Yet another cast aluminum plate topic...

-

@tletourneau A 3/8" cast plate will not have warped in shipping or any other way short of driving a fork lift over it, and if that had happened, it would be obvious from damage to the plate.

It looks to me like your Y axis guide rails are skewed in the YZ plane.

-

@gtj0 Care to share what your mounting system looks like?

-

@mrehorstdmd said in Yet another cast aluminum plate topic...:

@tletourneau A 3/8" cast plate will not have warped in shipping or any other way short of driving a fork lift over it, and if that had happened, it would be obvious from damage to the plate.

It looks to me like your Y axis guide rails are skewed in the YZ plane.

LOL.

Yeah, I had to step away from the keyboard for a bit before I could finish.

If the plate is not warped, as verified by the machinist's straight edge, then what's warped is your print head movement, in which case you either want to fix that, or keep/use the mesh compensation to keep your prints flat relative to the bed. Usually if there is a sag in the rails, you'll see what looks like a hump in the center, instead of a dish like this. It doesn't appear to be in just the X or Y axis, but as a combination of both, almost exactly at 45 degrees.

This could be a misalignment of the 2 Y linear rails, introducing a twist in the gantry movement. Like I said earlier, the amount is small, less than 0.5mm. (Well, maybe the misalignment is more like 0.6mm at the one end.)

-

I use printed alignment tools for all linear rails just for this reason.

-

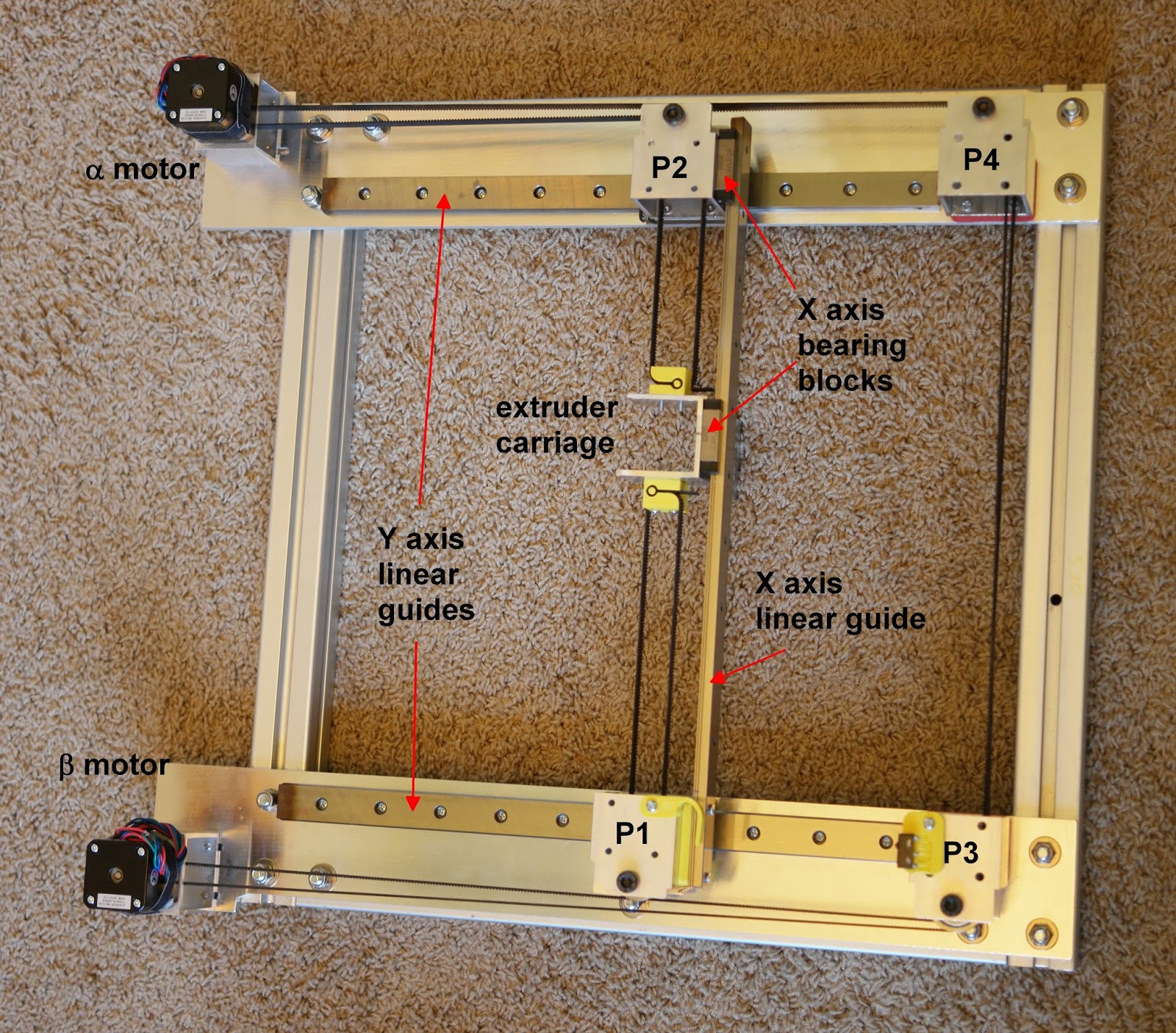

I mounted the Y axis rails on 1/4" MIC6 plates bolted to a 40mm square t-slot frame. That whole assembly then bolted into the printer's frame:

My original intention with this was to make a couple different height printer frames into which I could just drop this assembly. I didn't end up doing that, but it does seem to keep the rails parallel to each other.

-

@supraguy I'll get a machinist straight edge and check the plate, some of it could be in the allowed flatness as ATP-5 is has an allowed variance of +/- 0.127mm. The bed is not rigidly attached to the frame, I used a variation of the kinematic mount so the bed rests on three ball head screws and springs are used to ensure the bed remains stable. I did use alignment blocks when I installed the linear rails. However when I used a square to check the upper frame it appeared to be very slightly out of square. So I think the overall frame may be slightly out of square, I may take it apart and reassemble it using the square to validate this time and see if that helps.

-

Got mine in!

It ended up being straight forward.

It's only 300W but I like that it warms slowly as to evenly heat for the first layer and there is less possibility for overshoot.

Literally the first print so I'm not sure how well the PEI will stick- I didn't realise when I ordered it, it was so thin, less than a mm- those are not bubbles, it is where I squeegeed the water out.

The SSR came with a chunky heat sink, with this low of power is it even necessary?

-

@wyvern I use 0.7mm thick PEI and it lasts for years. It's very tough stuff.

-

Cool.

The test block popped off at 45C no problem, almost like glass with hairspray.

I lost 10mm Z build volume 390vs 400, I could shim the bearings even more, but I'ts not often I build that high anyway.

Next step is to route the wires so they are clean and out of the way- cable chain might be nice.

-

@wyvern said in Yet another cast aluminum plate topic...:

Got mine in!

It ended up being straight forward.

It's only 300W but I like that it warms slowly as to evenly heat for the first layer and there is less possibility for overshoot.

Literally the first print so I'm not sure how well the PEI will stick- I didn't realise when I ordered it, it was so thin, less than a mm- those are not bubbles, it is where I squeegeed the water out.

The SSR came with a chunky heat sink, with this low of power is it even necessary?

I am running a 1000 watt heater with my SSR, measured temp on the back of the SSR without a heatsink was around 35-40C which I think is reasonable so I am not going to install the big heatsink. 1000 watts at 120v is 8.333 amps, well under the 20 amp rating of the SSR.

-

Is there a possibility to set max bed temperature?

-

@taconite said in Yet another cast aluminum plate topic...:

Is there a possibility to set max bed temperature?

It should be in your config.g file already, it'll be under ; Heaters and look something like this:

M143 H0 S120 ; Set temperature limit for heater 0 to 120C M143 H1 S280 ; Set temperature limit for heater 1 to 280CH0 is my bed heater and H1 is my hot end.

I also use a 184C thermal fuse for redundancy.

-

Yeah, that is a concern of mine, there is always power available to the bed should the SSR short closed. A short circuit shouldn't be an issue since it's fused.

-

@wyvern Something like this: https://www.be-electronics.com/product_p/ecg8149.htm

-

-

Would taped to the mat suffice? I will probably source a lower temp one around 150C as I don't intend on heating it past 110C or so.

-

@wyvern A blob of RTV silicone is a good way to stick it on.

-

Never thought of that! I'm an auto/machine technician so I have tons of that crap.

-

Hmm, before I start working on cad files for making my removable mechanical bed probe.

Is it possible to say, have the machine home X and Y and ignore Z and wait until you say, click the Z end-stop to start probing?

Does the probe always need to do a Z- offset on startup?I really haven't dabbled in bed probing, only used the built in code on my Anycubic delta (and that thing is wonky)

I plan on using probing for a bed level map, as the level should almost never change.

-

@wyvern said in Yet another cast aluminum plate topic...:

wait until you say, click the Z end-stop to start probing?

You could add a M291 pop-up prompt with a blocking wait until you click ok or cancel.

@wyvern said in Yet another cast aluminum plate topic...:

Does the probe always need to do a Z- offset on startup?

I don't understand what this means.