Toolboard Heater Fault

-

@phaedrux I ran PID tuning again without the "F" parameter and I got

M307 H1 B0 R2.837 C252.0:103.7 D9.60 S1.00 V25.7

previously with the layer fan on it was

M307 H1 B0 R2.824 C282.4:110.0 D9.82 S1.00 V25.7

-

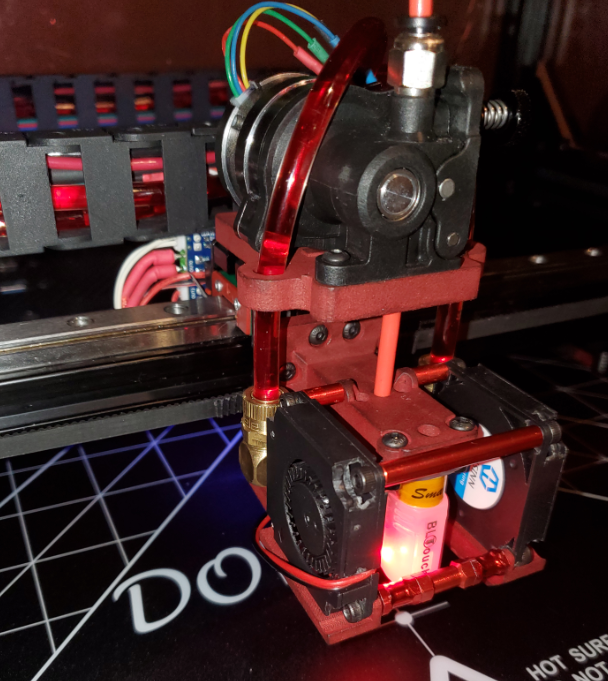

What does the hot block look like?

Did tuning without the F param help at all?

-

@dhusolo said in Toolboard Heater Fault:

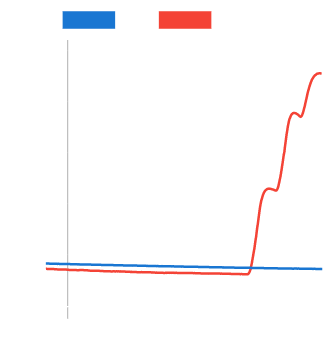

@phaedrux No change. Started heating to 220C from 30C. It faults once it gets to about 90c. Reset fault and continue heating right away. This time it gets to 180c and faults. Reset again and it'll heat the rest of the way.

I'm not sure if it helps, but I recently had such a heating curve with the same error. The solution was a loose Crimp on the Duet Board, so I would say double-check the thermistor wiring with the crimps.

-

@siam Thanks for the suggestion. I suspected bad crimps so I re-did them just to make sure they had a good connection. The curve is due to the hotend going to a fault state and stops heating. I clear the fault and start heating again

-

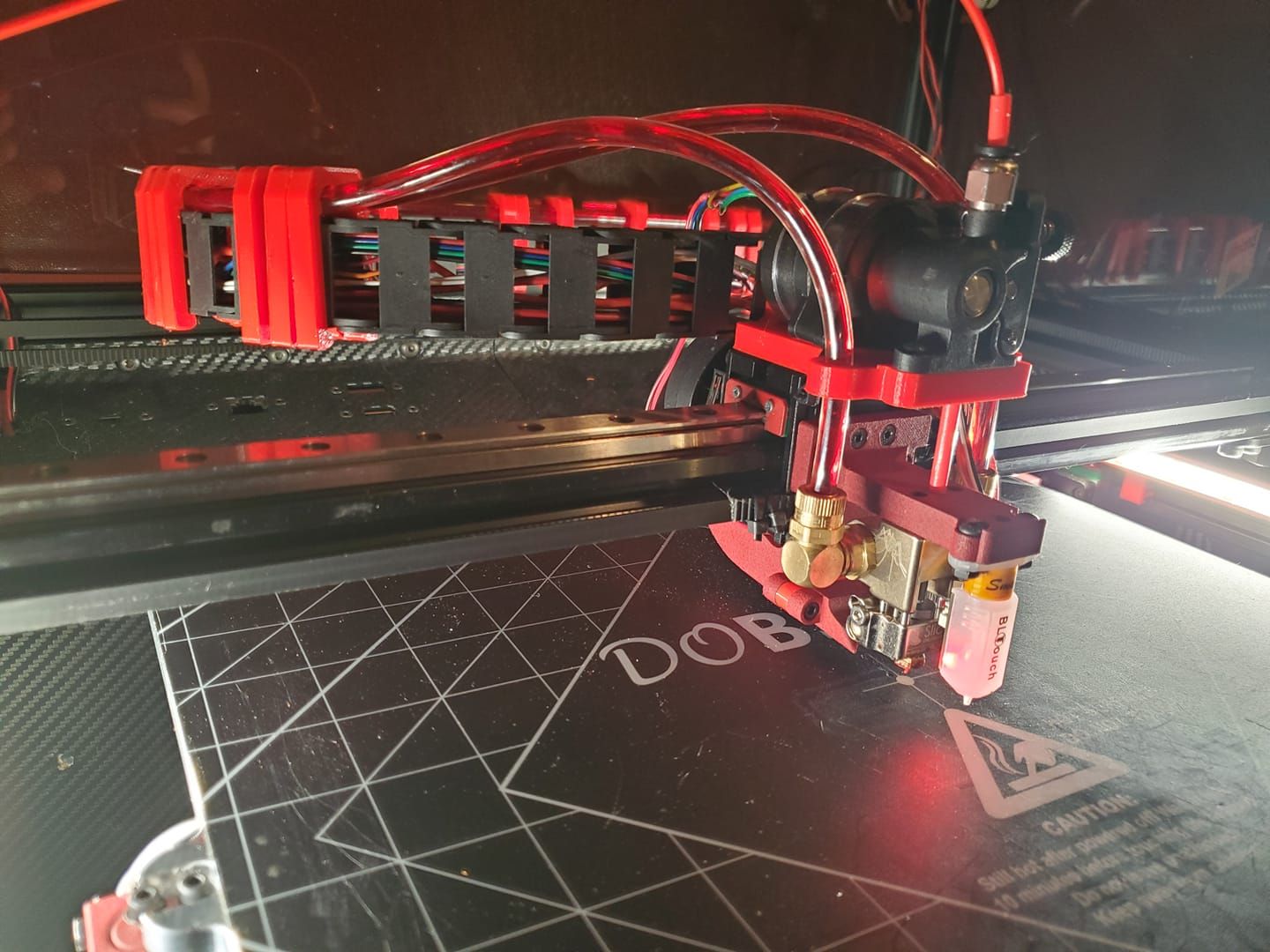

@phaedrux It's an older design but for the most part the only thing changed between this and my current setup is now I'm using twin blower fans instead of 1

-

I've found out that if I heat in increments it doesn't fault. If I go directly to 210 it'll fault. It didn't fault if I set it to 80c, wait for it to heat up, set it to 160c, wait to heat up, than set to 210.

-

@dhusolo said in Toolboard Heater Fault:

M307 H1 B0 R2.824 C282.4:110.0 D9.82 S1.00 V25.7

-

From those parameters, I think your hot end must have a high thermal mass, a high powered heater, and good insulation. However, turning on the print cooling fan cools the heater a lot. Does that sound right?

-

Please run M307 H1 and check that it reports that those are the parameters.

-

I suggest you try reducing the R parameter. Too high and it will fault while heating up; too low and the temperature will overshoot. Try R2.0.

-

-

@dc42 It's a mosquito liquid hotend from Slice Engineering. Yesterday I received a new thermistor and heater cartridge from them for that block. I double checked the crimps on the thermistor JST connectors and the wire ferrules on the heater cartridge are good. I don't think it's the cooling fan though. I re-ran PID tuning without the fan and this is the result.

M307 H1 B0 R3.722 C283.2:94.4 D8.95 S1.00 V25.7

This is my sensor settings

M308 S1 P"20.temp0" Y"thermistor" A"Hotend" T100000 B3950 C7.06e-8M307 H1

Heater 1 model: heating rate 3.722, cooling time constant 283.2/94.4, dead time 8.95, max PWM 1.00, calibration voltage 25.7, mode PID Computed PID parameters: setpoint change: P5.4, I0.106, D33.6, load change: P5.4, I0.263, D33.6mosquito liquid

50w heater cartridge

thermistor high temperature -

@dhusolo I have the same problem with dyze extruder, something new about your PID tuning ?

-

@tom33 Nothing new that I can know of. I've been dong the same method for 2 years now

-

@dhusolo you and I have pretty much the same hardware; I don’t see any of that behavior. I’m perplexed.

-

@nuramori With the exception of me using the orbiter and a twin 4010 blower setup vs your custom planetary extruder extruder and 5015 blower they're identical. My design is highly inspired by yours LOL.

-

@dhusolo as I suggested before, try reducing the R parameter in the M307 command.

-

@dhusolo the only thing I can think of is, did you fill the heater and temp sensor with the boron nitride paste to ensure thermal transfer for both the heater and sensor?

-

@nuramori I have not. I'm using a slice thermistor and heater cartridge. I know with the glass bead thermistor you're supposed to fill with the paste but I didn't think I needed to with the cartridge style

-

@dhusolo yep. The instructions say to fill the space with the paste and set the heater and cartridge temp sensor in it.

-

-

@dhusolo odd - when I received my mosquito liquid it had a tube of it - I’m not sure about the thermal paste you linked - I would find out it’s temperature range. The thing about the boron nitride paste they include/sell; it hardens into a ceramic like mass that holds the thermistor and heater in place as well as transfer the thermal energy.

-

I've added the Boron Nitride Paste, replaced the tool board with a new one and uploaded the board and the Tool Board to RRF3.3 but the situation hasn't changed.

I've re-ran the PID tune with

M303 H1 S210and this was the resultAuto tuning heater 1 completed after 3 idle and 10 tuning cycles in 606 seconds. This heater needs the following M307 command: M307 H1 B0 R2.919 C268.2:112.6 D6.85 S1.00 V24.7If I try to heat to 210c I get a heater fault at around 80c. But I've noticed I don't get a fault if I heat to 60c, wait for the temperature to stabilize, than heat to 120c, than to 180c than to 210.

As a temporary fix I set the hotend temp in the slicer to 0 and created a macro that is called during the starting script. I know it's a bit archaic but it works.

T0 ; Select tool 0 M568 P0 S60 ; set active tool temperatures to 60c M116 G4 S1 M568 P0 S120 ; set active tool temperatures to 120c M116 G4 S1 M568 P0 S180 ; set active tool temperatures to 180c M116 G4 S1 M568 P0 S210 ; set active tool temperatures to 210c M116 G4 S1; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3 on Sat Jul 11 2020 20:25:37 GMT-0500 (Central Daylight Time) ; ================= General preferences =================== M80 ; Turns on the ATX power supply G4 S1 ; Wait for tool board G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M669 K1 ; select CoreXY mode ; ====================== Network =========================== ;M586 P0 S1 ; Enable HTTP ;M586 P1 S0 ; Disable FTP ;M586 P2 S0 ; Disable Telnet ; ======================= Drives =========================== M569 P20.0 S1 ; physical drive 0.0 goes backwards-Extruder M569 P0.1 S0 ; physical drive 0.1 goes backwards-X stepper M569 P0.2 S0 ; physical drive 0.2 goes backwards-Y stepper M569 P0.3 S0 ; physical drive 0.3 goes backwards-Z left stepper M569 P0.4 S0 ; physical drive 0.4 goes backwards-Z right rear stepper M569 P0.5 S0 ; physical drive 0.5 goes backwards-Z right front stepper M584 X0.1 Y0.2 Z0.3:0.4:0.5 E20.0 ; set drive mapping Z3=Left Front, Z4= Right Rear, Z5=Right Front ; ===================== Drive Settings ===================== M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation XY .9 degree ZE 1.8 degree M92 X100.00 Y100.00 Z400.00 E675.35 ; set steps per mm XY .9 degree ZE 1.8 degree -Orbiter M203 X12000 Y12000 Z800 E7200.00 ; Set maximum speeds (mm/min) mm per minute/60=mm per second X12000 Y12000 M201 X1800.00 Y1800.00 Z100.00 E800.00 ; Set accelerations (mm/s^2) M566 X800.00 Y800.00 Z150.00 E700.00 ; Set maximum instantaneous speed changes (mm/min) M906 X1600 Y1600 Z1600 E1000 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S120 ; Set idle timeout ; ================ Independent Z Leveleing ================= M671 X-20:344:344 Y162.2:303.7:48.7 S10 ; leadscrew pivot point: ; ===================== Axis Limits ======================== M208 X-18 Y0 Z0 S1 ; set axis minima M208 X325 Y325 Z445 S0 ; set axis maxima ; ======================= Endstops ========================= M574 X1 S1 P"20.io1.in" ; configure active-high endstop for high end on X via pin i01.in M574 Y2 S1 P"0.io3.in" ; configure active-high endstop for high end on Y via pin i02.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ;M591 D0 P1 C"0.io4.in" S1 ; configure filament runout sensor for high end on extruder drive 0 via pin i03.in ; ======================== Z-Probe ========================= M950 S0 C"20.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"^20.io0.in" H10 F300 T9000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y-19.2 Z2.760 ; set Z probe trigger value, offset and trigger height ; ======================== Heaters ========================= M308 S0 P"0.temp0" Y"thermistor" A"Bed" T100000 B4725 C0.0000000706 ; configure sensor 0 as thermistor on pin temp0 M308 S1 P"20.temp0" Y"thermistor" A"Hotend" T100000 B4680 C6.455513e-8 ; configure sensor 1 as thermistor on pin temp1-Matrix M950 H0 C"0.out1" T0 ; create bed heater output on out0 and map it to sensor 0 M950 H1 C"20.out0" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H0 R0.238 C1283.9 D25.20 S1.00 ;Set PID for bed heater POST RRF 3.2.3 beta M307 H1 B0 R2.919 C268.2:112.6 D6.85 S1.00 V24.7 ; Set PID for Hotend .4Bmm nozzle RRF 3.3 M140 H0 ; map heated bed to heater 0 M143 H0 S100 ; set temperature limit for heater 0 to 100C M143 H1 S260 ; Set temperature limit for heater 1 to 260C ;M308 S2 P"mcu-temp" Y"mcu-temp" A"Duet" ; Configure MCU sensor ;M307 H1 B0 R3.722 C283.2:94.4 D8.95 S1.00 V25.7 ; ========================= Fans =========================== ;M950 F0 C"20.out1+^out2" Q500 ; create fan 0 on pin out9 and set its frequency M950 F0 C"20.out1" Q500 ; create fan 0 on pin out9 and set its frequency M106 P0 C"Layer Fan" S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"0.out8"; Q25000 ; create fan 1 on pin out8 and set its frequency M106 P1 C"WC Fan" H1 T40 ; set fan 1 value. Thermostatic control is turned on ;M106 P1 C"WC Fan" H-1 S0 ; set fan 1 value. Thermostatic control is turned on ; ======================== Tools =========================== M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 R0 S0 ; set tool 0 axis offsets ; ===================== Custom settings ==================== M564 H0 ; Let the Jog buttons work blv: added to allow jog buttons ; ====================== Miscellaneous ===================== M575 P1 S1 B57600 ; enable support for PanelDue M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ;M574 S1 P"^!0.io1.in" ; Define Emergency endstop - emergency stop switch condition M950 J1 C"0.io5.in" ; Create GPIO pin for On button wired NO M581 T2 P1 S1 R0 ; T2-Run Trigger 2; P1-J1; S1-When button pressed; R0-trigger any time M582 T2 ; Monitor external trigger 2 ; ====================== Duet 3 (ID#0) ==================== ;0.out0 NC ;0.out1 Bed heater ;0.out2 NC ;0.out3 NC ;0.out4 NC ;0.out5 NC ;0.out6 NC ;0.out7 NC ;0.out8 Fan 1-Layer Fan ;0.out9, ;0.out4.tach NC ;0.out5.tach NC ;0.out6.tach NC ;0.io0.in PanelDue ;0.io1.in NC ;0.io2.in NC ;0.io3.in Y Endstop ;0.io4.in NC ;io5.in GPIO pin for on trigger ;0.io6.in NC ;0.io7.in BLTouch Signal pin ;0.io8.in Off button C ;0.io0.out PanelDue ;0.io1.out NC ;0.io2.out NC ;0.io3.out NC ;0.io4.out NC ;0.io5.out NC ;0.io6.out NC ;0.io7.out BLTouch Servo pin ;0.io8.out NC ;pson Power on SSR 3+ ;0.spi.cs0 NC ;0.spi.cs1 NC - this can be your PT100 board ;0.spi.cs2 NC ;0.spi.cs3 NC ;0.temp0 Bed heater ;0.temp1 NC ;0.temp2 NC ;0.temp3 NC ;0.mcu-temp Virtual Temp Sensor ; ================ Toolboard 1 (CAN ID#20) ================ ; 20.out0 - Hotend Heater ; 20.out1 - NC ; 20.out2 - Parts cooler on printhead ; 20.out2_tach0 - NC ; 20.out1_tach0 - NC ; 20.io0.in - NC ; 20.io1.in - X min active low endstop switch ; 20.io2.in - Reserved for filament monitor ; 20.io0.out - NC ; 20.temp0 - Extruder Thermistor ; 20.temp1 - NC ; 20.button0 - NC ; 20.button1 - NC ; 20.CAH_H - Duet CAN1_H ; 20.CAH_L - Duet CAN1_L -

@dhusolo it sounds to me that tuning has over estimated the M307 R parameter. Try reducing it by 25%.