RC Low-Pass Filter for Blower Fan

-

@wilriker I'm glad it helped you to understand whats going on.

With your open question; the PWM cycle does not reset, so the remaining 1ms after the filter would be added to the next cycle.

cycle 1)

high for 5ms, low for 4mscycle 2)

low for 1ms, high for 5ms, low for 3mscycle 3)

low for 2ms, high for 5ms, low for 2msI agree with @dc42, to get the best output is to use a L-C filter.

-

Thanks @dc42 and @Iamturbo1978 for all your patience with me so far and for your very understandable explanations in this topic!

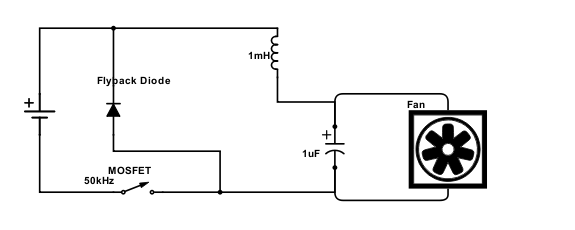

Just to make sure I understood everything correct here is a drawing of what it should look like:

Of course power-source, MOSFET and flyback diode are already on the board and I would have to add the right half of the diagram. Right?

-

Yes, that's correct.

-

@dc42 Yesterday I connected the tacho output of the fan to my Duet. Although this fan is obviously not a 4-wire PWM fan it gives me quite stable RPM readings when I set my fan to a specific speed.

You said it might be that still this would give me bogus values and I found something really strange so maybe you could tell me if that could fall under what you warned me about:

My fan according to its specs (TFD-B5015M12B) has a top speed of 4500 RPM@12V. If I run it with

M106 S1it will get fullVinwhich in my case is 13.6V so of course it will run faster. But tacho readings tell me it runs at 6500 RPM. If I then run it withM106 S0.88it should get very close to 12V and the tacho reads 5500 RPM. Interestingly there is another model of the same family that would have exactly this speed @12V but I checked my order as well as the type label on my fan to not be the faster model.Of course there is a chance that my fan is labelled wrong or that they have changed the specs since this specific fan was produced. But I just wonder would it be possible for the RPM reading to be off at around 1000 RPM and scale according to this?

-

@wilriker so this could be the H type with 5500. If you measure the current also, and it is 0.18 A instead of 0.14, then you have the other type.

-

@joergs5 To measure the current I would have to put my multimeter in series, right? Never done that so far.

-

@wilriker directly into one of the main lines of the blower. Disconnecting the line and putting the current meter at those two open contacts. Be aware to set the maximum measure value of the current meter high first (above the maximum ampere, e. g. 1 A).

If it's a Molex connection, you can turn current off, draw out one of the cables (the pin have a barb, by pressing down you can remove the cable), connect to amperemeter at both sides, turn on and then measure.

-

@joergs5 OK, thanks for confirming. As I already cut my wires to the fan I think I can quite easily insert the multimeter in this circuit using some screw terminals... I need to put ferrules on the wire ends anyway, so that's up next.

Then again it would be really strange to have the

Htype when buying theMtype that is also labelled as being theMtype (including the amperage). I would expect this on a super-cheapo Chinese fan but not from a brand. But let's wait and see.

-

@wilriker maybe labeled by someone who needs better glasses, M and H are similar

I thought it may be the H type because your 5500 measuring fits exactly to this higher model.

-

@joergs5 I know it would fit perfectly. Also about 6500 RPM @13.6V would match that quite well.

-

@phaedrux said in RC Low-Pass Filter for Blower Fan:

I was reading through this thread and was hoping someone could clarify the value of the inductor in the diagram above? I'm familiar with 1uH (micro-Henry) and 1nH (nano-Henry), but what does 1mH stand for? mili-Henry (1000uH)? for such a small amount of current?

-

@snowcrash said in RC Low-Pass Filter for Blower Fan:

I was reading through this thread and was hoping someone could clarify the value of the inductor in the diagram above? I'm familiar with 1uH (micro-Henry) and 1nH (nano-Henry), but what does 1mH stand for? mili-Henry (1000uH)? for such a small amount of current?

Yes, mH is milli-Henry.

-

Thanks @wilriker!

But that's HUGE just for a fan that draws maybe 0.15mA, no? (ok, the fan will draw more current at startup but still...). Is there some calculation behind this value?

-

@snowcrash Actually I have no clue about all this stuff. I just took those numbers for granted (even though I would also like to learn about where they come from).

But just as an update: I dropped all this anyway since connecting the signal line showed that the fan actually turns at the speed I set it to, it just feels/sounds a lot lower - but then my ears and fingers are probably the worst way of measuring fan speed in the first place.

-

@wilriker happy you got your fan working quietly (though perhaps not in the way you were hoping to achieve this

)

)Anyway, at another discussion, @dc42 insisted that an inductor-capacitor circuit is necessary for preventing a non-PWM fan from potentially being damaged while being run with a high frequency PWM signal, and just I started looking into the idea of making a little add-on module that would provide this circuitry for all 3 PWM outputs on the Duet (plus the ability to choose between 12V and 24V for each fan which is the main reason for the module).

So hopefully @dc42 or someone else familiar with this subject would chime in and clarify this point about the inductor's value.

-

@snowcrash said in RC Low-Pass Filter for Blower Fan:

Thanks @wilriker!

But that's HUGE just for a fan that draws maybe 0.15mA, no? (ok, the fan will draw more current at startup but still...). Is there some calculation behind this value?

Yes 1mH. The fan draws 0.15A (150mA), not 0.15mA.

-

Thanks for the confirmation, @dc42! But what's the calculation behind it?

-

The calculation is L = V * t/I where V is the voltage across the inductor, I is the maximum ripple current current you want to allow, and t is the time involved. Or, turning it around, I = V * t/L. If we take the case of a 24V fan running at 50% PWM and 50kHz PWM frequency, then for L=1mH and 12V across the fan, we have I = 12V * 10us/1mh = 120mA. This is around the same as the fan current, so a capacitor is needed after the inductor to reduce the ripple current in the fan. For the capacitor, C=I*t/V where V is the allowed peak ripple voltage. So V=I * t/C and 1uF will give 120mA * 10us/1uF = 1.2V. This is 10% of the 12V average voltage at 50% PWM, so it is likely to be low enough.

-

I recently added a Berd air pump for cooling the part, and I noticed that increasing the PWM frequency increased the efficiency: for the same PWM ratio, the higher was the frequency, the higher was the rotation speed. I went up to 100kHz.

Is it normal? Could such low -pass filter improve things?

-

That doesn't necessarily mean that the efficiency was increased. The increased rotation speed may have been caused by a EMI suppression capacitor within the motor having a smoothing effect.