CoreXY - X-Axis Vibration Issues

-

also check that there is no twisting of the belts on direction change.

i.e make a gcode file with rapid 5mm movement back and forth at high speed and look at the belts during this. -

@deckingman Thanks, I will try and add some more info.

The belt arrangment is stacked and looks almost exactly like e3d's tool changer machine. I have included a short video from the other night. The noise isn't an issue in that video as it doesn't occur until it's moving a little faster.I have tried increasing and decreasing belt tension to no avail. Could it possibly be motor setting related?

-

create a gcode that can replicate the noise.

Then while its making the noise try to narrow down the location.

the frame looks like it could be resonating at certain frequencies. -

@veti It definitely sounds like it's coming from the x-axis carriage. I am going to give tuning the acceleration and max speed a go. Any suggestions of a good starting point?

-

Is the X axis linear guide a "preload" type? How is the X axis rail mounted so that it can slide? If it is free to move, it may be free to rattle, depending on how it's mounted.

-

how stable is the x carriage? Push the nozzle in different directions and see if there is play.

Also check the fans. I had some fans that created a rattle caused by the blades moving inside the fan at higher speeds. and banging on the casing -

@mrehorstdmd yes it’s preloaded. It is secured to a cross-brace by a few cap head screws.

-

Hi,

It's hard to tell from the video but are the belts on either side of the X slide parallel to the slide?

Frederick

-

@fcwilt as best as I can get them. I’m going to try re-aligning everything again. Annoying, but I am going to wait for some new gates pulleys from E3D to make sure everything is the best it can be.

Or maybe I will re-align it all first? I can’t decide. Either way I will keep trying.

-

Well I think it has to be something about your build.

I built a D-Bot CoreXY printer and it has no binding issues at all. BUT it uses wheels-on-extrusion tech, not slides.

My next CoreXY will try slides.

Frederick

-

@fcwilt my thoughts exactly hence the slight rebuild. At least I can do it by only removing the top plate!

-

@syko_symatic just press f5 untill it loads ...

-

@fcwilt Having a think about it, the E3D design uses the fabtotum style corexy which places the belts in front and behind the x carriage. It is technically possible to move them both behind the carriage, would that help?

-

@syko_symatic said in CoreXY - X-Axis Vibration Issues:

@fcwilt Having a think about it, the E3D design uses the fabtotum style corexy which places the belts in front and behind the x carriage. It is technically possible to move them both behind the carriage, would that help?

It might. But moving both belts to the centre line of the X carriage would be better - as per my post of 12th Feb above.

-

@deckingman Without a massive change to the placement of pulleys and such it's unfortunately not possible.

-

I don't think belt attachment at the extruder carriage is an issue. My printer uses linear guides in all axes and the belts are offset both vertically and laterally and there's no problem with vibration or noise.

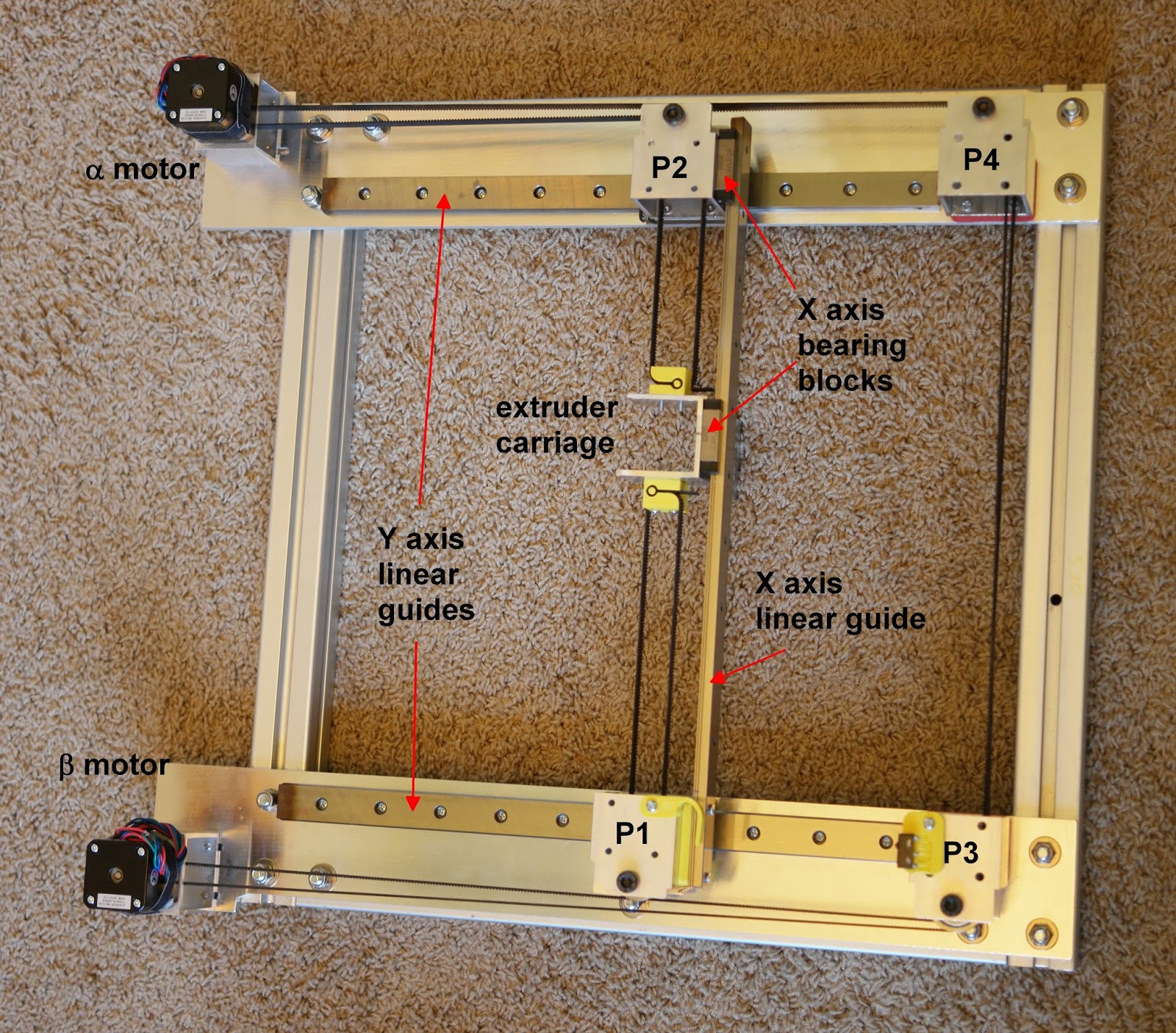

Here are the belt clamps on the extruder carriage in my printer (the carriage has changed a lot since this photo but the belt attachment is the same).

If your X axis rail is able to move that means it isn't clamped securely- the hole it sits in has to be bigger than the rail or the rail couldn't move. That means it can flop around inside the hole which will cause rattling/buzzing/vibrating. I'd probably start by clamping the rail securely there and see if the noise goes away.

Here's my printer's XY stage. The X axis rail is bolted to the Y axis bearing block at P1, and it's attached to the other Y axis bearing block using an extra X axis bearing block at P2. The X axis rail can move in the X direction when the printer heats up and the Y axis rails move apart, but it can't move in any other direction. There's no noise or vibration, and the mechanism never binds.

-

@syko_symatic said in CoreXY - X-Axis Vibration Issues:

@fcwilt Having a think about it, the E3D design uses the fabtotum style corexy which places the belts in front and behind the x carriage. It is technically possible to move them both behind the carriage, would that help?

My D-Bot has belts in front and behind. It seems to be working just fine.

Have you visited this site, it has some good information:

https://drmrehorst.blogspot.com/2018/08/corexy-mechanism-layout-and-belt.html

-

Syko@, have you solved the problem?

I have a similar issue with a new Hypercube Evolution. It seems to happen at a certain speed ~F4000. First I thought it's the bearings (Misumi 8mm rods and bearings) so changed to aluminum rods and bushings that I happened to have but still the same. Hard to tell where it's coming from so ordered from Amazon a mechanic stethoscope, will see if it will help.

I also plan to remove the X rods and run the test pattern with the X carriage hanging. This may eliminate the rods as a suspect.

I think that the speed of ~F4000 hits the resonance frequency of some mechanical part. Not sure which one, but despite the occasional noise, the printer prints just great.

-

@zapta I also have a Hypercube Evolution and been fighting this issue in the past. My last suspicion is that the motors start resonating. I've looked at some of the ripples that get visible during the vibration and tried to measure the amplitude. They appear to be exactly under a full step in my case (0.2mm).

I've replaced every single thing on my printer except the motors so far. I think the CoreXY setup exaggerates the problem since the motors are basically moving not two separate axes but a single object and could be working against eachother depending on the resistance of guides. Plus, not all microsteps are equal, so... I'll be adding a gearbox or replacing them with 0.9 deg steppers.

I've looked through loads of information and, no, linear rails don't solve everything...

-

could be working against each other

@Edgars, this is an interesting observation. In CoreXY the motors moves on diagonal and guides are horizontal/vertical so if the pulses of the two motors are not in sync in horizontal/vertical movement, the head moves in tiny zigzag against the guides.

I wonder how this test will work on your machine. It moves one motor at a time, keeping the other one stationary. I am still getting a little bit of buzz on one of the diagonals. F4000 is the speed where I get the most noise on my machine. Amazon B0015DLMOO is supposed to arrive today. Will see if it will help.

; Diagonal X motor only G1 X150 Y150 F4000 G1 X250 Y250 F4000 G1 X50 Y50 F4000 G1 X250 Y250 F4000 G1 X50 Y50 F4000 ; Diagonal Y motor only G1 X150 Y150 F4000 G1 X50 Y250 F4000 G1 X250 Y50 F4000 G1 X50 Y250 F4000 G1 X250 Y50 F4000