Nema 17 intergrated servo motor possible?

-

Is it possible to wire up and use Nema 17 servo motors on the Duet 2 wifi?

I have a CoreXY build and have two of these.[link text]https://www.ebay.com/itm/IHSV42-40-07-24-NEMA17-Integrated-Servo-Motor-24VDC-78W-w-1000-Lines-Encoder-/202698244485?_trksid=p2349624.m46890.l49292(link url)

-

Yes these motors work quite fine with the duet. I have two of these in a corexy too.

-

@rabbit said in Nema 17 intergrated servo motor possible?:

Yes these motors work quite fine with the duet. I have two of these in a corexy too.

Nice.. Anything special you needed to do in the setup? I guess you just wire them up as external stepper motors. I found some guide for that, but not sure if I need to do something more.

-

Yes you can connect it directly to the duet board. But I would recommend the expanson board to you, because this has a higher trigger voltage. I also use a 3:1 belt reduction gear because the servomotors are difficult to tweak.(without gear I had salmon skin)

-

@rabbit @IBICO I tried them in my corexy machine driving the mechanism directly- no reduction from pulleys- and got the salmon skin effect. Can you post photos of the prints your machine produces with these motors and 3:1 reduction? When the motors were in my printer they were completely silent.

I have the software to tweak the driver settings, but there's no information on how to do it anywhere that I can find, so I used them with factory default settings.

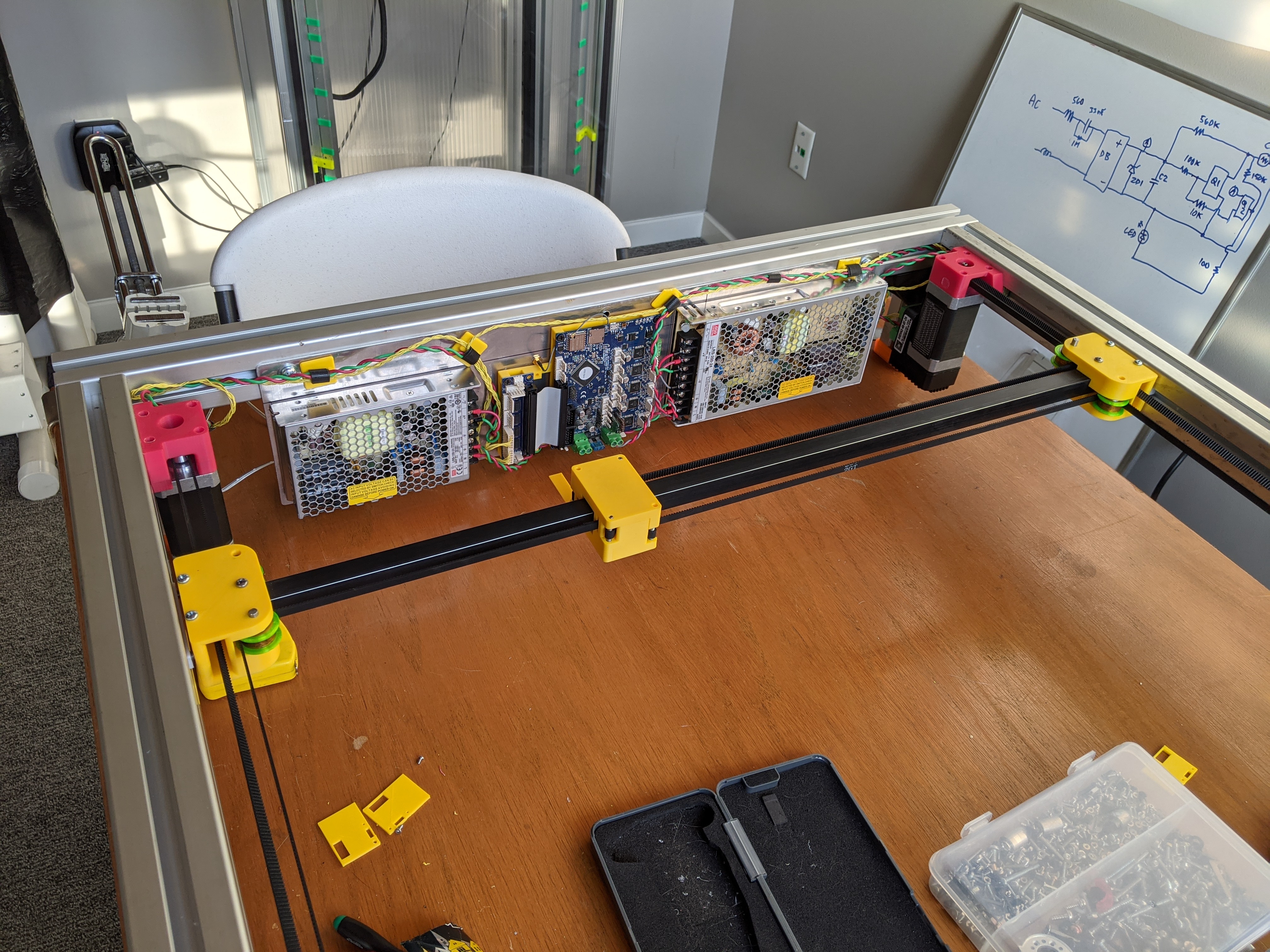

I used a duet expansion board to get the step/driection/enable signals to drive the motors. It works fine, but requires a little tweaking of the signal timing to get them to work right. I have the motors installed in a corexy sand table mechanism now:

arrakis mechanism

Here's how I configured the motors with the Duet expansion board:

M584 X5 Y6 ; remaps the X and Y motor drives to the Duet expansion board M569 P5 S1 R1 T4.0:5.0:6.0:11.0 ; sets the timing parameters for the X motor servo drive signals M569 P6 S1 R1 T4.0:5.0:6.0:11.0 ; sets the timing parameters for the Y motor servo drive signals M92: X500 Y500 ; sets steps/mm for motors using 20 tooth drive pulley and 20,000 steps/rev M350 X1 Y1 ; sets Duet to output full steps (microstepping is handled by the servomotor drivers) M201 X10000 Y10000 ; set maximum acceleration limits for each axis M204 P2000 T2000 ; set print and travel move acceleration M566 X20 Y20 ; set maximum jerk speed for each axis M203 X240 Y240 ; set maximum speeds for each axisThe servomotors will take as much current as they need to keep up with the input signal, so if you're going to run them hard, you need beefy power supplies. I run the sand table with acceleration at 10k-20k and speeds up to 2000 mm/sec and use a 150W supply for one motor and a 200W supply for the other, and sometimes the supplies shut down. I would think that a single 200W supply would be able to provide all the juice needed to power two motors in a 3D printer.

I wrote a couple blog posts on these motors:

https://drmrehorst.blogspot.com/2020/11/heres-what-happened-when-i-swapped.html

https://drmrehorst.blogspot.com/2020/04/ihsv-servomotor-information.html

https://drmrehorst.blogspot.com/2020/04/the-spice-must-flow-gets-servo-motors.html -

Hi,

I can post some pics on friday. -

Hi,

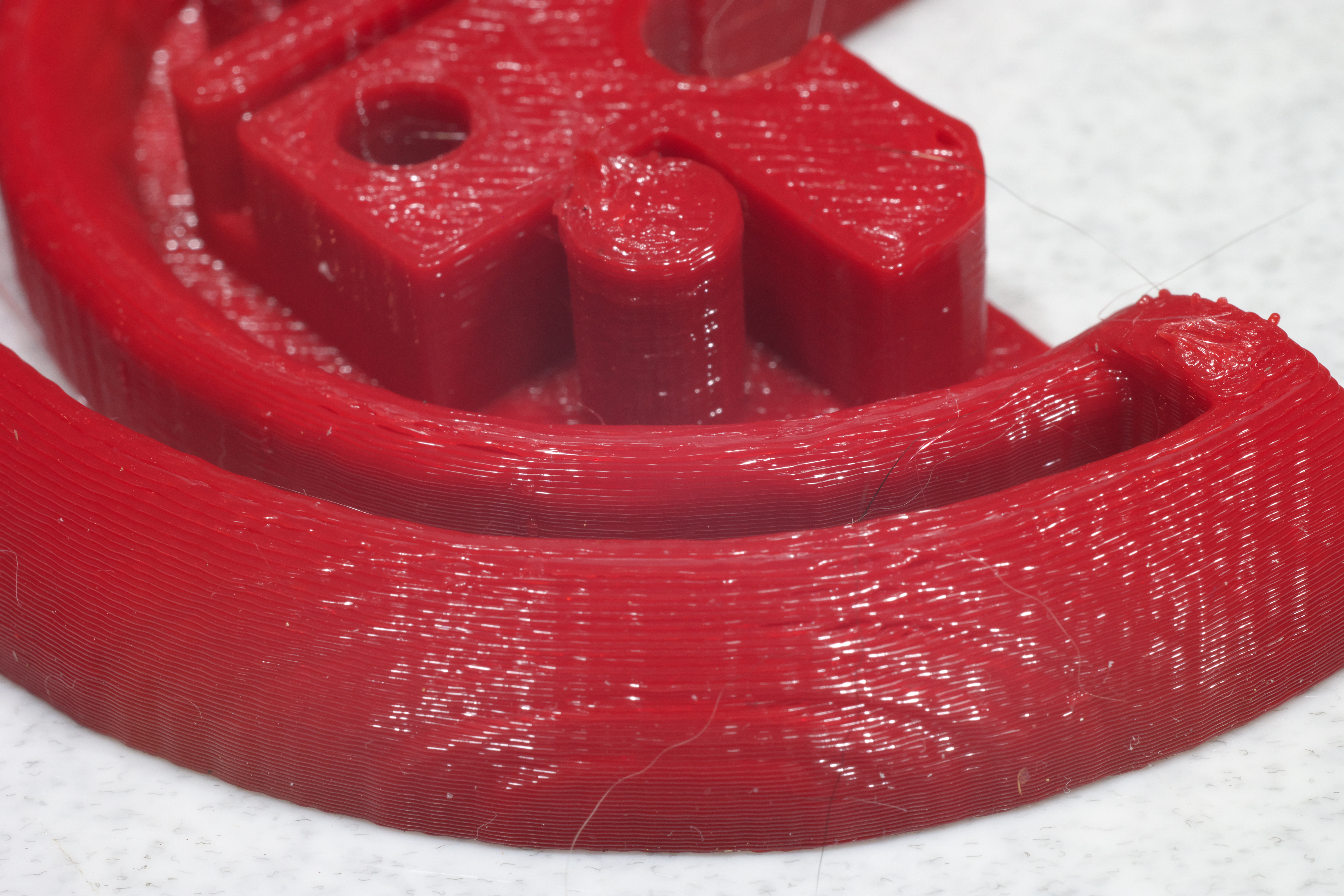

Here is a picture of a print before the gear reduction:

And after:

Printspeed was 100 mm/s @20 000 mm/s² acc -

Here are some pics from the printer

and from the final belt reduction gear:

-

@rabbit Looks great! That was 3:1 reduction? Can you post the M569 statements from config.g? Are there any special config tweaks?

-

yes that's the 1:3 reduction with a 60t and a 20t gt2 belt.

M569 P5 S1 T3.5 ; physical drive 4 goes forwards M569 P6 S1 T3.5 ; physical drive 4 goes forwardsI set the rigidity of the motors (Parameter P01-03) to 22.

-

@rabbit I set the rigidity of the motors (Parameter P01-03) to 22.

How do I change this parameter? Do I just buy a cable and download a program? I too am getting a salmon finish to my prints. I have a 2:1 reduction in the Y but not in the X. I would like to try to reduce the effects of this if possible with tuning. If not I may look into other motors or possible mechanical reduction.

-

@taylo708 I have been gathering iHSV servo info on a blog page here: https://drmrehorst.blogspot.com/2020/04/ihsv-servomotor-information.html

You need a USB to RS-232 adapter like this one to program the driver parameters: https://www.amazon.com/UGREEN-Converter-Adapter-Chipset-Windows/dp/B00QUZY4UG/ref=sr_1_3?dchild=1&keywords=usb%2Brs232%2Badapter%2BPL2303&qid=1592150850&sr=8-3&th=1

There are many different ones made- just look for the PL2303 chip and it should work.

You'll also need the software for programming the motors - there's a link on my blog page for that.

-

Your blog is phenomenal! I have been trying to find information on these for about a month. I finally got them working but always wanting better.

-

@taylo708 Thanks! What is the filament you used in that print? It's beautiful!

If you find any info I don't have yet, send me a link so I can add it to the blog post.

-

I noticed the voltage on those servos is advertised as 24. Is there a maximum or range stated in it accompanying literature?

-

-

I've just ordered a couple of these from china to play with.

£60 each at the moment https://www.aliexpress.com/item/1005002331999899.html -

@mrehorstdmd thank you

-

@jay_s_uk I ordered 4 of them. That's the best price I've ever seen on them.