BL Touch

-

I cannot change the fan speed as I could previously slide in the older firmware version.

-

I still need to find a way to reset the bl touch before each homing.

-

@Gost101 you’ve got some strange settings. Your tools are defined with fans only! You need to include heater and drive number. Also best to start at T0. Do you have two tools? I don’t think you do. You have:

; Tools

M563 P1 S"Side Fan" F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P2 S"Front Fan" F0 ; define tool 2

G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets

G10 P2 R0 S0If you assign a fan to a tool, there will be no slider for it until the tool is active. Try

; Tools M563 P0 S"Hot end" H1 D0 F1:2 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0CFor the heated bed )assuming it’s connected), you need to tune it with m303; see https://duet3d.dozuki.com/Wiki/Tuning_the_heater_temperature_control

Edit: also, fan1 and 2 are thermostatically controlled, so are not displayed.

Ian

-

-

@droftarts said in BL Touch:

; Tools M563 P0 S"Hot end" H1 D0 F1:2 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0CI do not have two tools.

The only things that I wanted to control were the Hotend temp, Bed temp, and the extruder side and front fans.But thanks to your code the hotend temp now works. As for the bed using M303 it first errored but after getting around 49.3 degress but I'm running it again so hopefully I can get to 70*C as I could before the firmware upgrade.

Still having problems with the z probe. -

You still have the default thermistors set which are unlikely to be correct for your printer, so reported temperature may be inaccurate. Is the heated bed very slow to heat up?

Still having problems with the z probe.

I think it’s still your wiring, but possibly config. What is the probe value (0 or 1000) when you turn the printer on?

Ian

-

Hi,

I don't see how the following can work:

G91 ; relative positioning G1 H2 Z5 F9000 ; lift Z relative to current position G1 H1 X-505 Y-505 F21600 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F9000 ; go back a few mm G1 H1 X-505 Y-505 F7200 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X15 Y15 Z10 F9000 ; go to first bed probe point and home Z G30 ; home Z by probing the bedSince Z is not homed I would think this line would generate an error:

G1 X15 Y15 Z10 F9000Frederick

-

@droftarts

For the hotend I'm rocking this: https://e3d-online.com/collections/printer-parts-electrical/products/high-temperature-heater-cartridges

As for the heated be i'm rocking the stock heater. The heated bed takes forever to heat up and the highest I was able to heat it up to was 72*C. I want to upgrade to a kennvoo bed but dont have the money right now. :https://www.creality3d.shop/products/12v-heater-bed-aluminum-hotbed-board-with-cable-installed-well-for-cr-10-cr-10s?_pos=6&_sid=5ca702ec0&_ss=r

The heated bed is still running M303 and is at 62.7*C.

@fcwilt it originally didn't have the code line in it

G1 X15 Y15 Z10 F9000I put that in there so the probe dosen't strike the edge of the bed as it sticks out over and under the bed by 2cm out and 2 cm down. So to get around that I tried to put that snippet there.

-

@droftarts The Z probe is at 1000 when I turn it on to answer your question.

-

@fcwilt it originally didn't have the code line in it

G1 X15 Y15 Z10 F9000I put that in there so the probe dosen't strike the edge of the bed as it sticks out over and under the bed by 2cm out and 2 cm down. So to get around that I tried to put that snippet there.

Hi,

Thanks. I guess you can understand why it doesn't work and is the source of the error message about un-homed axes.

But what do you mean by 2 cm down?

Frederick

-

@fcwilt The probe is encountering some problems at the moment. Homing all the axis will leave the extruder and probe past and under the bed.

The M303 command for auto tunning keeps canceling due to the bed taking to long to heat up and I'm unable to get the results using M500 due to the process not completing.

-

@fcwilt I'm still getting the error even after commenting G1 X15 Y15 Z10 F9000

line out.

line out. -

@fcwilt I'm still getting the error even after commenting G1 X15 Y15 Z10 F9000

line out.

line out.You either have a configuration problem, a wiring problem or a defective probe.

Let's work on that:

When you first power up the printer:

- does the probe perform it's power up sequence?

- what does the DWC (web interface) report for the Z probe sensor status?

Frederick

-

@Gost101

@fcwilt is correct you can't move Z unless it is first homed.

so G1 X15 Y15 Z10 F9000 will error because G30 should be before it .; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Mon Sep 28 2020 07:45:49 GMT-0600 (Mountain Daylight Time) G91 ; relative positioning G1 H2 Z5 F9000 ; lift Z relative to current position G1 H1 X-505 Y-505 F21600 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F9000 ; go back a few mm G1 H1 X-505 Y-505 F7200 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X15 Y15 Z10 F9000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F150 ; lift Z relative to current position ;G90 ; absolute positioning -

@peter247 @fcwilt

Alrighty guys, to make sure we are all on the same page. I talked with @droftarts through the pm system on here. Wiring is verified in the correct position. The BL Touch is not defective. Because by unplugging the all connected wires to the BL Touch it will perform its power up sequence and status a solid red pin up status. After which by pressing the home all :; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Mon Sep 28 2020 07:45:49 GMT-0600 (Mountain Daylight Time) G91 ; relative positioning G1 H2 Z5 F9000 ; lift Z relative to current position G1 H1 X-505 Y-505 F21600 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F9000 ; go back a few mm G1 H1 X-505 Y-505 F7200 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G30 ; home Z by probing the bed G1 X15 Y15 Z10 F9000 ; go to first bed probe point and home Z ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F150 ; lift Z relative to current position ;G90 ; absolute positioningThe BL touch will status solid blue and pin down until contact with the build surface is made. After which the BL Touch will status solid red pin up. If home all is pressed again then the printer will home the X & Y axis in accordance with the home all gcode. Then the BL Touch will status solid blue and pin down while Z is trying to go down. However where it is trying to home is off the build platform here is the picture:

In doing so the Z Axis will continue to try and home z when it cannot.

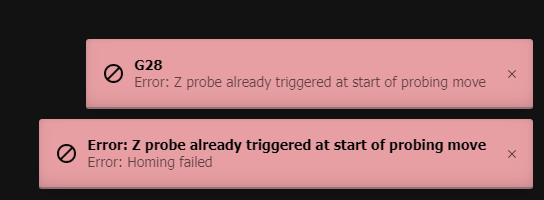

Once in this state if the printer is reset and home all is executed it will perform the X & Y Axis homing however in doing so the BL Touch will status the following error code:G28 Z Error: Z probe already triggered at start of probing move Error: Homing failedDue to the BL Touch striking the side of the bed.

Any recomendations? Or should I just throw the printer off the balcony and buy an i3 MK3S. Just kidding about throwing the printer and the i3 MK3S. -

you keep missing the important bits .

So back to the 20 questions .

if you tell it to home does it stop if you press the pin ? , if it does that part is working ?.

-

OK you moved the G30 about the G1 that had the Z10 parameter in your home all file.

I think this is what you want to do.

G1 X213 Y250 ; this positions the probe near the center of the bed

G30

G1 Z10 ; this positions the nozzle at the desired height.Frederick

-

@Gost101 Looks like it's the bed limits that need to change now. M208 sets the where the bed is in relation to the endstops. For example, at the moment you have:

M208 X0 Y0 Z0 S1 ; set axis minima ... M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop ... G31 P500 X37 Y0 Z2.5 ; set Z probe trigger value, offset and trigger heightThe above effectively says "the X endstop is at the low end (this should be on the left of the X axis, defined by M574), and when the X endstop is triggered, X is set to 0 (defined by M208 X0 S1). The probe is at X37 when the nozzle is at X0 (defined by G31)"

But when the X carriage hits the endstop, the nozzle is off the bed, by what looks to be about 50mm? If you jog X until the nozzle is right on the edge of the bed, it'll be around X50. That's where you want X0, so set

M208 X-50 Y0 Z0 S1. Then repeat for the Y axis. Position X0 Y0 should be with the nozzle on the front left corner of the bed.Ian

-

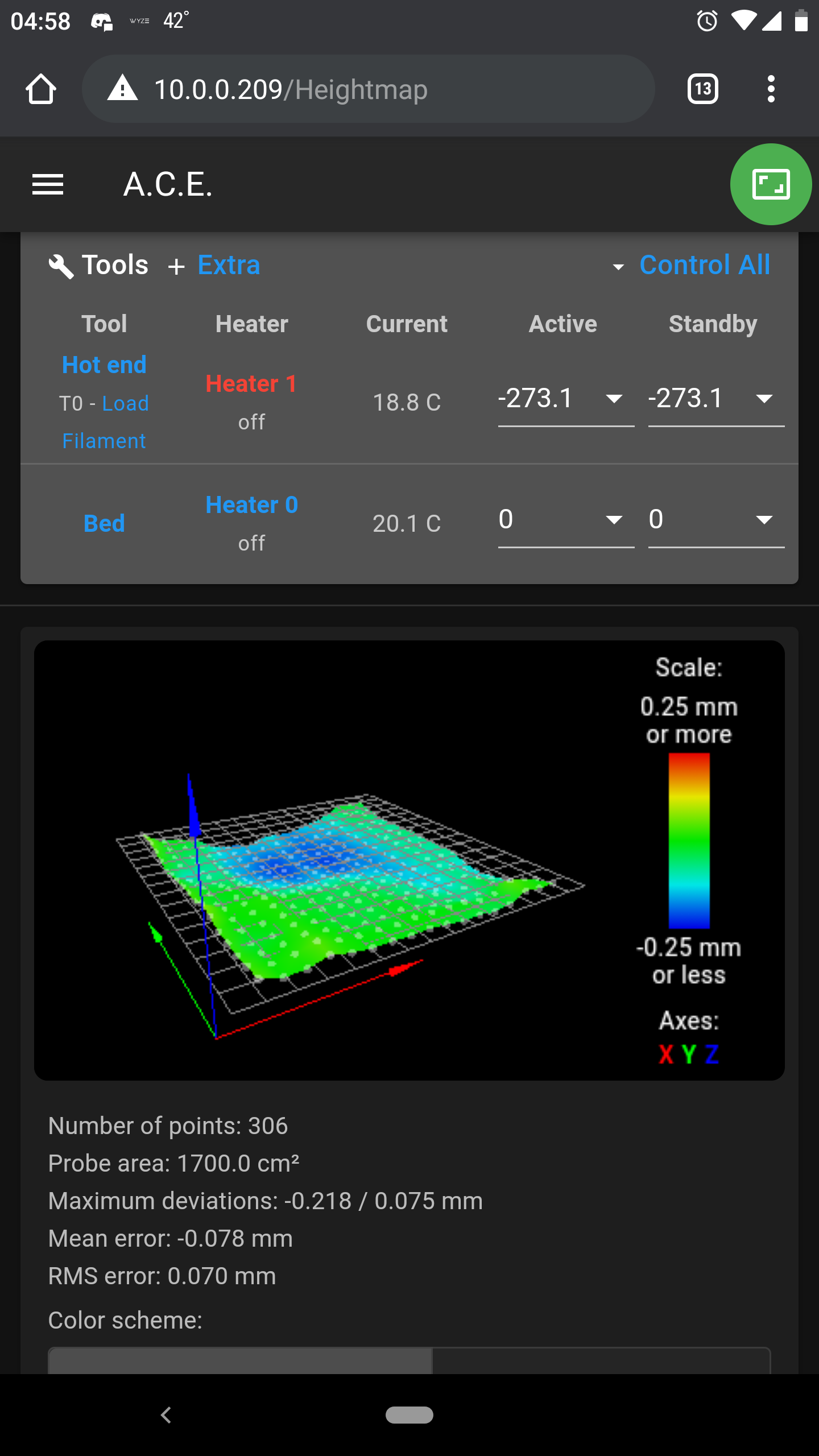

@peter247 @fcwilt @droftarts The printer homes fine now in addition to making the mesh configuration. Is there any code that I have to put in cura so that it will print based of the bed mesh? This is what I was able to get it to:

-

@Gost101 Great! No, just need to load the mesh before printing; you can put

G28thenG29 S1in the slicer start gcode to load the mesh. Best to probe the bed when it's at temperature, in case heating the bed causes it to change shape.Not sure why the bed has got a 0.25 mm dip in it; you may want to check it really has. Sometimes it's actually caused by the cables pulling on a loose X carriage, and the bed isn't really that shape.

Ian