Sovol SV08 Multiple Motion System Upgrade.

-

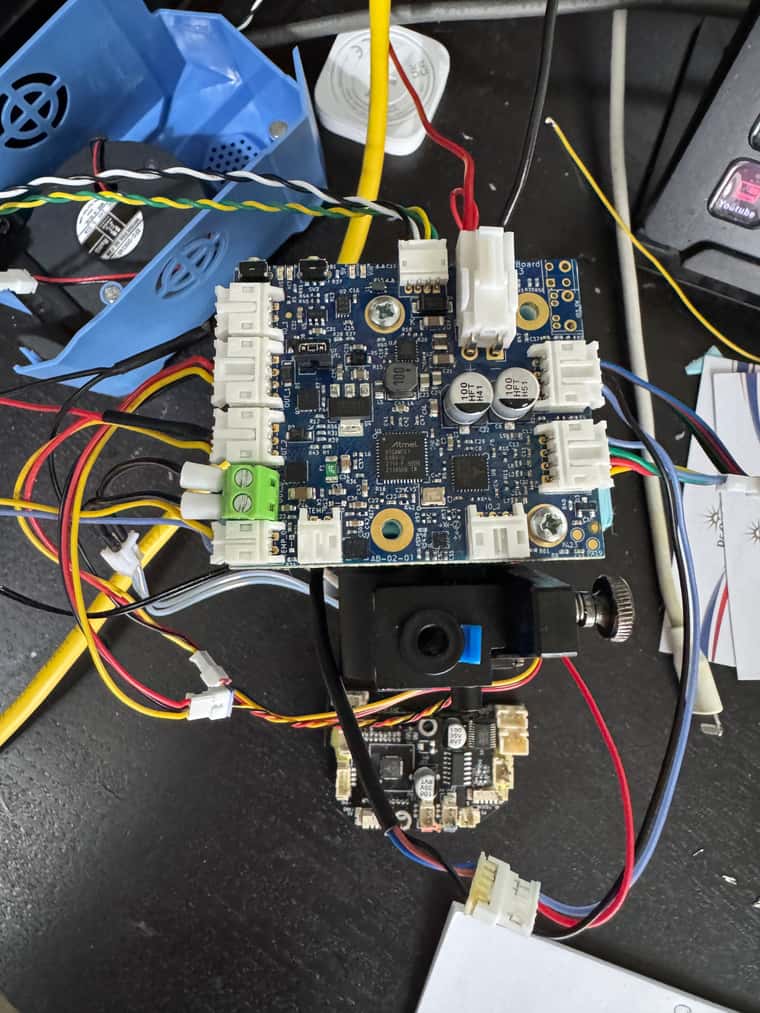

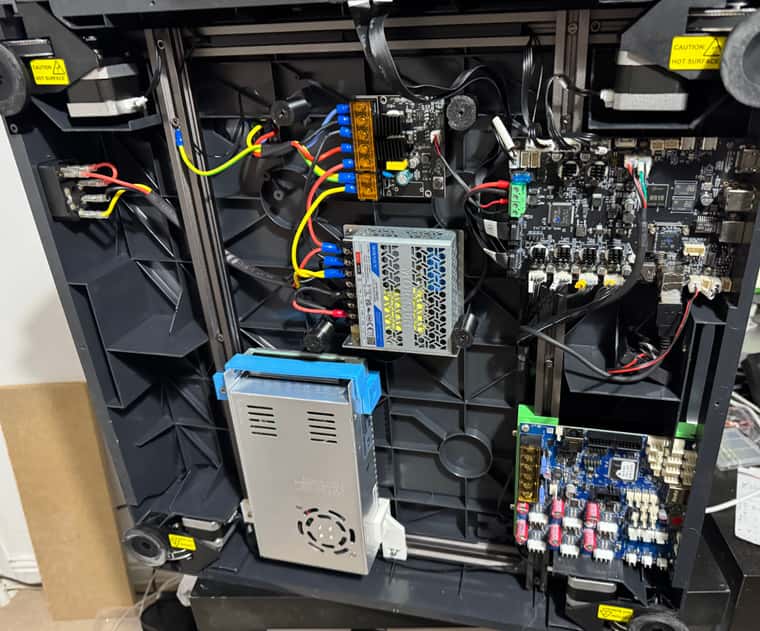

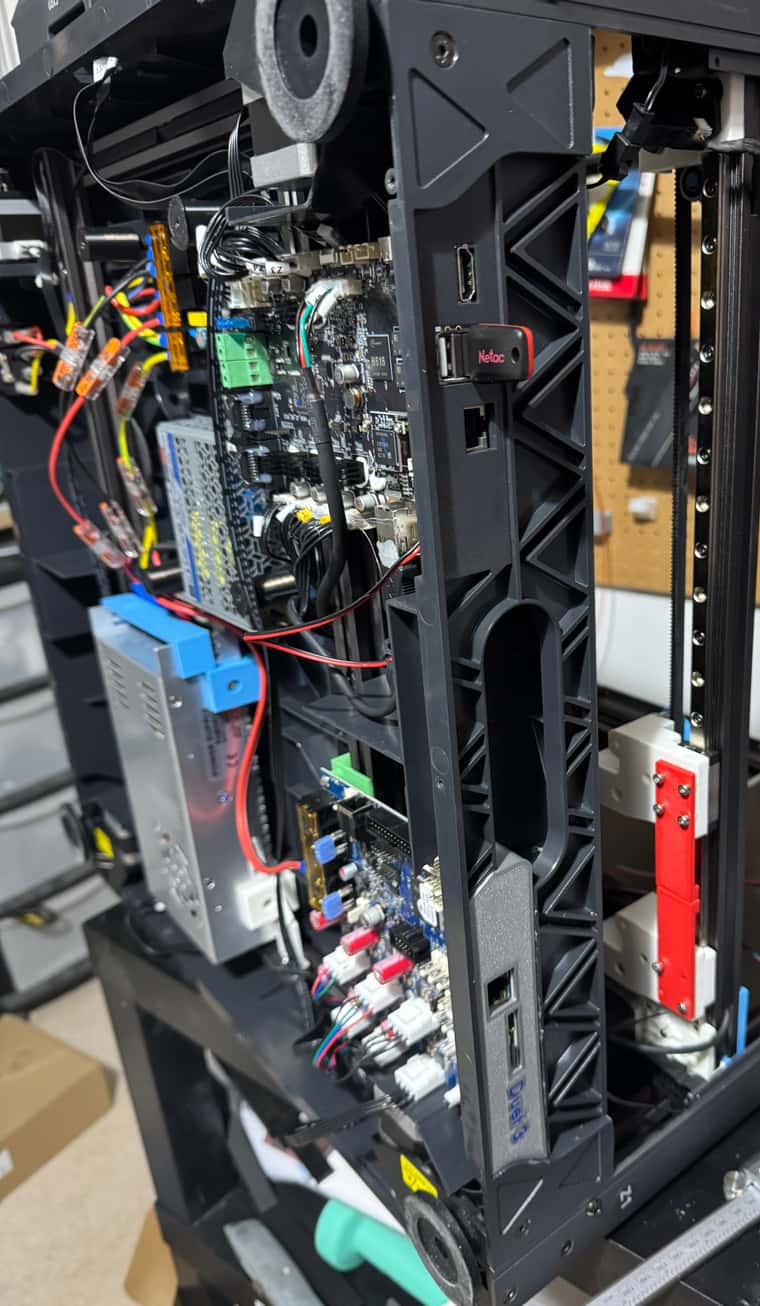

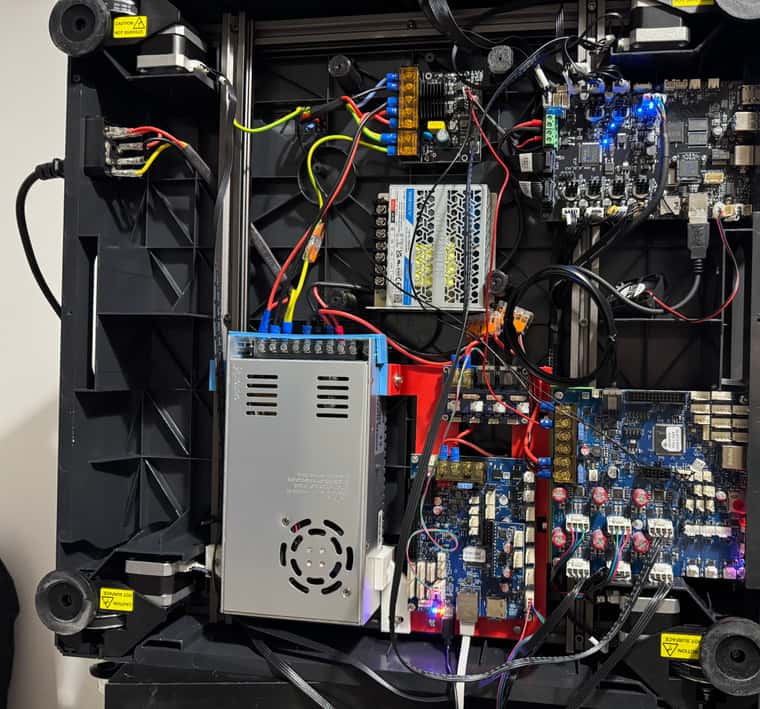

@dwuk Duet3 6HC board now installed - now for lots of wiring up.

-

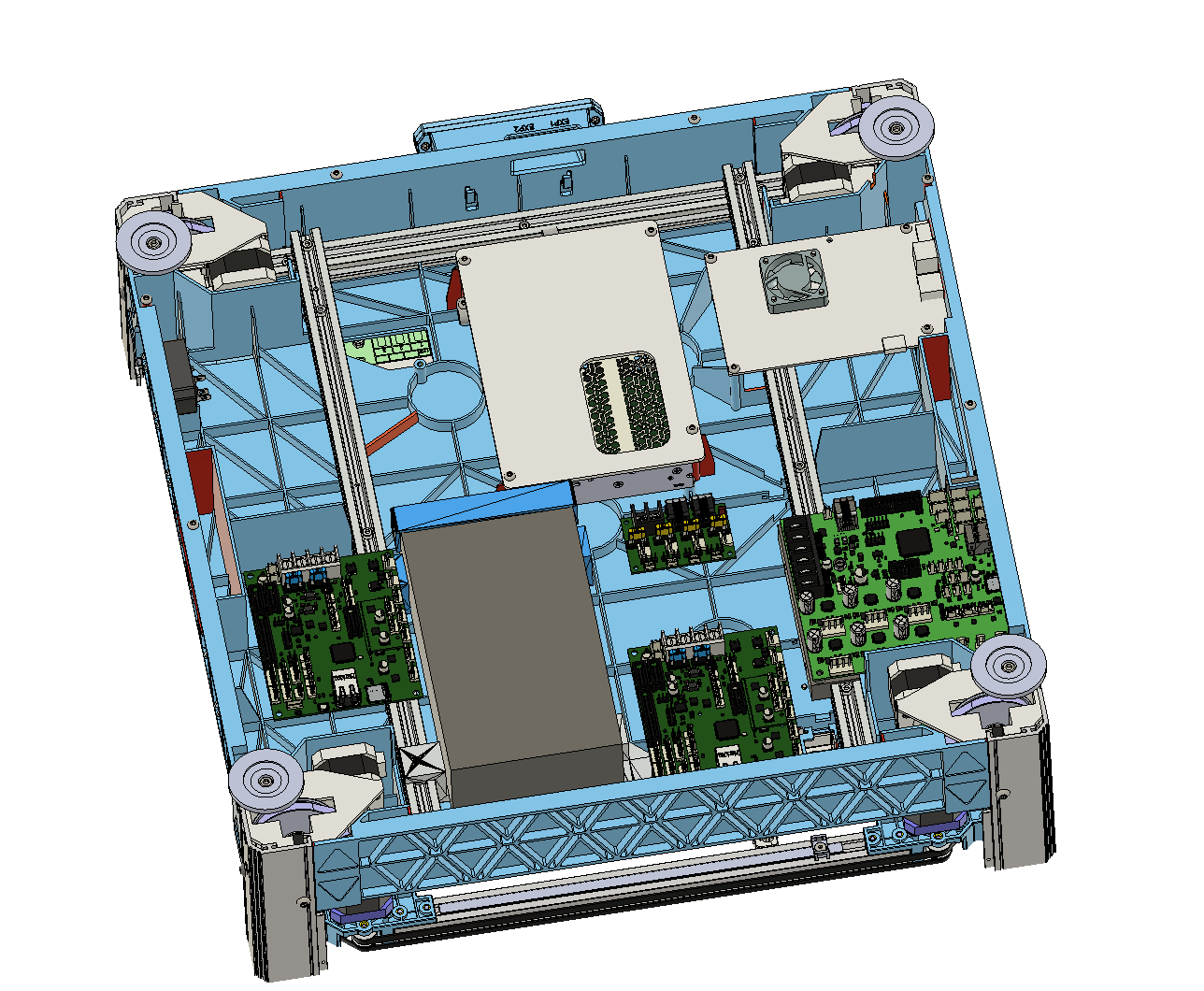

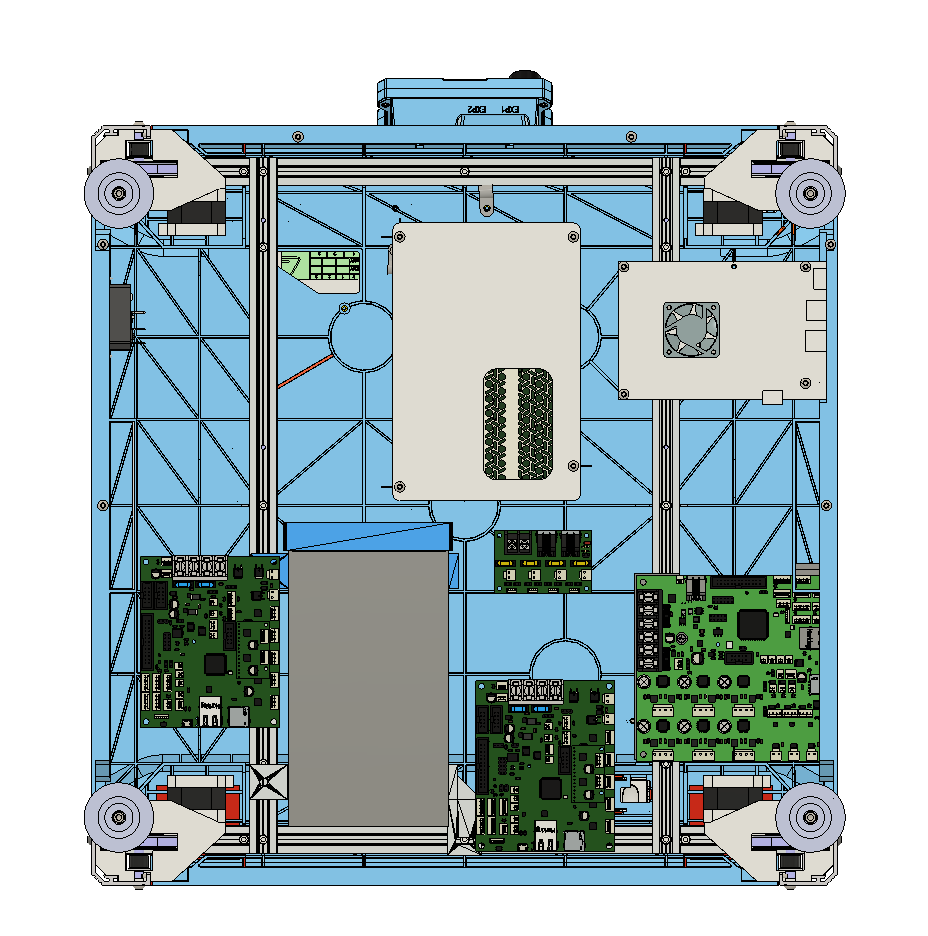

Starting to plan for expansion boards - looks like there is room,

Tool Distribution board and first Mini5+ needed for Dual Gantry, with further Mini 5 probably needed for IDEX - unless I can reduce the stepper requirement - by using less for IDEX and Servo's for Z Hoppers.

-

@dwuk This is all such an amazing project, along with your work on splitting the slicer output for two tools to print at the same time. Keep up the good work, and thanks for documenting it so well!

Ian

-

Good progress made on Duet6hc commissioning. Power and first 6 steppers wired up, and firmware upgraded.

Think I will try and see if I can get some movement tomorrow - before tackling the harder problem of the 1LC wiring.

Old board and wiring left in place for now - if nothing else it will be useful for it to provide the camera feed.

-

@droftarts. Thanks - really enjoying the project so far - I can see why people spend so much effort on printer upgrades and self builds. Will be really interesting to see whether parallel printing is practical.

-

@dwuk said in Sovol SV08 Multiple Motion System Upgrade.:

interesting to see whether parallel printing is practical.

I'm sure there is a niche for it, same as for tool changers or MMU-printers. Each system has some drawbacks, here:

Building/commissioning/homing and maintaining perfect z-height will be a nightmare. -

@o_lampe Agreed Automated alignment, homing, maintaining perfect z-height are all essential, plus also speed, reliability, filament colour/material management & slicing.

In terms of niche MMU - I use the AMS on my BL printers 99% of the time - always for filament selection for single colour prints - but also pretty often for 4-11 colour prints -

I wasn't sure how much use I would get out of a 2nd identical multi colour printer (which I bought to double my printing speed) -

In my usage scenarios when I am using one of the printers I find I end up using the second one too for at least half of the time. It's usually only filament management that stops me from using the 2nd one even more often. i.e. Not having two sets of every filament needed. I've got a few ideas on how to solve this problem too - with some sort of automatic on demand filament roll splitter.

Tool changers I agree are more niche - probably due to the expense of having so much print head hardware sitting around unused for 99% of the time, plus also being limited on the number of colours supported. I think MMU/AMS type multiplexers are more practical for prints with many colours in them - but 2 to 4 extra 'tool changer' print heads I think could help speed up print times and reduce waste quite a bit without adding massively to the cost. A solution that only changes the nozzle and hot end would be even more useful too.

Building and Commissioning I would see as a separate problem - which would ideally be solved by a manufacturer taking up the idea.

-

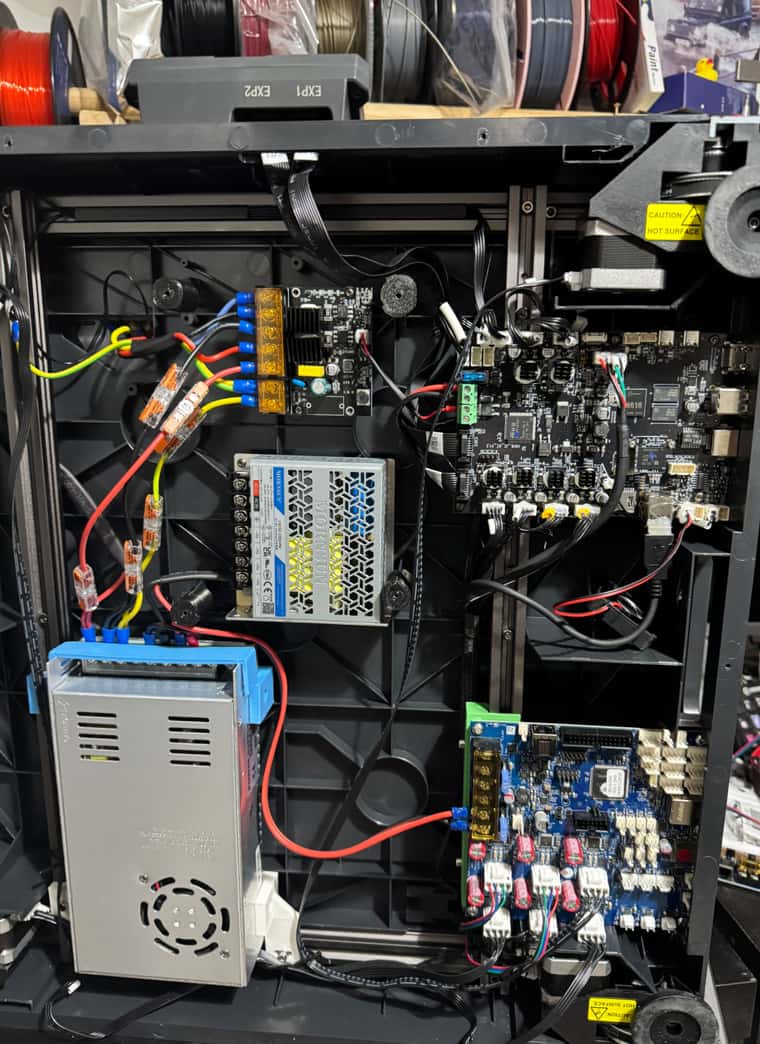

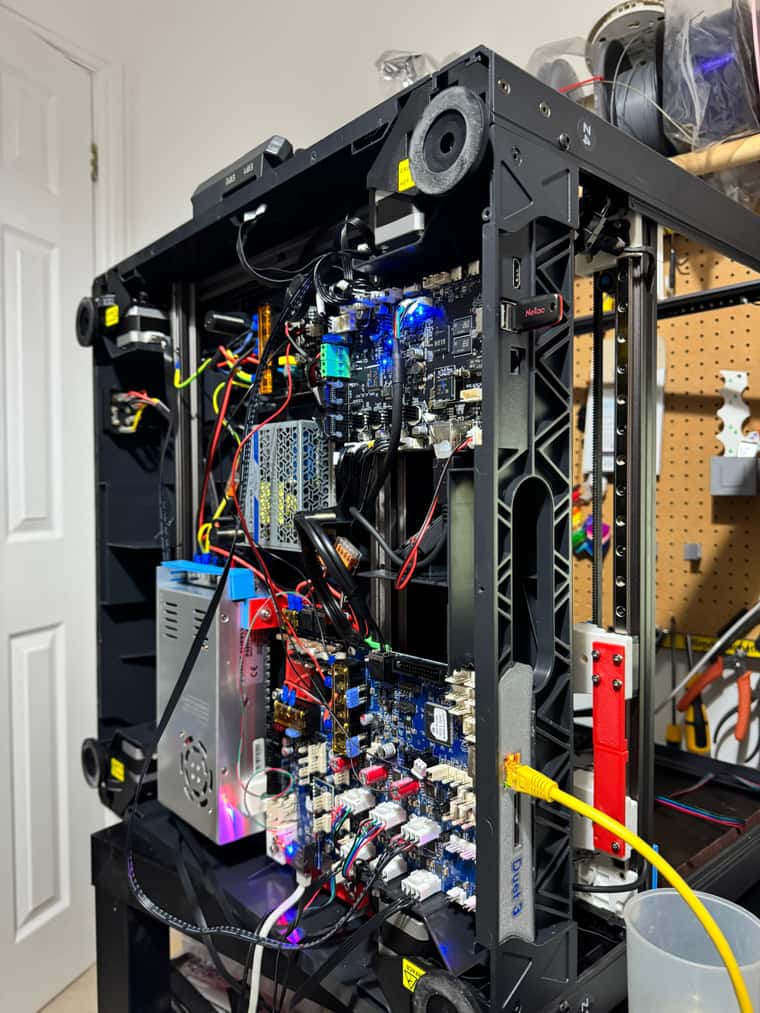

Other boards now installed.

Biggest issue was finding Duet3_CANiap32_Mini5plus.bin - it isn't in the current release - and GitHub search didn't find it. Eventually found it in previous release.Just about every cable from the printer is a different size to the Duet boards.

Hardest ones are the tiny extruder connections. I've ordered some male versions of the existing connections which are 1.25mm - so I can make up adaptors. For the bed thermistor I decided to leave both connectors attached.

-

@dwuk said in Sovol SV08 Multiple Motion System Upgrade.:

- it isn't in the current release - and GitHub search didn't find it. Eventually found it in previous release

thanks. I have added them to the 3.5.4 release.

-

Thanks.

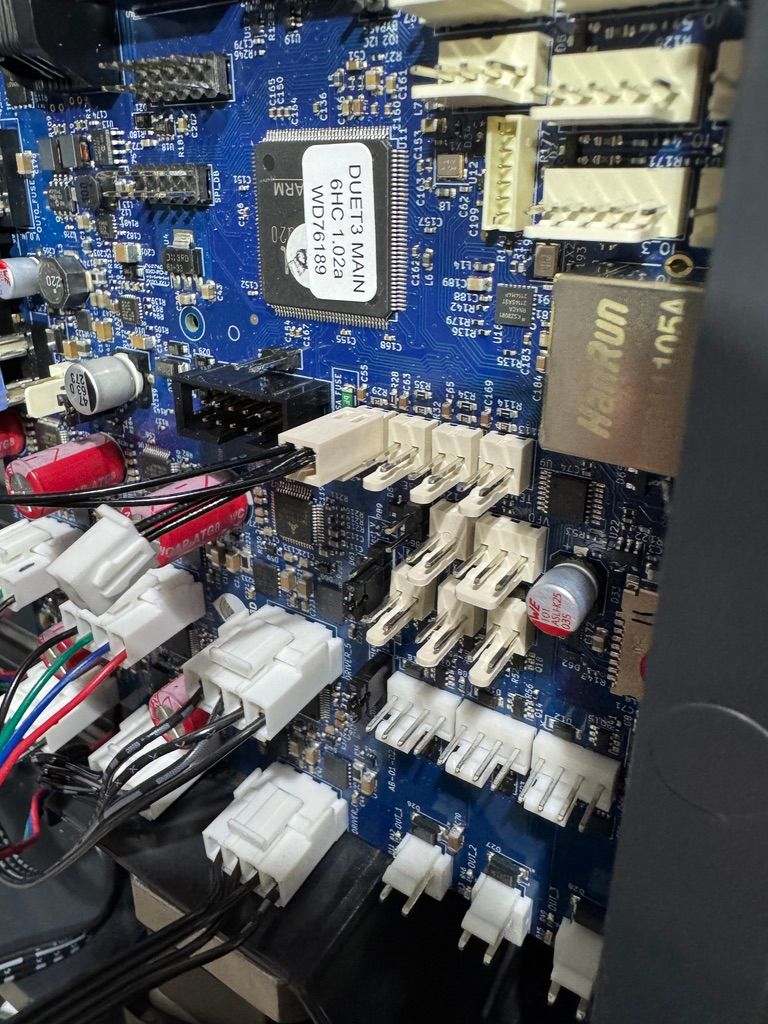

Update from today - is that I thought I have updated the firmware on the Mini5+ board yesterday - but actually there was a timeout and it didn't update.

I could check the firmware etc. and run other commands - but firmware updates wouldn't work

The main 6HC board was on 3.5.4 and the Mini5+ on 3.4.0.

I spent most of the morning checking cables and making up two more cables - which I tried running from the tool expansion board but still got the same error.

Eventually though I figured out the problem - which was related to 3.4.0 not seeming to like being updated via CAN-FD

So I manually upgraded the Mini5+ board via SD card and usb terminal to 3.5.1 - and downgraded the main system - and all was then ok.

I then upgraded them both to 3.5.4 and they worked ok.

Motors for first gantry now all connected up - and X,Y & Z movement now working.

Mains Heatbed basic function also working. I had forgotten to install the in power initially - but figured it out after a while. Will have to do PID tuning at some point.

I was going to configure sensorless homing next - but based on the Duet documentation mentioning how inaccurate that method is I think I will add some limit switches and use them instead for the homing.

-

@dwuk sensorless homing isn't as good as homing with a limit switch, but it's OK if you don't need the facility to resume a print that has been interrupted due to power failure. I still use sensorless homing for the X and Y axes of my tool changer.

-

@dc42 Thanks - Will get the printer working on Sensorless first as you suggest and leave looking into limit switches until a bit later.

Update: Got X and Y Sensorless homing working in about 10 mins - its much easier to do than it was on Klipper.

-

@dwuk Sensorless homing will do for now, but with more and more toolheads involved you'll need perfect homing positions relative to each other.

Otherwise it'll look like that:

-

@o_lampe good point, I'd forgotten that it was an IDEX machine.

-

@o_lampe Agreed - I would if possible like to include auto head alignment in the design - so it could work in that case I suppose if you auto align every time you power on, or for every print.

The other issue is the fact that after quite a few goes at trying to get sensorless homing working on the 2nd Gantry (the U & V axis) I have found out that it doesn't work on Mini5+'s used as a tool board - even with the latest 3.6 firmware.

So will add switches for U&V initially, and eventually X&Y too.

-

@dwuk that's one for @dc42 to look at then with sensorless homing on CAN boards being a new feature

-

@dwuk said in Sovol SV08 Multiple Motion System Upgrade.:

The other issue is the fact that after quite a few goes at trying to get sensorless homing working on the 2nd Gantry (the U & V axis) I have found out that it doesn't work on Mini5+'s used as a tool board - even with the latest 3.6 firmware.

I thought the 3.6.0-beta.3 release had it partially working on the Mini5+ as-expansion, possibly only on drivers 0, 1 and 5. I’ve been testing this, and @dc42 has supplied me with fixed firmware that fully works. Let me know if you would like to try it.

Ian

-

@dwuk said in Sovol SV08 Multiple Motion System Upgrade.:

The other issue is the fact that after quite a few goes at trying to get sensorless homing working on the 2nd Gantry (the U & V axis) I have found out that it doesn't work on Mini5+'s used as a tool board - even with the latest 3.6 firmware.

There's a build at https://www.dropbox.com/scl/fo/bx70c7u0bshq79ez83mnn/AKMj4UCEimtQuGYxRj_d0ew?rlkey=7yiq3x5fcae3v2ogslfocx1op&dl=0 in which this is fixed.

-

@dc42 Thanks will try that out this afternoon - will use sensorless just for testing purposes - and move over to switches at some point.

-

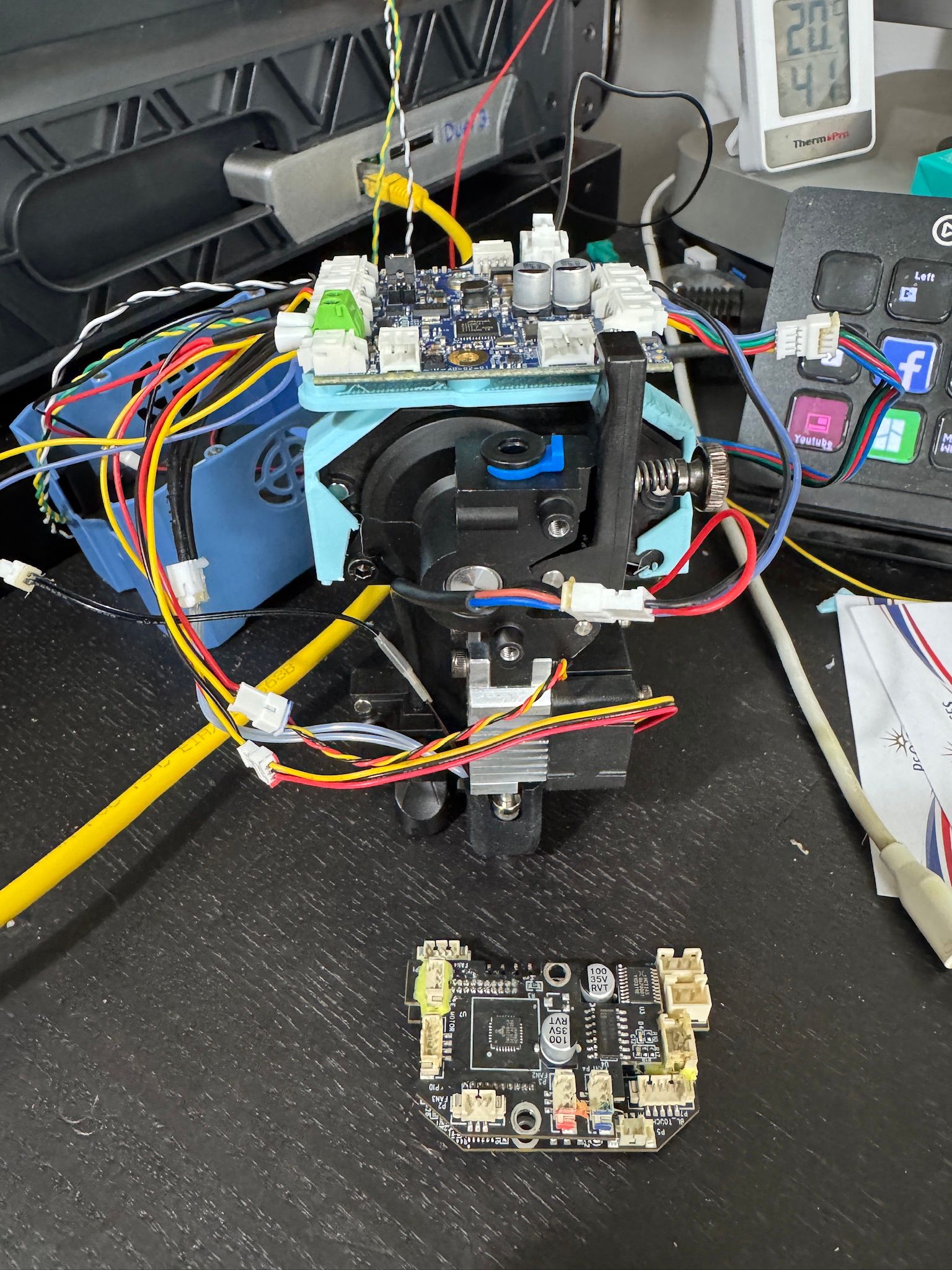

Good progress made on wiring up first extruder.

Main issues I faced were:

- Sizes of connectors - 95% of the Sovol connectors are tiny 1.25mm Female, and most of the Duet are 2mm Female. So made up some adaptors 1.25mm Male to 2mm Female - found a nice kit with pre-crimped 1.25mm wires and sockets and plugs.

Didn't want to cut off existing connectors as may want to go back, plus wires a bit short to reach board too.

-

Inductive Probe 24V power - ended up splicing in an extra plug on the VIN power feed - but not ideal as it means two plugs to disconnect

-

Blower fans - The extruder has two - one of which is 3 pin and the other 2 pin - so wired them together, and - with VOUT and Tacho In on Out_2. and GND from unused IO1.

-

Heater power is a 2mm Female - whereas the 1LC is a screw connector. Didn't have any 2 way Male Sockets - so cut down 5 way temporarily - have order some pre-crimped from the same place as the 1.25mm ones as a more permanent solution. Also had trouble getting the crimped cable to fit into the screw connector.

Overall though - ready for a test this afternoon.

Wiring still a bit messy - and adaptors longer than they need to be - but not 100% where I am going to end up placing the 1LC board - so left them long for now.