Best lead screw - ball bearing mount system

-

@claustro That looks very familiar

-

@deckingman eh eh

-

I am thinking to change my setup.

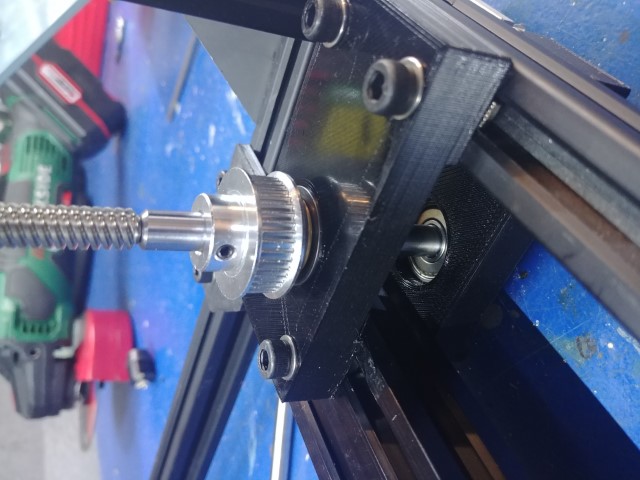

with only one bearing when I tension the belt the shaft tend to be dragged towards the centre, creating tension on the lead screw, for this reason I am making another support for another ball bearing under the previous one fixed on the other side of the vslot. The 4cm distance between the 2 bearing should improve the stiffness of the system. -

this is what I did

-

I have had issues with the z-axis due to that the 8mm hole on the pulleys are slightly oversized. Advertised 8mm, real world 8.07mm. And the lead screws tend to be slightly undersized, typically 7.9mm. This may lead to that the pulley is mounted at a slight angle causing massive z-banding. With an 8mm pitch screw it is not very visible, but with a 1.5mm pitch screw it certainly is.

The nice screw @claustro has should solve that problem. Where did you find such a screw?

My goto screw-peddler offers them with a machined 5mm end, I'm very tempted to get one of those.@sinned6915 said in Best lead screw - ball bearing mount system:

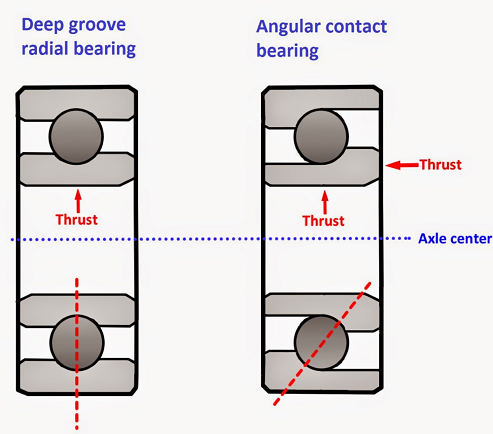

Proper design would be to use a pair of angular contact bearings that bear on a shoulder, but those are $$$

$5 a piece on ali, seems to be good quality. A bit scary with an open bearing.Edit: Typo

-

@bondus - what bearing is that? you have piqued my curiosity.

looking at my printer now, i realize that i might have left out and important bit- i used a shaft collar on there too between the pulley and the thrust bearing-

https://www.mcmaster.com/6655k54

and i think

https://www.mcmaster.com/6157k32 -

@sinned6915. Clamping shaft collar, should get a straighter clamp than with a set screw, I need to get some of those.

The bearing is a 798C, 15 degree angle bearing. Mochu has their own shop on ali, lots of specialized bearings. I have bought many bearings from them, they are good.

-

I got the best results with this solution (assuming that the Chinese friends inserting the axis exactly)

-

yes the sfu1204 are working nicely on my printer as well.

no play and very rid-git. you might even be able to use them without linear guides. -

@bondus said in Best lead screw - ball bearing mount system:

The nice screw @claustro has should solve that problem. Where did you find such a screw?

I am not a native english speaker so maybe I am l misunderstanding something.

My lead screw is a regular 2mm pitch Chinese lead screw and it is connected with a 8mm to 8 mm coupler with a 8mm shaft.

I am having quite difficult aligning perfectly the lead screws but I think that it will not affect a lot the Z if the bed is correctly fixed in X and Y ( with V slot wheels in my case).I can't understand the shaft collar and 15 degree angle bearing. What would be the advantages over thrust bearing and regular ball bearing like I did?

-

@claustro said in Best lead screw - ball bearing mount system:

I can't understand the shaft collar and 15 degree angle bearing. What would be the advantages over thrust bearing and regular ball bearing like I did?

I realize now that your picture above shows the screw and shaft, without the coupler mounted.

A shaft collar:

An angular bearing is very similar to a regular deep groove, but the surfaces the balls contact are at a slight angle. They can take axial load, in one direction, and radial load. They seem to be a specialist bearing only available with tight tolerances and a high price.

-

@claustro Came across this, Instead of an intricate belt path, I just put 4 motors under my bed, one at each corner. Works lovely because it's super strong now as well.