Stop Thermal Transfer from Bed to Frame

-

I've build a large delta with a 300mm build plate made from 6mm cast aluminium and 500W mains silicone heater attached to the bottom and the BuildTak Flexplate system on the top.

My first attempt to mount the plate to the frame I used aluminium spacers secured to the bed with metal screws, which were very accurate and resulted in great results for levelling and calibration. However the aluminium standoffs were also great for thermal transfer and the heater ended up heating the whole lower frame. Which is not good.

So I've tried replacing the aluminium spacers with nylon spacers and nylon screws. While these are great for stopping the thermal transfer to the frame they are not so good for accuracy and I don't get as good results for levelling and calibration.

I don't really want to try printed spacers as I'd probably get similar results to the nylon spacers. Does anyone have any suggestions on a good accurate way of mounting my bed to the frame.

-

what about ceramic spacers?

-

@veti oh now there is an idea. I'll see if I can find some. Thanks.

-

@richardmckenna or PTFE Spacers and def use Stainless screws works well for me

-

@richardmckenna I used a sheet of semi rigid insulation under mine. It's some sort of fibrous material sandwiched between layers of glass fibre. Can't remember the name but it's of a type used with under floor heating. IIRC it was about 6mm thick and it was cheap as chips so I used 2 layers. Insulating the entire aluminium plate in this manner has the advantage of reducing all thermal loss, not just to the frame, so warm up time is accelerated and it reduces energy consumption if that is of any importance to you. The downside is that it takes forever to cool down - not a problem for me because I use a removable glass build surface.

-

@deckingman yeah I've looked at so many different types of insulation. If you do ever remember the name, I'll give it a try.

I ended up settling on 10mm thick sheet of cork stuck to the underside of the heater with aluminium tape on the heater side to help reflect it up. Seems to do the job quite well as since using the nylon spacers I hardly see any increase in temperature under the bed.

Unfortunately the nylon is no where near as accurate as the aluminium spacers, but the aluminium spacers just provide a direct route for the heat of the 6mm plate to transfer straight into the frame it's attached to.

-

Why do you care about heat trasnfer to the frame? Just use the aluminum spacers and be done with it. If you're really that concerned then put a neoprene washer between the spacer and the bed.

-

@surgikill because it heats up all the electronics under the bed and it's certainly a waste of energy heating up the whole bottom section of the frame rather than just the bed plate. It's like turning your oven on and leaving the door open.

Thanks for the Neoprene suggestion though. Other mounting ideas was exactly what I was asking for in the op

-

I've been happy with stainless spacers and fasteners. Stainless steel has roughly 1/4th of the thermal conductivity of aluminum.

You can get ceramic spacers but their length tolerance is very loose and I was worried that they would bend the bed out of shape. If you are willing to lap ceramic spacers to the same length it could be an improvement. I would probably always use stainless fasteners, but nylon plus ceramic might be rigid enough.

I also purchased an insulated heater from Keenovo and shaped the bed to reduce heat transfer:

-

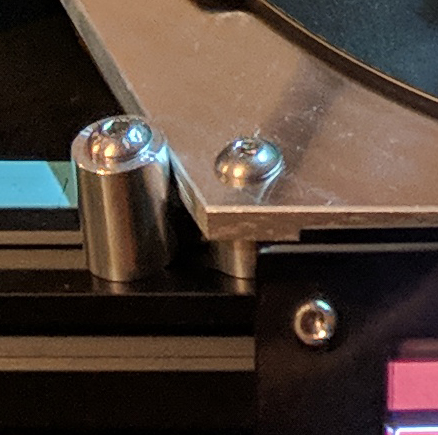

My plate is mounted using these:

No issues with excessive heat transfer to the frame.

-

@richardmckenna Well you can use the nylon and settle for sub par prints, or just suck up the extra energy cost and go with the aluminum spacers. How hot does the frame get?

-

For each mount point, you could mount a block of ptfe (teflon) to your extrusion using one scres, and then in an offset hole, with a different screw, mount the bed to it. That would thermally insulate the frame from the bed.

-

@surgikill I don’t think they are my only two options given some of the suggestions from other people here. I don’t quite understand why you are being so negative about me wanting to improve the performance of my bed and stopping heat where it shouldn’t be.

After an hour or so it is pretty much the same temperature as the bed.

I think I’m gonna try the stainless steel suggestion a fraction of the thermal conductivity and hopefully nice and accurate.

-

@blt3dp I like that idea I remember seeing some thick sheets of PFTE on eBay months ago. I will have a look. Thanks.

-

Just asking ... why is the idea of printed parts so bad in terms of accuracy?

-

@richardmckenna You're still going to get transfer if you are using metal screws. Seeing as the bed is aluminum, you might want to put a piece of steel or a magnet on the top side of the bed. Then you can use a magnet pressed into a printed piece underneath the bed and there will be 0 metal pieces connecting the bed to the frame. Personally I wouldn't worry about it unless it is negatively affecting your printer. Just make sure there is some airflow over your electronics and it will be fine.

-

I use teflon blocks with slightly undersized holes for the leveling screws. The holes grip the screws tightly and prevent them from wobbling, and the teflon plus steel screws minimizes heat transfer, and teflon doesn't mind the heat at all.

Here's one of the leveling screws on a bed-flinger printer (SoM) I recently converted to a kinematic bed mount.

I don't insulate the underside of the bed because I close the printer to print ABS. Any heat "lost" from the underside of the bed warms the enclosure. Electronics are mounted below and outside of the enclosure.

-

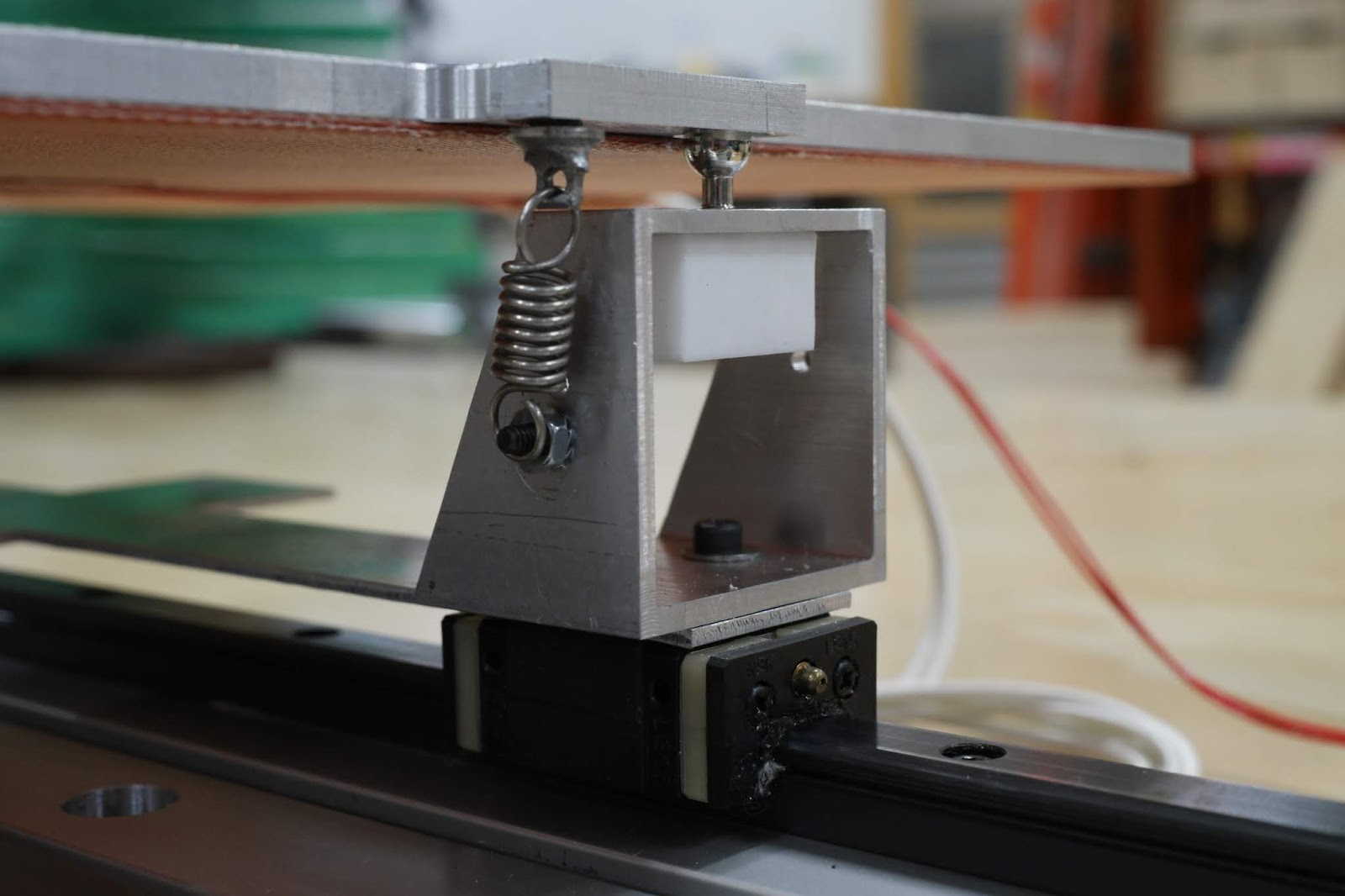

@richardmckenna

I have had the same issue my printer is 300mm x 600mm also with an aluminum bed. I had exactly the same issue of heat transfer to the aluminum profile extrusion frame. I found some round garolite rod about 25mm long 15mm diameter. (you can get various sizes from McMaster Carr althought there are other suppliers that are cheaper. I drilled the rod and inserted Heli Coils in both ends. For the end that goes to the profile aluminum I used the profile nut with a set screw of the proper size. I threaded the Garolite rod onto the set screw and tightened the just bolted the cast aluminum plate to the other end of the garolite. There is absolutely no heat transfer. Make sure that the set screw and bolt do not touch as this will defeat the purpose. -

Here is an image of the setup that I used for the garolite

https://1drv.ms/u/s!ArsUUgUVyLkdhq02CHFbp6Ctv00auw -

As you guys know, I only got my grade 10 but my thinking thoughts are saying that if the heat transfers to the frame then could it be possible for the frame to experience thermal expansion on some level or another and then obviously it could be for to say that the frame might flex or mess with the calibration?