Auto bed compensation working just not very well

-

I decided to print a bird house. This is the largest print I've done since I built my core xy printer. As can be seen in the picture the first layer is not very consistent. As the nozzle moves around laying down the first layer it can be seen that in some areas the filament is layed down perfectly in other areas the nozzle is high resulting in poor adhesion to the bed and other areas the nozzle is too close.

Is this a result of poor resolution of the height map requiring more probing points in the X and Y axes or some other issue?

I printed a Z axes wheel so I can easily observe Z axes movement during a layer and the bed is being moved but the compensation doesn't seem to be enough. What do I need to do to correct this?

Also I wasn't happy with the bed that came with the printer so Mandella Roseworks made me a cast aluminum bed which is quit a bit better than the stock bed. I have the bed installed and have of course ran a G29.

-

Hi,

It's hard to be sure but it looks like your first layer Z height is too close to the bed.

What kind of Z probe do you have?

What are the dimensions of the grid (M557) you are using when creating your height map?

Are you performing a G30 before the G29?

Frederick

-

The Z height is definatly too close to the bed in some places and in others it's not close enough.

Using a BLtouch

M557 X15:295 Y0:240 S40:40

G30 is performed at the end of home all and home ZAlthough the BLtouch has X and Y offsets I'm currently configured with no offsets. The reason for this is when I configure with the correct offsets a G29 is unable to probe all points necessitating the need to run a G29 after every power down. I've tried to configure so that with probe offsets the machine probes all points but so far haven't been able to do so, probably a lack of understanding on my part. That is why Y is 240 instead of 295. I may be wrong but I don't think this is causing my first layer issue but want to mention it because maybe it is.

-

@luckyflyer looking at the way the stripes obviously go with the different infill sections I'd wonder if its actually your z height varying over time (I.e. a mechanical issue, not the compensation).

Where are your z lead screws located on your bed? On my printer I used to have one on either side, slap bang in the middle. This meant the bed could actually rock a little if anything disturbed it (e.g high xy jerk etc). It only moved maybe 50um but it's enough over a smaller layer height -

What are your probe offset values?

-

@engikeneer said in Auto bed compensation working just not very well:

Where are your z lead screws located on your bed? On my printer I used to have one on either side, slap bang in the middle. This meant the bed could actually rock a little if anything disturbed it (e.g high xy jerk etc). It only moved maybe 50um but it's enough over a smaller layer height.

Two lead screws in the middle such as yours with two very large stabilizing brackets. The bed is very stable.

-

@Argo said in Auto bed compensation working just not very well:

What are your probe offset values?

Offset values are 0:0 for the reasons stated in my post above.

-

If your offset values are zero, you are probing points that the Duet doesn't know about and you are then taking those probing points to adjust the mesh height. You are creating a bad height map and then applying it.

I don't understand how you can possibly expect any results but crap. You might as well work without any height map.

It's odd that you get stripes but before anyone can give you any suggestions about what is wrong, you MUST set things up properly !!! -

Hi,

You need to set the offsets of your Z probe - otherwise nothing will work as designed.

To deal with the offset when probing you can...

1 - limit the probing to points it can reach

2 - use M564 to allow moving to points you normally couldn't reach so you can probe the desired pointsTo use 2 you have to determine if you can move the probe to the desired points without something hitting something else.

On my printer the Z probe offset is X = 0 Y = +25 BUT I can actually move safely to Y = -25 (past the normal min of Y = 0) so M564 works for me and the probe can get to any point the nozzle can normally go.

Frederick

-

@fcwilt

Thanks for that info I'll do that when the bird house is finished. -

Post your config.g.

To maximize the grid and not skip any points you need to take the offsets of the probe into consideration. M577 = M208 - G31 XY. Does that make sense?

Having correct offsets is critical to mesh compensation working properly otherwise the firmware is compensating where it thinks the nozzle is rather than where the nozzle actually is.

Thankfully, it sounds like you have a really nice and flat bed, so you might not even need much of a mesh at all. a 3x3 grid might be enough.

-

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Wed Apr 29 2020 12:52:20 GMT-0600 (Mountain Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name M669 K1 ; select CoreXY mode ; Configure panelDue M575 P1 S1 B57600 ; set to channel 1, panel due mode with checksum, baud 57600 ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes backwards M569 P0.3 S0 ; physical drive 0.3 goes backwards ; Bed leveling M671 X0.0:155.0:300.0 Y-8.0:242.0:-8.0 ; Define position of bed leveling screws M584 X0.1 Y0.0 Z0.2 E0.3 ; set drive mapping Y = drive 0 X = drive 1 Z = drive 2 Extruder drive 3 M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X200.00 Y200.00 Z1600.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z100.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z-3 S1 ; set axis minima M208 X300 Y310 Z300 ; set axis maxima ; Endstops M574 X1 S1 P"!io1.in" ; configure for low end, active-low endstop on X via pin io1.in M574 Y1 S1 P"!io2.in" ; configure for low end, active-low endstop on Y via pin io2.in M574 Z1 S1 P"!io3.in" ; configure for low end, active-low endstop on Z via pin io3.in ; Z-Probe M950 S0 C"io4.out" ; create gpio servo 0 for BLTouch M558 P9 C"io4.in" H2 F120 R.350 T6000 ; set Z probe to bltouch, set input to io 4 in, set dive height,set feed rate, set delay, set speeds G31 P500 X-4 Y59 Z3.20 ; set Z probe trigger Height, X and Y offset and trigger height M557 X10:300 Y0:251 P3:3 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C M307 H0 A236.8 C516.8 D3.0 V24.1 B0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M143 H1 S260 ; set temperature limit for heater 1 to 260C M307 H1 A445.5 C173.0 D5.5 V24.1 B0 ; disable bang-bang mode for hotend heater and set PWM limit ; Fans M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"E3D-V6" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Lights M950 P1 C"out3" ; Create port on out 3 to power lights, 12v led strips are wired in series ; Custom settings are not defined ; Miscellaneous T0 ; select first toolMy M557 looks wonky since the pei sheet size is 310X310, this was my attempt to compensate for no offset, I'm now aware of this flawed logic.

-

Alright, first steps are to make sure the M208 is correctly sized. 0,0 being the front left corner of the bed. The minima would be the far left and front positions where the endstops trigger and then from there you can move the head to the far right and back positions of travel to get the m208 maxima.

Then you can measure the probe offset with this: https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe#Section_Measuring_Probe_X_Y_Offset

Then you can maximize the mesh grid by choosing the starting points for the minimum X Y that can actually be reached based on the offset. For example, If the probe is to the right of the nozzle by 20mm, it can't reach X10.

-

@Phaedrux said in Auto bed compensation working just not very well:

Alright, first steps are to make sure the M208 is correctly sized. 0,0 being the front left corner of the bed. The minima would be the far left and front positions where the endstops trigger and then from there you can move the head to the far right and back positions of travel to get the m208 maxima.

Then you can measure the probe offset with this: https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe#Section_Measuring_Probe_X_Y_Offset

Then you can maximize the mesh grid by choosing the starting points for the minimum X Y that can actually be reached based on the offset. For example, If the probe is to the right of the nozzle by 20mm, it can't reach X10.

Ok, everything you have stated I understand. For reference my Z probe is 59mm behind and 4mm to the left of the nozzle. So for my offsets I have X-4 and Y59 as can be seen in the config.G file above.

This is what happens when I do a G29 with the above config.G. The nozzle heads for the front left corner 0,0 but stops short at 41mm in the Y plane which puts the probe at 100mm from the front edge of the pei plate, I'm losing 41mm of probe area. If I leave the Y offset at 0 then a G29 will probe with the nozzle going to Y0 putting the probe at 59mm. So why is 41mm sacrificed when there is an offset? Also I get the points not probed message, I don't get that message with 0 offset. This is the main reason I tried using 0 offsets. -

Can anyone tell me why I lose 41mm of probe(able) Y bed area when I have a 59mm Y offset? And what if anything can be done to correct it?

-

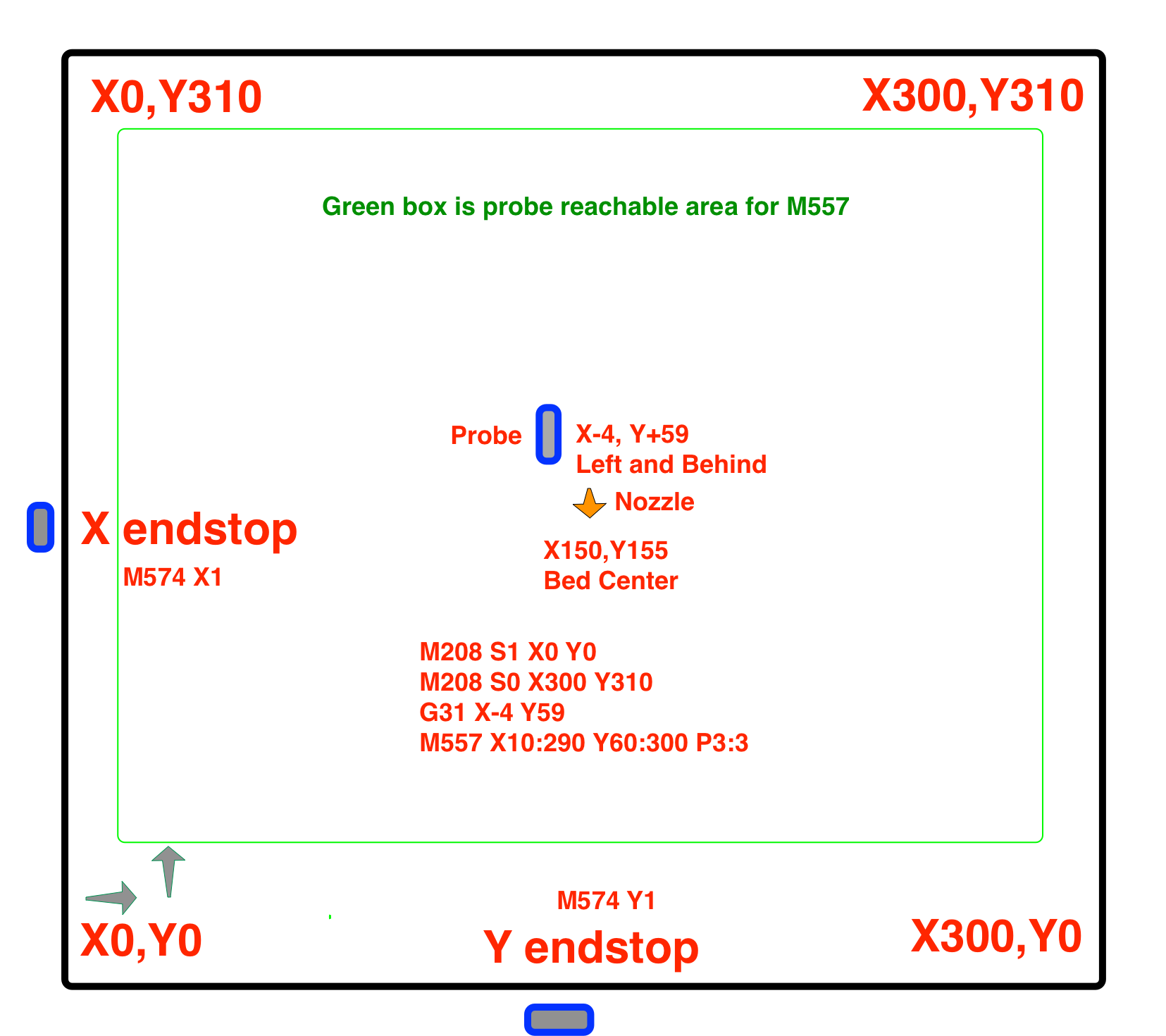

Please try

M557 X10:290 Y60:300 P3:3This should give you a 3x3 grid of the reachable area based on your values

M208 S1 X0 Y0 M208 S0 X300 Y310 G31 X-4 Y+59If those values are correct this is what your reachable area looks like.

The green box isn't quite right, but you get the idea.

-

@Phaedrux Yes sir thank you for that. I've been playing with the offsets the better part of the day to try to understand The "if I do this it causes that". Getting my first layer down consistently over a large area is the only major thing I have left to tune on this printer.

Pretty well fried for the day will try your settings tomorrow. Very nice diagram btw.

-

@Phaedrux I used your M557 and G31 X-4 Y59 numbers and then a G32 which is .00 and .01 Then a G29. Then did a one layer test print with auto height adj active.

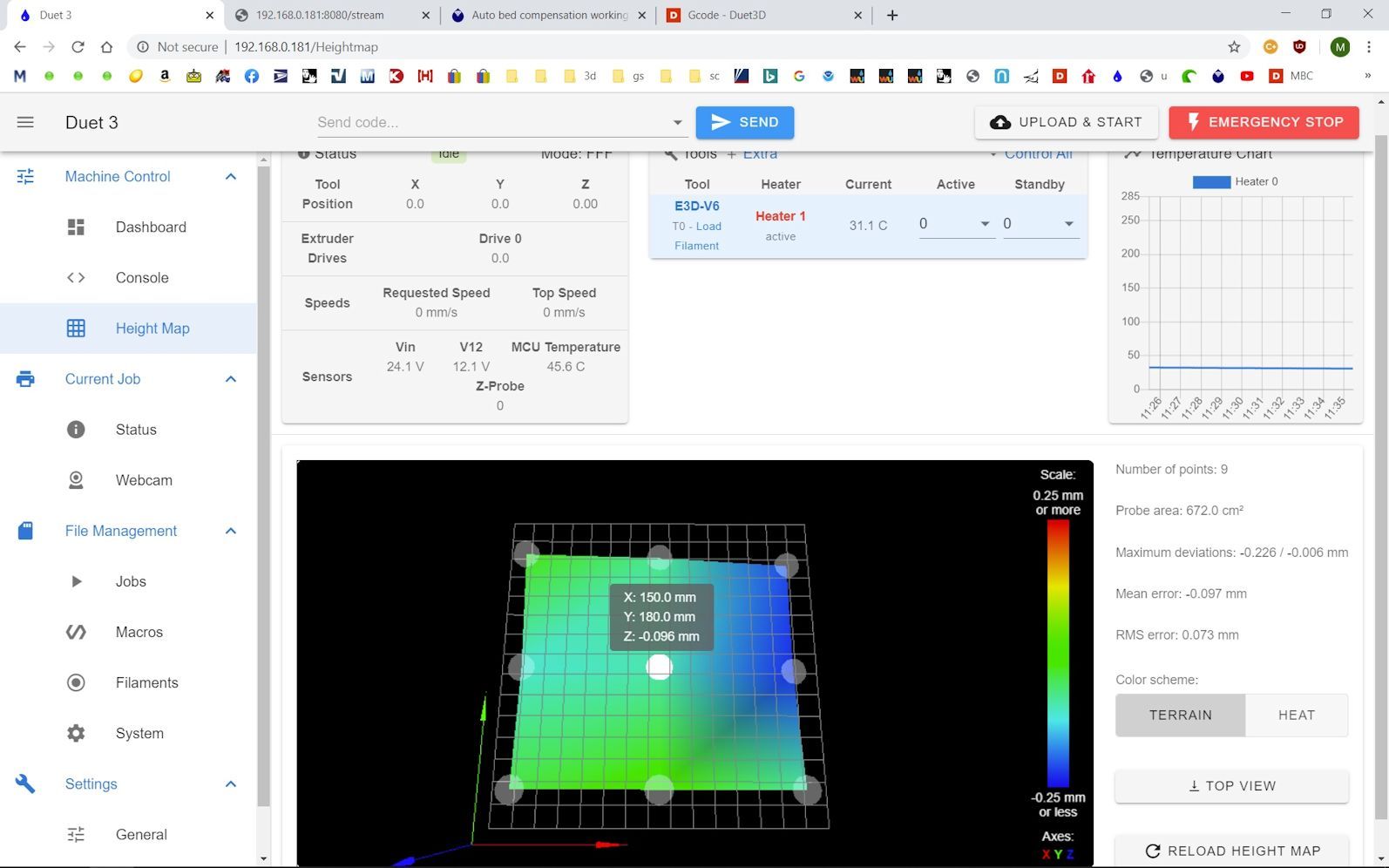

The print started in the lower left corner and is perfect. But right after the square of holes you can see an abrupt change. The nozzle is not as close to the bed. Bed adhesion is poor. As the print progresses from the lower left to the top right into the X it gets really bad getting a little better towards the print end. It is interesting (at least to me )that I got basically the same quality of print with and without the proper offsets. Here is height map.

What I don't understand is why is Z -.096 for the center measurement? Since I'm using a BLtouch my homeall ends in a G30 at the center of the bed. Shouldn't the center measurement always be 0.00? I'm not aware of any further mechanical adjustment that should be done or redone to correct my first layer issues. My G32 is either perfect or near perfect.

All thoughts on this appreciated. -

Hi,

I always do a G30 right before probing with G29 and right before printing to try and compensate for any mechanical/temperature changes.

Also 9 points can give you a good overview of the bed but unless you know your bed is truly flat from edge to edge you will have to probe a lot more points for mesh comp to work well.

I probe by 300 x 300 bed using X and Y spacing of 20 mm.

Frederick

-

At this point I think it would be good if you could post your homing files and bed.g as well as your current config.g and your slicer start gcode so we can see the entire sequence of gcode events. Now that you have the grid correct there are some tweaks you can do to improve the results of the mesh.