Stall detection with 2 motors

-

Well what behaviour do you want when a stall is detected? stop both motors or stop each individually?

https://duet3d.dozuki.com/Wiki/Gcode#Section_M574_RepRapFirmware_Num_3

New endstop type S4 means use motor stall detection (like S3) but if there are multiple motors, stop each one individually as it stalls. S3 means use motor stall detection but as in RRF 2: stop all relevant motors when the first one stalls.

What did you calculate for the H value?

Can you send M98 P"config.g" in the gcode console and report the results?

-

@Phaedrux

And I'm not sure of my calculation of the H parameter and speed. This is my Y motors (2 in series) of my Y axis specifications :

Spécification électrique

Numéro de pièce du fabricant: 17HS24-2104D

Type de moteur: Bipolar Stepper

Angle de pas: 1.8 deg

Couple de maintien: 65Ncm(92.3oz.in)

Courant/phase: 2.10A

Tension: 3.360V

Résistance/phase: 1.60ohms

Inductance: 3.00mH ± 20%(1KHz)I've found more than 1000 mm/s. It's crazy !

-

@Phaedrux said in Stall detection with 2 motors:

Well what behaviour do you want when a stall is detected? stop both motors or stop each individually?

I want to stop both motors. No choice, they're in series on the same driver.

This is the results of my M98 P"config.g" :

09/09/2020 à 22:16:49 M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

Warning: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 365C

Warning: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 269CNote my My PID aren't done for heaters errors.

-

@noisettetbou said in Stall detection with 2 motors:

I've found more than 1000 mm/s. It's crazy !

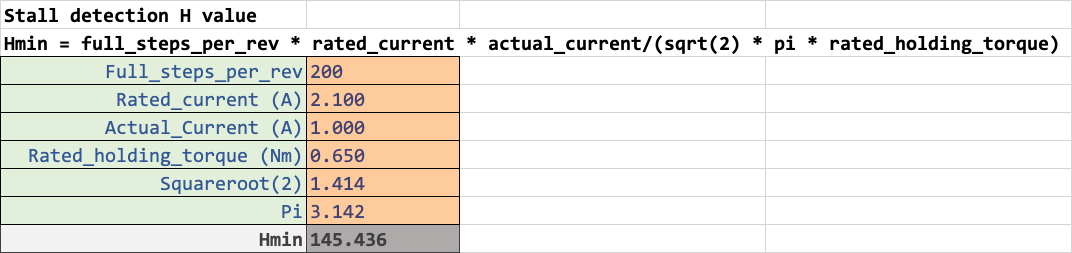

That seems wrong based on your motor specs. My calculation gives 145mm/s

Stall detection H value Hmin = full_steps_per_rev * rated_current * actual_current/(sqrt(2) * pi * rated_holding_torque) Full_steps_per_rev 200 Rated_current (A) 2.100 Actual_Current (A) 1.000 Rated_holding_torque (Nm) 0.650 Squareroot(2) 1.414 Pi 3.142 Hmin 145.436You may be able to reduce that speed further if you reduce the motor current further. You should try reducing it as much as possible such that you still have reliable movement. Right now you're using 50%, try 30%.

-

@Phaedrux

Thanks for the calculation. I've confused the units of torque.I've tried speeds up to 300 mm/s and differents current between 20 and 100% but nothing.

-

When you say the motors rotate in opposite directions, what do you mean?

Can you post a photo of the printer?

-

@Phaedrux

That's a link to a photo of Y axis :

https://photos.app.goo.gl/oeFLBnE1iaKtcJMNA

The motors are biaxials and synchonysed by a shaft -

@noisettetbou possibly crazy talk but could you disable one stepper for homing only? As they're synchronized by a shaft you should be able to live with that.

-

@oliof

It's a good idea. I've tried and it is the same problem.

So 2 motors on same driver and the series wiring aren't the source of the problem.

I'm trying to invert drivers. -

I've tried to invert driver with X and always the problem. As if my Y motors aren't compatibles with the stall detection.

Is it possible ? Crazy, no ? -

Oh two steppers on a single driver? I can see how that will be bothersome/impossible. Maybe if you drive each motor independently ...

-

@oliof

It's no a problem if current is respected. I use two motors on same driver in X axis and no problem. And I done as you said for trying, so there is only one motor right now, and no good stall detection... -

I think an endstop switch might be in your future.

-

@Phaedrux

I think too... but I would like to understand

but I would like to understand -

Have you used the motor EMF calculator at reprapfirmware.org to verify that you have enough VIN voltage to drive 2 motors in series without loss of torque?

-

Difference between X and Y is often that Y moves more mass and there for needs better tuning. But I agree that an endstop likely will give you reliable results faster.

-