CoreXY - X-Axis Vibration Issues

-

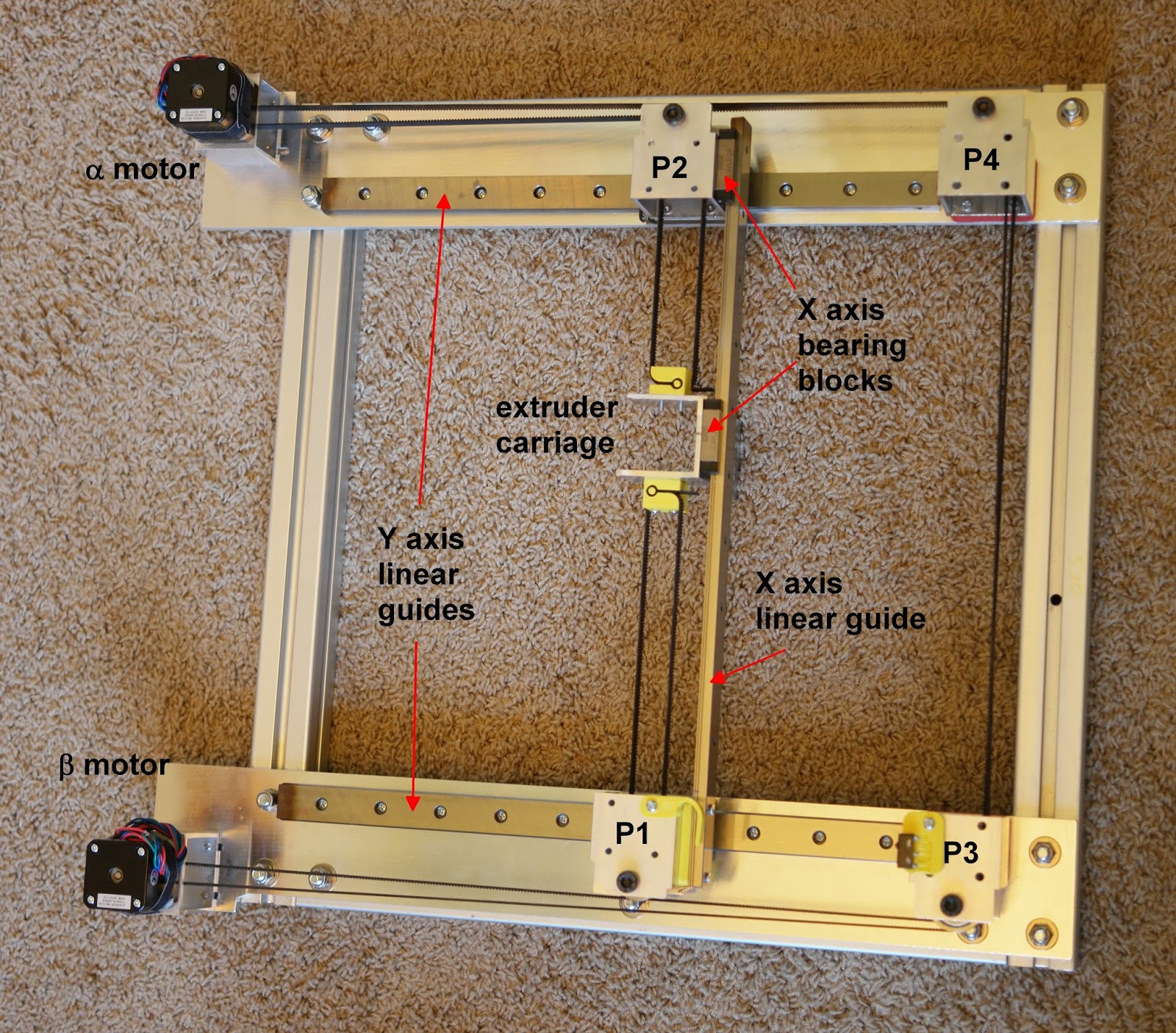

I don't think belt attachment at the extruder carriage is an issue. My printer uses linear guides in all axes and the belts are offset both vertically and laterally and there's no problem with vibration or noise.

Here are the belt clamps on the extruder carriage in my printer (the carriage has changed a lot since this photo but the belt attachment is the same).

If your X axis rail is able to move that means it isn't clamped securely- the hole it sits in has to be bigger than the rail or the rail couldn't move. That means it can flop around inside the hole which will cause rattling/buzzing/vibrating. I'd probably start by clamping the rail securely there and see if the noise goes away.

Here's my printer's XY stage. The X axis rail is bolted to the Y axis bearing block at P1, and it's attached to the other Y axis bearing block using an extra X axis bearing block at P2. The X axis rail can move in the X direction when the printer heats up and the Y axis rails move apart, but it can't move in any other direction. There's no noise or vibration, and the mechanism never binds.

-

@syko_symatic said in CoreXY - X-Axis Vibration Issues:

@fcwilt Having a think about it, the E3D design uses the fabtotum style corexy which places the belts in front and behind the x carriage. It is technically possible to move them both behind the carriage, would that help?

My D-Bot has belts in front and behind. It seems to be working just fine.

Have you visited this site, it has some good information:

https://drmrehorst.blogspot.com/2018/08/corexy-mechanism-layout-and-belt.html

-

Syko@, have you solved the problem?

I have a similar issue with a new Hypercube Evolution. It seems to happen at a certain speed ~F4000. First I thought it's the bearings (Misumi 8mm rods and bearings) so changed to aluminum rods and bushings that I happened to have but still the same. Hard to tell where it's coming from so ordered from Amazon a mechanic stethoscope, will see if it will help.

I also plan to remove the X rods and run the test pattern with the X carriage hanging. This may eliminate the rods as a suspect.

I think that the speed of ~F4000 hits the resonance frequency of some mechanical part. Not sure which one, but despite the occasional noise, the printer prints just great.

-

@zapta I also have a Hypercube Evolution and been fighting this issue in the past. My last suspicion is that the motors start resonating. I've looked at some of the ripples that get visible during the vibration and tried to measure the amplitude. They appear to be exactly under a full step in my case (0.2mm).

I've replaced every single thing on my printer except the motors so far. I think the CoreXY setup exaggerates the problem since the motors are basically moving not two separate axes but a single object and could be working against eachother depending on the resistance of guides. Plus, not all microsteps are equal, so... I'll be adding a gearbox or replacing them with 0.9 deg steppers.

I've looked through loads of information and, no, linear rails don't solve everything...

-

could be working against each other

@Edgars, this is an interesting observation. In CoreXY the motors moves on diagonal and guides are horizontal/vertical so if the pulses of the two motors are not in sync in horizontal/vertical movement, the head moves in tiny zigzag against the guides.

I wonder how this test will work on your machine. It moves one motor at a time, keeping the other one stationary. I am still getting a little bit of buzz on one of the diagonals. F4000 is the speed where I get the most noise on my machine. Amazon B0015DLMOO is supposed to arrive today. Will see if it will help.

; Diagonal X motor only G1 X150 Y150 F4000 G1 X250 Y250 F4000 G1 X50 Y50 F4000 G1 X250 Y250 F4000 G1 X50 Y50 F4000 ; Diagonal Y motor only G1 X150 Y150 F4000 G1 X50 Y250 F4000 G1 X250 Y50 F4000 G1 X50 Y250 F4000 G1 X250 Y50 F4000 -

i think this is why BLV uses 16 tooth pulleys and 0.9 Steppers on his cube.

after switching to those that as well resulting in 200steps/mm the tiny zigzags have become unnoticeable. -

@zapta said in CoreXY - X-Axis Vibration Issues:

@Edgars, this is an interesting observation. In CoreXY the motors moves on diagonal and guides are horizontal/vertical so if the pulses of the two motors are not in sync in horizontal/vertical movement, the head moves in tiny zigzag against the guides......................

It's easy to test that theory. Print a rectangular object, then orientate the same part at 45 degrees in the slicer and print it again. In the latter case, the perimeters will be printed using one motor.

-

@zapta said in CoreXY - X-Axis Vibration Issues:

@Edgars, this is an interesting observation. In CoreXY the motors moves on diagonal and guides are horizontal/vertical so if the pulses of the two motors are not in sync in horizontal/vertical movement, the head moves in tiny zigzag against the guides.

I wonder how this test will work on your machine. It moves one motor at a time, keeping the other one stationary. I am still getting a little bit of buzz on one of the diagonals. F4000 is the speed where I get the most noise on my machine. Amazon B0015DLMOO is supposed to arrive today. Will see if it will help.

I'll do it for reference as soon as I get to it (adding gearboxes to the feeder motors currently). All in all I've done A TON of tests and I can assure you that I get the resonating noise at exactly that speed. I've done a thread about this a while ago: https://forum.duet3d.com/topic/8213/ringing-at-20-70mm-s-mostly-during-acceleration-deceleration

I've improved a ton since then, but you'll see this zig-zagging in the thread above. I don't have a better explanation for it. I can hear and feel the vibration, it's definitely the motor buzzing somewhere roughly at 50-200Hz or so (haven't measured it).

@deckingman said in CoreXY - X-Axis Vibration Issues:

It's easy to test that theory. Print a rectangular object, then orientate the same part at 45 degrees in the slicer and print it again. In the latter case, the perimeters will be printed using one motor.

If the other motor is stationary or executes exactly the same acceleration steps then you'll be less likely to see how it struggles or oscillates during move to next microstep. I think it is the worst when printing circles. I'll do the tests again nevertheless, as it's all imagination and assumptions since I don't have equipment to measure any of this.

-

@veti said in CoreXY - X-Axis Vibration Issues:

i think this is why BLV uses 16 tooth pulleys and 0.9 Steppers on his cube.

That's a great pointer. Thanks. Found it on Thingiverse.

-

@zapta said in CoreXY - X-Axis Vibration Issues:

That's a great pointer. Thanks. Found it on Thingiverse.

also on this forum. https://forum.duet3d.com/topic/8874/blv-mgn-cube-3d-printer-project

-

@veti said in CoreXY - X-Axis Vibration Issues:

i think this is why BLV uses 16 tooth pulleys and 0.9 Steppers on his cube.

I just install same 0.9 stepper as the (x-y) motor of my printer and the vibrations of the (x-y) diagonal movements test are gone! I have another one on order for the (x+y) motor. It seems that 0.9deg steppers do make a difference.

-

@zapta said in CoreXY - X-Axis Vibration Issues:

I just install same 0.9 stepper as the (x-y) motor of my printer and the vibrations of the (x-y) diagonal movements test are gone! I have another one on order for the (x+y) motor. It seems that 0.9deg steppers do make a difference.

Was your printer already setup with a 24 volt power supply?

Thanks.

Frederick

-

Was your printer already setup with a 24 volt power supply?

Yes, all parts are on 24V, including heaters and fans, no buck converters and such. The only add-on is this SSR to reduce heat on the Duet https://www.auberins.com/index.php?main_page=product_info&products_id=288

-

@zapta said in CoreXY - X-Axis Vibration Issues:

Was your printer already setup with a 24 volt power supply?

Yes, all parts are on 24V, including heaters and fans, no buck converters and such. The only add-on is this SSR to reduce heat on the Duet https://www.auberins.com/index.php?main_page=product_info&products_id=288

And I just finished tidying up the wiring on my 12 volt setup making the conversion a bit more work. Sigh...

So, let's see, I need new heaters, new fans, new steppers and a new bulb for my illuminated emergency stop button...

Thanks for the info.

Frederick

-

@zapta said in CoreXY - X-Axis Vibration Issues:

I just install same 0.9 stepper as the (x-y) motor of my printer and the vibrations of the (x-y) diagonal movements test are gone! I have another one on order for the (x+y) motor. It seems that 0.9deg steppers do make a difference.

Same for me. But can anyone give an explanation as to why this solves the problem?

My current theory is that the microstepping can not hold the inbetween steps in all cases.

i.e at some steps closer to the full step the holding force is not great enough which causes the driver to move/remain at the full step resolution. causing more filament to be extruded at the full step position.edit: found this https://www.machinedesign.com/archive/microstepping-myths

-

@fcwilt said in CoreXY - X-Axis Vibration Issues:

And I just finished tidying up the wiring on my 12 volt setup making the conversion a bit more work. Sigh...

And I just tied up my wiring, which resulted in the SSR giving up smoke and dying. Apparently I connected the control input in reverse polarity.

This was an opportunity to look inside the SSR. It's built like a tank and the power Mosfet has a large chunk of silicon in it.

Connected the 12A/24V bed to the Duet directly and everything works like champ. Not sure if I want to install a new SSR. I like the current simplicity.

-

@veti said in CoreXY - X-Axis Vibration Issues:

Same for me. But can anyone give an explanation as to why this solves the problem?

My current theory is that the microstepping can not hold the inbetween steps in all cases.I think that my experiment of having vibration in a single stepper diagonal move (I as actually holding the other belt with my finger to make sure that there are no vibrations from the stationary motor) supports that this is not necessarily a result of an interaction between the two motors.

Your explanation sounds reasonable to me. Microstepping and Interpolation have their limits, especially that it is a modulation of the underlying PWM and not direct linear current source.

Another potential factor is that the 0.9 steppers are also larger (for same torque) and thus have higher mass and smoother rotation (?)

-

i found this very good analysis of microstepping https://hackaday.com/2016/08/29/how-accurate-is-microstepping-really/

-

@zapta said in CoreXY - X-Axis Vibration Issues:

Connected the 12A/24V bed to the Duet directly and everything works like champ. Not sure if I want to install a new SSR. I like the current simplicity.

12A is well within the rating of the Duet. I recommend that at regular intervals you check that the screws in the VIN and bed heater terminal blocks of the Duet are still tight, until you are sure that they are staying tight. This is because high currents can cause creep in wires. Crimping the correct ferrules on to the wire ends reduces this risk.

-

@zapta said in CoreXY - X-Axis Vibration Issues:

Connected the 12A/24V bed to the Duet directly and everything works like champ. Not sure if I want to install a new SSR. I like the current simplicity.

My heaters are all line voltage heaters (110 VAC) and thus an SSR is needed.

Frederick