Help Core XY

-

Hi

I finished my corexy, I mad few prints and this is my result, who can help me to fix this kind of problem?

This is my conf:; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E415.00 ; set steps per mm

M566 X600 Y600 Z60 E600 ; Maximum jerk in mm/min

M203 X12000 Y12000 Z1200 E2500 ; set maximum speeds (mm/min)

M201 X800 Y800 Z60 E1200 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

-

Is your slicer changing your acceleration on you? The config values are pretty conservative, but the amount of ringing would indicate a very high acceleration or loose mechanics of some kind. Loose belts? Broken plastic part? Cheap stretchy belts?

-

@Phaedrux I'm using simplify 3d, I don't have special script.

From simplify I print at 70mms.

I don't know if can be the belts.I'm using 6mm belt, what do you suggest to buy?

-

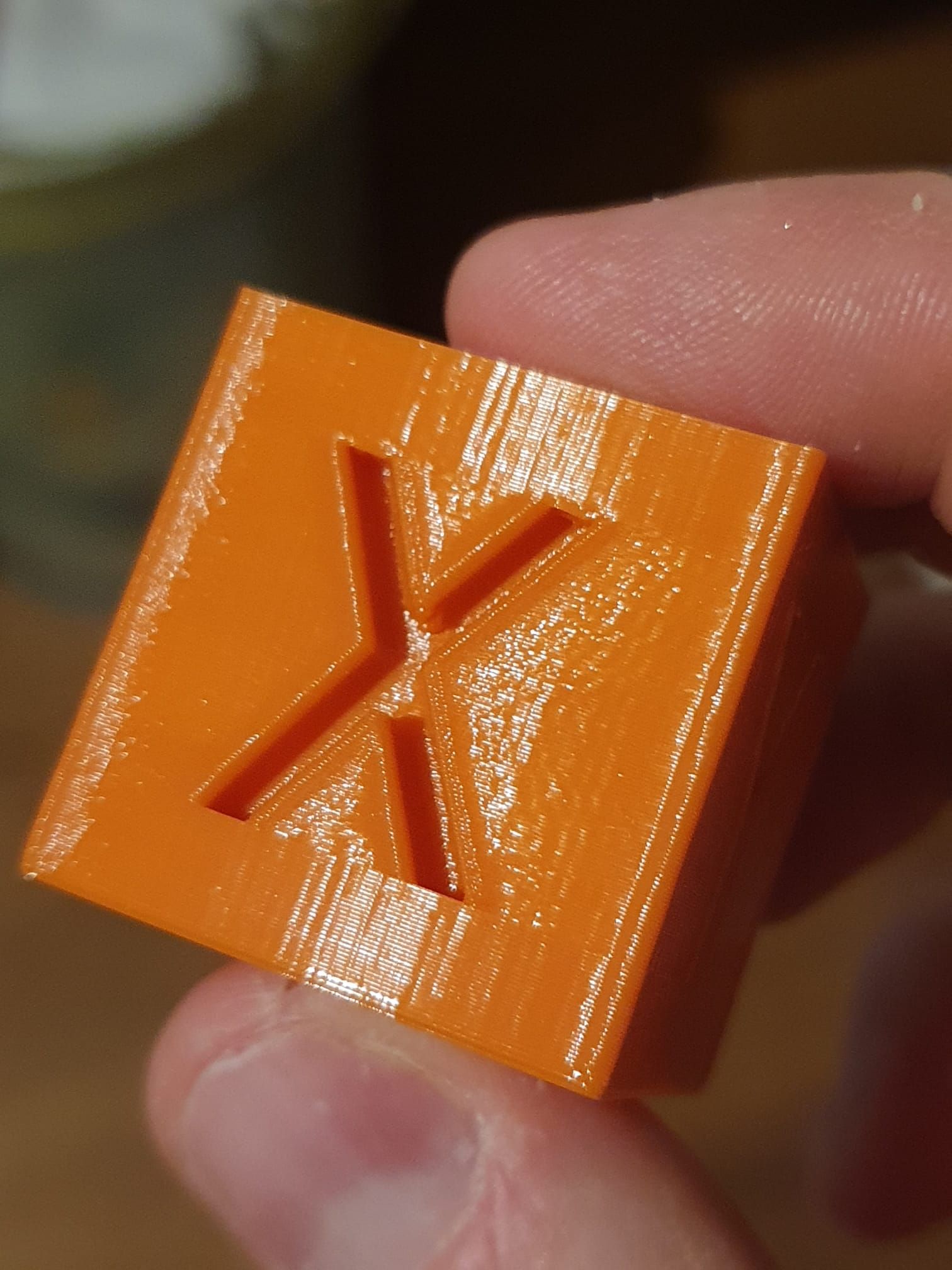

@Phaedrux this is a cube with the same configuration

-

@Phaedrux do you suggest to change the 6mm belt with 9mm?

-

@Dav 6mm belts are fine - 9mm won't cure your problems. What hot end and extrude are you using. How are they mounted? Is it Bowden or direct drive? Can you post some pictures of the printer.

-

@deckingman it's a sapphire plus printer, all mechanical parts are in metal, I changed the power supply with meanwell and motherboard with duet.

I use bowden configuration with bondtech.

At the moment the original parts are belt and e3d non original.

-

Are you able to tension the belts?

-

@Dav If you put a finger on the nozzle with the motors on and belts locked, can you move it back and forth or from left to right?

-

@Phaedrux I changed right now old belts with gates gt2 6mm,now I'm printing again same cube.

-

@deckingman no I can't

-

On the left old non original belts, on the right gt2 belts... Same result..

Do you have a profile for simplify or slic3r to test?

-

PrusaSlicer 2.2 RC config.csv

Rename it to config.ini. You'll need to change the nozzle size and extrusion width for your printer. I'm using 0.6mm nozzle.

If you disconnect the belts and move the print head around manually, does it feel smooth?

Are there any belt tensioners? Are both belts equally tensioned?

If you wiggle things around, is there anything that feels loose?

Are the belt teeth riding on toothed idlers or flat idlers? -

If this is the same printer that was causing your Z axis problems, the belt layout is wrong for corexy and the belt tension is going to vary as the extruder moves around. That can easily lead to excessive ringing and the amount of it may vary depending on where the print sits on the bed. I suggest that you fix the belt path problem first, then tackle the print quality problems that remain.

-

@mrehorstdmd I don't think the diagram from the other thread is accurate to how the sapphire plus is actually laid out. At least not from any of the reviews I've seen of it. From what I gather it's a correctly designed corexy.

-

@Phaedrux It looks like the diagram came from an review of the Sapphire Plus and Sapphire Pro printers at All3DP. If that is a diagram supplied by 2Trees, it doesn't look good...

-

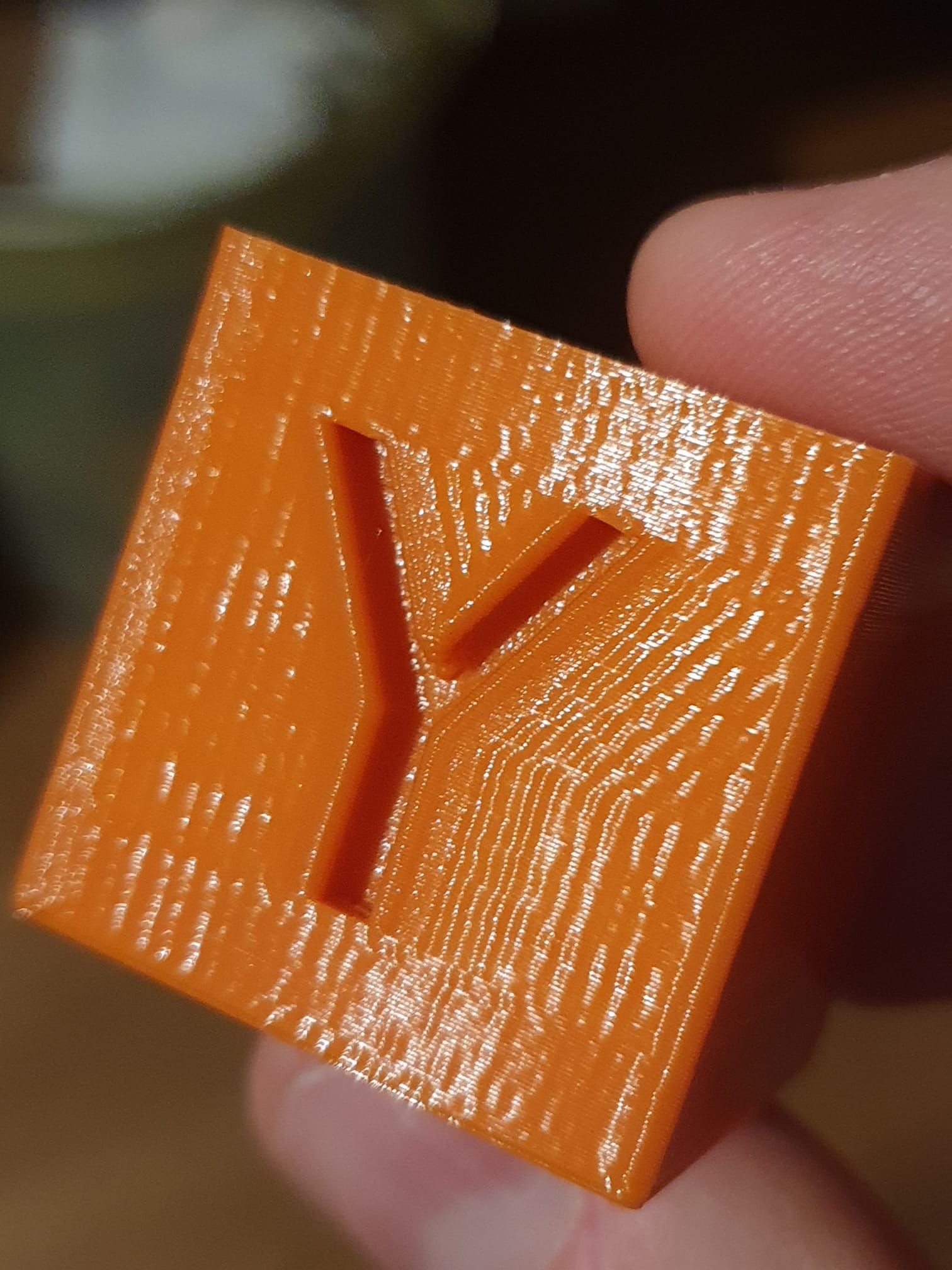

@Phaedrux ok tried with your profile and I think is much better

On the left your profile.

I think there is something to change for jerk to optimise all edges.

What do you think?

Without belt x and y are very smooth, all mechanic I think is good and ok.

Could you share your conf.g?

-

-

@Dav said in Help Core XY:

M566 X600 Y600 Z60 E600 ; Maximum jerk in mm/min

M203 X12000 Y12000 Z1200 E2500 ; set maximum speeds (mm/min)

M201 X800 Y800 Z60 E1200 ; set accelerations (mm/s^2)This isn't far off from my own config.g settings.

-

It looks like it could be printed a bit hot. Do you know the thermistor settings for that hotend? Have you tried a temperature tower?