Sovol SV08 Multiple Motion System Upgrade.

-

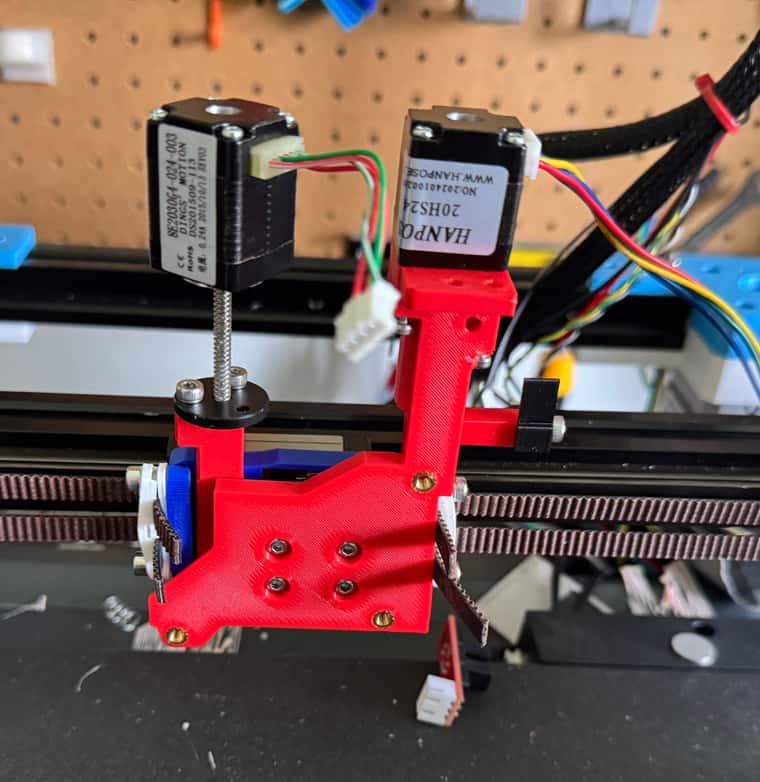

@dwuk3d Initially I was finding that the Nema 8 motors were not powerful enough to reliably lift the gantry.

The Non Lead screw one was I thought rated at 0.4a and the Lead Screw one at 0.24A.

However it looks like on further investigation that the Non lead Screw one is actually rated at 0.8A - and when I set it to 0.6A in Config.g it is working very reliably.

Before I found this out I ordered some smaller (28mm) Nema11-s however as the Nema8's look ok I have ordered two more of those too

Short video attached of Nema8 in operation, and also showing what may or may not be a good idea - using the same (very cheap) optical sensor for

- MicroZ (A Axis)

- U Axis

- Z Axis tapping

In order to swap the 122.io2.in pin between the 3 axis - I found I had to first swap the other axis to dummy IO pins - so that they would release 122.io2.in - so that it could be assigned to the correct axis using M558 commands.

-

Little time saver GCode command created,

M98.1 - For running Macro's - without needing to specify the full path, or .G suffix

M98.1 A"ClearAllocs"

Instead of

M98 P"0:/macros/ClearAllocs.g";m98.1.g - Run Macro if exists(param.A) var P ="0:/macros/"^{param.A} if fileexists(var.P) M98 P{var.P} else var P2 =var.P^".g" if fileexists(var.P2) M98 P{var.P2} else echo "M98.1 Macro file not found",{var.P} else echo "M98.1 Macro Parameter A not found" -

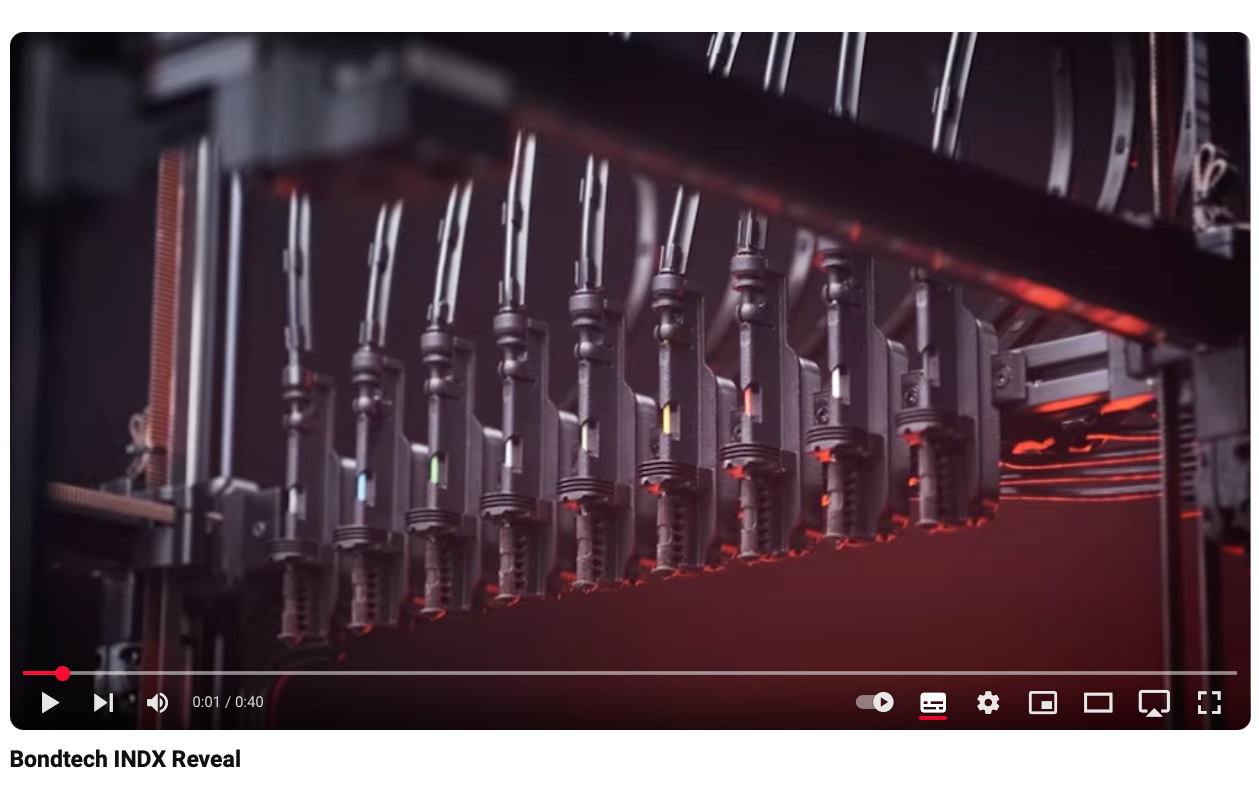

Got a bit distracted today by the BondTech INDX - which looks like a very interesting Nozzle Changing solution - although I suspect it might end up being a bit expensive to be practical for my Proof of Concept.

https://youtu.be/BCmGoP0uNlM?si=9z8oPViQpQ6cfGIo

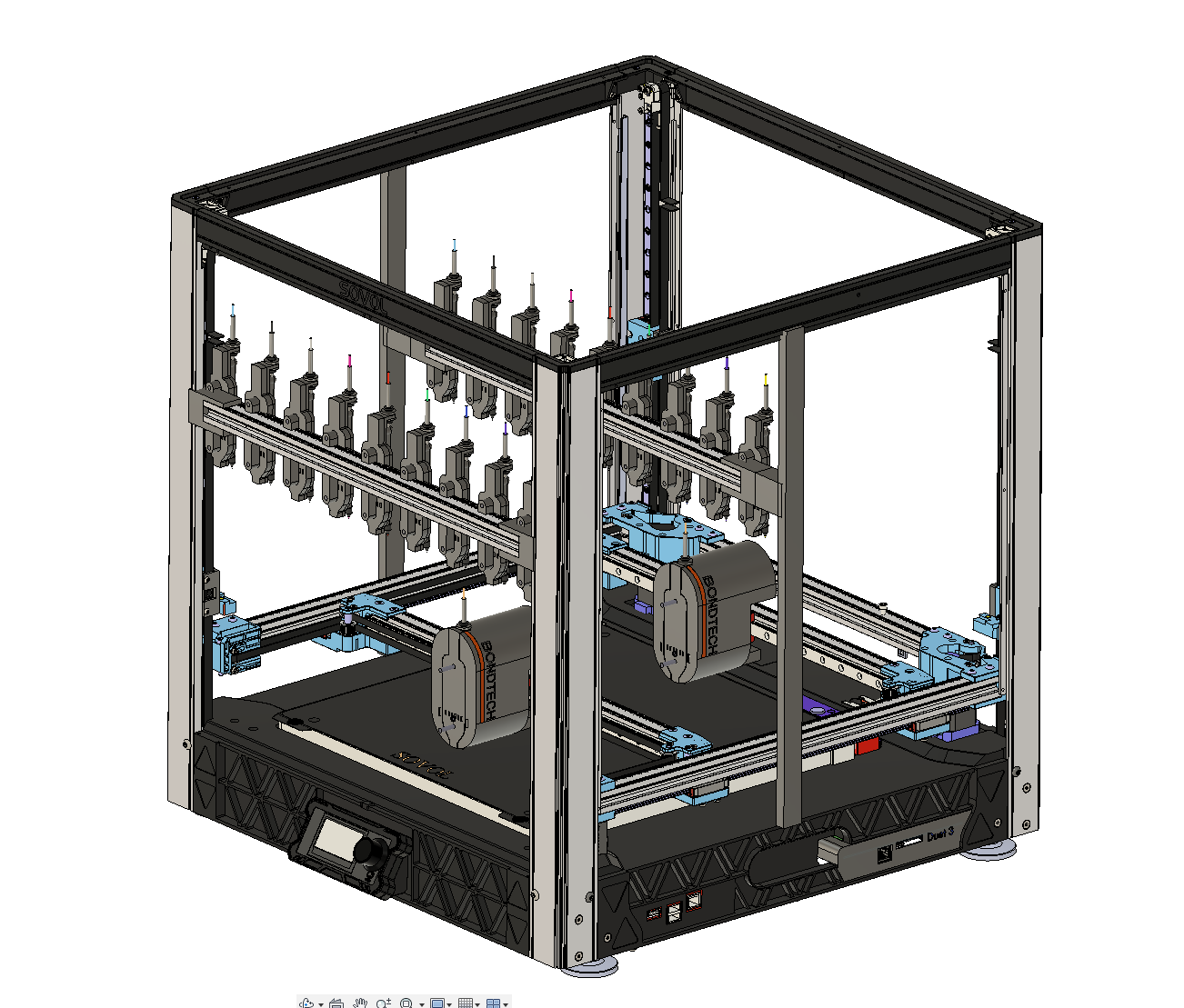

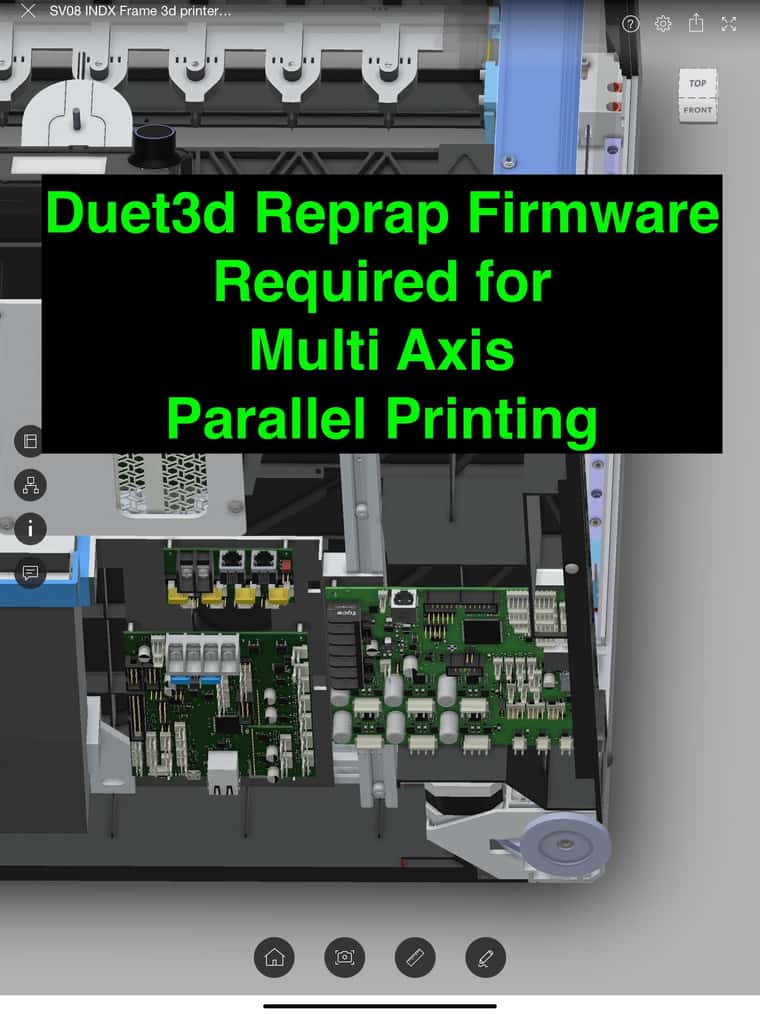

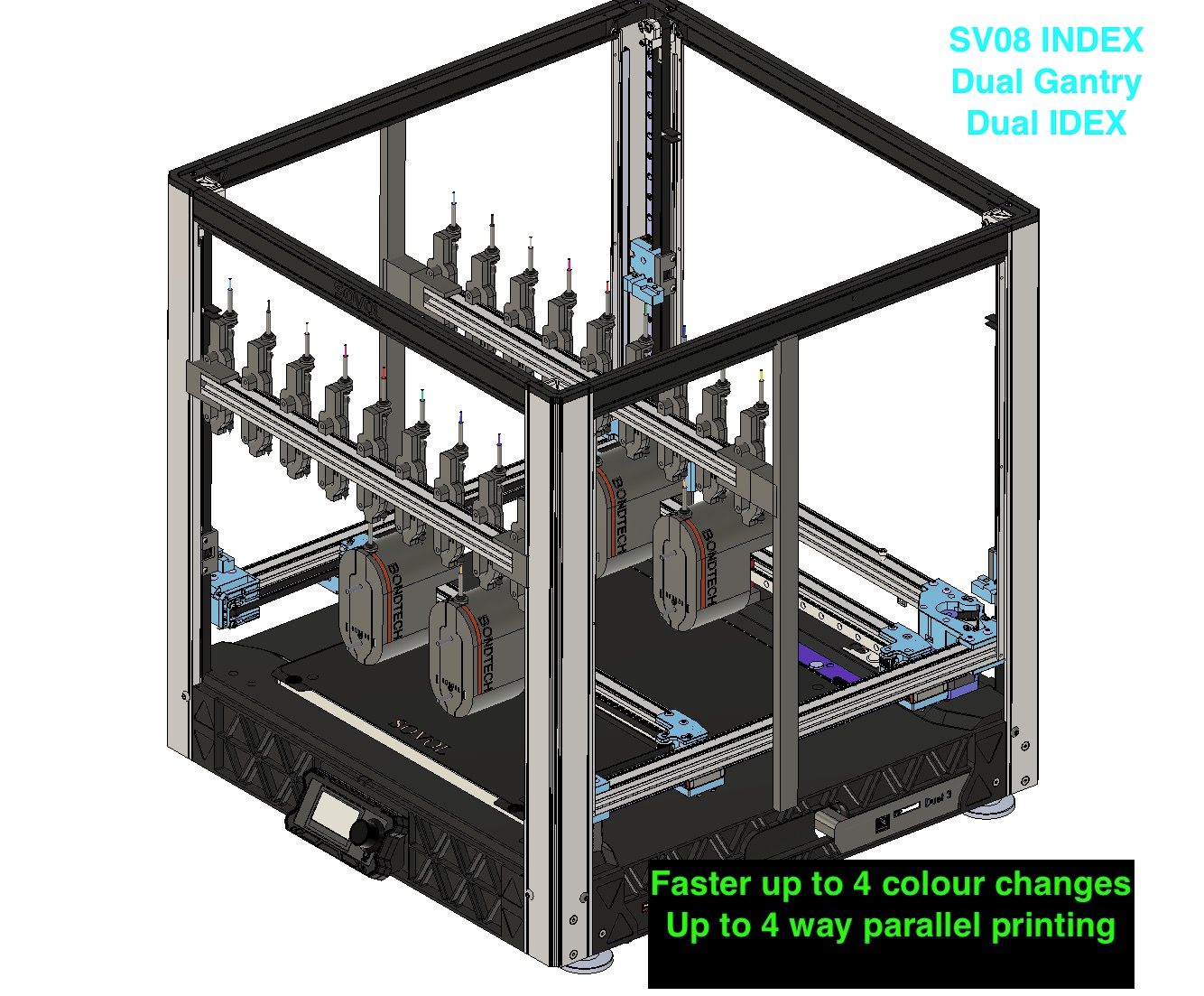

Double Gantry SV08 - with 9 way INDX on each gantry - for parallel tool changes and parallel printing

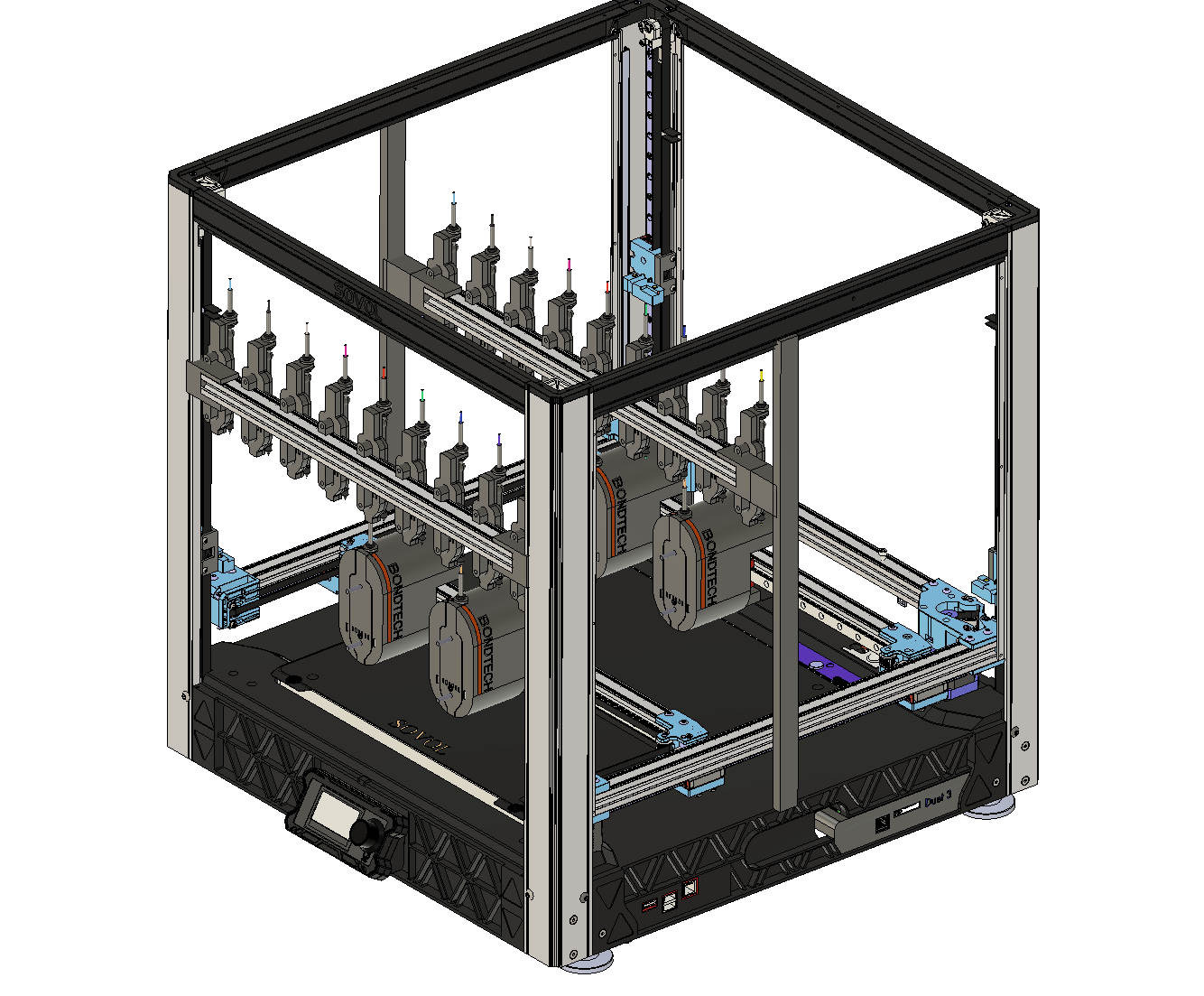

Double IDEX version ultimate parallel printing / multi colour solution

-

@dwuk3d I played around with multicolor prints, but they all looked like (R)designed by Toys'R'us.

It was hard to find decent colors and mixing hotends where a fail, too. -

@o_lampe thanks for all of your input on my project.

I've not tried any colour mixing - but agree that it would be good if they come up with a really good way of doing full colour printing without needing masses of different pre-coloured filaments.

The ink injection method recently featured by teaching tech looks like it has some potential - but I was put off trying it by the slightly washed out look, and high postage costs quoted for the prototype.

I've tried a few different non mixing methods such as Prusa MMU2, Mosaic Palette and IDEX plus combinations- but didn't really have anything I wanted to print until I decided to start doing ship modelling, plus when Bambulab finally came out with a reliable solution that can produce some surprisingly detailed results

- lots of stuff about my multi colour printing stuff here if anyone is interested https://forum.bambulab.com/t/cruise-ship-print/5122

The multi colour challenge I am trying to address is print time - as even tool changers are quite slow when you have 1000s of colour changes in a model - especially when the printing and tool changing are single threaded.

I'm also though trying to get the print time of big objects single or multi colour down too without needing them to be split into multiple parts.

I think massive printers like the Elegoo Orangestorm Giga would really benefit from having 4, 9 or even 16 heads.

-

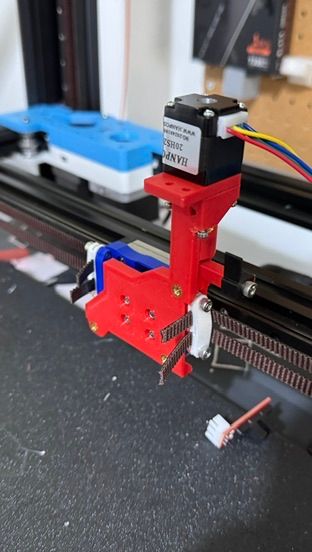

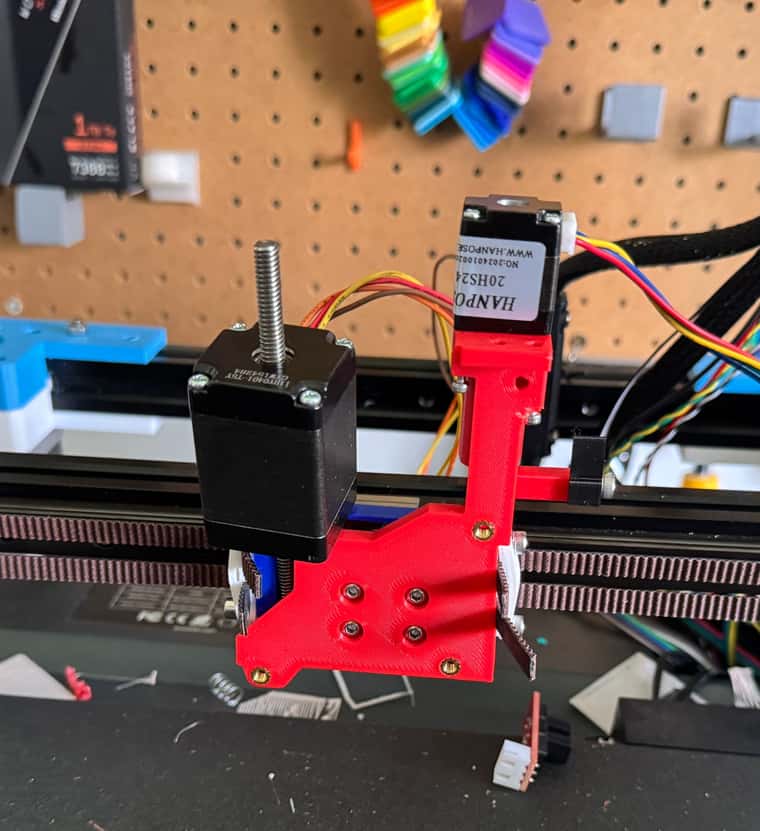

Still working on Z hoppers - taking longer than I expected to get working well.

I've moved the Z hopper off of the tool board holder onto the main extruder holder - which has the advantage that it doesn't need to be offloaded when I get to the tool changer stage. Will need two sets of wires going to each extruder - one for the Z Hopper, and one for the Tool with the 1LC board and PTFE.

Not completely sure they will be strong enough - they are not very heavy - so I could put a 2nd one on the other side - and run them in parallel - with double the current. Would also be better to be lifting from both sides - but does seem a bit excessive to have 2 motors.

Another option is to switch the 'lead bolt' from M4 0.7mm pitch to M3 0.5mm pitch - as that will increase the gearing.

Size comparison with the larger NEMA11 motor - I'm still waiting for shorter ones to be delivered.

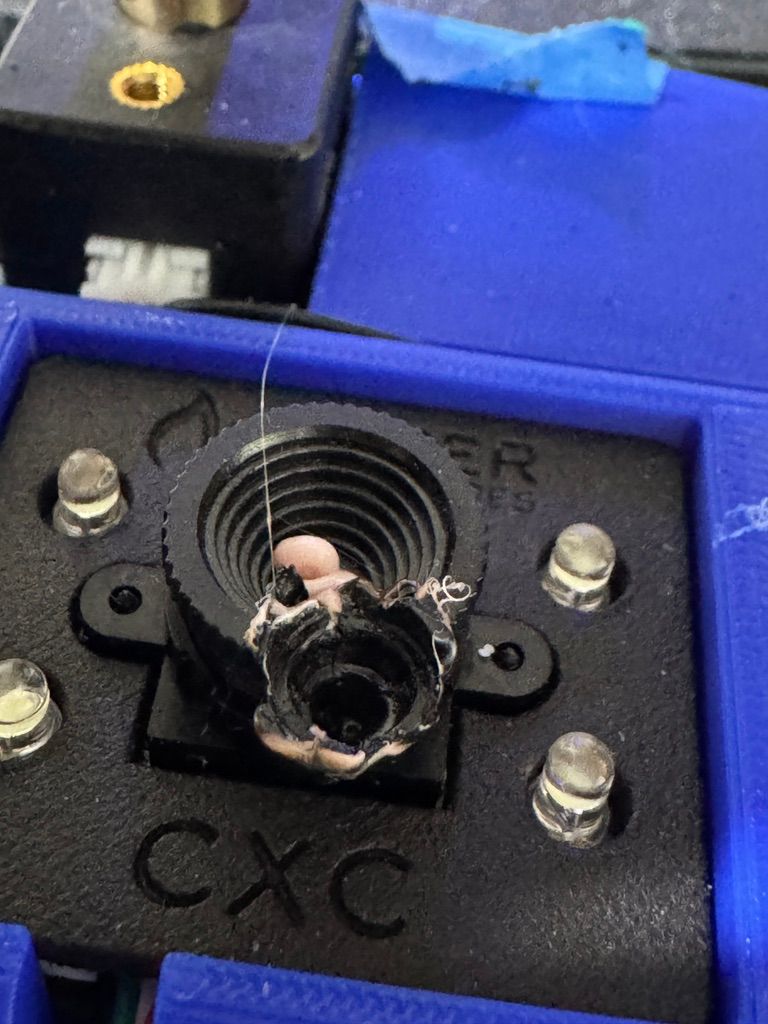

Also had a nasty accident with my alignment camera - accidentally took the gantry down to 5mm nearly over the top of it.

Luckily it still seems to workNew 3.6.0.rc1+3 looks like it solves my motion system non release issue - so should hopefully be able to proceed with further testing now on that version. Will be good to turn on head avoidance, plus will probably switch the XY gantry into M596 P0 now that the UV no longer has the servo on it.

-

Nema8 update - spent quite a lot of time yesterday (in between looking at Bambulab H2D videos) trying to get my improved Nema8 design to work.

Either the motors are getting weaker or my design has introduced more resistance - as the motors no longer seem to be able to lift the extruders despite a few changes to the 3d printed components and oiling up the linear rail.

Also managed to mess up firmware on Mini5+ and 6HC board again as I thought 3.6.0 Rc1+3 might be having some impact on Nema8 motor power -

Accidentally downgraded to 3.4.0 instead of 3.5.4 - which the Mini5 board doesn't like moving up from.

Had to manually update the Mini5+ again via SD card, and erase a reflash the firmware on the 6HC board too. Luckily I followed my own instructions on how to overcome the Mini5+ 3.4.0 upgrade issue earlier in this thread.

Same Nema8 lifting power issue with 3.5.4 though - so will move back to 3.6.0rc1+3.

I think I am probably wasting too much time on Z hoppers trying to keep the extruders as light as possible - will drop the Nema8's for now and try to over-engineer instead by trying some of the heavier more powerful motors and thicker support structures next.

Probably best to get everything working functionally and with good print quality up to at least the double IDEX phase - then worry about optimising weight as part of later speed tuning phase.

-

@dwuk3d The NEMA8s can be pretty quick (eg. 3000RPM vs ~300RPM of a NEMA17)

They also have a long leadscrew. You could place them vertically and use an 90° arm to translate speed into force (long leg /short leg ratio) The arms anchor point could be above the center of the package to reduce sideload to the linear rail. -

@o_lampe thanks i hadn't spotted that nema8's are faster.

I have been toying with the idea of doing some sort of lever based force amplification as you suggest - perhaps backed up by some sort of springs or counterbalance.

Will probably be more efficient if I set up some sort of off gantry force testing mechanism to better investigate the options.

One concern I do have with adding lever type mechanisms though is play in the extra linkages / pivot points.

Could also be an idea for a fairly interesting video comparing different linear motion options - with different motor sizes / gearing . movement translation mechanisms - to show how they stack up in terms of speed, strength and weight.

-

Created short slideshow about the Bondtech INDX vs my Parallel printer - whether it is the answer for going beyond 4 colours depends a lot on the price....

-

@dwuk3d said in Sovol SV08 Multiple Motion System Upgrade.:

Created short slideshow about the Bondtech INDX vs my Parallel printer - whether it is the answer for going beyond 4 colours depends a lot on the price....

Get enough views and they might send you one... or two!

Ian

-

@droftarts Will be interesting to see if the video gets much pick up as it is certainly a very elegant design and could completely remove the need for me to add single nozzle multiplexing on top of tool changing - plus also remove the need for lots of electronics and motors etc. for the extra tools and multiplexer

Might do a better version of the video with a few animations of the different options next.

-

@dwuk3d Yes, I really like the look of it, would be great on my Sovol SV08! Though I'm expecting it to be pricey.

Ian

-

@dwuk3d The way you mounted the rear INDX tool bar will not work, because it blocks Y-motion of both IDEX arms. You'll need overlapping motion to have full access to the center of the bed.

You could turn around the rear IDEX arm and put the INDX tool bar to the very rear of the frame....

There would also be a problem with the number of filament-holders you've places on each tool bar unless you want 4 filament holders for each extruder + the center one available for both.Should Bondtech be aware of your virtual design, they might be convinced by an animated simulaton. If not, try to start a kickstarter campaign...

Edit: as a sidenote, if you had a moving bed (in Z) instead of a flying gantry you could even print while you change tools. That would be a huge timesafer

-

@o_lampe thanks for the comments - you are correct about the Y axis issue.

My initial plan to overcome this is for both of my INDX gantries to have their own independent Z movement (a bit like the MissChanger). I was already planning to do this with the normal toolchanger option.

I could as you said reverse the 2nd gantry too - but I would like to try first having a tool gantry in a place where both Y gantries could occasionally reach. This would allow individual tools to be loaded onto any of the 4 print heads- which firstly think would look interesting in a video, but more importantly would mean the full build plate area is accessible for every filament colour.

In terms of the number of tools - I am aiming for 12 colours - so a minimum of 12 in total.

But I also want a few extra to allow some colours to be duplicated to allow them to be parallel printed.

Ultimately where I think I am aiming to get to is being able to demonstrate doing up to 12 colour prints of models faster than a single colour print of the same model on most other printers. Plus also have no waste other than a few prime towers. With the prime towers being shaped so that they can be stacked and joined to make useful objects.

The Bondtech INDX would help me particularly in keeping waste down - as before this I was expecting to have to do some single nozzle multiplexing for a few of the colours.

I've posted some stuff on the INDX discord - but Bondtech understandably seem much more interested in simpler, single head designs - Even if their prices are quite high I think I will purchase two of their extruders heads and a few Nozzles for my project in a few months,

Fitting a Duet 1lc toolboard into one of their print heads, plus a Z Lift motor outside is probably going to mess up the aesthetics of the INDX extruder toolheads quite a lot though.

I am planning to design some covers for my existing toolheads soon to make them look a bit neater - I think I might make them look a bit like the INDX!

-

@dwuk3d Where did you find the CAD files for the INDX? Annoyingly, the Discord link on https://www.bondtech.se/indx-by-bondtech/ is not valid.

Ian

-

@droftarts I have posted about the problem on the Discord and they say they will update the link with a permanent one - so hopefully it will be fixed soon.

Re the CAD - it's not to scale - I just knocked up a rough presentation of the components from a few screenshots from the video an the 3D Musketeers Podcast - so that I could play with different configurations.

-

@dwuk3d Bondtech INDX Projected costs now out - $35 per tool head. Really happy with that.

$250 for the toolhead/extruder - a bit pricey - but worth it I think for the reduced complexity the solution brings.Availability Nov25 - which is quite a while off unfortunately.

Tool change time 12 secs, with heat up only 4 secs.

Overall looks very promising.

I don't think I could justify adding 4 toolheads at that price to my system - but two I think would work quite well - one on each gantry - with the IDEX extruders on the gantries being single colour, or maybe with an MMU/Box Turtle type add-on (which wouldn't have to wait until November).

-

Might have solved the problem with my Nema8's - which seemed to work before but then stopped working.

I first thought it might be my new improved design and secondly maybe the firmware.

With the help of Physics Teacher Anthony - who reminded me that I need to lubricate the bolt - that helped a fair bit and the lifting improved - but the motor still kept stalling.

The biggest issue though was an oversight on my part re motor speed. I was just using the Dashboard controls - and I'm not sure how to control the speed.

But when I do a G1 H2 A1 F100 for example it seems to works ok - so I think I was just running the motor too fast from the dashboard in my initial tests.

If I had just connected up the end stop, and ran the proper homea.g with lower feed rates- It probably would have worked ok.

Will still investigate over engineering the lift motors a bit - but a good step forward.

-

@dwuk3d said in Sovol SV08 Multiple Motion System Upgrade.:

The biggest issue though was an oversight on my part re motor speed. I was just using the Dashboard controls - and I'm not sure how to control the speed.

You can change the feedrate in Settings > Machine-specific > Feedrate for move buttons (mm/min). However, it applies to all axis buttons, except extruder axes.

Ian