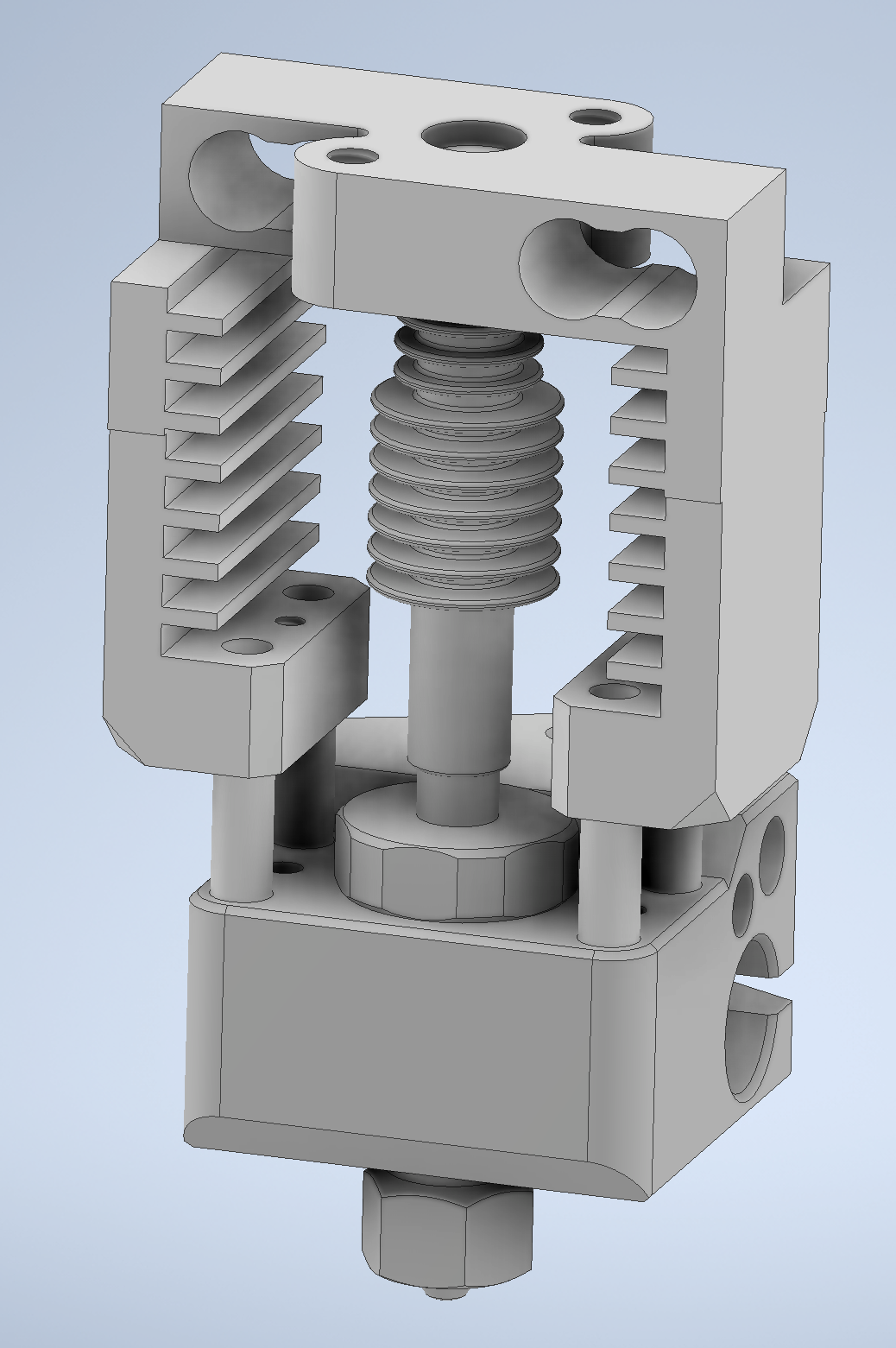

Just an updating.

-

-

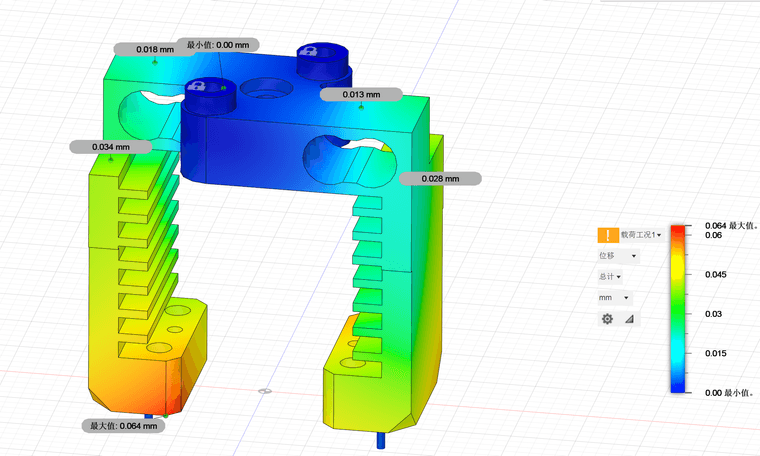

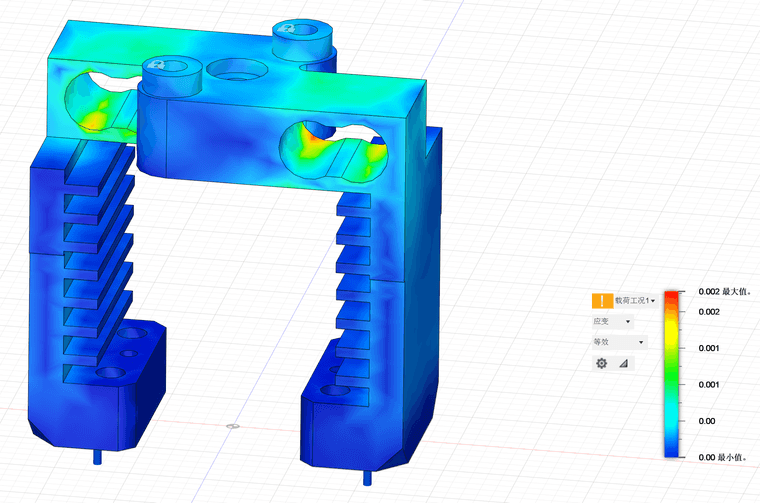

@penguinya I love it! I'm assuming that the geometry near the top is to allow for deflection that can be measured using a strain gage.

Random thought though. Would it be necessary to constrain it some other way to prevent loads from being transmitted from the model being printed to the load cell? Like, if you do a travel move, and the nozzle skips along the top of the print, it will transfer load to the load cell. Perhaps this can be mitigated in firmware (by not taking measurements unless its actively extruding) or filtering out certain frequencies.

-

@Charlie According to the simulation results, the impact on printing is unobservable.

Aluminum 6061, 100N force

-

@penguinya Just early version, I think it is ok.

-

@penguinya Cool work! And apologies if I was unclear, but I was thinking that the print itself may induce feedback that may skew how the strain is being determined. Not that the reduced material would affect print quality. But again, that may be able to be filtered out.