Bimodal layer shift

-

I am stumped with a "bi-modal" layer shift issue on my BLV Cube at 45 degrees - front right to back left. Hours of research have turned up nothing similar so I am looking for community help.

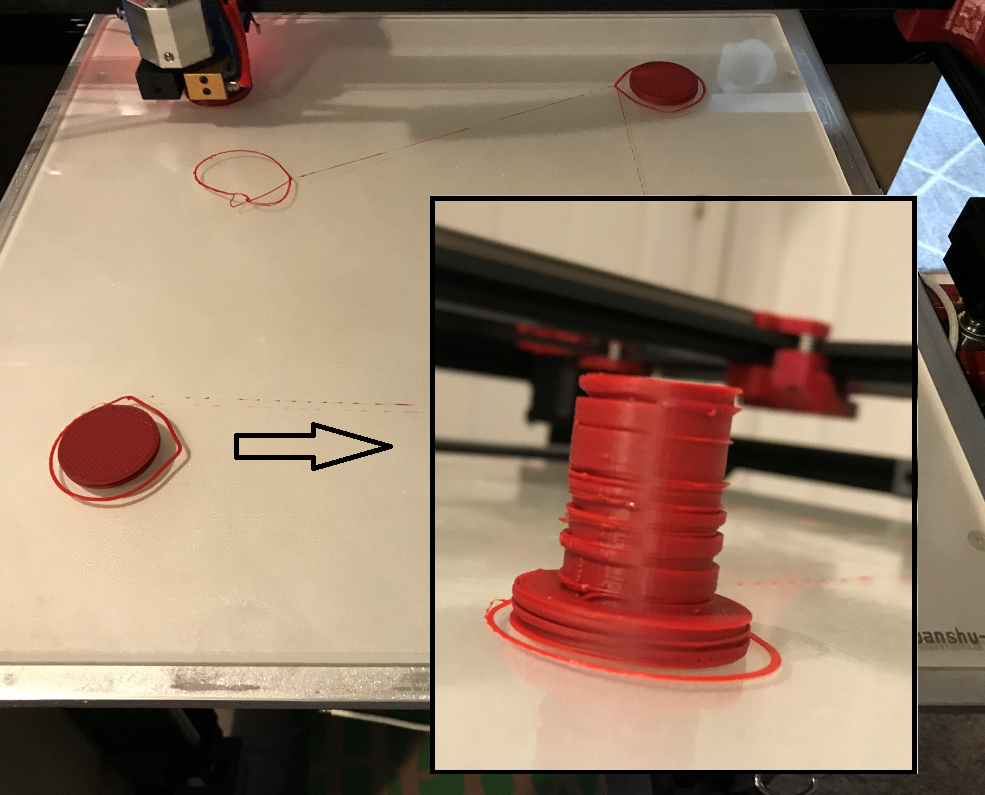

PHOTO1: As part of the troubleshooting I printed 4 tubes (solid base, then 0.8mm tubes) at the same time. The front right tube was good - not great. The back left was a little worse, the front left was a little worse and the back right was terrible.

I then printed a Moai(Easter Island head) and a shotgun rapid loader widget that both turned out perfect.

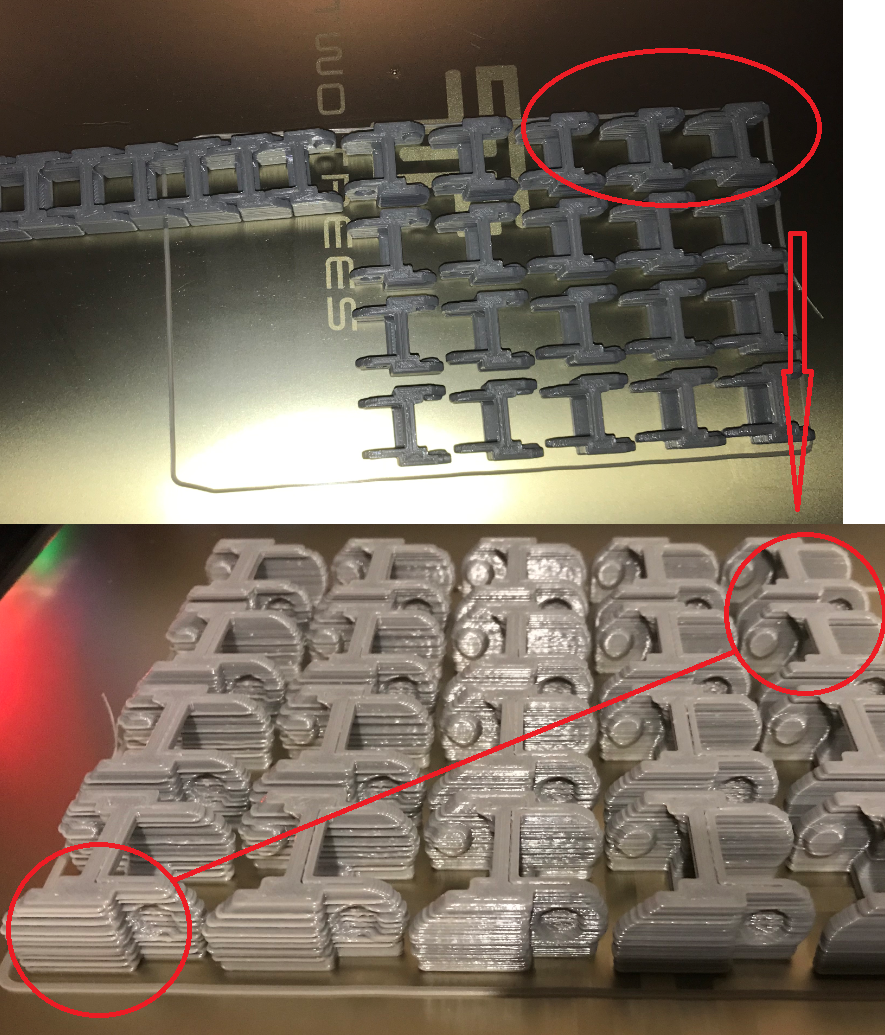

PHOTO2: Feeling confident I printed a 4x7 array of drag chain parts. The front left ones were passible, the back left ones are unusable.

So how-in-the-world am i getting good and bad parts in the very same print? How is the layer shift finding its way between 2 stable endpoints?

My setup: BLV Cube; Duet2WIFI, 0.9 Steppers for X-Y, 330x330 bed. Other than water cooling - built to standard BLV design on Thingiverse. 1800 current to steppers. No damage on belts or pulleys. (this printer is essentially new)

Checked so far: board is cool; steppers are cool; took belt off and verified MGN rails are smooth and no binding. The boden/wire umbilical is not catching on anything, the printhead mount feels solid, replaced the Y motor, then the X motor. Did find 58V being induced by an AC bed heater which I regrounded and is now 0V.!

Comments WELCOME please.

-

Perhaps some binding in the rails at that position?

-

Looks 100% like a loose pulley on one of the motors , explains why it is at 45° since it is a coreXY and it goes back and forth.

Make sure the pulleys set screws are set correctly on the detent of the motor shaft and not on the side or so

-

@Phaedrux With the belts off I could not detect any binding - but that could change under belt tension. During one print I did grab the Y bridge and apply considerable rotational pressure to try to force a layer shift. It continued to print fine. Is there anything you have seen or tried to help prove out a binding issue?

-

@NitroFreak I pulled both stepper motors in my initial troubleshooting and verified they are solid. I extended the "D cut" on one of them to make sure the set screw was hitting the flat. At this point I am not discounting anything, but I did pull and verify tight fit on both motors. I will try pulling them again this weekend.

-

@spudaddict said in Bimodal layer shift:

Try marking the side of the pulley to the stepper shaft with a marker and observe during the print if the line shifts.

Especially observe the stepper that is responsible of the 45 degree motion that is in the direction of the shift.I´m 100% sure that this is not a normal skipped step from the stepper because it is too uniform and back and forth to the exact same space, does not happen.

-

Carefully check the entire length of the belts. I've found stretched spots that are REALLY hard to see, and if they were in "one end" vs. "the other" it could explain the good/bad pattern across the bed.

-

Check that the ribs on the belts are not worn more in one section vs another , look for rubber dust as a sign of wear .

I had that happen on my delta and it caused all kinds of mysterious issues with travel being ok then not ok .

I actually saw the belt ribs ( the 3/4 worn ones ) riding on top of the drive pulley teeth rather than in between ! -

Is this a corexy printer? Do the belt tensions vary with the extruder position in the XY plane?

-

The BLV cube is a corexy printer....I have built one myself and don't have these issues.

If you have a duet board in your printer(which I assume since you posted here) I would run an M122 command during a print that is having these issues and look to see if any "hiccups" are reported which could translate into missed steps.

I would post up your config.g file so people here could review it and see if anything sticks out.

I do agree with the others who have posted that it seems more like a mechanical issue since it is worse in different locations on the print bed.

-

@JamesM Thanks, but I'd still like to hear what @spudaddict has to say. Self built printers are seldom identical, even if they start from the same set of plans/BOM. People make part substitutions and design changes all the time. Print quality varying with bed position is exactly the sort of problem you would expect from belts being improperly laid out, evidence of which is varying belt tension as the extruder carriage moves around.

-

@mrehorstdmd said in Bimodal layer shift:

@JamesM Thanks, but I'd still like to hear what @spudaddict has to say. Self built printers are seldom identical, even if they start from the same set of plans/BOM. People make part substitutions and design changes all the time. Print quality varying with bed position is exactly the sort of problem you would expect from belts being improperly laid out, evidence of which is varying belt tension as the extruder carriage moves around.

Thats a good point, thats true.

However belt tension would have a very sloppy effect on print quality, but just check the first red tower, the sections that are shifted within themselves are very properly aligned -

@mrehorstdmd As James M said, it is a CoreXY. I am not sure how I would measure tension variation on a moving belt - open to suggestions. IF the x and y rails are orthogonal there should be no tension variation. The strange thing is that in between the red tube print and the drag chain print, the printer made a perfect moai (Thingiverse: 144668). Its at work so I cant pull up a photo. Also, the "good" zones seem to move around the bed.

-

@Danal The belt is new, but I will do as you suggest. There are 2 belts on a CoreXY so I can easily check between them when I tear it down this weekend. I also have a new set of belts I may try as well.

-

@DigiD The belts are new, but I will definitely look them over. I also have a new set of belts I may try this weekend as well.

-

@NitroFreak I absolutely agree, which is why I ruled out most layer shifting "fixes." The pattern varies by location on the bed, is at random heights, but has two endpoints and then reverses back to the first layer origin. Very strange but specific.

-

@JamesM I will run a print tonight and try the M122 command. I too think it is mechanical, but I cant wrap my head around what it could be.

-

@mrehorstdmd See my reply to you above. A fellow 3D enthusiast from work built the same printer in tandem as I built mine. His BLV cube does not have this issue either. I'm not sure how to measure belt tension - maybe put a spring on the end and measure an elongation?

-

@NitroFreak Thats what is killing me! How is it so perfectly sloppy?

-

@spudaddict Here is a photo of the best and the worst pieces from the drag chain print. They were in diagonally opposite corners... which seems to indicate a mechanical issue due to the CoreXY configuration.

![IMG_0924[1].JPG](/assets/uploads/files/1584062626086-img_0924-1-resized.jpg)

These were printed at the same time just 150mms or so apart.