Yet another cast aluminum plate topic...

-

@wyvern said in Yet another cast aluminum plate topic...:

@tletourneau

Dat thicc boiIs that 1/2 inch?

Naw, it's only 3/8". When I started to think about a 500x500mm piece I figured that about 9.5mm thick should be rigid enough for a 3 point mount.

-

@tletourneau

Crazy, my 1/4 300x300 should be here tomorrow, I just did 12mm Z rod/motor upgrade and .9 extruder upgrade, took the wimpy 8mm bars and reinforced some of the frame.Been a busy last few days.

Since my platform is only ACM I need to go the 4 point route to prevent platform bow, but I can always add some 2020 on the underside if it clears the Z axis drive-train.

Putting PEI on top, never used it, but I finally am getting good results with glass, I found some magic hairspray!

-

@wyvern I stuck with the 8mm lead screw but changed it to a single start 2mm lead from a four start 8mm lead which helped prevent bed drop, I am also using derlin anti-backlash nuts. I already had 12mm linear guide rods on the Z axis so I changed the bearings on them to a longer LMF12 to help control wobble which seemed to help. I figured that if I have issues I can always change the lead screws to 12mm/2mm but that would require me rebuilding the plate they, and the linear rods and bed, mount to so I thought I would try this first. If I have to change the mounting plates I'll likely add a Duex5 and go with three Z motors to enhance the auto bed leveling.

-

I have 4 start leads but I also have 2:1 gearing, so I'm hoping the extra 3 pounds won't matter, I only have one larger .9 stepper

What has helped tremendously as far as bed drop is the use of anti-backlash nuts, they have a little pre-load and pushing down on the platform doesn't seem to make the axis go down.

I mostly am doing the bed upgrade so I do not have to rely on glass or auto-leveling, the less components and configuration I need, the better.

-

For your mesh grid, there's less than 0.5mm of warp measured, that is the difference in values from the high corners (1.222mm and 1.162mm and the centre at 0.739mm makes for a n average difference of 0.453mm.) This is really difficult to see with the naked eye, and the levelling report will exaggerate this.

First things first, I'd check with a machinist straight edge that this warp actually exists. Measuring corner to corner, and assuming that this is accurate; you should see a very nearly straight measurement one way, and a slight gap in the center the other way.

If indeed the plate is warped that way, you will want to see if this is from it being mounted down to the bed frame. It doesn't appear that it should be, but it's worth investigating. It may be that your machined flat plate has somehow become warped, perhaps in shipping, and maybe as an effect of the bed heater. 3/8" thick should be capable of maintaining flatness over that size, and your 3 point mount seems reasonable. Is it possible that this was machined to one side good, and you put the heater on the guaranteed flat side? It may be possible to have a local machine shop mill it flat, shouldn't be too unreasonably expensive, though it shouldn't need to be done for a piece that you bought specifically to be flat.

-

@tletourneau A 3/8" cast plate will not have warped in shipping or any other way short of driving a fork lift over it, and if that had happened, it would be obvious from damage to the plate.

It looks to me like your Y axis guide rails are skewed in the YZ plane.

-

@gtj0 Care to share what your mounting system looks like?

-

@mrehorstdmd said in Yet another cast aluminum plate topic...:

@tletourneau A 3/8" cast plate will not have warped in shipping or any other way short of driving a fork lift over it, and if that had happened, it would be obvious from damage to the plate.

It looks to me like your Y axis guide rails are skewed in the YZ plane.

LOL.

Yeah, I had to step away from the keyboard for a bit before I could finish.

If the plate is not warped, as verified by the machinist's straight edge, then what's warped is your print head movement, in which case you either want to fix that, or keep/use the mesh compensation to keep your prints flat relative to the bed. Usually if there is a sag in the rails, you'll see what looks like a hump in the center, instead of a dish like this. It doesn't appear to be in just the X or Y axis, but as a combination of both, almost exactly at 45 degrees.

This could be a misalignment of the 2 Y linear rails, introducing a twist in the gantry movement. Like I said earlier, the amount is small, less than 0.5mm. (Well, maybe the misalignment is more like 0.6mm at the one end.)

-

I use printed alignment tools for all linear rails just for this reason.

-

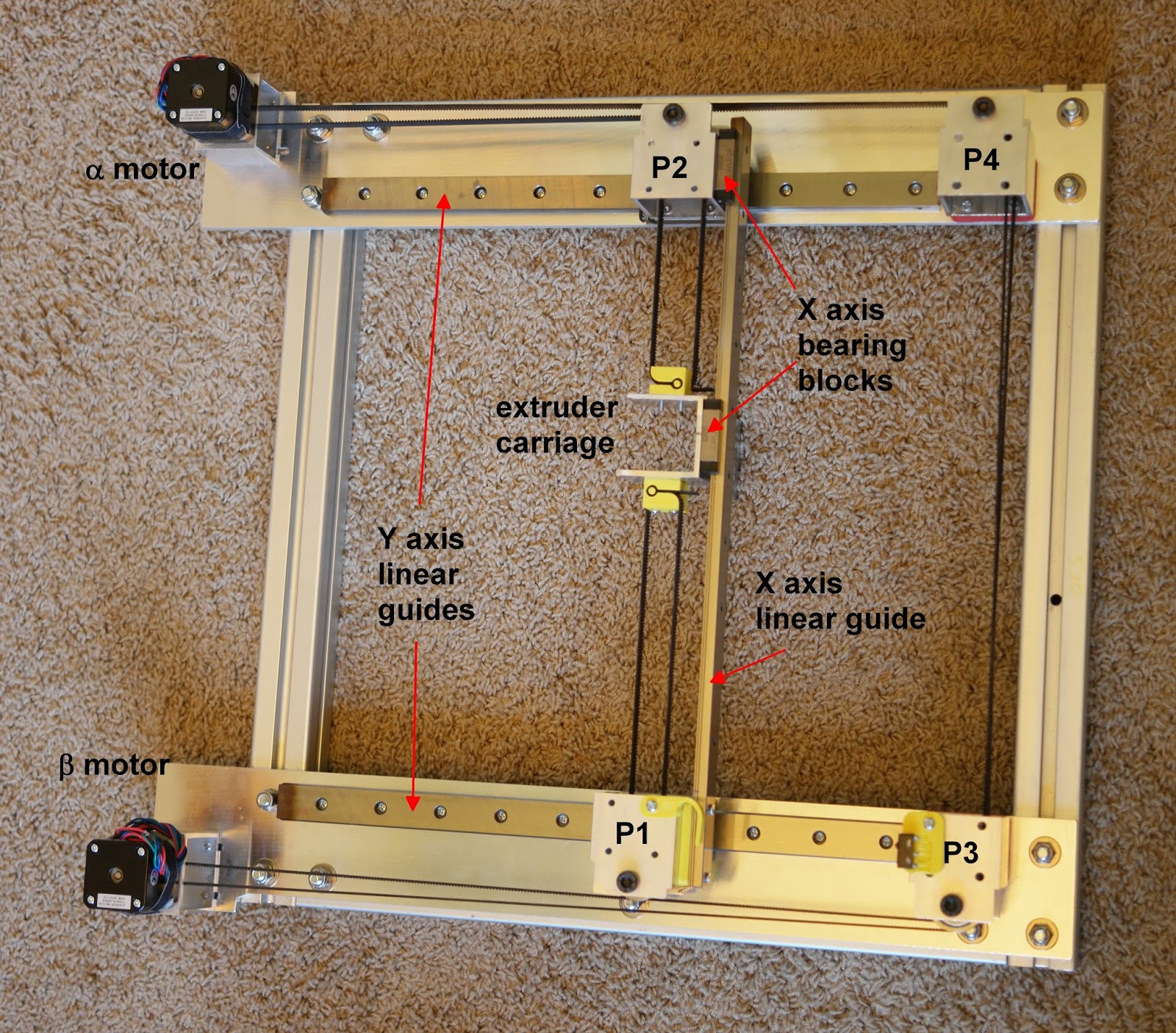

I mounted the Y axis rails on 1/4" MIC6 plates bolted to a 40mm square t-slot frame. That whole assembly then bolted into the printer's frame:

My original intention with this was to make a couple different height printer frames into which I could just drop this assembly. I didn't end up doing that, but it does seem to keep the rails parallel to each other.

-

@supraguy I'll get a machinist straight edge and check the plate, some of it could be in the allowed flatness as ATP-5 is has an allowed variance of +/- 0.127mm. The bed is not rigidly attached to the frame, I used a variation of the kinematic mount so the bed rests on three ball head screws and springs are used to ensure the bed remains stable. I did use alignment blocks when I installed the linear rails. However when I used a square to check the upper frame it appeared to be very slightly out of square. So I think the overall frame may be slightly out of square, I may take it apart and reassemble it using the square to validate this time and see if that helps.

-

Got mine in!

It ended up being straight forward.

It's only 300W but I like that it warms slowly as to evenly heat for the first layer and there is less possibility for overshoot.

Literally the first print so I'm not sure how well the PEI will stick- I didn't realise when I ordered it, it was so thin, less than a mm- those are not bubbles, it is where I squeegeed the water out.

The SSR came with a chunky heat sink, with this low of power is it even necessary?

-

@wyvern I use 0.7mm thick PEI and it lasts for years. It's very tough stuff.

-

Cool.

The test block popped off at 45C no problem, almost like glass with hairspray.

I lost 10mm Z build volume 390vs 400, I could shim the bearings even more, but I'ts not often I build that high anyway.

Next step is to route the wires so they are clean and out of the way- cable chain might be nice.

-

@wyvern said in Yet another cast aluminum plate topic...:

Got mine in!

It ended up being straight forward.

It's only 300W but I like that it warms slowly as to evenly heat for the first layer and there is less possibility for overshoot.

Literally the first print so I'm not sure how well the PEI will stick- I didn't realise when I ordered it, it was so thin, less than a mm- those are not bubbles, it is where I squeegeed the water out.

The SSR came with a chunky heat sink, with this low of power is it even necessary?

I am running a 1000 watt heater with my SSR, measured temp on the back of the SSR without a heatsink was around 35-40C which I think is reasonable so I am not going to install the big heatsink. 1000 watts at 120v is 8.333 amps, well under the 20 amp rating of the SSR.

-

Is there a possibility to set max bed temperature?

-

@taconite said in Yet another cast aluminum plate topic...:

Is there a possibility to set max bed temperature?

It should be in your config.g file already, it'll be under ; Heaters and look something like this:

M143 H0 S120 ; Set temperature limit for heater 0 to 120C M143 H1 S280 ; Set temperature limit for heater 1 to 280CH0 is my bed heater and H1 is my hot end.

I also use a 184C thermal fuse for redundancy.

-

Yeah, that is a concern of mine, there is always power available to the bed should the SSR short closed. A short circuit shouldn't be an issue since it's fused.

-

@wyvern Something like this: https://www.be-electronics.com/product_p/ecg8149.htm

-